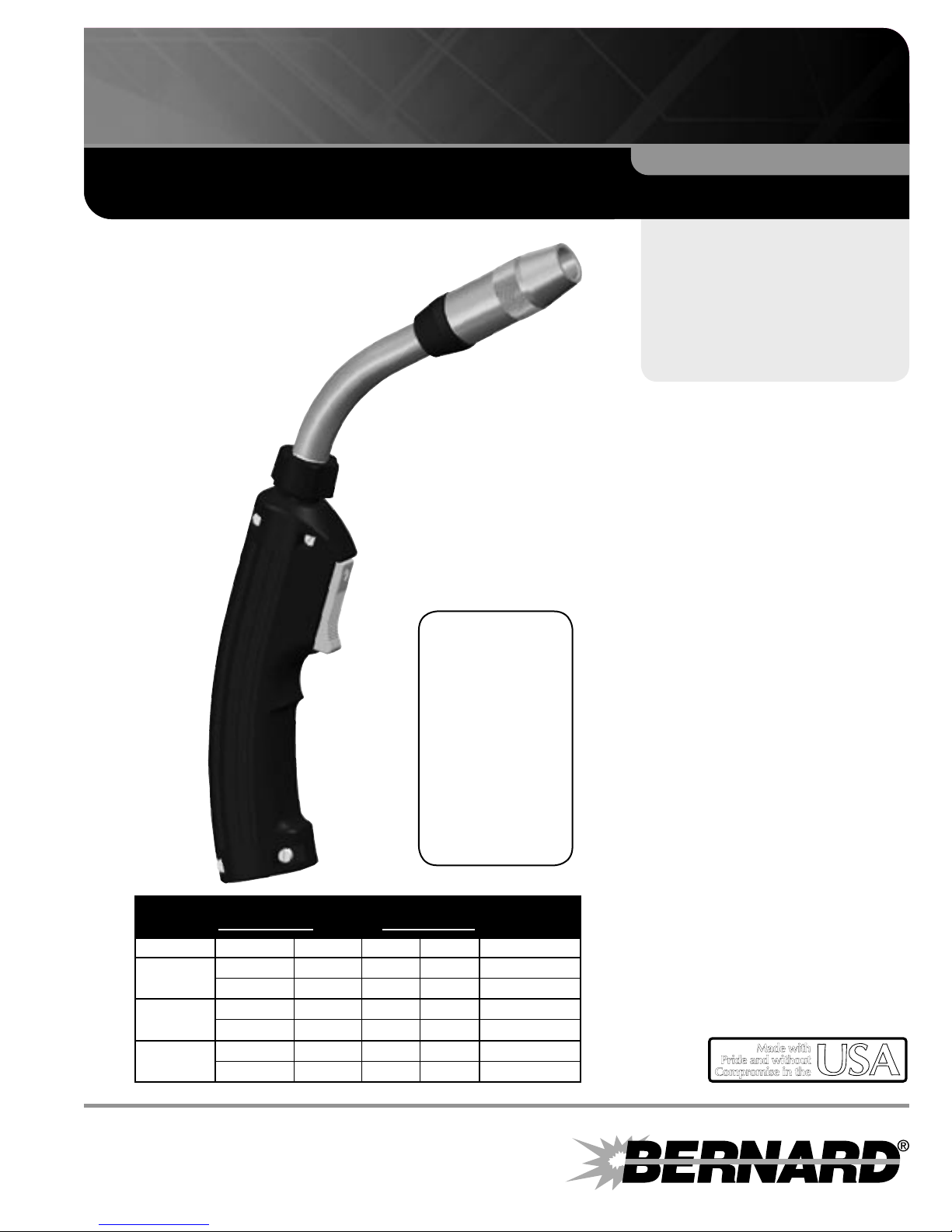

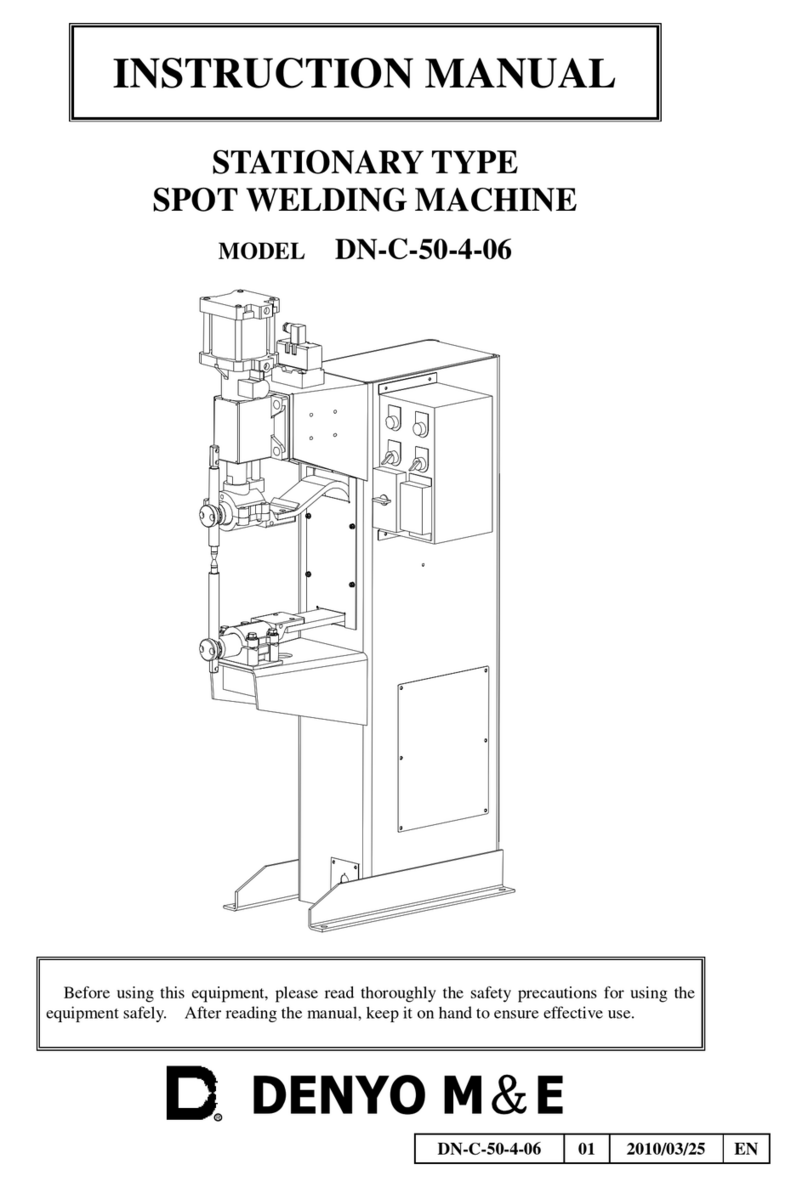

Q500 MIG Q-Gun™ shown with

OXO® style large curved handle,

medium 45˚ rotating neck and

standard trigger.

Issued Feb. 2008 • Index No. SPEC QS456X-1.1

USA

Made with

Pride and without

Compromise in the

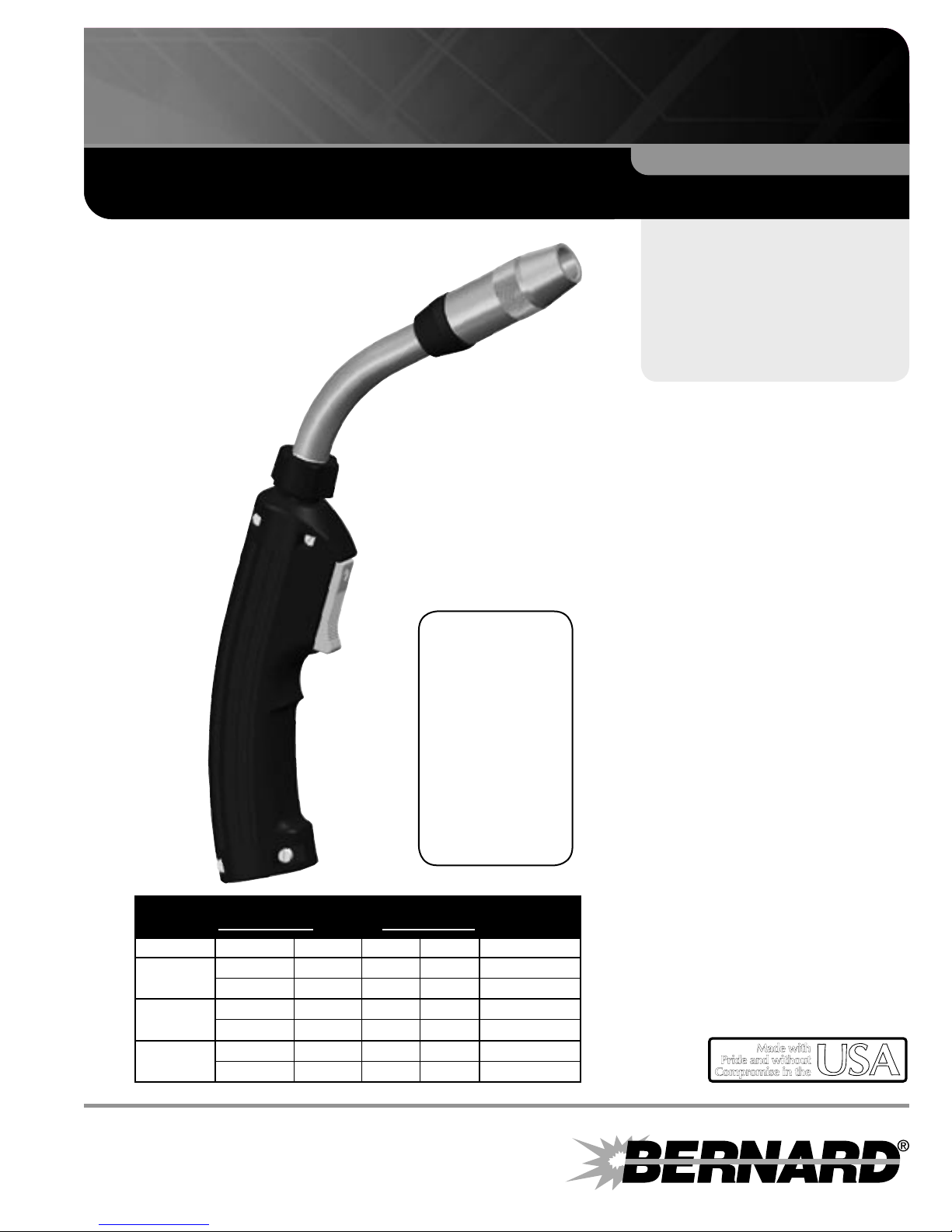

All Guns are Not Created Equal.

A MIG gun should be durable, easy to

use and customized to your specific

application. Our MIG guns put you in

control: you choose the options you need

and we'll build a gun to last. We even

ship most of our guns within 24 hours.

S-Guns™ built with ultra heavy-

duty steel monocoil power cables

are highly resistant to kinking for

exceptional gas flow and wire feed

in applications that cause other

guns to fail.

Phone: 800-946-2281 (US Only) 708-946-2281 (Outside US)

Fax: 708-946-6726

For more information, visit us at BernardWelds.com

Stay-Tite™ Technology

Long-lasting power cable

compression fittings

and necks with large

tapered gun connections

combine to form the

foundation of Bernard®

Stay-TiteTM technology.

This technology ensures

optimal conductivity to

increase weld consistency

and lessen heat output

while improving product

durability.

Bernard®

An Illinois Tool Works Company

449 West Corning Road, Box 667

Beecher, Illinois 60401 USA

Q™

and S™

Series with OXO® style large handle

400, 500, 600 Amp MIG Guns

Centerfire™ contact tips, nozzles and diffusers

are easy-to-use and high performing - they

provide better arc starts, less spatter and more

consistent welds - and also last up to three times

longer than competitive brands.

Necks available in fixed, rotatable and multiple

length options for optimal weld accessibility and

improved operator comfort. Rotatable necks

changeover without tools.

Patented Jump Liner allows quick neck change

and replacement of only most commonly worn or

clogged liner area, which reduces the amount of

time a gun is offline and minimizes inventory.

Liners coiled in-house with proprietary process

that improves wire feed performance and 100

percent tested to ensure smoothest wire feed in

the industry.

OXO® style handle option allows configuration

of Bernard Q-Gun or S-Gun with feel similar to

former OXO APX gun.

Back end with durable rigid strain relief and

easily interchangeable direct plugs and trigger

leads connect to wire feeders and machines

from major manufacturers and allow simple

maintenance.

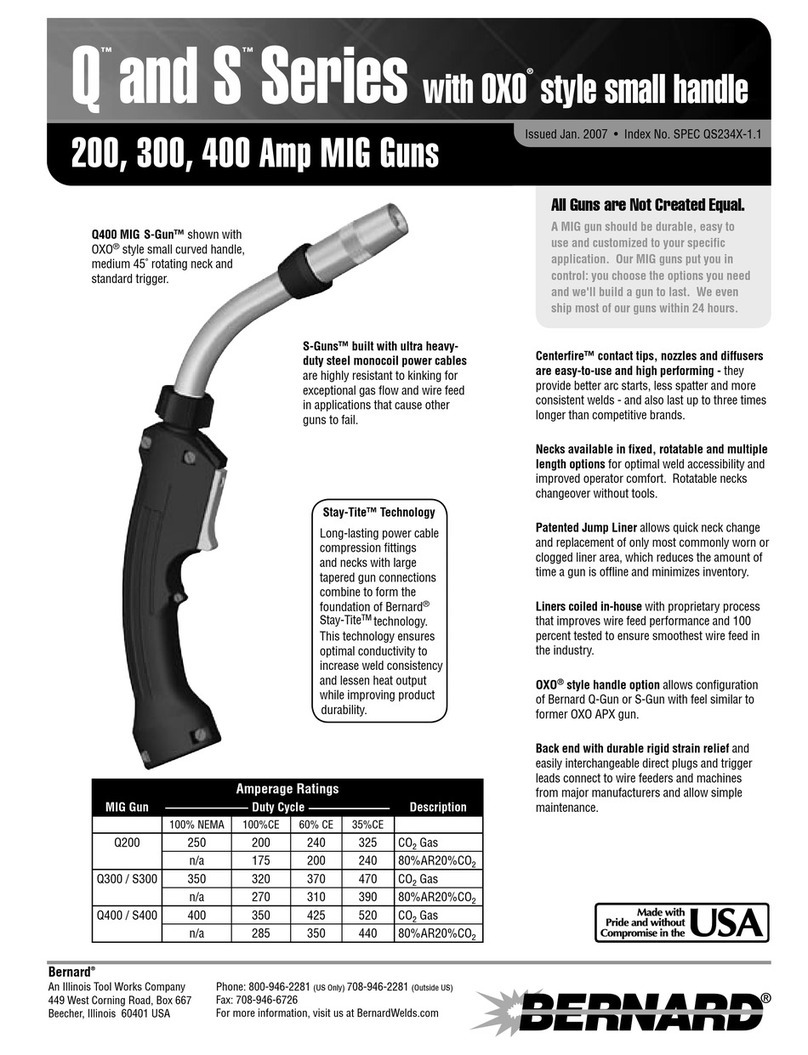

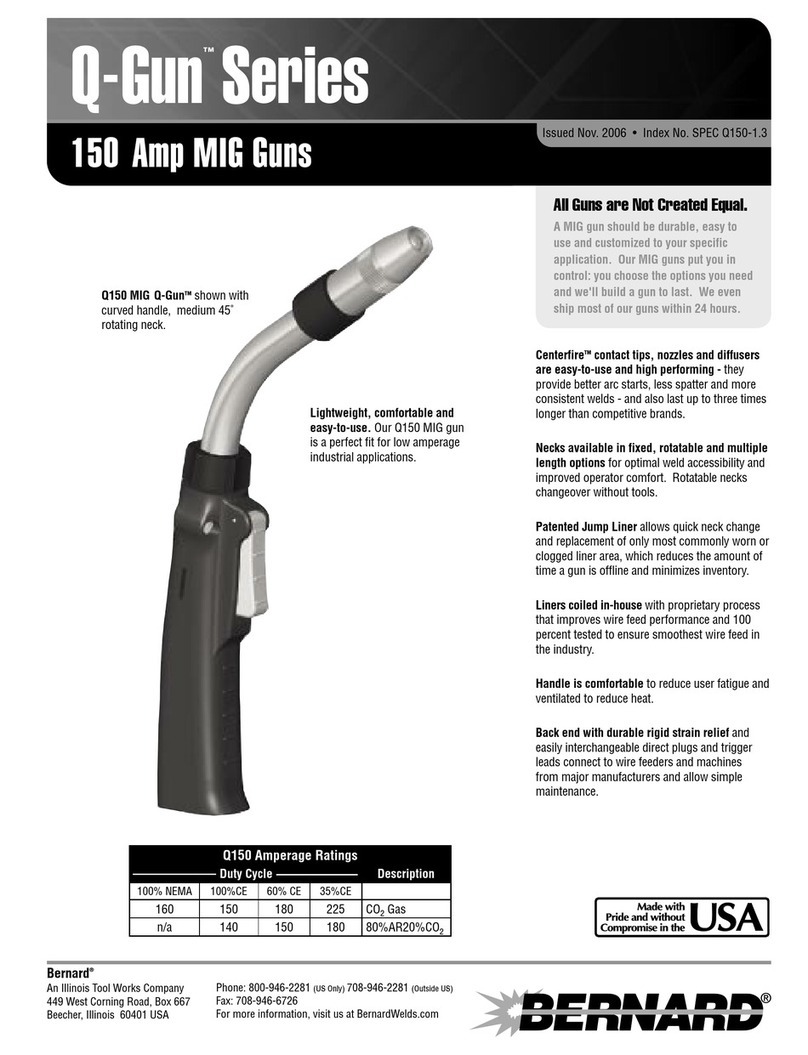

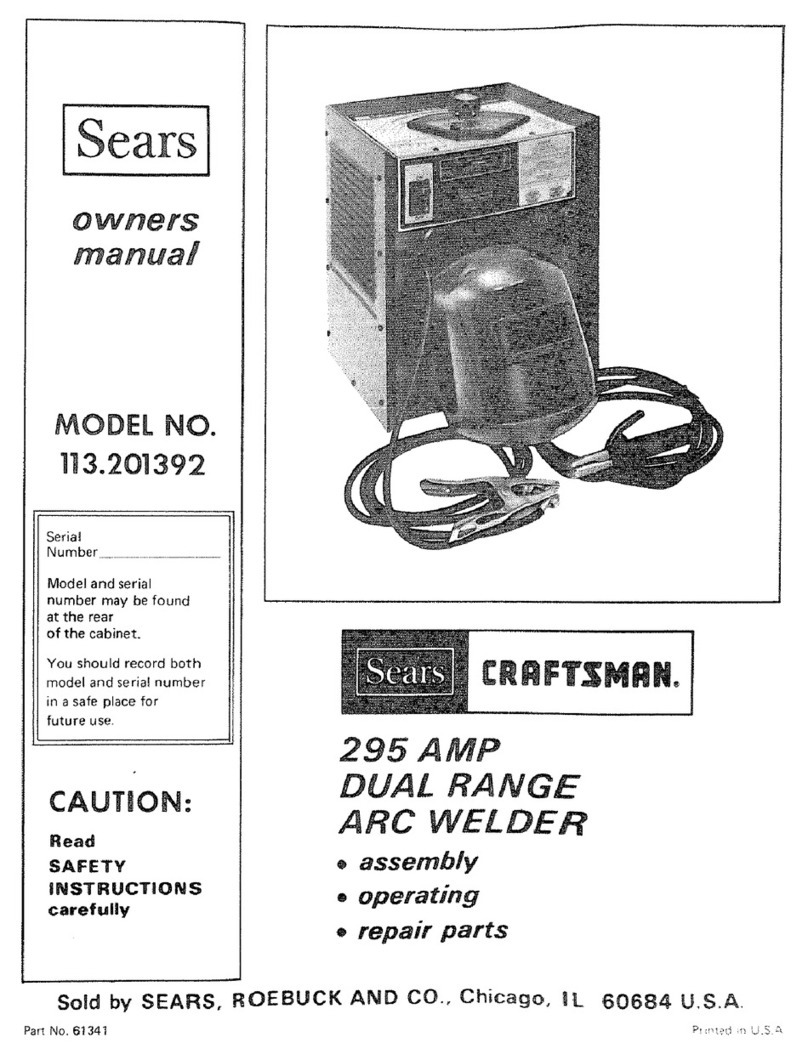

Amperage Ratings

MIG Gun Duty Cycle Description

100% NEMA 100%CE 60% CE 35%CE

Q400 / S400 400 350 425 520 CO2 Gas

n/a 285 350 440 80%AR20%CO2

Q500 / S500 500 420 480 575 CO2 Gas

n/a 370 420 500 80%AR20%CO2

Q600 / S600 550 440 540 650 CO2 Gas

n/a 420 500 550 80%AR20%CO2