Page 2 von 23 26.08.2014

Ver. 1.9 Copyright Berner Kochsysteme 2015

Content list

Content list .............................................................................................................................. 2

Safety instructions .................................................................................................................... 4

Description of warning symbols and indicators ........................................................................... 5

Danger result from not observing the safety instructions............................................................. 5

Safe application...................................................................................................................... 5

Safety instruction for the operating staff ................................................................................... 5

Improper operation................................................................................................................. 6

Modification / use of spare parts............................................................................................... 6

General information................................................................................................................... 6

Application ............................................................................................................................ 6

Product description.................................................................................................................... 6

Products................................................................................................................................ 6

Technical data........................................................................................................................ 6

Operation and control .......................................................................................................... 6

Technical unit data .............................................................................................................. 6

Function conditions.............................................................................................................. 7

Installation............................................................................................................................... 7

Electrical data of the units .................................................................................................... 7

Unit performance ( 7,5 kW - BFEM20, BFEE20 ) ...................................................................... 7

Unit performance ( 12,0 kW - BFEM30, BFEE30 )..................................................................... 7

Unit performance ( 16,5 kW – BFEM40, BFEE40 ) .................................................................... 7

Unit performance ( 15,0 kW – BFEM40/2, BFEE40/2 ) .............................................................. 7

Unit performance ( 19,5 kW – BFEM50/2, BFEE50/2 ) .............................................................. 7

Unit performance ( 24,0 kW – BFEM60/2, BFEE60/2 ) .............................................................. 7

Optional Filter System ( 0,12 kW – BEPSF1, BEPSF2 ).............................................................. 7

Installation requirements......................................................................................................... 8

Installation intructions ............................................................................................................ 8

Start up ................................................................................................................................... 9

Assembly .............................................................................................................................. 9

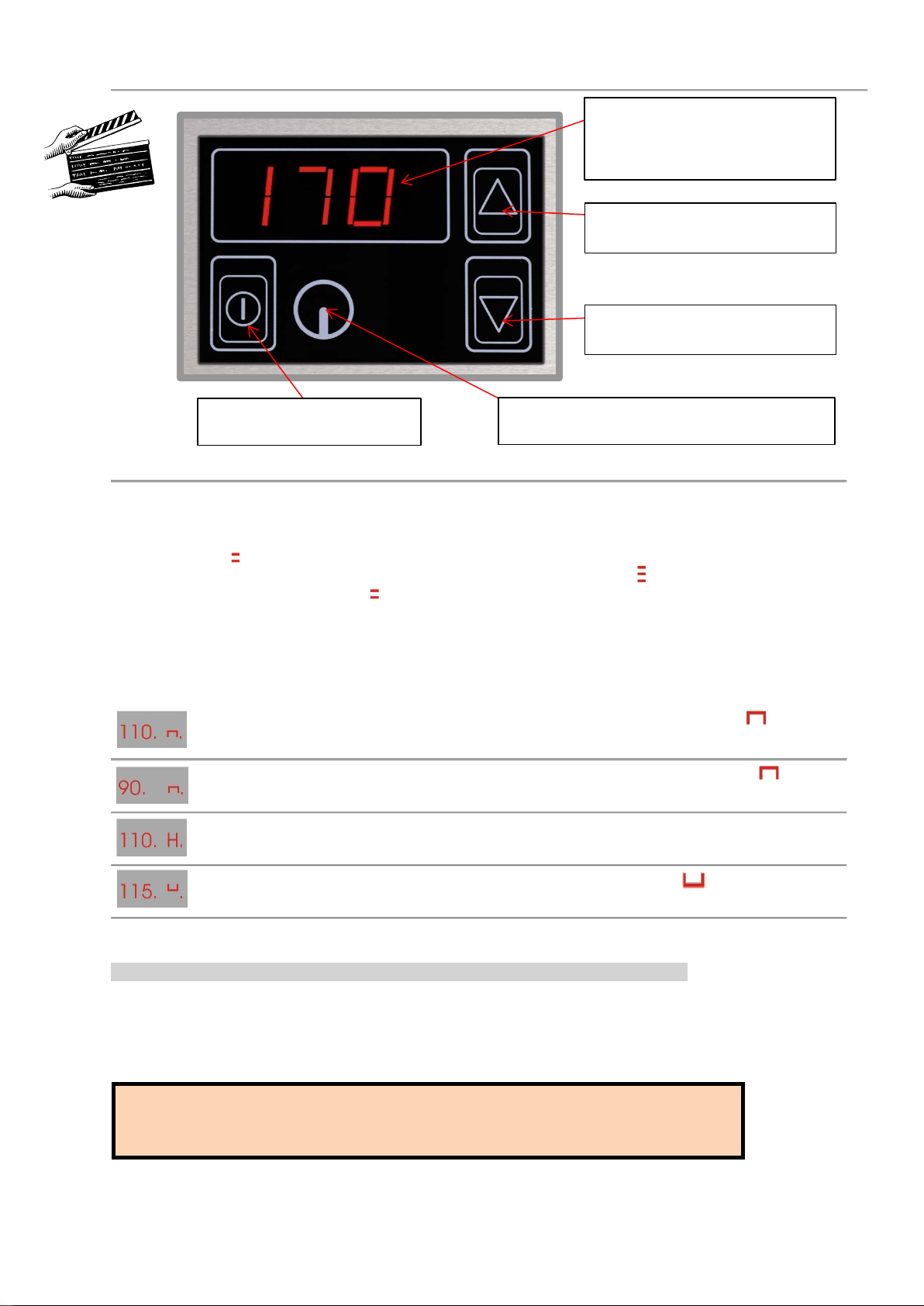

Control with knob................................................................................................................... 9

Temperature control with sensor touch control panel ................................................................ 10

Melting step...................................................................................................................... 10

Standby function ............................................................................................................... 10

Cooking process................................................................................................................... 10

Lift automatic ......................................................................................................................... 11

Lift control with sensor touch control panel.............................................................................. 11

Touch control for the basket lift system................................................................................... 11

Function test .......................................................................................................................... 12

Operating............................................................................................................................... 12

Cooking............................................................................................................................... 12

Not in use .............................................................................................................................. 12

Troubleshooting ...................................................................................................................... 13