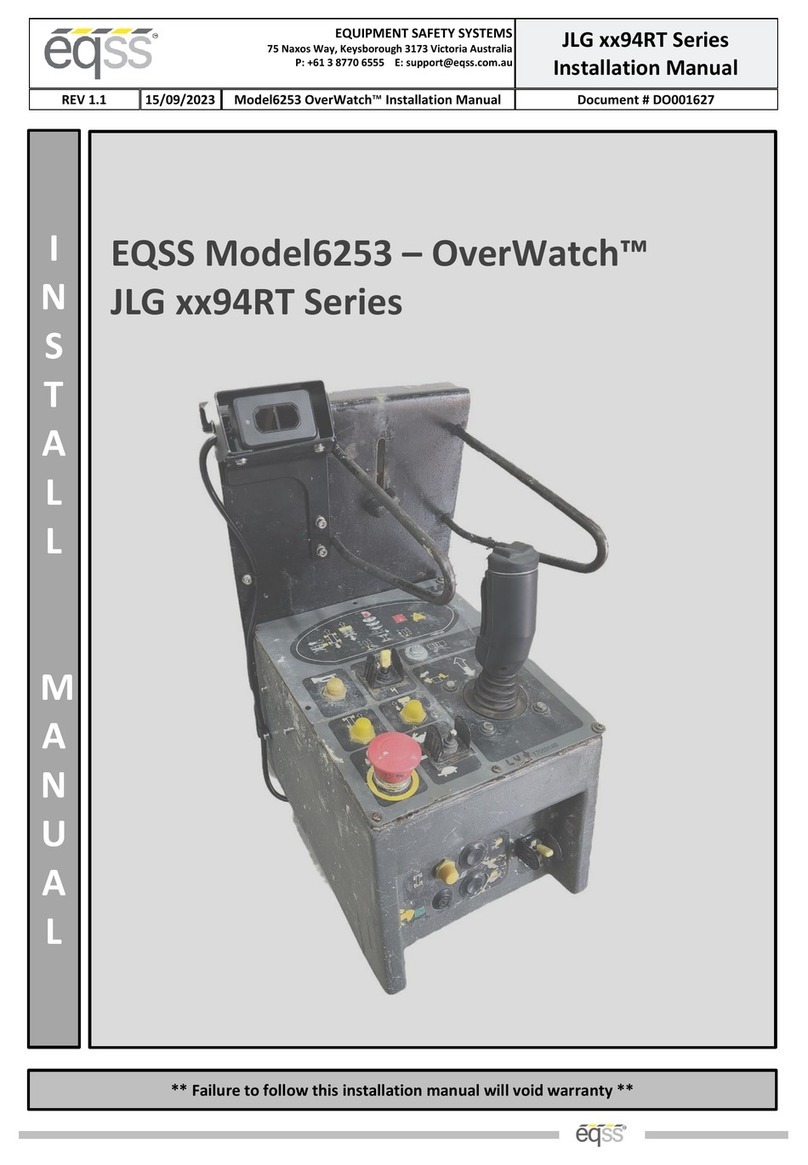

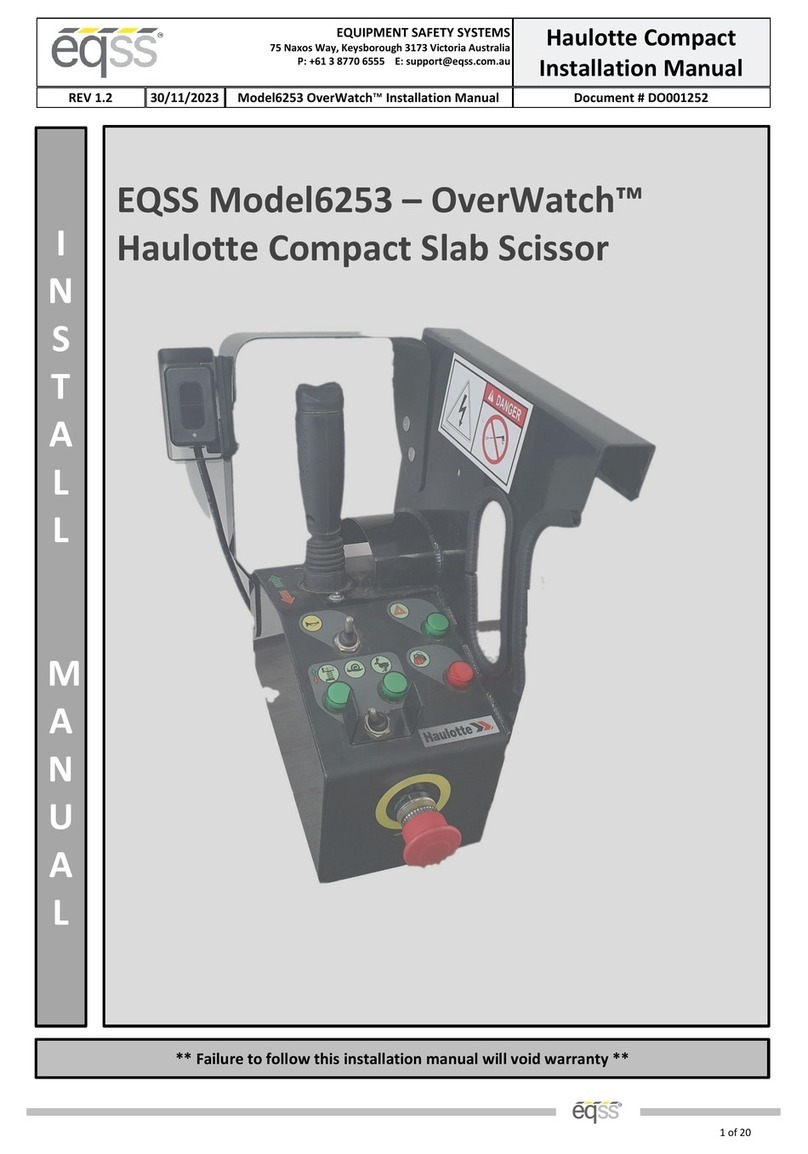

eqss Gen-3 LMS User manual

EQUIPMENT SAFETY SYSTEMS PTY LTD

eqss™ Gen-3 LMS

Telehandler Load Management System

Installation Manual for MLT840

Manual Tool Re ognition

VER: 20150513

Failure To Follow Installation Manual Will Void Warranty

Do umentation Conventions

The list below highlights important do umentation onventions.

Text presented in this manner is intended to provide the user

with some general information. The user should ensure

information presented in this manner is clearly understood.

Text presented in this manner provides the user with

information to assist in completion of the current procedure

being explained.

Text presented in this manner indicates that a failure to follow

directions could result in damage to equipment, loss of

information, bodily harm, or loss of life.

VER: 20150513 2 of 47

Important Information

Information ontained in this publi ation regarding this devi e's appli ations and the like is

provided only for your onvenien e and may be superseded by updates. It is your

responsibility to ensure that the appli ation or our equipment meets with your

spe ifi ations.

EQUIPMENT SAFETY SYSTEMS MAKE NO REPRESENTATIONS OR WARRANTIES

OF ANY KIND WHETHER EXPRESS OR IMPLIED, WRITTEN OR ORAL, STATUTORY

OR OTHERWISE, RELATED TO THE INFORMATION, INCLUDING BUT NOT LIMITED

TO ITS CONDITION, QUALITY, PERFORMANCE, MERCHANTABILITY OR FITNESS

FOR PURPOSE.

Equipment Safety Systems dis laims all liability arising from this information and its use.

Use of Equipment Safety Systems’ produ ts as riti al omponents in life support systems

is not authorised ex ept with express written approval by Equipment Safety Systems. No

li enses are onveyed, impli itly or otherwise, under any Equipment Safety Systems

intelle tual property rights.

VER: 20150513 3 of 47

Table of Contents

Tools Required for Installation.....................................................................................6

Installation Index...........................................................................................................7

overs.........................................................................................................................11

able Reeler Installation.............................................................................................13

able Reeler Mounting Position.............................................................................15

Pressure Sensor Installation.......................................................................................16

Main Lift ylinder – Standard onfiguration..........................................................16

Main Lift ylinder – Boom Suspension Option.......................................................18

ompensation Pressure Sensors............................................................................20

Reverse amera..........................................................................................................21

utout able Harness.................................................................................................23

Forward amera..........................................................................................................26

Light Tower Installation..............................................................................................28

Light Tower Bracket Mounting Position................................................................29

Machine Input Harness...............................................................................................30

an Pressure Input Module ( PIM)............................................................................31

External able ompletion.........................................................................................32

Display Installation......................................................................................................34

User Input ontrol.......................................................................................................35

an abin Interface Module ( IM)...........................................................................36

Override Wiring...........................................................................................................37

abin Loom..................................................................................................................38

Finalisation..................................................................................................................41

Sensor alibration.......................................................................................................44

VER: 20150513 4 of 47

Tools Required for Installation

The tools required to perform the installation of the TSS are listed below

•Pen il or Texta

•Drill

•Drill bits

◦3.3 mm

◦4.5 mm

◦5 mm

◦6.25 mm

◦6.8 mm

◦8.5 mm

•Centre pun h

•Tap T-Handle

•Taps

◦M6

◦M7 x 0.75

◦M8

•Drill and tap oil

•Metri Allen keys

•Phillips Head s rew driver

•Spanners and so kets

◦7 mm

◦10 mm

◦13 mm

•Lo ktite thread lo ker

•Side utters

•Stanely knife

•Crimpers

•Wire strippers

VER: 20150513 6 of 47

Installation Index

The omponents and ables of the Gen-3 Telehandler Load Management System are

outline in the tables below. The following pages show where the omponents are installed

and the able routing.

See the appropriate manual se tion for a detailed installation des ription for ea h

omponent.

Refer to this section for any component placement or cable

routing issues

Item omponent Description

1 able Reeler

2 Main Lift ylinder Pressure Sensors

3 ompensation ylinder Pressure Sensors

4 an Pressure Input Module ( PIM)

5 Forward amera

6 Light Tower

7 Rear amera

8 an abin Interface Module ( IM)

9 Display Module

10 SPU Module

11 User ontrol Dial

12 Joystick onnection X67

Table 1: Component Installation Index

VER: 20150513 7 of 47

olour able Description

Yellow Boom able

Dark Green Main ylinder Pressure Sensor ables

Dark Blue ompensation ylinder Pressure Sensors ables

Light Blue Forward amera able

Violet Light Tower able

Aqua Rear amera able

Dark Yellow IM able

Light Green utout Harness

Red Display able

Orange User Input ontrol able

Brown Machine Input Harness

Table 2: Cable Installation Index

VER: 20150513 8 of 47

Illustration 1: Machine Boom

VER: 20150513 9 of 47

Illustration 2: Machine Chassis

VER: 20150513 10 of 47

Covers

Remove the following overs before starting the installation

Step Description Diagram

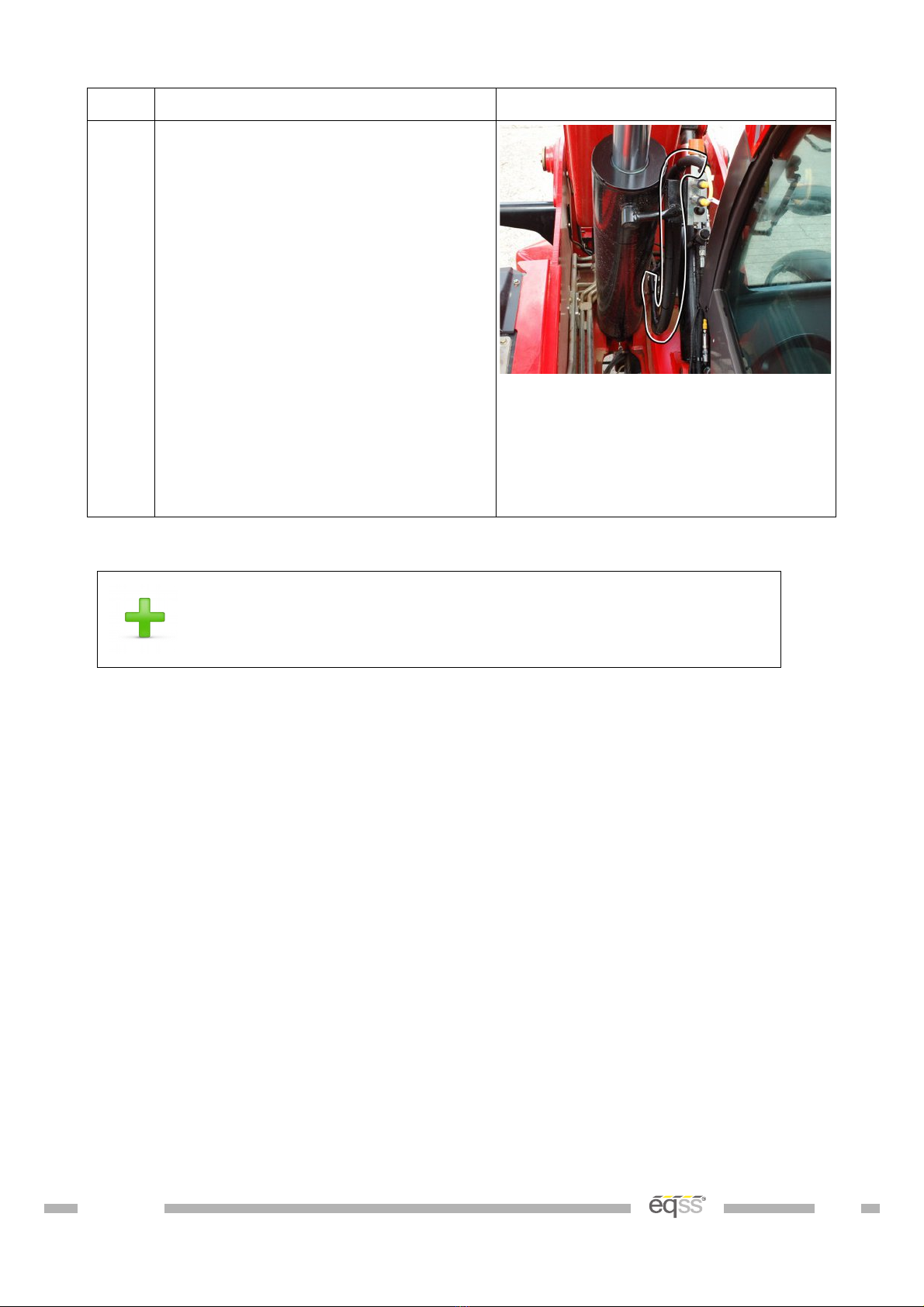

1. Remove the rear cover behind the

boom.

1. Remove the side panel next to the

cabin under the boom.

2. Remove the cover behind the cabin

VER: 20150513 11 of 47

Step Description Diagram

3. Inside the cabin remove the

dashboard display.

Table 3: Cover removal

VER: 20150513 12 of 47

Cable Reeler Installation

The able reeler is used to measure the boom extension to determine the maximum lifting

apa ity.

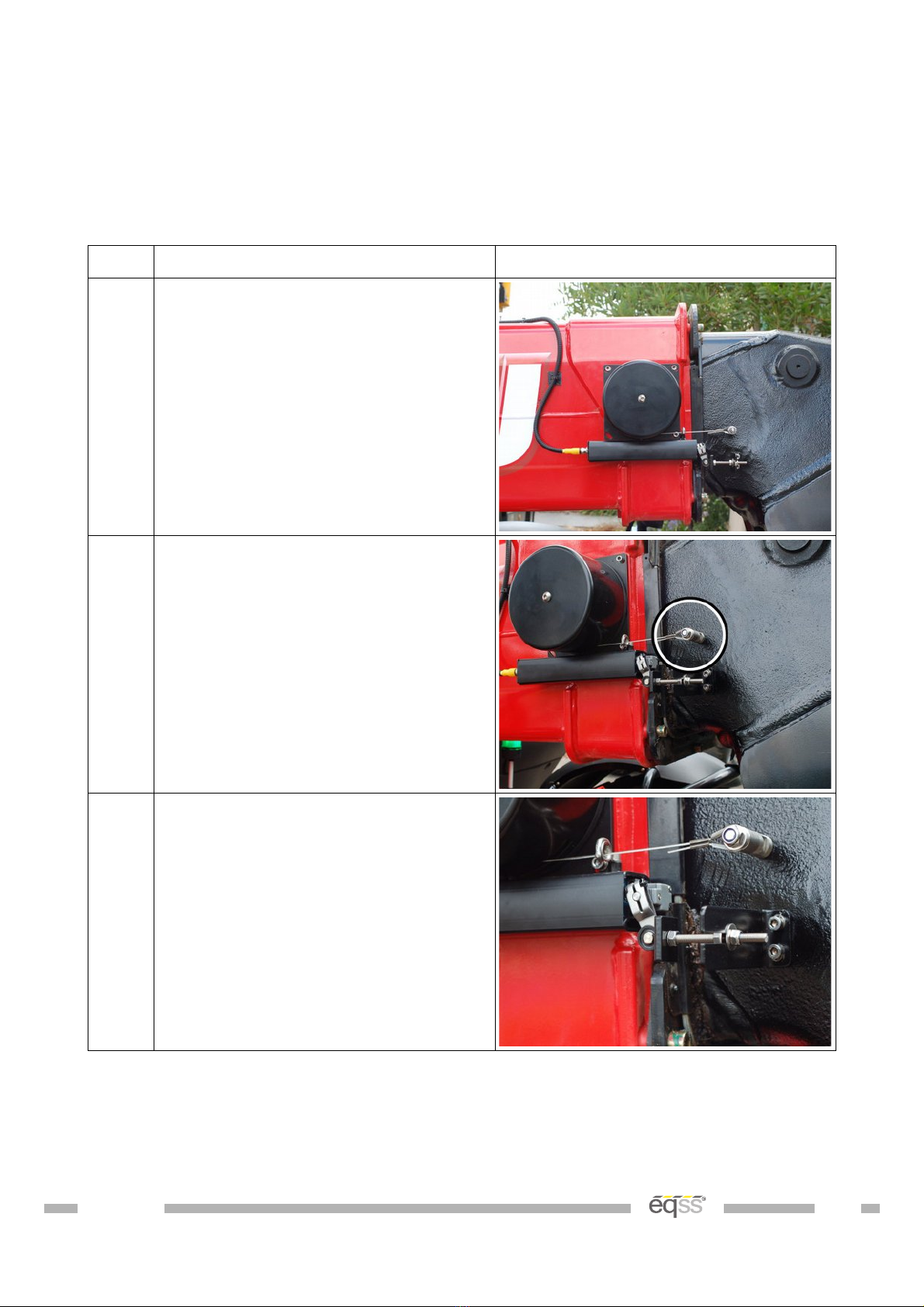

Step Description Diagram

1. Drill and tap the holes for the cable

reeler according to the mounting

diagram on page 15.

Mount using the supplied bolts and

washers.

2. Drill and tap an M8 hole for the

cable anchor. Ensure the cable

anchor is positioned so the cable

runs in line with the boom.

Mount the cable anchor and attach

the cable.

3. Drill and tap the M6 holes for the

stow switch trigger bracket.

Mount the stow switch trigger

bracket using the supplied M6 x 12

mm bolts and washers.

Adjust the length of the trigger plate

to ensure the stow switch is pressed

when the boom is retracted.

VER: 20150513 13 of 47

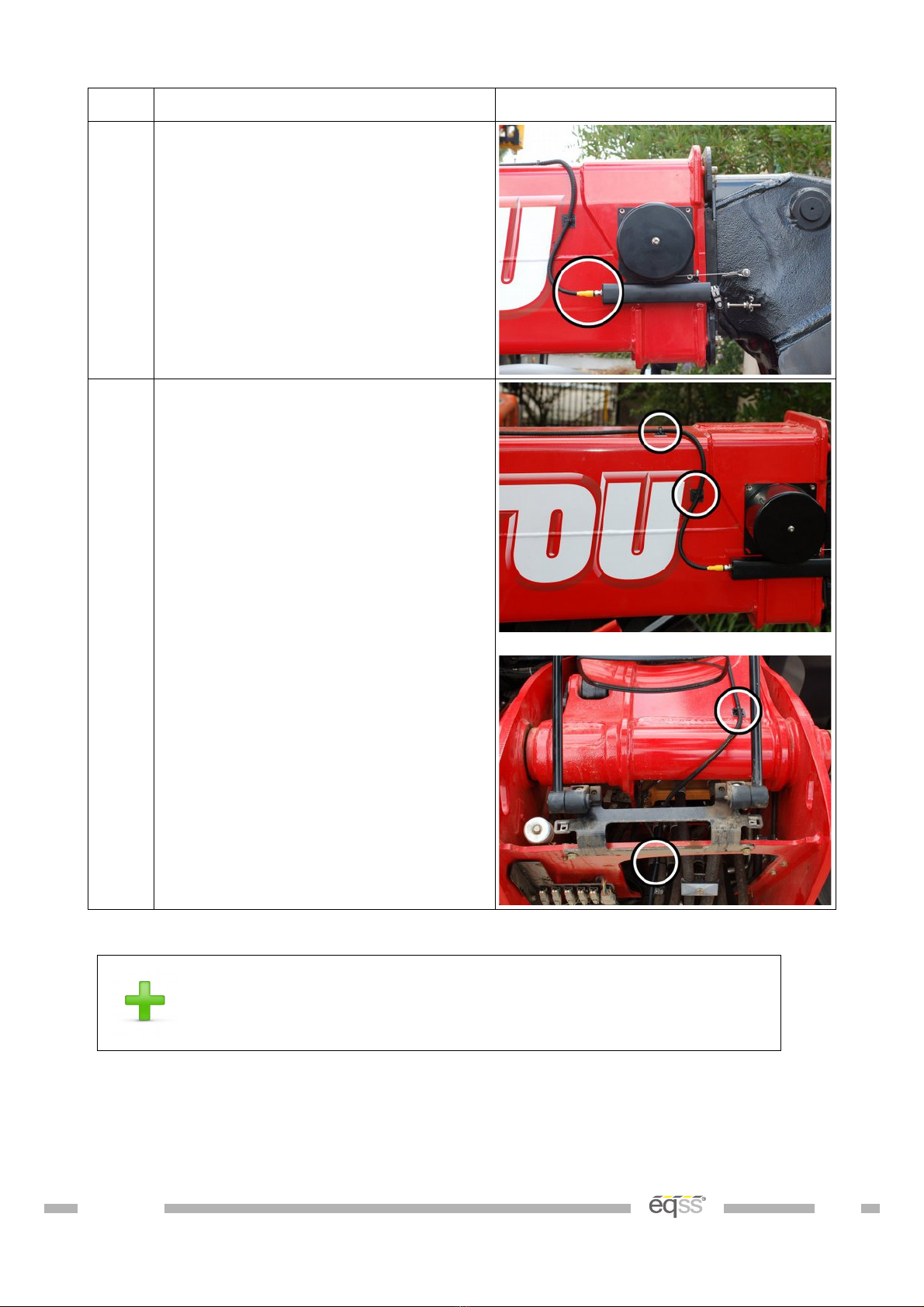

Step Description Diagram

4. onnect the supplied M12 10 metre

cable ( B001027) into the cable

reeler connection.

5. Run the cable down the top of the

boom, place cable tie points every

500 mm down the boom and secure

the cable to the cable tie points.

able tie to the flexible hydraulic

hoses down to the chassis. Make

sure the cable isn't pinched or

stretched when the boom is raised

or lowered.

Run the remainder of the cable out

the hole below the lift cylinder

towards the rear of the machine and

cable tie with the other cables

during External able ompletion on

page 32.

Table 4: Cable Reeler Installation

For further details on running the boom cable refer to the

Installation Index on page 7

VER: 20150513 14 of 47

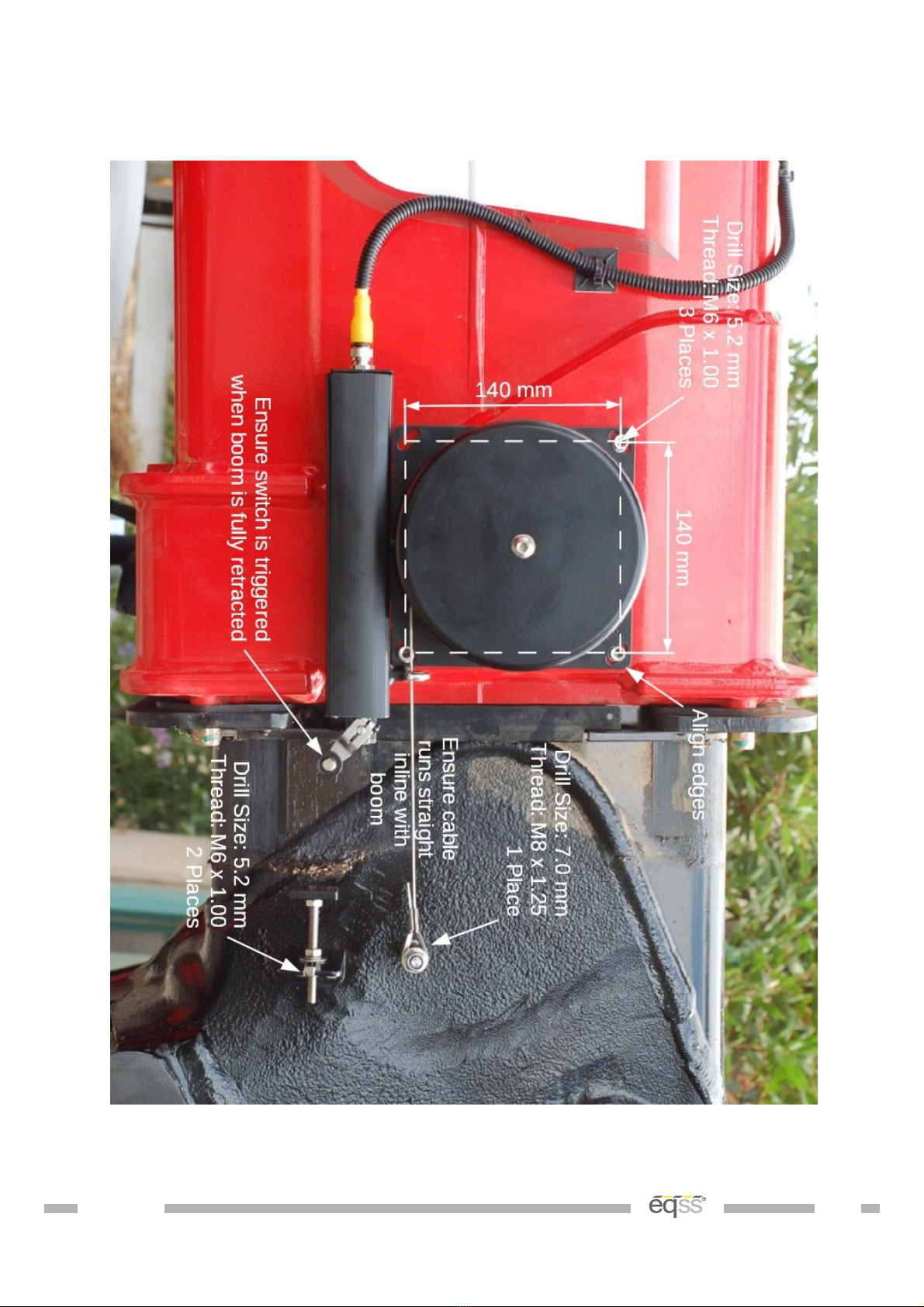

Cable Reeler Mounting Position

Illustration 3: Cable Reeler Mounting osition

VER: 20150513 15 of 47

Pressure Sensor Installation

The hydrauli pressure sensors are used to measure the lifting load of the telehandler.

Main Lift Cylinder – Standard Configuration

Failure to tighten the bolts to the correct torque on the

pressure manifold may result in a pressure failure on the

counterbalance valve causing an uncontrolled fall of the boom.

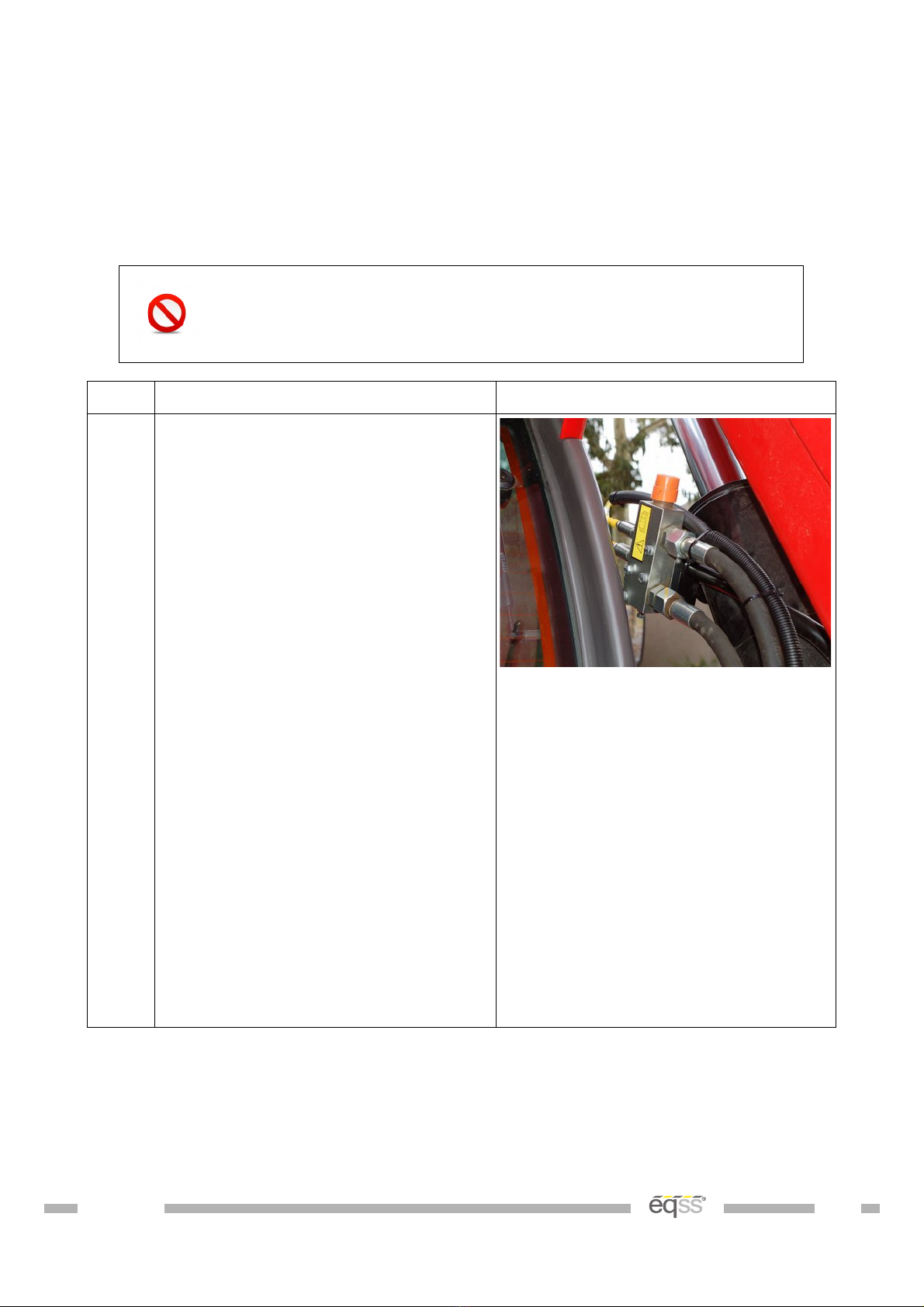

Step Description Diagram

1. Raise the boom to approximately 65

degrees, to access the bolts on the

counterbalance valve.

Support and secure the boom using

an A Frame or similar apparatus. It

must support at least 2 tons.

Apply the handbrake and insert

chock under wheels.

Remove the counterbalance valve on

the side of the hydraulic lifting ram.

Removing the counterbalance valve

will release the hydraulic pressure

which may result in a spray of oil.

Secure the pressure manifold using

the supplied 70 mm bolts and seals.

Tighten the bolts for the manifold to

25 NM using a torque wrench.

Start the machine, pressurise the

boom and check for leaks.

VER: 20150513 16 of 47

Step Description Diagram

2. onnect the supplied M12 4 metre

cables ( B001026) into each of the

pressure sensors.

able tie to the flexible hydraulic

hoses connected to the main lift

cylinder. Make sure the cable isn't

pinched or stretched when the boom

is raised or lowered.

Run the remainder of the cable out

the hole above the rear axle under

the lift cylinder towards the rear of

the machine and cable tie with the

other cables during External able

ompletion on page 32.

Table 5: Main Lift Cylinder – Standard Configuration

For further details on running the pressure sensor cables

refer to the Installation Index on page 7

VER: 20150513 17 of 47

Main Lift Cylinder – Boom Suspension Option

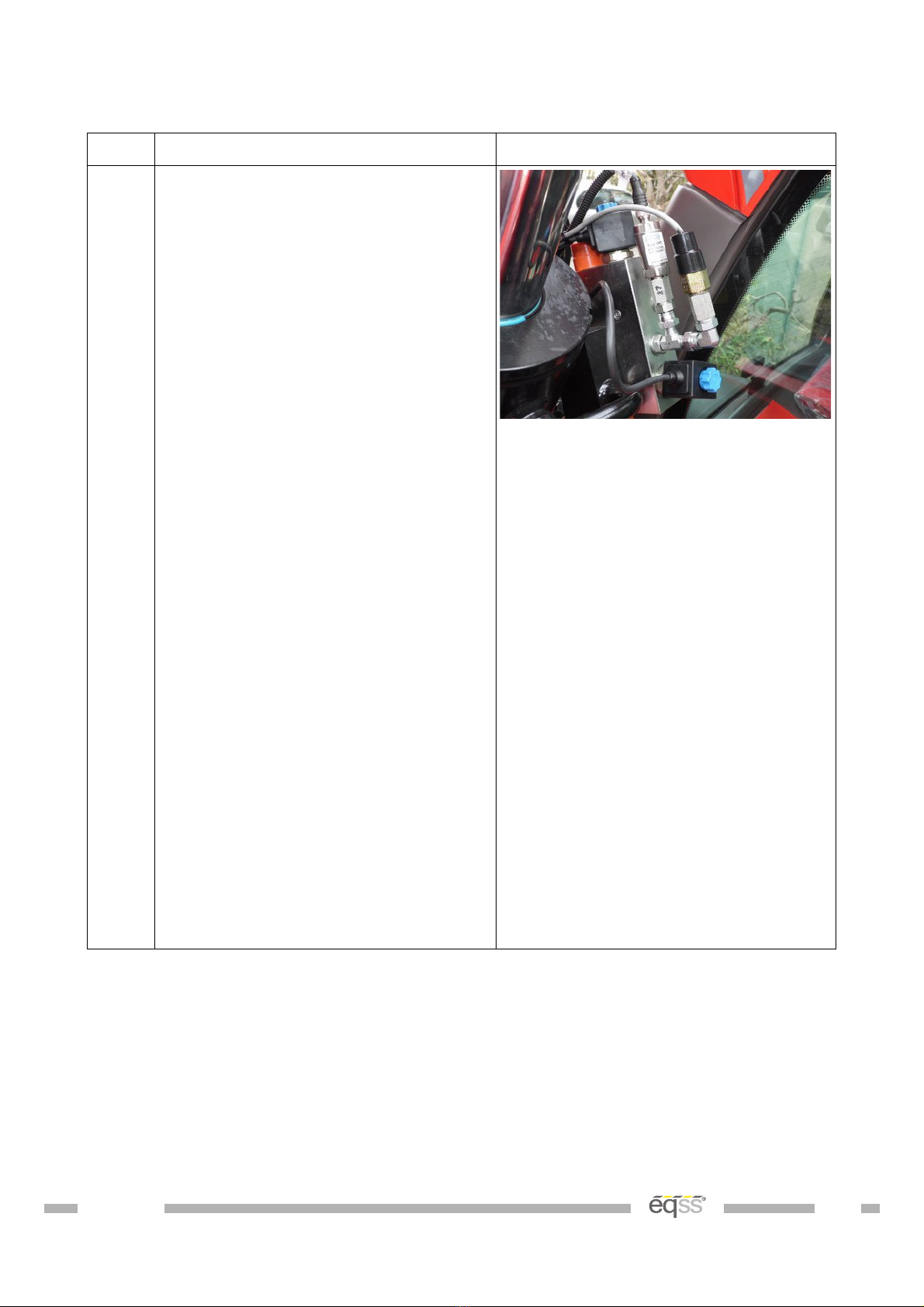

Step Description Diagram

1. Raise the boom and support and

secure the boom using an A Frame

or similar apparatus. It must support

at least 2 tons.

Apply the handbrake and insert

chock under wheels.

Remove the pressure sensor

connected to the PX port of the main

head pressure line on the

counterbalance manifold.

Removing the pressure sensor from

the counterbalance manifold will

release the hydraulic pressure which

may result in a spray of oil.

onnect the supplied hydraulic

connections and pressure sensor

into the PX port of the

counterbalance manifold and connect

the existing pressure sensor into the

available port on the supplied

hydraulic connections, as shown in

the picture.

Ensure the hydraulic connections

are orientated as shown in the

picture, so the hydraulic connections

are not damaged when the boom is

lowered.

View from under the boom towards

the main lift cylinder

VER: 20150513 18 of 47

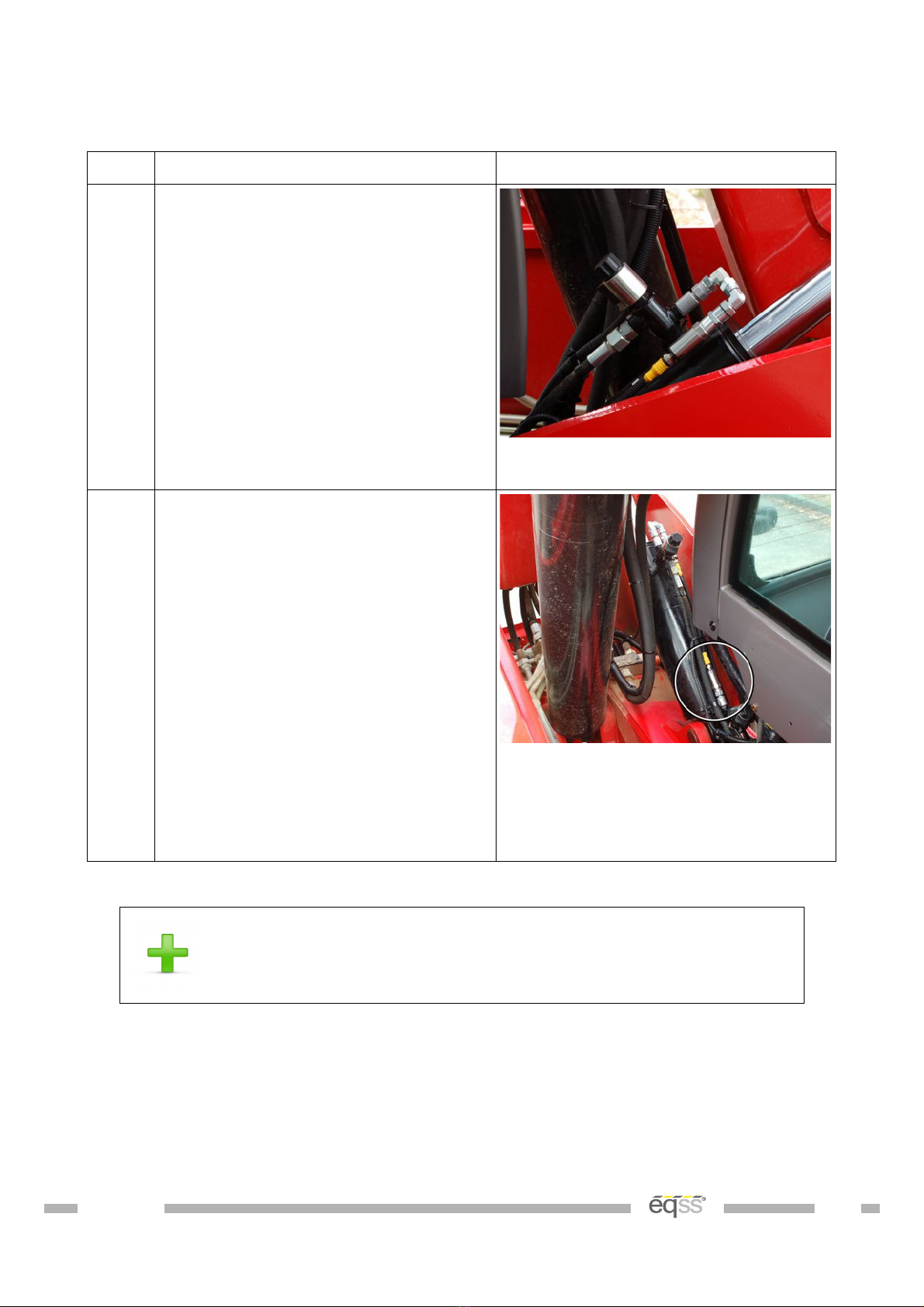

Step Description Diagram

2. Disconnect the hose coming from

the main rod pressure line into the

left side of the counterbalance

manifold mounted on the chassis.

onnect the supplied hydraulic tee

connection and pressure sensor into

the main rod pressure line.

Ensure the pressure sensor is

aligned as shown in the picture, so

the pressure sensor is not crushed

when the compensation cylinder is

moved.

Start the machine, pressurise the

boom and check for leaks.

View from under the compensation

cylinder

3. onnect the supplied M12 4 metre

cables ( B001026) into each of the

pressure sensors.

able tie the main head pressure

sensor cable to the flexible hydraulic

hoses connected to the main lift

cylinder. Make sure the cable isn't

pinched or stretched when the boom

is raised or lowered.

Run the remainder of the cable

towards the rear of the cabin and

cable tie with the other cables

during External able ompletion on

page 32.

Table 6: Main Lift Cylinder – Boom Suspension Option

For further details on running the pressure sensor cables

refer to the Installation Index on page 7

VER: 20150513 19 of 47

Compensation Pressure Sensors

Step Description Diagram

1. Install the pressure sensor with the

U shaped hydraulic connection into

the rod of the compensation cylinder

View from behind the cabin towards

the center of the machine

2. Install the head compensation

pressure sensor into the

compensation cylinder

Start the machine, pressurise the

boom and check for leaks.

onnect the supplied M12 4 metre

cables ( B001026) into each of the

pressure sensors.

Run the snake tube and cables

towards the cabin and cable tie with

the other cables during External

able ompletion on page 32.

View from under the boom towards

the rear of the machine

Table 7: Compensation ressure Sensor Installation

For further details on running the pressure sensor cables

refer to the Installation Index on page 7

VER: 20150513 20 of 47

Other manuals for Gen-3 LMS

11

Table of contents

Other eqss Control System manuals

eqss

eqss Gen-3 LMS User manual

eqss

eqss OverWatch 6253 User manual

eqss

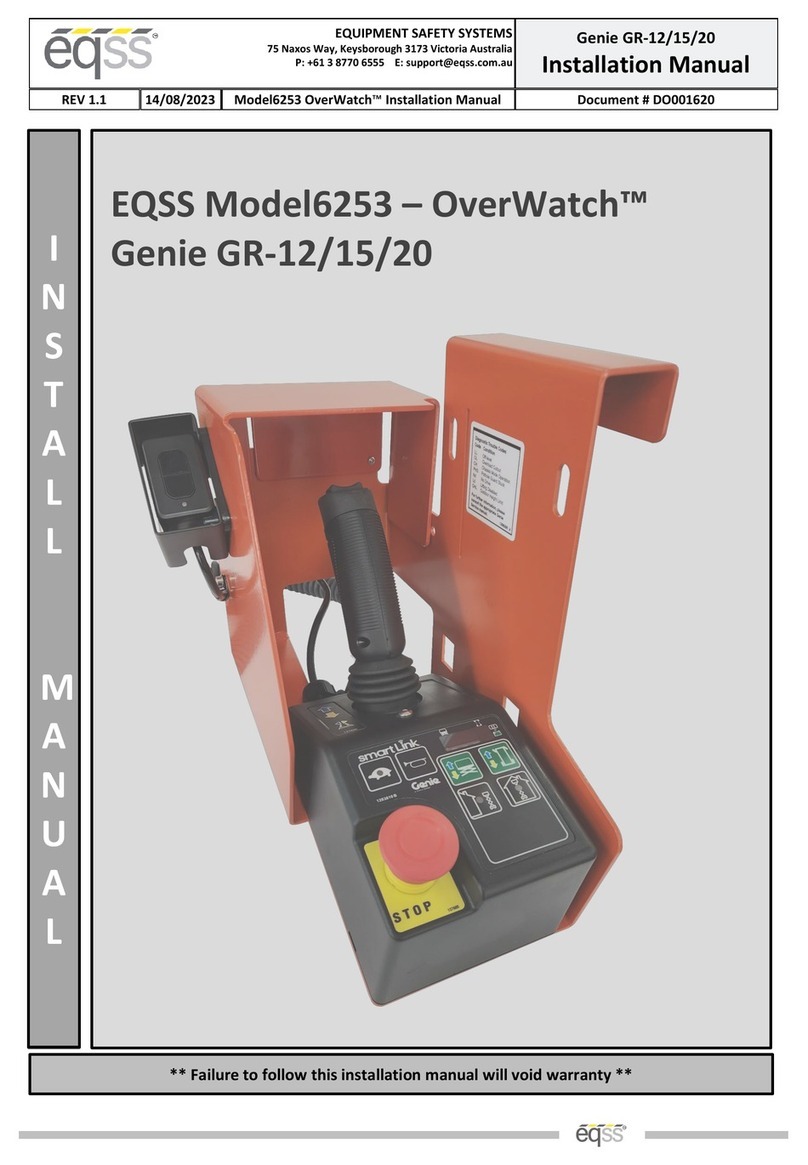

eqss OverWatch Genie GR-12 User manual

eqss

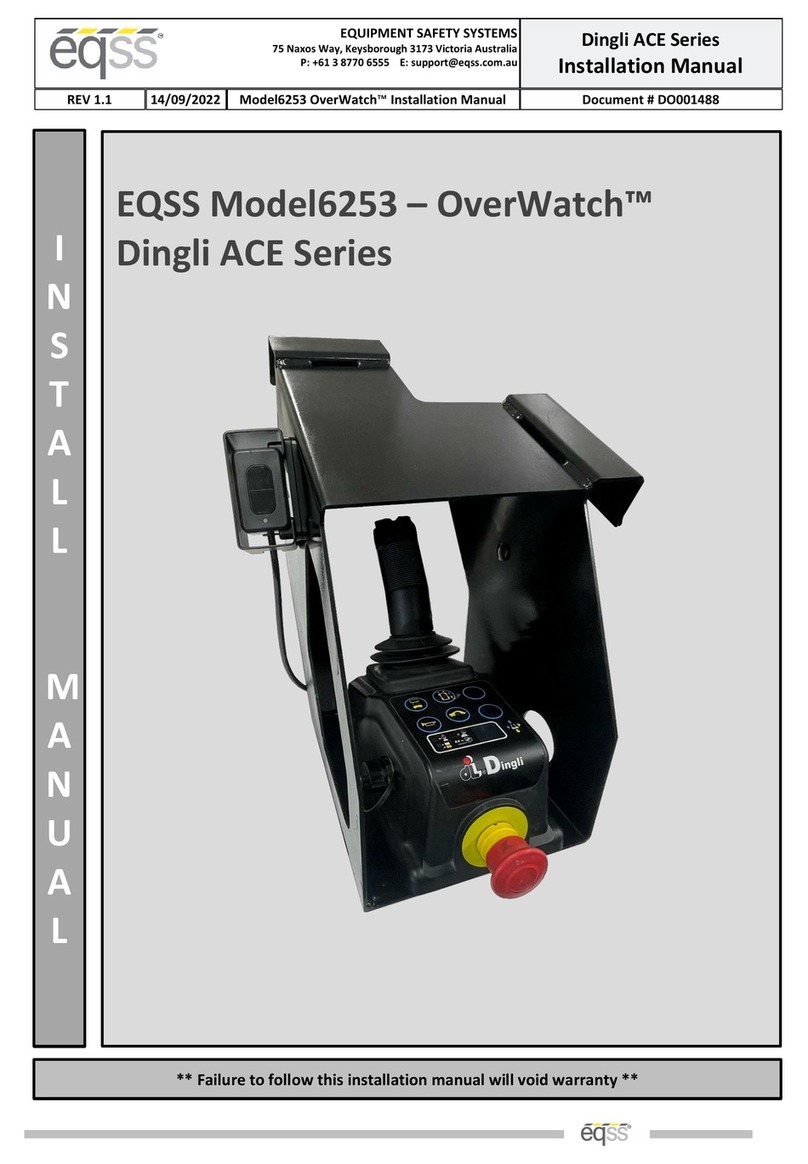

eqss OverWatch Dingli ACE Series User manual

eqss

eqss OverWatch Dingli S03-ACE Series User manual

eqss

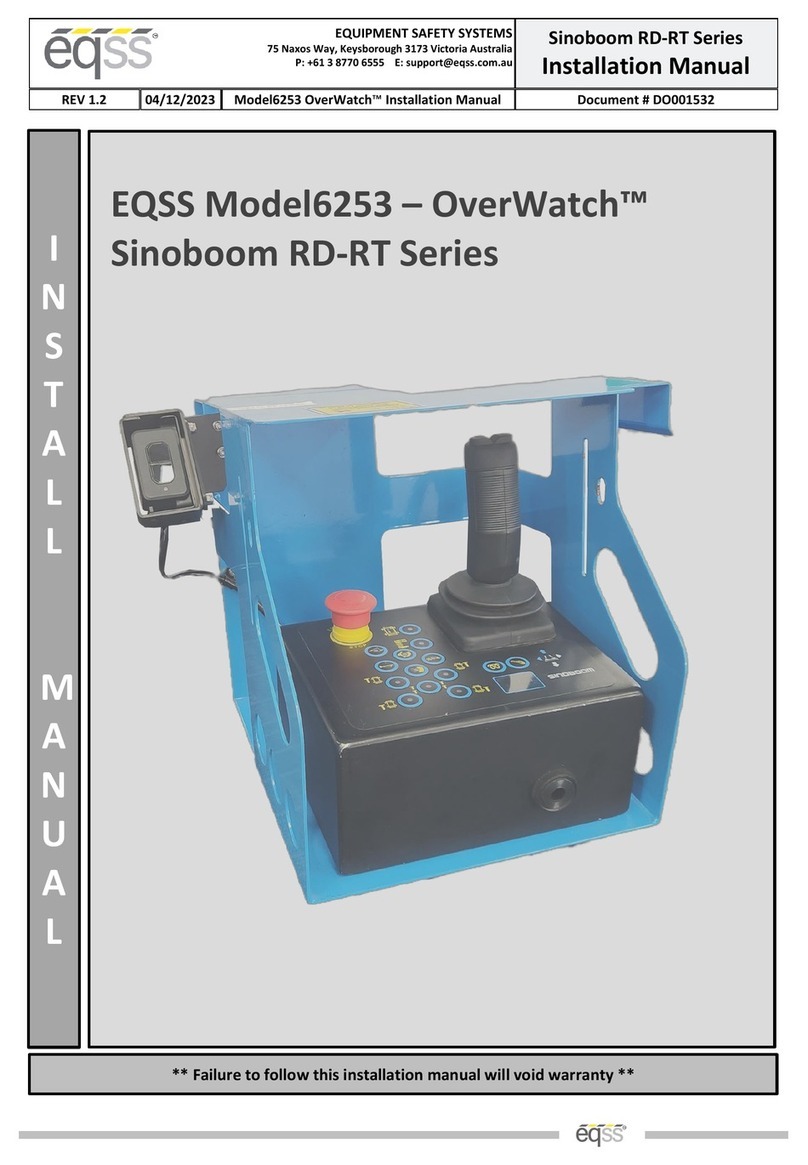

eqss OverWatch Sinoboom RD-RT Series User manual

eqss

eqss OverWatch 6253 User manual

eqss

eqss Overwatch JLG ES Series User manual

eqss

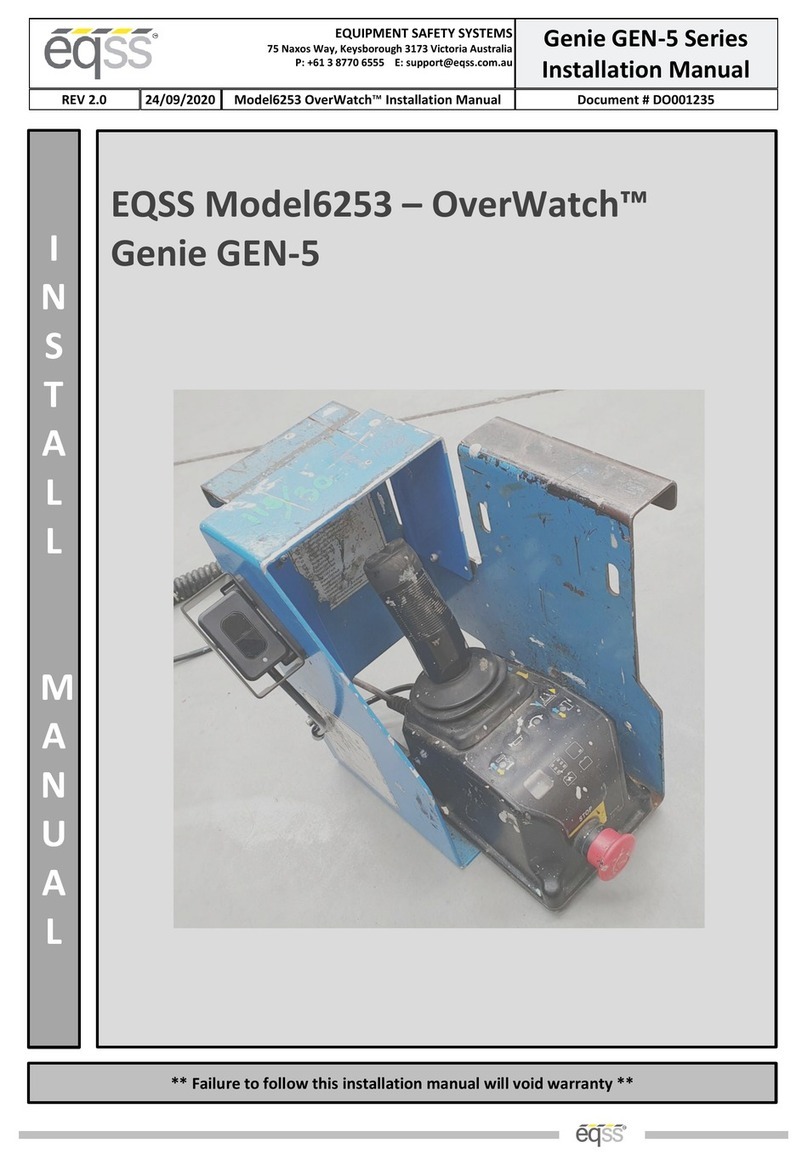

eqss Genie GEN-5 Series User manual

eqss

eqss OverWatch 6253 User manual