Bernard Controls MASTER STATION MS212 User manual

1

A 15/11/2010 First version L.Maissin D.Schwebel G.Aubert-

Maguero

nd. Date Modifications Edited by Verified by Approved by

NR 1177

MASTER STATION MS212

TECHNICAL MANUAL

2

CONTENTS

CONTENTS ............................................................................................................................................... 2

I. Introduction ..................................................................................................................................... 4

SETTING UP .............................................................................................................................................. 6

II. Mounting and connecting your Master Station .............................................................................. 7

a. Mec anical fixing ......................................................................................................................... 7

b. Power supply ............................................................................................................................... 8

c. Links between t e two racks ....................................................................................................... 8

i. Link between t e PLC .............................................................................................................. 9

ii. Et ernet redundancy ............................................................................................................... 9

d. Communication wit t e DCS ................................................................................................... 11

i. Modbus RTU communication ................................................................................................ 11

ii. Modbus TCP configuration .................................................................................................... 12

e. Communication wit t e Web Server ....................................................................................... 13

f. Communication wit t e actuators – Profibus DP V1 ............................................................... 13

g. Communication wit t e PC Workstation ................................................................................. 13

III. Setting up t e Modbus RTU communication ............................................................................ 14

a. Default parameters ................................................................................................................... 14

b. Setting up t e Modbus slave address wit t e touc screen ................................................... 14

c. Setting up t e Modbus RTU/TCP gateway ................................................................................ 16

i. MGate Manager Installation ................................................................................................. 16

ii. Setting up using MGate Manager ......................................................................................... 20

IV. Setting up t e Modbus TCP communication ............................................................................. 24

a. Default parameters ................................................................................................................... 24

3

b. Step 1 – Using MGate Manager ................................................................................................ 25

c. Step 2 – Using t e Touc Screen ............................................................................................... 27

V. Setting up t e Touc Screen ......................................................................................................... 29

a. Language ................................................................................................................................... 29

b. Clock .......................................................................................................................................... 29

VI. Activating t e actuators ............................................................................................................ 30

UTILISATION .......................................................................................................................................... 34

VII. Touc Screen ............................................................................................................................. 35

a. Log in access .............................................................................................................................. 35

b. Touc Screen Layout ................................................................................................................. 37

c. Actuators ................................................................................................................................... 38

i. Actuator status ...................................................................................................................... 38

ii. Command your actuator ....................................................................................................... 42

iii. Configure your actuator .................................................................. Erreur ! Signet non défini.

iv. C aracteristics and activity of your actuator ........................................................................ 47

v. Torque profile ........................................................................................................................ 49

d. Master Station Status ................................................................................................................ 50

e. Master Station and actuators alarms ........................................................................................ 51

VIII. Server Web ................................................................................................................................ 55

a. Making t e Internet connection ............................................................................................... 55

b. Web Pages Layout ..................................................................................................................... 55

c. Home page ................................................................................................................................ 56

d. Actuators Status ........................................................................................................................ 56

e. Master Station Status ................................................................................................................ 61

4

I. Introduction

Our Master Station is a ready-to-work solution which eases the command and control of

large quantities of motor operated valves by the mean of a fieldbus. t will help you saving

time and resources.

t is an interface located between the DCS and the actuators, which can replace your

standard industrial computer. Because BERNARD CONTROLS Master Station is already set

up, you will save precious time during the commissioning phase. Just cable it and the

system is quickly ready to work! Overall start up time of your site is now reduced to the

minimum.

Our Master Station is also able to work without the DCS. n case of default of your DCS or if

you do not want to include one in your installation, you can still communicate with your

actuators through the Master Station’s manual control, from the color touch screen. You

can thus keep the control of your valves even if the DCS is on hold or disconnected.

The Master Station is able to interface with a monitoring computer (optional) to control

directly valves' automation. This PC workstation, equipped with specific software, allows

to operate the MOVs and to retrieve data and alarms from the field units.

By choosing the PC workstation, you opt for greater user friendliness. ndeed, we can work

together on demand to schematize your installation in the software interface so as to

overview all the actuators of your site easily. And for simple use, the software is available

in English, French, Spanish, German and talian.

5

n order to ensure secure management of your site, considering the several control units, a

control hierarchy is set up. The standard control priority is defined from the closest device

to actuators, to the device which is the farthest:

Actuators > MS > PC workstation > DCS

The consequence is that if an opposite order is received at the same moment from the

Master Station and from the DCS, the priority order is the one coming from the Master

Station.

6

SETTING UP

7

II. Mounting and connecting our Master Station

a. Mechanical fixing

Master Station MS212 is composed of two 19-inch racks.

They must be installing in a 19-inch cabinet, one above the other. t is better to put the

rack ‘PLC1’ above the rack ‘PLC2’. Use M6 screws to fix those (8 by rack).

All connections are accessible inside the racks, so unscrew the two screws on the right of

the panel to open it.

For make wiring easier there is a hole on the back side for the passage of the cables.

Holes for M6

screws

Unscrew to

open the

front panel

Hole for the

passage of the

cables

8

b. Power suppl

Each rack is supplied separately. Power supply is wired on unit D1 and the switch must be

on ‘ON’. Earth is wired on the Earth Terminal.

Voltage: 115 VAC (+10%, -30%)

230 VAC (+10%, -30%)

Frequency: 47 to 63 Hz

Electrical power consumption: 75 W for each rack

c. Links between the two racks

To assure the redundancy of the system there are any links between the two racks of the

Master Station MS202. First there is a link between the two PLC which allows to transfer

the data corresponding to the commands and the signals from the actuators, and to

diagnose the status of the Master Station itself.

Then, there is a link between two Ethernet concentrators which assures the

communication between the DCS and the two PLC even there is just one DCS line.

At last, the Ethernet concentrators have a redundant power supply input which allows

them to keep powered on even if one rack is powered off.

Unit D1

Switch on ON

Earth Terminal

9

i. Link between the PLC

To link the both PLC together take the cable labeled Profibus 2 (which is provided) and

plug its two 9 ways D-type connector on the PROFIBUS input of the both units labeled M3,

after you had opened their cover.

ii. Ethernet redundanc

To assure the redundancy of the communication of the DCS with the both PLC there is a

link between the both Ethernet concentrators.

So, take the cable labeled ETH 3 (which is provided) and plug its two RJ-45 connectors on

a free port of the both Ethernet concentrators labeled M9.

Uni

t M3

Cable labeled

Profibus 2

9 wa s D

-

t pe

connectors

RJ

-

45 connector

10

n addition there is redundant power input on the Ethernet concentrators; they are each

powered on by the both Power supply labeled M8.

So you have to wire as shown below.

For more details refer to wiring diagram S94400175.

11

d. Communication with the DCS

The Master Station MS202 is made up of two Master Station racks, which each possess an

RS485 communication input for the Modbus RTU link and an Ethernet communication input

for the Modbus TCP link.

These inputs provide a redundant communications system between the DCS and the Master

Station MS202.

Reminder: Communications are made either by the Modbus RTU protocol or by Modbus

TCP, so refer the part i. Modbus RTU communication or ii. Modbus TCP communication.

The DCS can communicate indifferently by either of these two ways.

For more information about the Modbus communication refer to the SPEB 1246 Functional

Analysis of the Modbus communication on the Master Station MS202.

i. Modbus RTU communication

The Modbus RTU connection is via the 9 ways D-type connector of the M7 module inside

the Master Station.

Physical description:

RS 485 type interface

Transmission medium: Single pair armoured cable

Connection: female 9 ways D-type

Multi-drop supported.

9 wa s D

-

t pe

connectors

12

Terminating resistances:

To eliminate echo phenomena on the line, terminating resistances of 120 Ohms must be

placed on the ends of the bus, the best solution being to put them directly in the SUB-D9

connector.

Communication parameters:

Type of protocol: Master Station is the Modbus RTU slave

Transmission speed: 50 to 921.6Kbits/s

Parity: odd, even, none

Slave address: 1 to 254

ii. Modbus TCP configuration

The Modbus TCP connection is via the RJ-45 connector of the Switch Ethernet labeled M9

inside the Master Station or via the RJ-45 port on the front panel.

Physical description:

Ethernet type 10/100 Mbits/s interface

Transmission medium: Armoured Ethernet cable

Connection: Socket for RJ45 plug

Communication parameters:

Type of protocol in use: Modbus TCP

RJ

-

45 connector

of unit M9

RJ

-

45 connector

on the front panel

13

e. Communication with the Web Server

n each rack there is a Web Server including any Web pages, so there is a TCP/ P

connection to access to these pages. This connection is via the RJ-45 connector of the

Switch Ethernet labeled M9 inside the Master Station.

Physical description:

Ethernet type 10/100 Mbits/s interface

Transmission medium: Armoured Ethernet cable

Connection: Socket for RJ45 plug

Communication parameters:

Type of protocol in use: TCP/ P

f. Communication with the actuators – Profibus DP V1

The Master Station MS202 is an interface between DCS and actuators who manages the

redundancy. So, each rack manages a Profibus line. The fieldbus network must be correctly

cabled and connected to the Master Station via the D-type connector of the X2 DP input of

the M2 module.

Physical description:

RS485 type interface

Connection: S EMENS S MAT C BUSCONNECTOR (ref: 6ES7 972-0BB52-0XA0)

Communication parameters:

Type of protocol in use: Profibus DP V1

Transmission speed: 93.75Kbits/s

Salve address: 1 to 122

For more information refer to the NR1150 Profibus DP V1 for ntelli+.

g. Communication with the PC Workstation

The Master Station is able to interface with a monitoring computer (optional) to control

directly valves’ automation. This PC Workstation, equipped with specific software, allows

you to operate the MOVs and to retrieve data and alarms from the field units.

To know how the PC Workstation is interfacing with the Master Station refer to the NR 11xx

PC Workstation for MS202 – Technical Manual.

14

III. Setting up the Modbus RTU communication

You can change the Modbus slave address of each rack of the Master Station MS202, the

available address are included between 1 and 254.

To manage the Modbus RTU communication the Master Station MS202 is equipped with two

Modbus RTU/TCP gateways, so there are 2 P address reserved for each rack (by default it

is 192.168.94.181 for the rack 1 and 192.168.94.183 for the rack 2).

f you want to change the Modbus slave address refer to the part b. Setting up the Modbus

slave address with the Touch Screen.

But, if you want to change the P address refer to the part c. Setting up the Modbus

RTU/TCP gatewa .

a. Default parameters

The defaults parameters are shown below:

Transmission speed: 19200 bauds

Format: 8 data bits, 1 stop bit, no parity

Communication protocol: Modbus RTU

Rack 1 Modbus address: 2

Rack 2 Modbus address: 4

As shown before, if you only want to change the Modbus slave address refer to the part

b. Setting up the Modbus slave address with the Touch Screen.

But, if you want to change the Transmission speed or the format refer to the part

c. Setting up the Modbus RTU/TCP gatewa .

b. Setting up the Modbus slave address with the touch screen

To change the Modbus address of a rack you must be logged in to the Master Station with

the Maintenance account. To see how log in refer to the part VII. Touch screen.

15

1. From the main page touch the MS button or press F4.

2. Touch the Tool button or press F2.

3. Touch the field who want to change, Modbus Address 1 or 2. A virtual Keyboard will

appear so enter the value and touch the Enter button. Then, touch the Valid button or

press F4. You can return to the main page by touching the Return button or by pressing

F1.

16

When you validate your choice it will reboot the device, so the link between the PLC and

the server web on the main page will blinking in red. Wait few seconds that the device

restarts successfully.

The Master Station is now ready to run with the news parameters.

c. Setting up the Modbus RTU/TCP gatewa

i. MGate Manager Installation

The following instructions explain how to install MGate Manager, a utility for configuring

and monitoring MGate MB3180 units over the network.

1. nsert the Document and Software CD into the CD-ROM drive. Locate and run the

following setup program to begin the installation process:

MGM_Setup_[Version]_Build_[DateTime].exe

The latest version might be named MGM_Setup_Ver1.1.0_Build_xxxxxxxx.exe, for

example:

17

2. You will be greeted by the Welcome window. Click Next to continue.

3. When the Select Destination Location window appears, click Next to continue. You

may change the destination directory by first clicking on Browse....

18

4. When the Select Additional Tasks window appears, click Next to continue. You may

select

Create a desktop icon if you would like a shortcut to MGate Manager on your desktop.

5. Click Next to start copying the software files.

19

6. A progress bar will appear. The procedure should take only a few seconds to complete.

7. A message will indicate that MGate Manager is successfully installed. You may choose to

run it immediately by selecting Launch MGate Manager.

20

8. You may also open MGate Manager through Start → Programs → MGate Manager →

MGate Manager, as shown below.

ii. Setting up using MGate Manager

1. Run MGate Manager and click on Broadcast Search, as shown below.

This manual suits for next models

1

Table of contents

Popular Control System manuals by other brands

BFT

BFT XPASS B 275/800C L Instructions for installation, use and maintenance

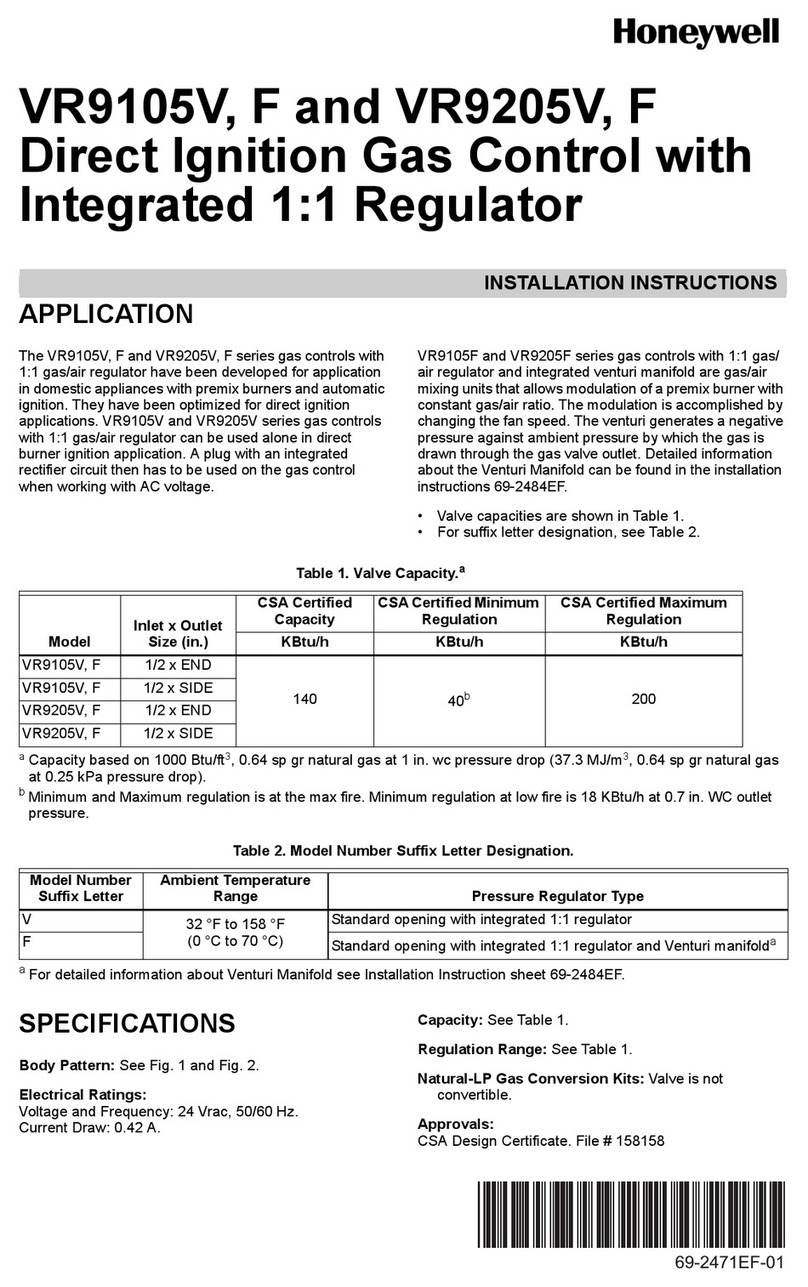

Honeywell

Honeywell VR9105V installation instructions

SOMFY

SOMFY Rollixo RTS Quick commissioning guide

Linear Logic

Linear Logic ScanGauge III user manual

Nordson

Nordson PowderPilot HD manual

Woodward

Woodward EGCP-2 to easYgen-3200XT instruction manual

Hubbell

Hubbell Microprocessor Radio Locomotive Control... Brochure & specs

TrolMaster

TrolMaster HCS-1 manual

Beninca

Beninca VE.650 Operating instructions and spare parts catalogue

Vicon

Vicon NOVA Powerplus VP3466 Programming manual

Siemens

Siemens SINUMERIK 840D sl Commissioning manual

J2

J2 Attitude Solo user manual