Bernhard EXPRESS RELIEF User manual

EXPRESS

RELIEF

Please read this manual carefully.

This manual should be kept in a safe place so that it can be used for future reference.

for Express Dual Spin Grinders with Lift Table

User’s Guide &

Instruction Manual

EXPRESS RELIEF

2

EXPRESS RELIEF

© Bernhard and Company Limited

BERNHARD & CO. LIMITED

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: info@bernhard.co.uk

USA Toll Free 1-888 GRIND IT (1-888 474 6348)

EXPRESS RELIEF

Contents

Welcome to the Bernhard Express Relief. If cared for and operated correctly this

machine will give you years of good service.

This manual will enable you to obtain the best results from your Express Relief so

please read it thoroughly before using your machine.

If you have any service or operational issues please contact your distributor or

phone our technical support hotline

Technical Helpline (USA only) 1-888 474 6348

Rest of World: UK Head Ofce, England (+44) 1788 811600

Email: support@bernhard.co.uk

Technical FAQs can be found on our web site: www.bernhard.co.uk

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION ARISING FROM THE

FITTING AND/OR USE OF NON-ORIGINAL SPARE PARTS.

Safety 4

Installation 5

User Instructions 7

Parts List and Diagrams 11

Please quote this serial number on all

correspondence:

Serial #:

Express Relief – 2010/10/ENG/RB

3

EXPRESS RELIEF

© Bernhard and Company Limited

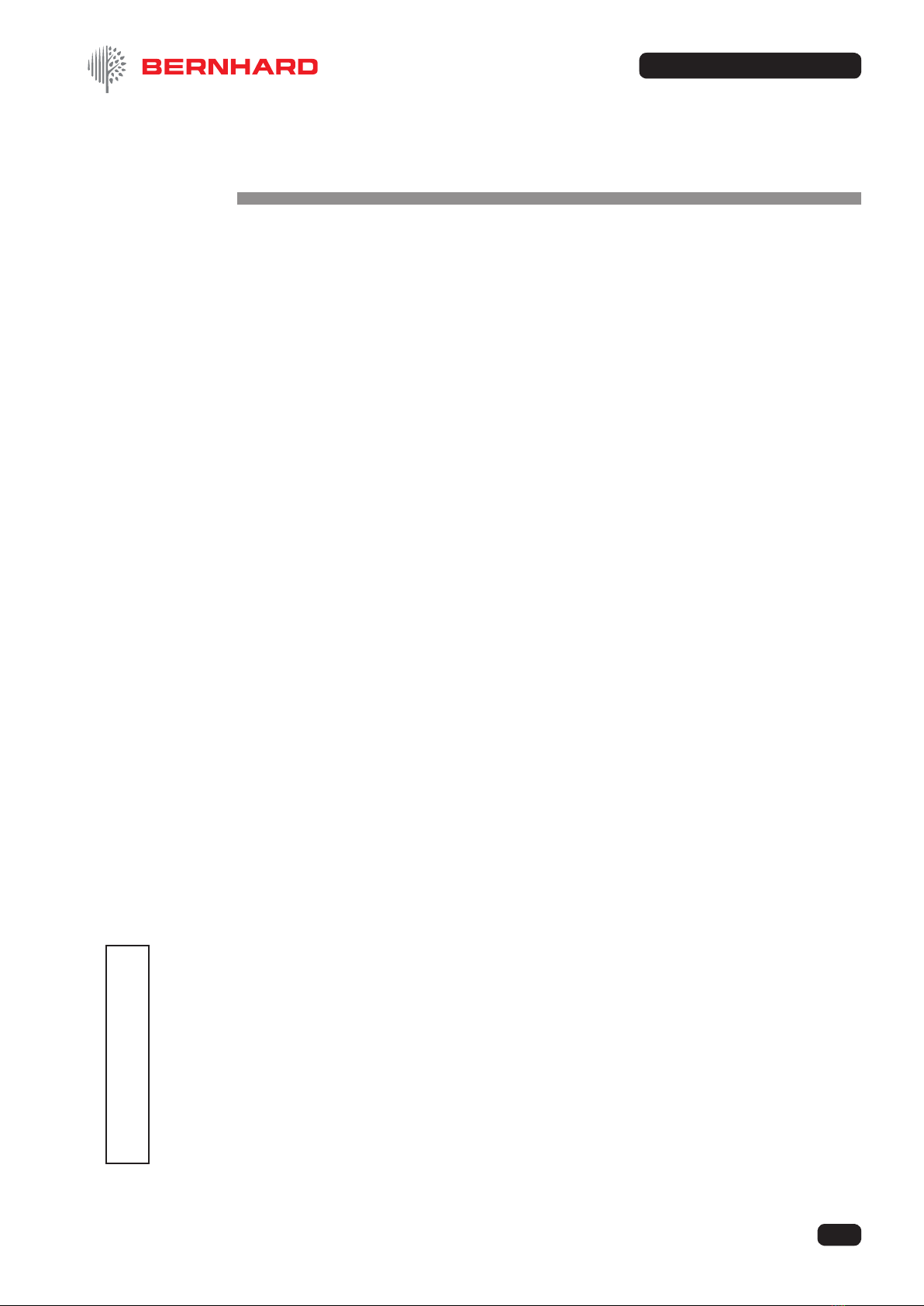

USER INSTRUCTIONS

EXPRESS RELIEF

in Up position

EXPRESS RELIEF

in Down position

4

EXPRESS RELIEF

© Bernhard and Company Limited

1.1 This machine is designed and manufactured ONLY for single blade grinding of lawn mower

reels and MUST NOT be used for any other purpose.

1.2 This machine should be installed, operated and maintained by competent personnel who

have received adequate training.

1.3 Before carrying out any work on the machine, other than grinding, ALWAYS SWITCH OFF

the main electrical supply, or remove the power lead from its socket.

1.4 NOISE - Owing to the widely varying conditions of use, noise emissions may vary

considerably. There may be occasions when the safe noise level may be exceeded (see

note on noise emission). In this case adequate ear protection MUST be worn.

1.5 NEVER t or use a grinding wheel (or other spares) other than those supplied specically

for use on the EXPRESS RELIEF (Warranty will be invalidated).

1.6 NEVER t or use a grinding wheel which has been dropped or subjected to any other form

of abuse.

NOTE: Grinding wheels should be tted O NLY by competent, trained personnel.

1.7 NEVER leave rags or tools on the machine or wear any loose clothing or other articles

which could be caught in moving components.

1.8 NEVER allow any combustible materials to be placed on or around the machine.

1.9 ALWAYS ensure that all parts of the cutting unit being ground are securely xed.

1.10 ALWAYS ensure that all electrical connections are sound and all cables are safely routed.

1.11 STAY ALERT. Watch what you are doing. NEVER operate the machine when tired, or

under the inuence of drugs or alcohol.

If the machine is raised to the UP position, ALWAYS secure it with the safety locking pin.

1. Safety

5

EXPRESS RELIEF

© Bernhard and Company Limited

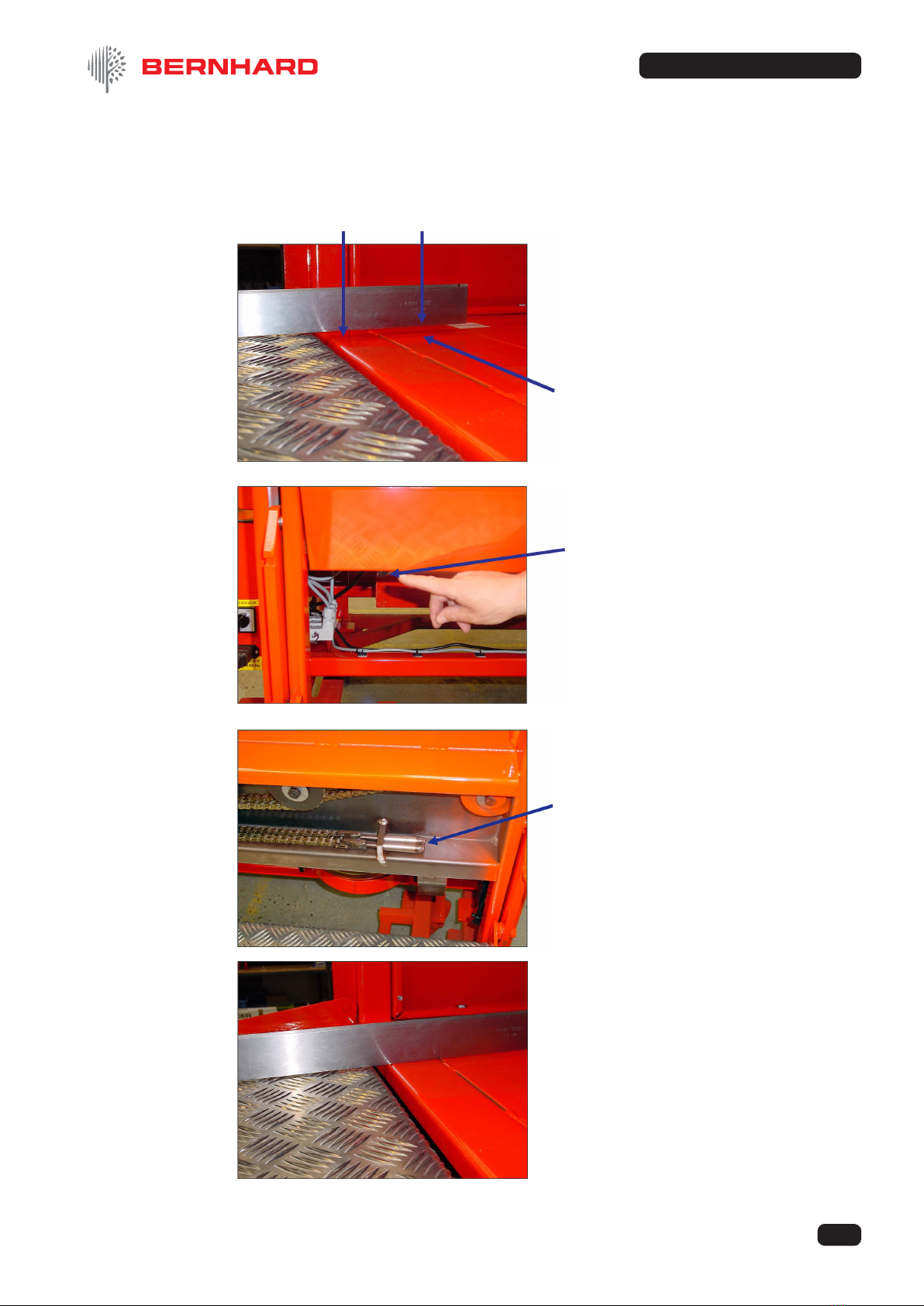

2.1 Check the height of the lift table platform – relative to the machine table.

If it is higher, as shown left, it will need to

be adjusted.

2 . 2 Undo the two wing knobs and remove the

cover from the lft table mechanism.

2.3 Using an ‘allen’ key in the adjusters, adjust

the chain length so that the platform and

the machine table are level.

2. Installation

6

EXPRESS RELIEF

© Bernhard and Company Limited

2.4 If necessary assemble the support/pivot

shaft to the Express Relief chassis.

Locate the chassis over the shaft as

shown, with the end of the shaft ush with

the outer chassis boss.

Position the two adjustable collars

as shown and secure in position with

the grub screws, to prevent lateral

movement of the chassis on the support/

pivot shaft.

2.5 Place the Express Relief on the lift table platform as shown (ensure that the bolts securing

the support/pivot shaft to the bracket go into the detents in the shaft).

2.6 Position the support bracket so that

it is central on the side plate of the

lift table chassis.

2.7 Mark the hole positions, using the

support bracket as a template.

Drill 8.5mm & Tap M10 (using the

drill and tap supplied).

Securely bolt the Express Relief to

the machine.

7

EXPRESS RELIEF

© Bernhard and Company Limited

These instructions assume that the Express Relief has been correctly tted to the lift table

of an Express Dual according to the supplied tting instructions.

3.1 If the Express Relief is in its "lowered"

position, supported on the lift table

platform, lower the lift table platform to the

ground.

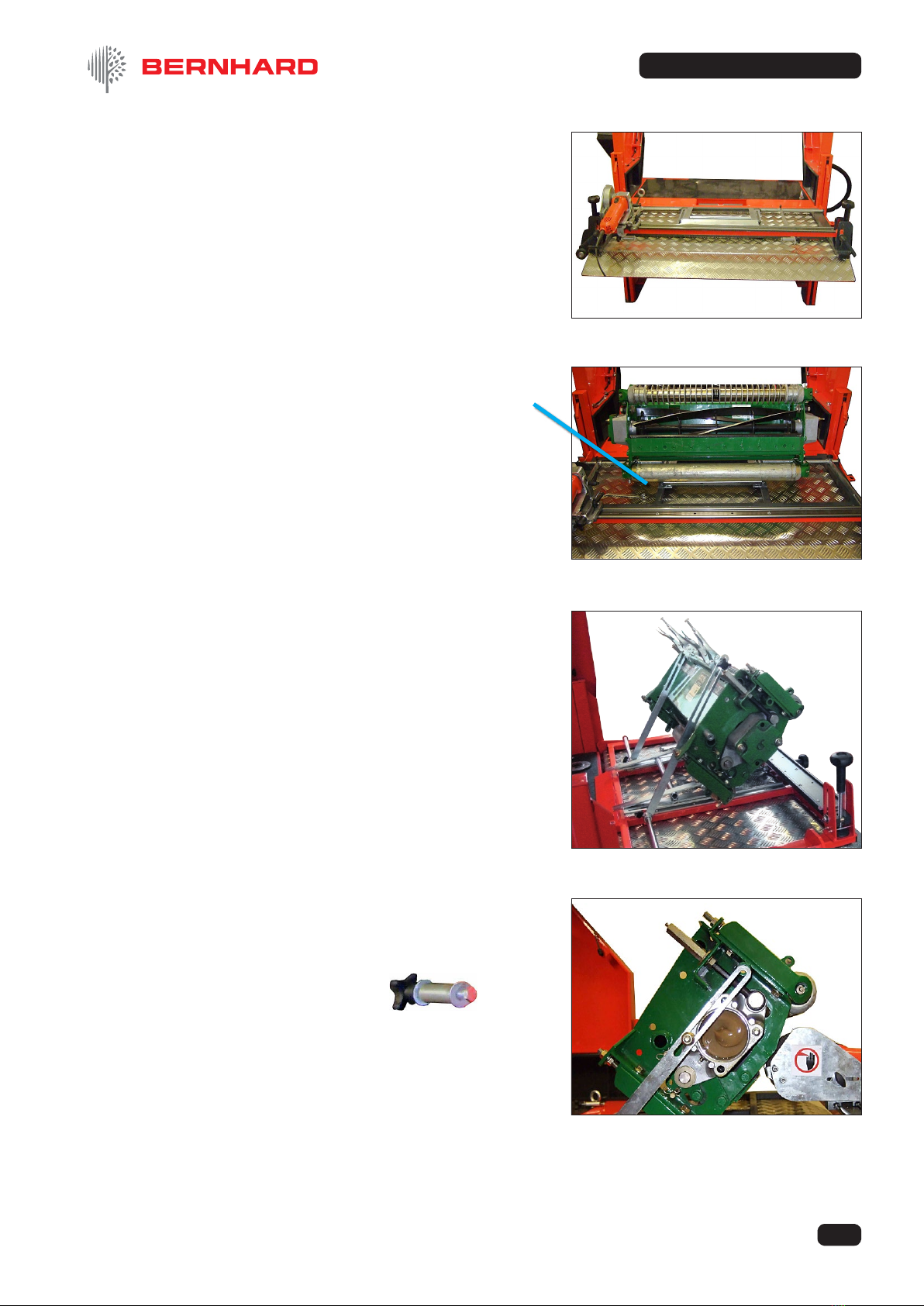

3.2 Slide the grinding head the left hand side of the guide

rail and pivot the Express Relief about its mounting, to the

vertical position and hold in position with the locking pin.

3.3 Place the cutting unit on the lift table, front facing away from the machine and raise the

platform so that the cutting unit can be slide onto the machine table.

3. User Instructions

8

EXPRESS RELIEF

© Bernhard and Company Limited

3.5 Bring the cutting unit onto the Express

Relief so that it’s rear roller is located in the

‘V’ support.

3.6 Position the adjustable clamps in the

slotted side supports so that they can

be attached to an appropriate (solid and

secure) part of the mower frame to secure

the cutting unit, starting at an angle of

approximately 45 degrees.

3.7 Alternatively, secure with a suitable bolt

directly through the side supports to the

cutting unit or (if necessary, use the spacer

bosses provided).

3.4 Lower the lift platform around 4” (100mm),

remove the locking pin and lower the

Express Relief to the horizontal position.

Raise the platform to it’s highest position

once more to support the Express Relief

frame.

9

EXPRESS RELIEF

© Bernhard and Company Limited

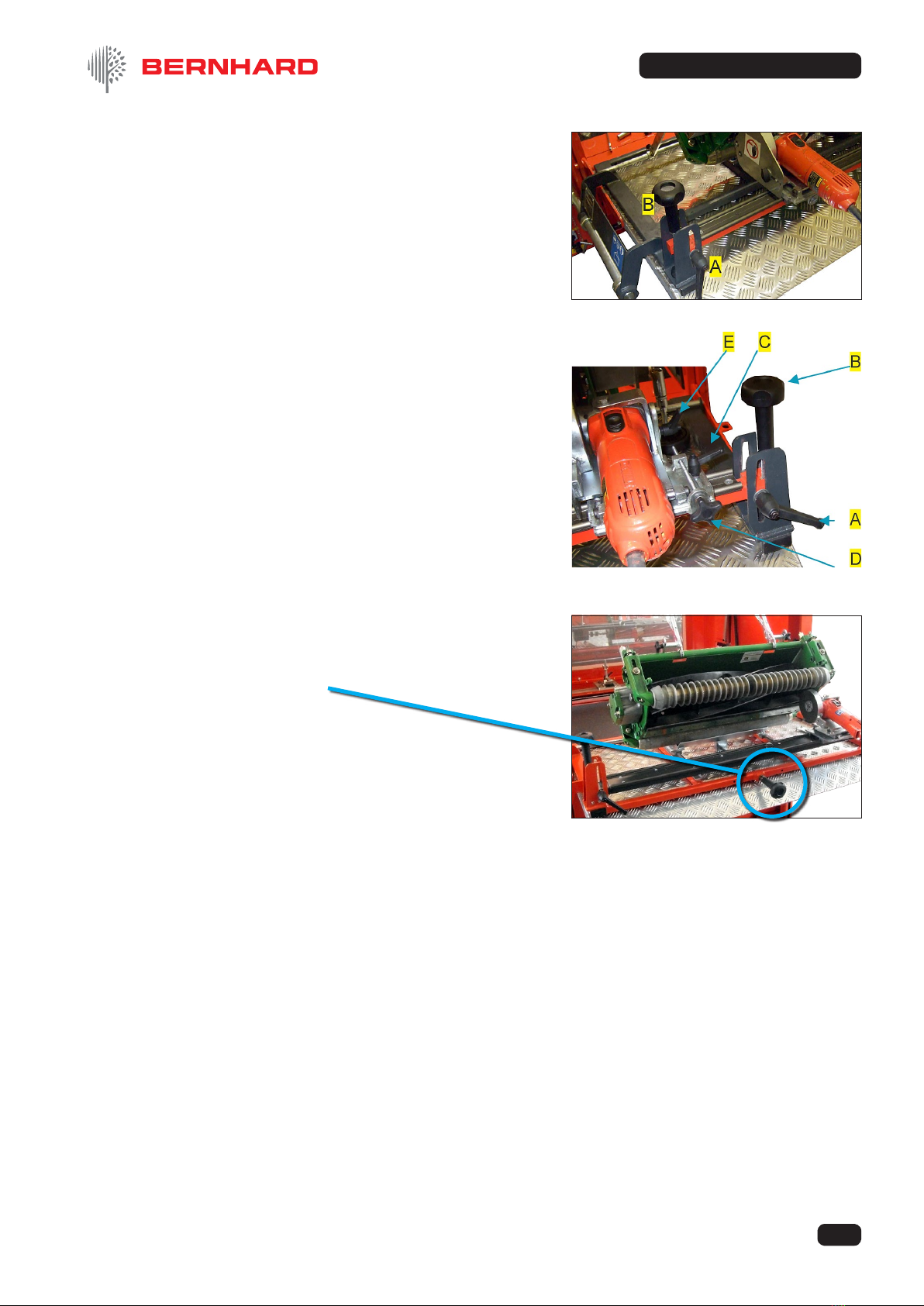

3.9 Loosen locking lever [C] to enable

horizontal infeed of the grinding head

using handwheel [D], Loosen locking lever

[E] to enable angular adjustment of the

grinding head.

3.8 Loosen locking levers [A] and raise

the guide rail by rotating adjusters

[B] at each end of the rail, for coarse

positioning of the grinding head relative

to the cutting unit.

3.10 Fine adjustment of mower position back

and forth can be achieved by moving the

vee support for the rear roller with the

handwheel.

10

EXPRESS RELIEF

© Bernhard and Company Limited

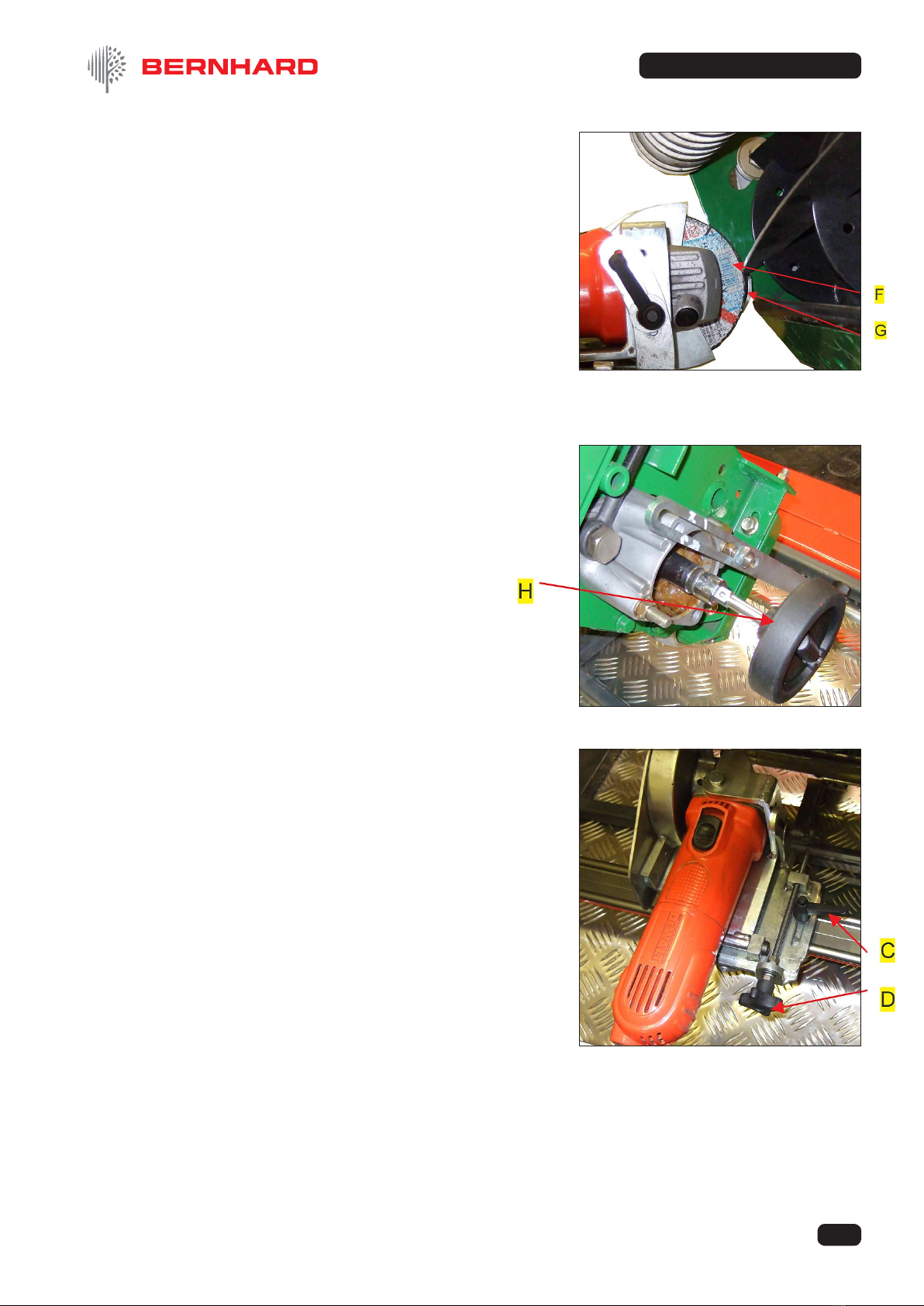

3.9 Position the grinder so that a reel blade can

be “trapped” between grinding disc [F] and

support nger [G] with the grinding disc

setting the required angle of relief to the blade.

Using the adjusting handwheels [B] at each

end of the guide rail, make ne adjustments

until contact between reel blade and grinding

disc is even along the length of the blade.

Lock this position using levers [A].

Note: Fine adjustments can later be repeated like

(with the grinder running) this to ensure an

equal width of land ground along the reel

blade.

3.10 With a suitable driver attached, insert the

reel control handwheel [H] into the cutting

unit so that each reel blade can be safely

held against the support nger and to allow

indexing from blade to blade.

3.11 Move the grinder to one end of the reel, back

the disc away from the reel blade slightly

using feed knob [D], switch on the grinder.

Feed the grinder in to apply a reasonable cut

and tighten feed locking lever [C].

3.12 Traverse the grinder back and forth along each reel blade, increasing cut as necessary,

until an acceptable amount of relief (blade thinning) has been applied.

Note: Ideally mark the rst blade that is ground, grind each blade in turn for one complete

revolution of the reel, then apply a ne nishing cut and repeat grinding for one revolution

of the reel in the opposite direction.

11

EXPRESS RELIEF

© Bernhard and Company Limited

4. Parts List

Page

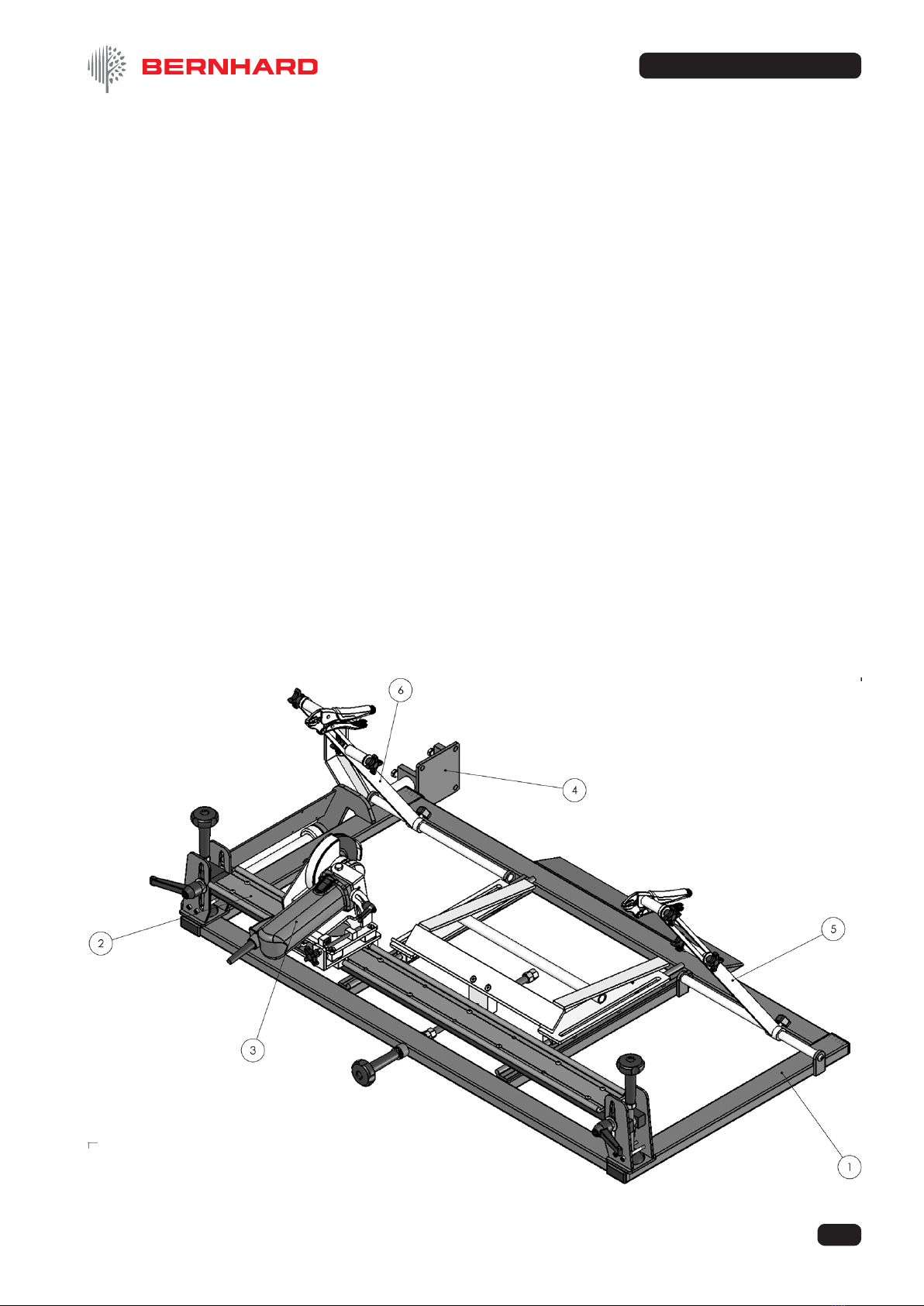

EXPRESS RELIEF COMPLETE ____________________________ 11

EXPRESS RELIEF FRAME ASSEMBLY _____________________ 12

FRONT RAIL ASSEMBLY _________________________________ 13

GRINDER TROLLEY ASSEMBLY __________________________ 14

HINGE ASSEMBLY ______________________________________ 15

RIGHT HAND MOWER SUPPORT ASSEMBLY _______________ 16

LEFT HAND MOWER SUPPORT ASSEMBLY ________________ 17

Ref # Name of Part Qty. Part #

EXPRESS RELIEF COMPLETE ________________________________

1 Express Relief Frame Assembly.............................................1 03938

2 Front Rail Assembly ................................................................1 03935

3 Grinder Trolley Assembly........................................................ 1 03714

4 Hinge Assembly ...................................................................... 1 03939

5 RH Mower Support Assembly.................................................1 03940

6 LH Mower Support Assembly ................................................. 1 03941

12

EXPRESS RELIEF

© Bernhard and Company Limited

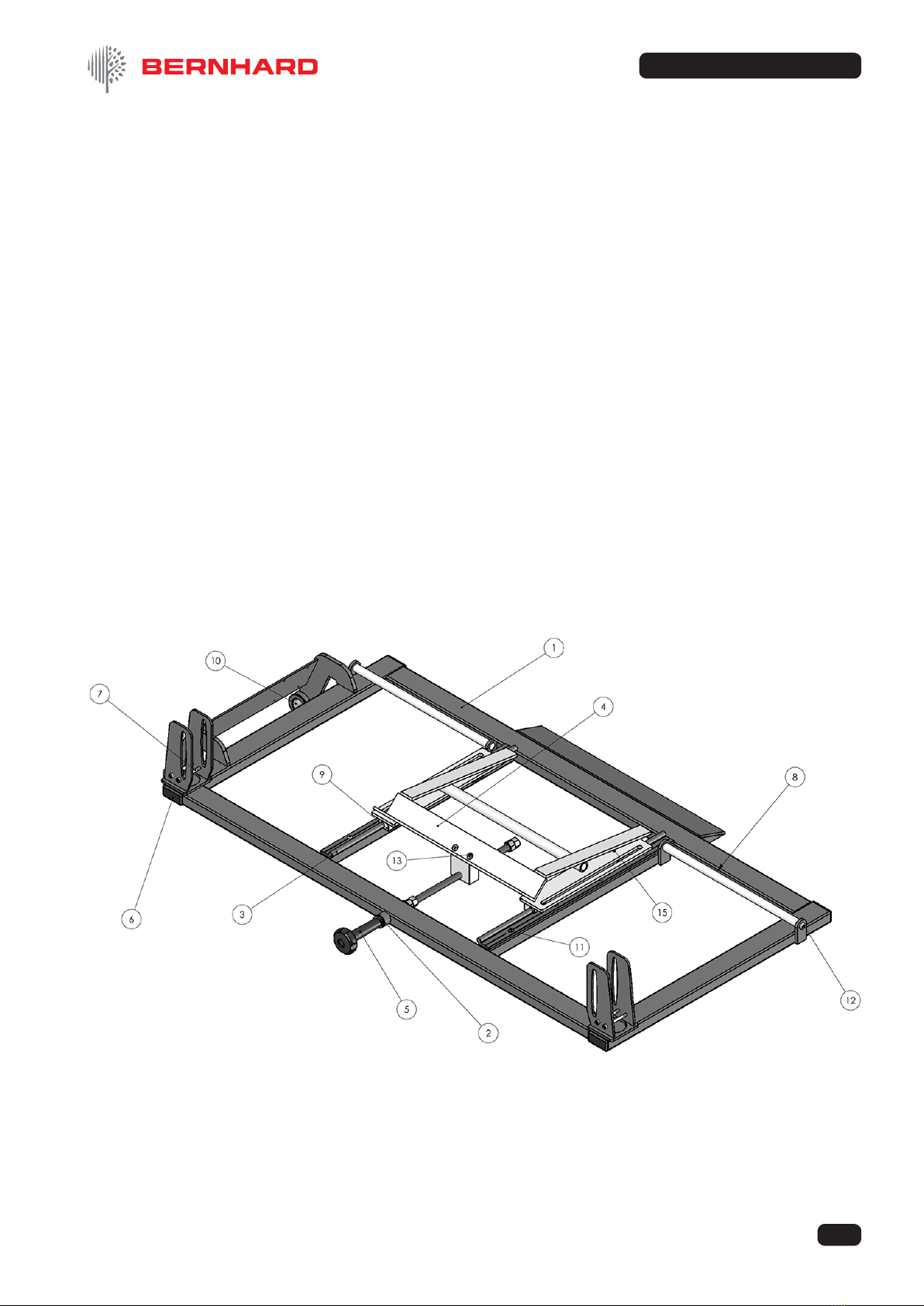

4. Parts List (Continued)

Ref # Name of Part Qty. Part #

EXPRESS RELIEF FRAME ASSEMBLY _________________________

1 Main Frame Fabrication .......................................................... 1 03934

2 Feed Screw Bush .................................................................... 1 03718

3 Single Slide Rail ......................................................................2 03422

4 BT Roller Cradle......................................................................1 04154

5 Roller Cradle Feed Assembly ................................................. 1 03717

6 Plastic Cap For Side Arm........................................................ 4 06151

7 M5 x 70 Cap Head Socket Bolt ............................................... 4 05200

8 Rear Shaft ............................................................................... 2 03363

9 DryLin Bearing ........................................................................ 4 03346

10 Oilite Bush 1 1/4” Bore ............................................................2 07701

11 ISO 7380 - M5 x 12 --- 12N..................................................... 8

12 ISO 7380 - M8 x 25 --- 25N.....................................................2

13 ISO 10642 - M6 x 16 --- 16N...................................................2

14 Hexagon Nut ISO - 4034 - M5 - N...........................................4

15 ISO 7380 - M5 x 20 --- 20N ....................................................4

13

EXPRESS RELIEF

© Bernhard and Company Limited

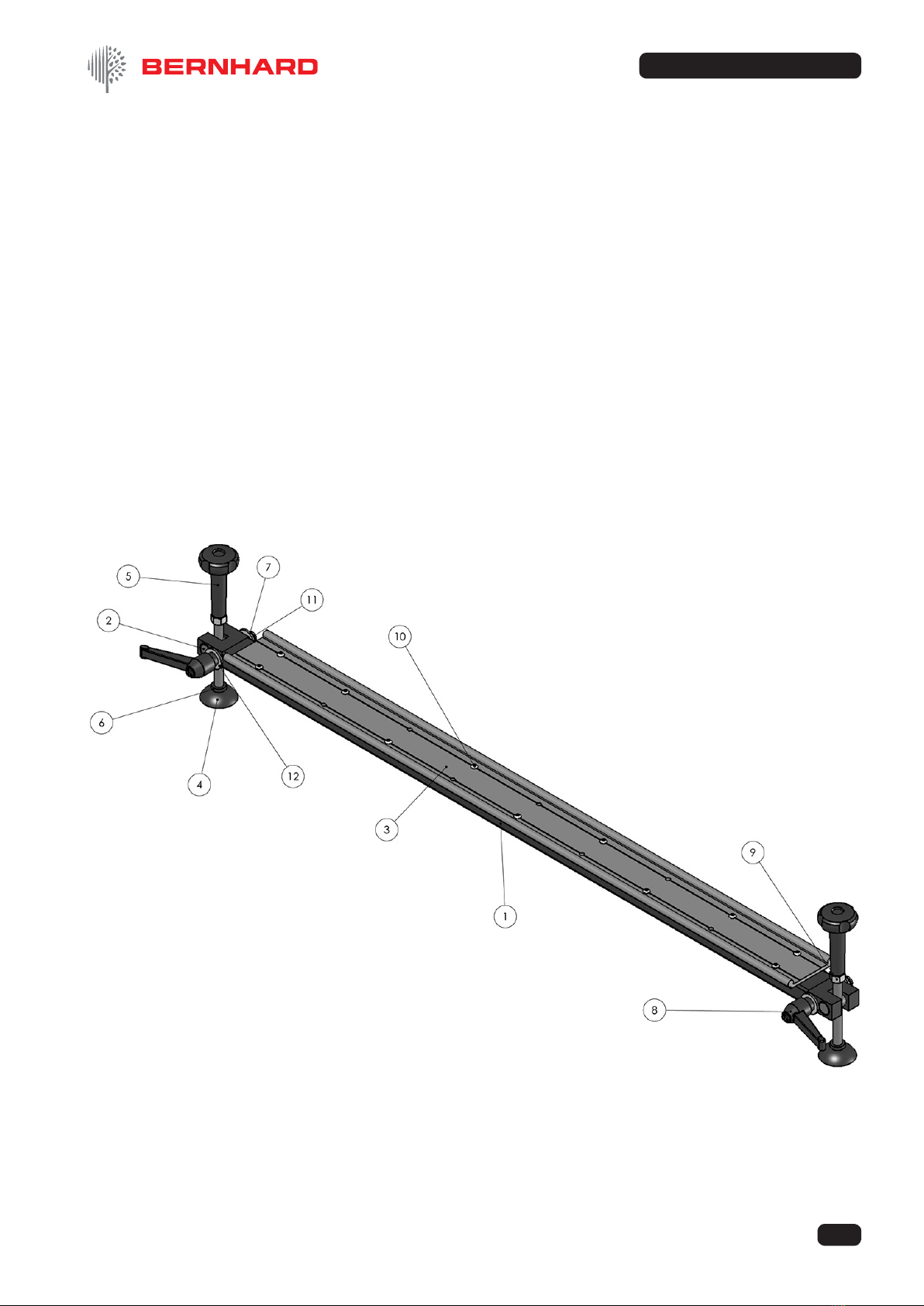

4. Parts List (Continued)

Ref # Name of Part Qty. Part #

FRONT RAIL ASSEMBLY _____________________________________

1 Main Rail Fabrication .............................................................. 1 03715

2 Mounting Bar Pivot Boss.........................................................2 03360

3 Wide Igus Rail .........................................................................1 03703

4 Self Aliening Foot .................................................................... 2 06147

5 4 Lobe Knob 50mm................................................................. 2 06135

6 Nylon Spacer........................................................................... 2 03511

7 M10 Double coil spinng M10 Double coil spring ..................... 2

8 Kip Lever M10x30.................................................................... 2 0 6119

9 Hexagon Nut ISO - 4032 - M12 - D - N ................................... 2

10 ISO 7380 - M5 x 12 --- 12N................................................... 11

11 ISO 7380 - M10 x 30 --- 30N................................................... 2

14

EXPRESS RELIEF

© Bernhard and Company Limited

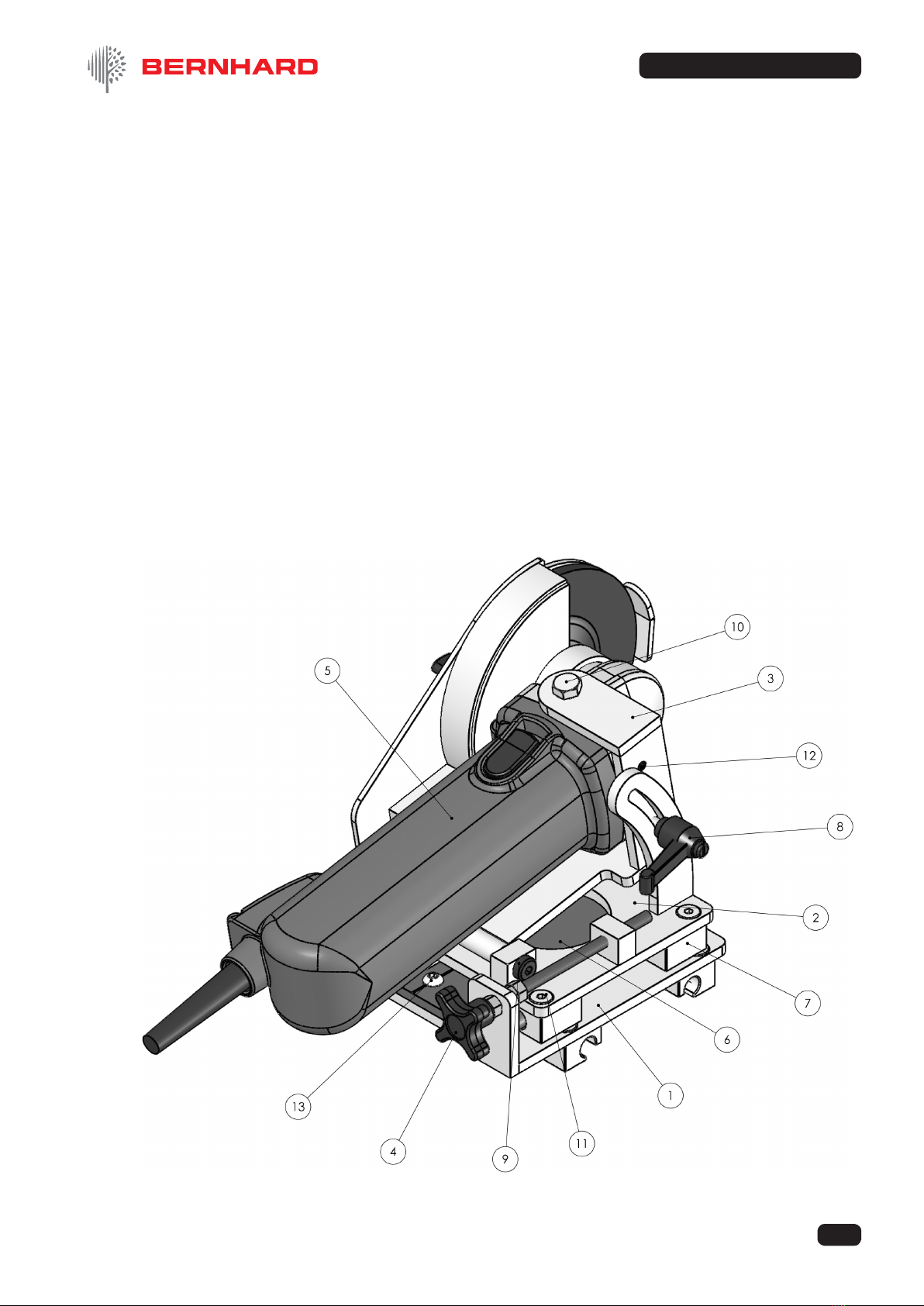

4. Parts List (Continued)

Ref # Name of Part Qty. Part #

GRINDER TROLLEY ASSEMBLY ______________________________

1 Base Carriage Fabrication ......................................................1 03711

2 Grinder Slide Carrage Fabrication ..........................................1 03709

3 Grinder Pivot Bracket Fabrication..........................................1 03706

4 Feed Screw Assembly ............................................................ 1 03379

5 Grinder Complete With Guard ................................................ 1 03374

6 Igus Cross Slide ...................................................................... 1 03713

7 DryLin Bearing ........................................................................ 8 03346

8 M6 x 16 Kip Lever F ................................................................ 1 06128

9 Shoulder Screw M8x12 ........................................................... 2 05165

10 ISO 4018 - M8 x 16-WN .......................................................... 2

11 ISO 10642 - M6 x 16 - -- 16N .................................................. 8

12 BS 4168-5 - M6 x 8-N ............................................................. 2

13 ISO 7380 - M6 x 12 --- 12N..................................................... 4

15

EXPRESS RELIEF

© Bernhard and Company Limited

4. Parts List (Continued)

Ref # Name of Part Qty. Part #

HINGE ASSEMBLY __________________________________________

1 Hinge Support Fabrication ......................................................1 03378

2 Hinge Fabrication .................................................................... 1 03377

3 T Pin ........................................................................................ 1 04262

4 1 1/4” Set Collar....................................................................... 2 04050-14

5 BS 4168-5 - M10 x 10-N.......................................................... 2

6 ISO 4018 - M8 x 30-WN..........................................................2

16

EXPRESS RELIEF

© Bernhard and Company Limited

4. Parts List (Continued)

Ref # Name of Part Qty. Part #

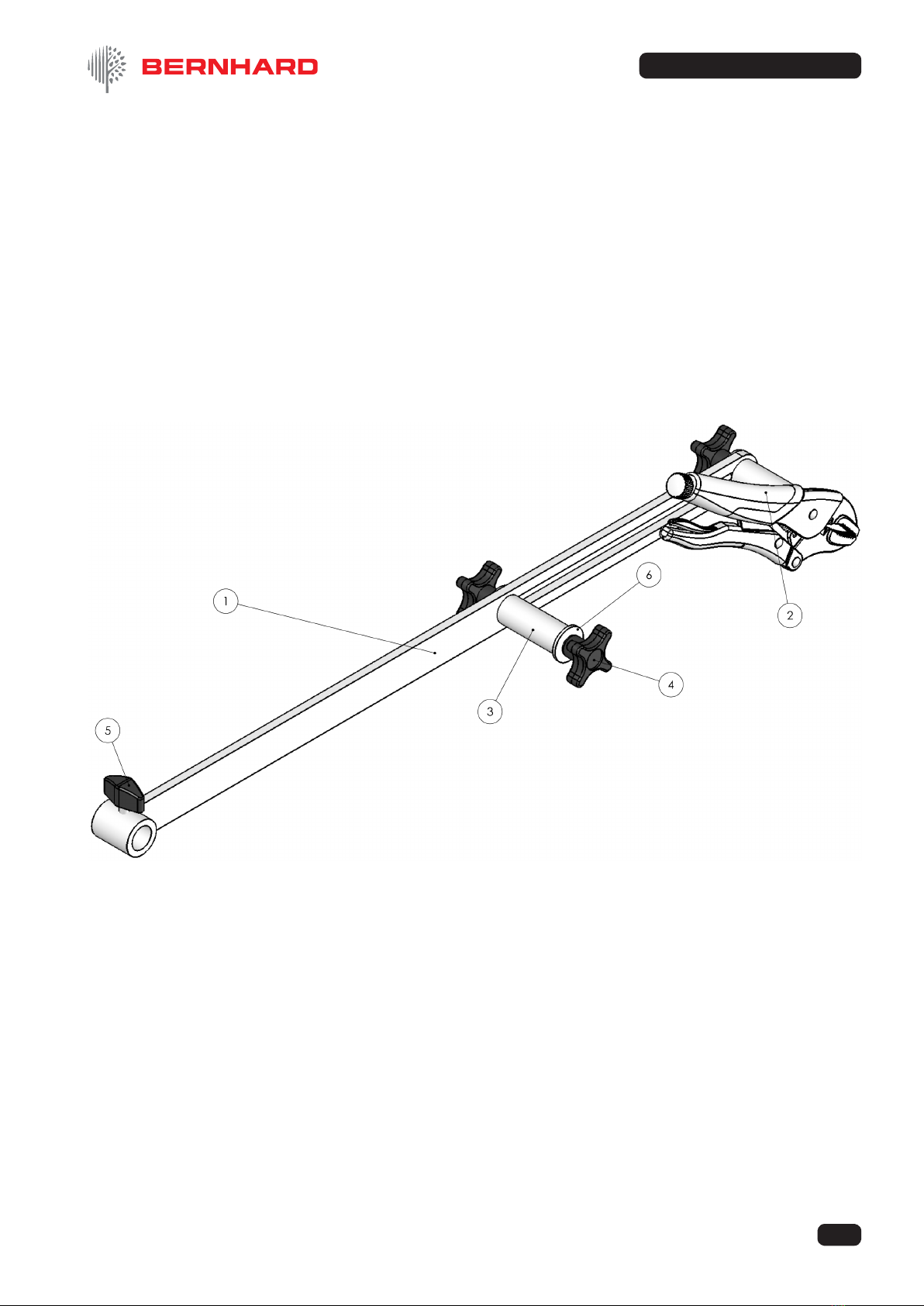

RIGHT HAND MOWER SUPPORT ASSEMBLY ___________________

1 Mower Support Stay Complete ............................................... 1 03369

2 LH Vice Grip Clamp Fabrication ............................................. 1 03727

3 Support Stay Spacer ...............................................................1 03366

4 M8 x 15mm Lobe Knob ........................................................... 3 06131

5 Wing Knob M6x10 ................................................................... 1 06126

6 Black washer BS 4320 - M8 (Form G) .................................... 3

17

EXPRESS RELIEF

© Bernhard and Company Limited

4. Parts List (Continued)

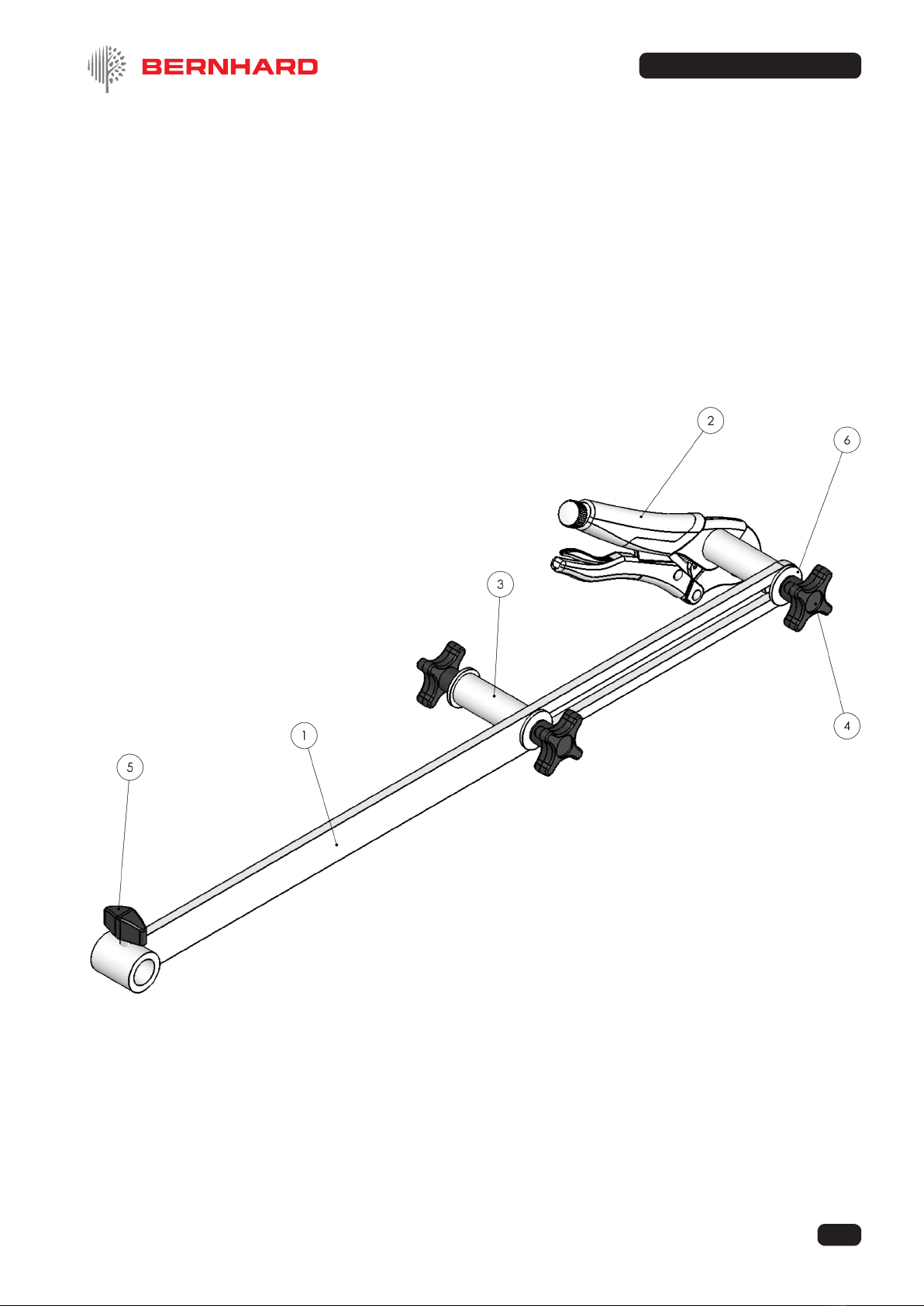

Ref # Name of Part Qty. Part #

LEFT HAND MOWER SUPPORT ASSEMBLY ____________________

1 Mower Support Stay Complete ............................................... 1 03369

2 RH Vice Grip Clamp Fabrication............................................. 1 03726

3 Support Stay Spacer ...............................................................1 03366

4 M8 x 15mm Lobe Knob ........................................................... 3 06131

5 Wing Knob M6x10 ................................................................... 1 06126

6 Black washer BS 4320 - M8 (Form G) ................................... 3

BERNHARD & CO. LIMITED

Bilton Road • Rugby • England • CV22 7DT

Tel +44 1788 811600 • Fax +44 1788 812640

Email: [email protected]

USA Toll Free 1-888 GRIND IT (1-888 474 6348)

If you have any service or operational issues please contact your distributor

or phone our technical support hotline

Technical Helpline (USA only) 1-888 474 6348

Rest of World: UK Head Ofce, England (+44) 1788 811600

Email: techsupport@bernhard.co.uk

Technical FAQs can be found on our web site: www.bernhard.co.uk

When ordering spare parts please quote the machine type and serial number.

THE MANUFACTURERS ACCEPT NO RESPONSIBILITY FOR ANY SITUATION ARISING FROM

THE FITTING AND/OR USE OF NON-ORIGINAL SPARE PARTS.

Table of contents

Other Bernhard Lifting System manuals

Popular Lifting System manuals by other brands

Nussbaum

Nussbaum JUMBO NT 3500 Operating Instruction and Documentation

probst

probst AKZ-UNI-H operating instructions

Vestil

Vestil HDC-305 Series manual

Nuvo

Nuvo Navigator Lift 180 Single operating instructions

North American Ramps

North American Ramps CHECK OUT ProMaster MANUAL & SAFETY INSTRUCTIONS

Basta Boatlifts

Basta Boatlifts Over-Center 36k60 Assembly and installation instruction