STINAR PS-813B/E Manual

sales@stinar.com |P651.454.5112 |F651.454.5143 |www.stinar.com REV.10.2020

PASSENGER STAIRWAY

OPERATION & MAINTENANCE MANUAL

MODEL: PS-813B/E

Passenger Stairway PS-813B/E Boeing | 2

EFFECTIVE PAGES SECTION PAGE DATE

Title Page 1

List of Eective Pages 2

Contents 3

Introduction 7

SECTION 1

Section 1-1 8-13

Section 1-2 14-18

Section 1-3 19-20

SECTION 2

Introduction 23

Section 2-1 23-26

Section 2-2 27-29

Section 2-3 30

Section 2-4 31-32

SECTION 3

Section 3-1 33

SECTION 4

Intoduction 34

Section 4-1 35

Section 4-2 36

Passenger Stairway PS-813B/E Boeing | 3

TABLE OF CONTENTS GENERAL INFORMATION & OPERATING INSTRUCTIONS � � � � � 7

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES � � � � � � � � � 8

1�1 Description � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

1.1.1 | Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.2 | Stairway, Platform and A-frame. . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.2.1 | A-frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.1.2.2 | Lower Stairs Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.2.3 | Upper Stairs Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.1.2.4 | Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.2.5 | Stabilizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.2.6 | Gasoline Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.3 | Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.1.3.2 | Hydraulic Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.3.3 | Lock Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.3.4 | Flow Control Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.3.5 | Return Line Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1.4 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.1.4.1 | Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.2.1 | Operating Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . 13

1.2.1.1 | Engine Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.2.1.2 | Primary Control Station (see Figure 1.2.1.2) . . . . . . . . . . . . . . . . . 13

1�2 Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 14

1.2.1.3 | Ratchet Release Handles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.1.4 | Auxiliary Hand Pump (see Figure 1.1.3) . . . . . . . . . . . . . . . . . . . . 14

1.2.1.5 | Battery Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.2 | Pre-Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.3 | Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.2.3.3 | Towing and Positioning the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.2.3.4 | Raising the Stairway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.3.5 | Lowering the Stairway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.3.6 | Operating A-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2.3.7 | Boarding and Disembarking Passengers . . . . . . . . . . . . . . . . . . 16

1.2.3.8 | Removing the Stairway from Aircraft . . . . . . . . . . . . . . . . . . . . . 17

1.2.3.9 | Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.4 | Emergency Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 17

1.2.4.1 | Operating Auxiliary Hand Pump . . . . . . . . . . . . . . . . . . . . . . . . . 17

1.2.4.2 | Raising Stairway or A-frame Using Hand Pump . . . . . . . . . . . . . 18

1.2.4.3 | Lowering Stairway or A-frame Using Hand Pump . . . . . . . . . . . 18

1.2.4.4 | Operating stabilizers Using Hand Pump . . . . . . . . . . . . . . . . . . . 18

1.3 Specications and Capabilities � � � � � � � � � � � � � � � � 19

1.3.1 | General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.2 | Capacities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.3 | Engine Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.3.4 | Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Passenger Stairway PS-813B/E Boeing | 4

1.3.5 | Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

SECTION 2 - SERVICING PASSENGER STAIRWAY � � � � � � � � � � 23

2�1 Servicing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 23

2.1.1 | Structural Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.1.1 | Sheet, Bar and Tubular Member (Non-Load Bearing). . . . . . . . 23

2.1.2 | Gasoline Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.2.1 | Servicing the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.3 | Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.3.1 | Hydraulic Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.3.2 | Hydraulic Oil Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1.3.3 | Pressure Relief Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.3.4 | Flow Control Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.4 | Electrical System (12 VDC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.4.1 | Electrical Cables, Wiring and Lights. . . . . . . . . . . . . . . . . . . . . . . 24

2.1.4.2 | Batteries and Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.5 | Scheduled Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 2.1.5 | Scheduled Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.1.6 | Non-Scheduled Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 2.1.6 | Non-Scheduled Servicing . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.1.7 | Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.1.7.1 | Chassis, Stairway and A-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 2.1.7.1 | Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.2 Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � � 27

Table 2.2.1 | Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.3 Adjustments � � � � � � � � � � � � � � � � � � � � � � � � � � � 30

2.3.1 | Hydraulic Pressure Relief Valve Adjustment . . . . . . . . . . . . . . 30

2.3.2 | Flow Control Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.3.3 | Stairway Clearance Adjustment Bolts . . . . . . . . . . . . . . . . . . . 30

2.3.4 | Gasoline Engine Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.4 Removal and Installation � � � � � � � � � � � � � � � � � � � � 31

2.4.1 | Stair Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4.1.1 | Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.4.1.2 | Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SECTION 3 - OVERHAUL � � � � � � � � � � � � � � � � � � � � � � � � 33

SECTION 4 - PARTS � � � � � � � � � � � � � � � � � � � � � � � � � � � 34

4.1 Manufacturer Identication � � � � � � � � � � � � � � � � � � 35

4.2 Detailed Parts List � � � � � � � � � � � � � � � � � � � � � � � � 36

4.2.1 | Understanding the Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1.1 | Figure/Item No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1.2 | Manufacturer’s Part No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1.3 | Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1.4 | Vendor Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2.1.5 | Qty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Passenger Stairway PS-813B/E Boeing | 5

4.2.2 | How to Order Parts and Assemblies . . . . . . . . . . . . . . . . . . . . 36

PARTS ORDER FORM � � � � � � � � � � � � � � � � � � � � � � � � � � 37

Fig 1.1 | Passenger Stairway, Model PS-813B/E 38

Fig 1.1.2.1 | A-frame 39

Fig 1.1.3 | Hydraulic Schematic 40

Fig 1.1.3.1 | Primary Control Station 41

Fig 1.1.4 | Electrical Schematic 42

Figure 1.2.1.2 | Primary Control Station 43

Figure 2.1.7.1 | Lubrication Points 44

Figure 2.1.7.2 | Lubrication Points 45

Figure 2.1.7.3 | Lubrication Points 46

Figure 2.2.1.1 | Hydraulic Schematic 47

Figure 2.2.1.2 | Electrical Schematic 48

Figure 2.3.1 | Primary Control Valve 49

Figure 2.3.3 | Adjustment Bolts 50

Figure 4.3.1 | Passenger Stairway, Model PS-813B/E 51

Figure 4.3.1 | Passenger Stairway, Model PS-813B/E - Table 52

Figure 4.3.1 | Passenger Stairway, Model PS-813B/E - Table Pt.2 53

Figure 4.3.2 | Stairway Chassis Assembly 54

Figure 4.3.2 | Stairway Chassis Assembly - Table 55

Figure 4.3.3 | Upper Stairs and Platform 56

Figure 4.3.3 | Upper Stairs and Platform - Table 57

Figure 4.3.4 | Lower Stairs Assembly 58

Figure 4.3.4 | Lower Stairs Assembly - Table 59

Figure 4.3.5 | Stairway Ratchet Assembly 60

Figure 4.3.5 | Stairway Ratchet Assembly - Table 61

Figure 4.3.6 | A-frame Assembly 62

Figure 4.3.6 | A-frame Assembly - Table 63

Figure 4.3.7 | Hydraulic System 64

Figure 4.3.7 | Hydraulic System - Table 65

Figure 4.3.8 | Stairway Extend Cylinder 66

Figure 4.3.9 | Electrical Schematic 67

Figure 4.3.9 | Electrical Schematic - Table 68

Figure 4.3.10 | Control Station 69

Figure 4.3.10 | Control Station - Table 70

Passenger Stairway PS-813B/E Boeing | 6

SECTION / SECTION PAGE DATE

REVISIONS PAGE

Passenger Stairway PS-813B/E Boeing | 7

This publication provides operating and maintenance instructions,

including detailed part lists for the Passenger Stairway, Model PS-813B/E.

This unit was manufactured by:

Stinar, LLC

10061 State Hwy. 30

Blooming Prairie, MN 55917

Section 1

Includes a unit description, recommended procedures for operation, plus

specications and capabilities.

Section 2

Provides unit maintenance information, service and lubrication data, a

troubleshooting guide and adjustment information.

Section 3

Presents instructions for component overhaul and repair.

Section 4

Contains a manufacturers’ list and illustrated parts lists for the

assemblies, sub-assemblies and systems within the unit.

GENERAL INFORMATION & OPERATING INSTRUCTIONS

Passenger Stairway PS-813B/E Boeing | 8

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

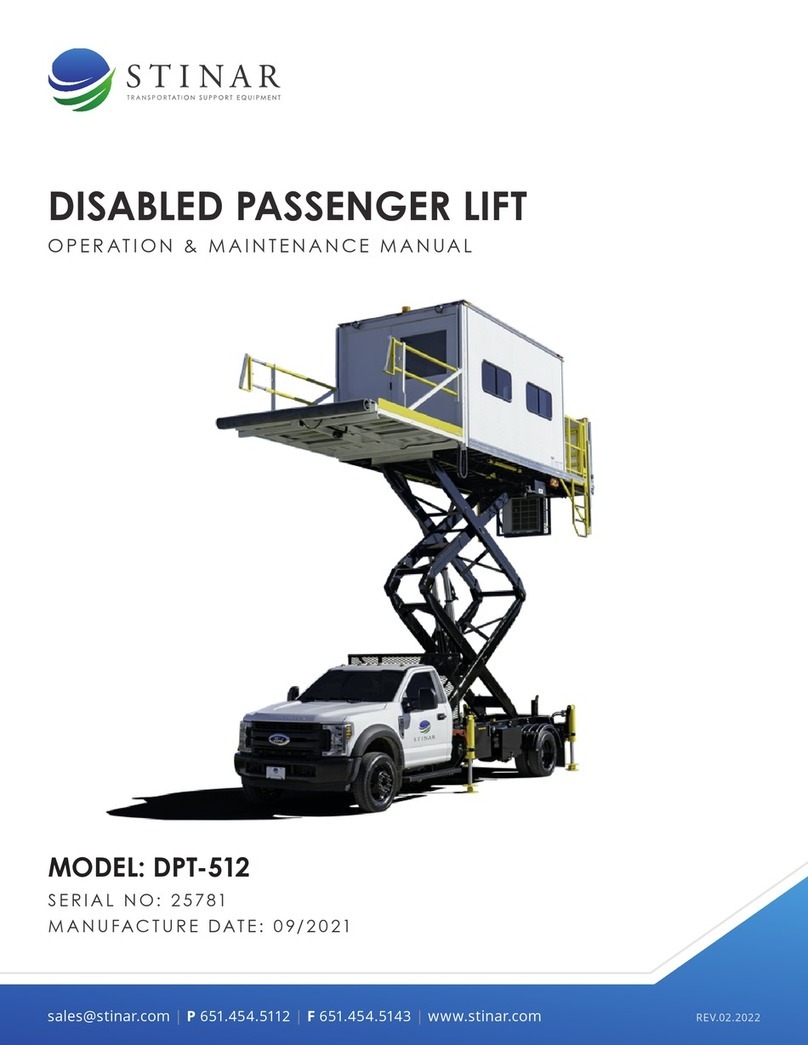

The Stinar Model PS-813B/E Passenger Stairway (see Figure 1.1) is a towable

passenger boarding stairway. Height adjustment is made by means of a

telescoping A-frame mechanism and the upper stairs telescoping into the

lower stairs. The stairway incorporates an aircraft boarding platform at

the top of the stairs. The platform provides access to aircraft cabins with

doorsill heights ranging from 96 in. (2440 mm) to 228 in. (5790 mm) above

ground level. Four hydraulically-operated stabilizers provide stability when

the stairway is raised.

A gasoline engine on the chassis is coupled to a hydraulic pump that

operates whenever the engine is running. The pump provides hydraulic

power to raise and lower the stairway, A-frame and stabilizers. A

hand pump provides emergency power in case of main power failure.

Mechanical ratchets lock the stairway and A-frame in position. A 12 VDC

electrical system provides power for illuminating the stairs and for the

engine electric starter.

1.1.1 | Chassis

The stairway chassis is a steel channel frame to which the stairway sub-

assemblies are attached. The chassis is tted with spring-loaded dual-

wheel casters at the stairs end and with a rigid axle beneath the A-frame.

The axle is tted with hubs having automotive-type bearings. The wheels

have ve bolts and 8 in. rims and are tted with 4:00 x 8 solid tires.

Mounting brackets for the stairway and A-frame are provided at opposite

ends of the chassis. A stabilizer is attached to each corner of the frame.

The frame provides mounting brackets for the electrical system and the

hydraulic system and for the engine.

A tow bar is attached to the stairway/chassis for towing purposes. When

not in use, the tow bar should be lifted and latched to the chassis.

1.1.2 | Stairway, Platform and A-frame

The elevating stairway consists of two stair sections supported by a

telescoping A-frame. The lower stairs assembly is attached to the chassis

by a shaft, which enables the stairs to pivot. The top of the lower stairway

is connected to the chassis by the A-frame assembly. The A-frame

permits the angle of inclination (and thus the platform height) of the

stairway to be adjusted. The upper stairs section, which includes the

platform, can be extended and retracted.

1.1.2.1 | A-frame

The A-frame assembly (see Figure 1.1.2.1) supports the stairs sections and

can be raised or lowered to adjust the angle of the stairway and platform.

The A-frame consists of two sections.

1. The inner A-frame is the lower of the two sections. The base of the

inner A-frame is secured by pivot pins to a support bracket welded

to the chassis.

1.1 DESCRIPTION

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

Passenger Stairway PS-813B/E Boeing | 9

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

2. The outer A-frame is the upper A-frame section. This section slides

up and down over the inner section. Two hydraulic cylinders raise or

lower the outer A-frame. The top of the outer A-frame is attached to

the lower stairs section.

3. NOTE: The A-Frame ratchet does not have to be locked in ratchet

stop for normal operation. It is intended as a safety device in the

event of cylinder failure. The ratchet assembly (dogs) must operate

freely into any position on the ratchet stops on the A-Frame.

The A-frame ratchet assembly mechanically locks the A-frame at

various positions. The ratchet assembly consists of a ratchet shaft

equipped with ratchet dogs and a hand lever for engaging the ratchet

dogs to ratchet stops on the A-frame. The ratchet is secured in the

engaged position by the o-center weight of the handle.

1�1�2�2 | Lower Stairs Section

The lower stairs section consists of fteen aluminum steps with tread

surfaces and two side panels, which incorporate handrails. The stairs may

be illuminated by lights installed in the side panels.

The base of the lower stairs section is mounted to the stairway chassis

by means of a shaft, which enables the lower section to pivot when the

A-frame is extended.

The upper portion of the lower stairs section is supported by the

A-frame. Rollers at the upper end support the upper stairs and permit it

to slide freely.

A stair ratchet assembly is attached to the underside of the lower stairs

section. This assembly consists of a ratchet shaft, ratchet dogs and a

manually-operated lever. The ratchet dogs lock the upper stairs section

in position by engaging stops welded to the bottom of the upper stairs

section. The stairs ratchet is released manually by operating the hand

lever.

1�1�2�3 | Upper Stairs Section

The upper stairs section consists of fourteen aluminum steps with tread

surfaces, two side panels with handrail and the service platform. The

upper section is attached to the lower section through a channel on each

side of the lower stairs section. Two rollers are installed on each side at

the lower end of the upper section, enabling the upper section to move

up and down smoothly.

The upper section is raised and lowered by the stairway hydraulic cylinder.

The upper end of this long, slender cylinder is attached to the platform. The

lower end of the cylinder is secured at the base of the lower stair section.

NOTE:

The A-Frame ratchet does not

have to be locked in ratchet

stop for normal operation. It

is intended as a safety device

in the event of cylinder failure.

The ratchet assembly (dogs)

must operate freely into any

position on the ratchet stops

on the A-Frame.

Passenger Stairway PS-813B/E Boeing | 10

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

1.1.2.4 | Platform

The platform is part of the upper stairway and is welded to the upper

stairway side channels. The platform oor is fabricated from diamond

tread plate. Side panels on the platform slide back and forth on rollers

and can be latched in place by means of foot latches. Two platform

lights illuminate the platform during night operations. The front of the

platform has a rubber bumper to protect the aircraft. A 12” extension

and swivel assembly are to help nal positioning and alignment of the

platform to the aircraft.

1.1.2.5 | Stabilizers

This unit is equipped with four stabilizer assemblies at the corners to

stabilize the stairway and to keep it locked in place. The stabilizers are

hydraulic cylinders with stabilizer pads at the bottom that are raised and

lowered hydraulically.

1.1.2.6 | Gasoline Engine

The engine which drives the hydraulic pump is a gasoline engine with an

electric starter. It receives fuel from an integral fuel tank located above

the engine. Engine controls are located on the engine.

1.1.3 | Hydraulic System

The hydraulic system (see Figure 1.1.3) provides hydraulic power to raise

and lower the upper stairway, A-frames and stabilizers. It consists of the

following components:

COMPONENT DESCRIPTION

Hydraulic Tank

The hydraulic uid tank is located on the side of the

chassis. The tank is provided with an in-tank uid

strainer. A dipstick is incorporated into the tank ll

cap. A clean-out port is located on top of the tank. A

drain plug is located at the bottom of the tank.

Hydraulic Pump

The hydraulic pump provides hydraulic power to

operate the stairway, A-frame and stabilizer cylinders.

The hydraulic pump is an internal gear (rotor) pump

coupled to the gasoline engine output shaft. It

operates whenever the engine is running. The pump

draws hydraulic oil from the hydraulic tank.

Auxiliary Hand Pump

The hand pump is located adjacent to the hydraulic

control valve and is equipped with an extension

handle. The hand pump provides emergency hydraulic

power for operating the stairs, A-frames and stabilizer

cylinders if the engine-driven pump is disabled.

Passenger Stairway PS-813B/E Boeing | 11

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

COMPONENT DESCRIPTION

Check Valve

The check valve is included in the hydraulic pump

line to prevent hydraulic pressure from backing up

against the main pump when the hand pump is used.

Directional Control

Valve (see Figure

1.1.3.1)

The directional control valve is a three-spool valve

incorporating an adjustable pressure relief valve.

One valve spool directs oil to and from the A-frame

cylinders. Another controls the stairway cylinder. The

third spool controls the four stabilizer cylinders. Each

spool is manually-operated by a control handle.

The control valve is considered “power beyond”. If

equipped, excess oil from the control valve ows to

the control valve which controls the ow of hydraulic

oil of the hydraulic motor powering the drive wheel.

Pressure Relief Valve

The system relief valve is part of the directional

valve. It can be adjusted manually by turning an

adjustment screw.

1.1.3.2 | Hydraulic Cylinders

This unit has seven hydraulic cylinders for raising and lowering the

stairway, A-frame and stabilizers.

COMPONENT DESCRIPTION

Stairway Cylinder

The stairway cylinder is located beneath the

stairway. A lock valve and a ow control valve are

located near the inlet/outlet port of this cylinder.

A-frame Cylinders The A-frame contains two cylinders. A lock valve and

a ow control are provided for these two cylinders.

Stabilizer Cylinders

Four stabilizer cylinders are located near the corners

of the stairway chassis. There is one lock valve on

each cylinder.

1.1.3.3 | Lock Valves

There are six lock valves in the system (see Hydraulic Cylinders above).

The lock valves trap uid under pressure when the pump is shut o,

locking the cylinders in position.

1.1.3.4 | Flow Control Valves

Flow control valves on the A-frame and stairway cylinders regulate the

lowering speed of the A-frame and stairway.

1.1.3.5 | Return Line Filter

The return line lter puries hydraulic oil returning to the tank. This lter

Passenger Stairway PS-813B/E Boeing | 12

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

has a 10–micron replaceable canister. It is located at the front of the

hydraulic tank.

1.1.4 | Electrical System

The electrical system is a 12 VDC system used for illuminating the stairway

and powering the stairway engine electrical starter. Major electrical

components are described below. See Figure 1.1.4 for electrical schematic.

COMPONENT DESCRIPTION

Battery Charger

The battery charger is provided for maintaining the

batteries at peak levels. The battery charger has a 15

amp. maximum output and an automatic charging

rate. The charger receives 120 VAC current through a

power cord on the charger.

Batteries

The two 6V marine deep cycle batteries provide

power for the electrical lighting and the engine

electric starter. The batteries are located in plastic

battery boxes. They are kept charged by a battery

charger (located in an adjacent battery box) that has

a rated capacity of 220 amp./hr. at 32˚F.

Fuse

The 30 amp. mini fuse protects the lights circuit from

overloads. The fuse is located inside a plastic fuse

holder near the hydraulic motor.

Circuit Breaker

A 80 amp. re-settable circuit breaker protects

the engine start circuit from overloads. It is

located on the chassis frame near the batteries.

Lighting Control

Switch

The LIGHT ON/OFF control switch (toggle) for

the stairway, platform and A-frame lights is

mounted on the primary control station.

Alternator

The engine alternator provides current to the

batteries which keep them from being depleted

during stairway operations. The engine on this

unit is equipped with a heavy duty 18 amp.

alternator and rectier.

1.1.4.1 | Lighting

COMPONENT DESCRIPTION

Stairway Lights

The stairway lights mounted in the upper and lower

stairs side panels illuminate the stairway during

night operations.

Platform Lights

The two platform lights faired into the front of the

platform illuminate the platform during nighttime

operations.

NOTE:

Electrical power for the stair-

way is provided by two 6 V

deep cycle batteries, which are

kept charged by a battery char-

ger. The charger operates when

plugged into an external 120

VAC power source. When the

engine is running, the engine

alternator helps keep the bat-

teries from becoming depleted.

Passenger Stairway PS-813B/E Boeing | 13

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

Floodlight The oodlight located on the A-frame illuminates the

aircraft as it is being approached by the stairway unit.

This section of the manual provides information on the operating

controls and indicators and provides operating procedures for the

Passenger Stairway. Prior to operating the passenger stairway, all

operators and maintenance personnel should become thoroughly

familiar with the instructions given in this manual. They should then be

checked out by a qualied instructor before operating the unit.

1.2.1 | Operating Controls and Indicators

1.2.1.1 | Engine Controls

The hydraulic pump on this unit is powered by the gasoline engine. The

engine controls are located on the engine. See the engine manual in

Appendix A for illustrations and information.

1.2.1.2 | Primary Control Station (see Figure 1.2.1.2)

COMPONENT DESCRIPTION

Lighting Control

Switch

The ON/OFF switch controls the stairway

courtesy lights and the A-frame oodlight.

Stairway Control

Handle

The handle controls the cylinder that raises the

upper stairs/platform. Placing the handle in

the UP position raises the stairway. Placing the

handle in the DOWN position releases the stairs

cylinder lock valve and retracts the cylinder.

This handle is used along with the stair ratchet

release handle to lower the stairway. The

stairway cylinder cannot retract unless the

ratchet is rst released manually.

A-frame Control

Handle

The handle controls the cylinder that raises the

A-frame. Placing the handle in the UP position

raises the A-frame. Placing the handle in the

DOWN position releases the A-frame lock valve

and retracts the cylinder.

This handle is used along with the A-frame

ratchet release handle to lower the A-frame. The

A-frame cannot retract unless the ratchet is rst

released manually.

Stabilizer Control

Handle

The handle controls the four stabilizer cylinders.

Placing the handle in the DOWN position extends

(lowers) the stabilizers. Placing the handle in the

UP position retracts (raises) the stabilizers.

NOTE:

A cord reel near the base of

the stairway enables the wiring

cord for the upper stairs and

platform lights to extend and

retract as the stairway is raised

and lowered.

Passenger Stairway PS-813B/E Boeing | 14

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

1.2.1.3 | Ratchet Release Handles

COMPONENT DESCRIPTION

A-frame Ratchet

Release Handle

The handle on the side of the A-frame manually

unlocks the A-frame ratchet to permit lowering

the A-frame.

Stairway Ratchet

Release Handle

The handle on the side of the stairway manually

unlocks the stairway ratchet to permit retracting

the upper stairs and platform.

1.2.1.4 | Auxiliary Hand Pump (see Figure 1.1.3)

The hand pump is located adjacent to the hydraulic control valve and

is equipped with an extension handle. The hand pump is intended for

Emergency Operation Only in the event the primary power system

cannot be used.

1.2.1.5 | Battery Charger

The battery charger charges the batteries that power the engine starter

and the stairway and A-frame lights.

1.2.2 | Pre-Operation Checks

Carefully check the following before putting the unit in service.

1. Check to see that all nuts, bolts and other fasteners are tight.

2. Check wheels and casters for proper operation.

3. Check the level of the hydraulic uid in the hydraulic oil tank. Add

hydraulic oil if level is low.

4. Check engine oil level.

5. Check battery terminals for corrosion and tightness.

6. Fill engine gasoline tank.

7. Check electrical system for proper operation.

8. Check stairway and platform lights for damage and proper operation.

9. Make sure that the stairs are free from any objects that could cause

a passenger to slip or fall.

10. Check platform modesty panels for free movement and proper latching.

1.2.3 | Operating Procedures

11. Start engine in accordance with procedures below. Read engine

manual in Appendix A before starting engine.

1.2 OPERATION

Passenger Stairway PS-813B/E Boeing | 15

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

• Move the fuel valve lever to the ON position.

• Move choke lever to CLOSED position if engine is cold. To restart

a warm engine, leave the choke lever in the OPEN position.

• Move engine throttle about 1/3 of the way to the FAST position.

• Operate the starter by moving the engine switch to the START

position.

• If engine cranks but will not re, it may be necessary to adjust

the choke. See Appendix A for illustrations and procedure. If

engine cannot be started using electric starter, it may be started

manually by means of pull starter.

12. After engine starts, move choke to OPEN position as the engine

warms up. Operate engine with choke in OPEN position and throttle

in FAST position.

13. When engine is running smoothly, stairway operations may begin.

14. Shut o engine by moving throttle lever to the SLOW position and

moving engine switch to the OFF position.

15. Turn the fuel valve lever to the OFF position.

1.2.3.3 | Towing and Positioning the Unit

1. Connect tow bar to tow vehicle.

2. Ensure that the stairway is disconnected from 120 VAC electrical power.

3. Ensure that stabilizers are raised.

4. Tow stairway to vicinity of aircraft. Do not tow at speeds over 15 mph.

5. Position unit in line with the aircraft doorway, 20 to 30 ft. from the

aircraft.

6. Start engine following procedures above. Engine powers hydraulic

pump.

7. Raise stairs to proper aircraft service height following procedures

below.

8. Raise A-frame to aircraft door sill height.

9. Push unit forward until rubber bumper makes slight contact with

aircraft.

10. Lower stabilizers as follows:

• Move STABILIZER control valve handle to DOWN position (with

engine running).

• Hold control valve handle in DOWN position until all stabilizers

are fully lowered.

WARNING!

Do not allow any part of the

unit to come into contact with

electrically charged wires. STAY

OFF THE STAIRS AND PLAT-

FORM while towing or operat-

ing the stairway.

CAUTION!

Make sure there is hydraulic oil

in the hydraulic oil reservoir be-

fore starting the engine. This is

necessary because the hydrau-

lic pump operates whenever the

engine is running.

Passenger Stairway PS-813B/E Boeing | 16

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

11. Adjust A-frame height until platform is level with door sill and

platform bumper makes slight contact with aircraft.

1.2.3.4 | Raising the Stairway

1. Ensure that the stairway engine is running.

2. Raise stairway by holding STAIRWAY control valve handle (Figure

1.1.3.1) in UP position. Continue to raise stairway until upper stairs

steps are about 1 inch above lower stairs steps.

3. Lower stairs until the mechanical lock on the stairs ratchet engages.

See procedures below.

1.2.3.5 | Lowering the Stairway

1. Raise stairway approximately 1 inch to clear ratchet.

2. Raise stairway ratchet release handle.

3. Move STAIRWAY control valve handle to DOWN position. Hold until

stairway is at desired height. Stairs may be stopped at any ratchet

position by releasing the ratchet handle.

1.2.3.6 | Operating A-frame

1. Push unit forward until platform bumper makes slight contact

with aircraft.

2. Ensure that engine is running.

3. Lower the stabilizers, as this will cause the platform to raise slightly.

4. Adjust A-frame height so that platform is level with door sill and

platform bumper makes slight contact with aircraft.

5. To raise A-frame, proceed as follows:

• Move A-FRAME control valve handle to UP position and hold

until A-frame is at desired height.

6. To lower the A-frame, proceed as follows:

• Move A-FRAME control valve handle to UP position. Raise

A-frame approximately 1 in. to clear ratchet.

• Raise A-frame ratchet release handle.

• Move A-FRAME control valve handle to DOWN position. Hold

until platform is at desired height.

1.2.3.7 | Boarding and Disembarking Passengers

1. Push stairway into position using procedures above. With engine

running, adjust platform height and position stairway so that

platform bumper is in contact with aircraft.

2. Lower stabilizers by holding the stabilizer down lever until all

stabilizers are fully down.

WARNING!

Do not start or run engine in

a closed or poorly ventilated

building where exhaust gases

can accumulate. Avoid breath-

ing these gases as they contain

poisonous carbon monoxide,

which can endanger your

health or life.

CAUTION!

Using the electric starter for

more than ve seconds at a

time will overheat the starter

motor and can damage it.

CAUTION!

DO NOT MOVE CHOKE CON-

TROL TO CLOSED POSITION TO

STOP ENGINE. Backre or en-

gine damage may occur. Move

throttle control to SLOW posi-

tion, then switch engine OFF.

Passenger Stairway PS-813B/E Boeing | 17

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

3. For night operations, turn on stairway, platform and A-frame lights

by engaging LIGHTS switch (Figure 1.1.3.1).

4. Proceed to top of stairs and slide platform side panels rearward.

5. Open aircraft door as prescribed in the airline manual.

6. Slide side panels forward until they latch.

1.2.3.8 | Removing the Stairway from Aircraft

1. Slide platform side panel away from door.

2. Close the aircraft door as prescribed by the aircraft manual.

3. Secure platform side panels by latching with foot latch in one of

the stops.

4. Raise stabilizers as follows:

• Ensure that the engine is running.

• Place and hold STABILIZER control valve handle in UP position

until stabilizers are fully raised.

5. Pull stairway a short distance away from aircraft. Stairway can now

be lowered.

6. Tow stairway away from vicinity of aircraft.

1.2.3.9 | Charging the Battery

Two 6 V batteries provide electrical power for the engine electric starter

and the stairway and A-frame lights. These batteries are charged by

means of a battery charger which requires external 120 VAC power

supplied through a power cord on the charger.

1. To charge the batteries, connect facility 120 V, 60 Hz power to

stairway battery charger cord. Charger functions whenever the unit

is plugged in.

2. Always disconnect external power cord before towing stairway.

1.2.4 | Emergency Operating Procedures

In case the engine, hydraulic system or electrical system is disabled, the

stairway unit should be towed away from the aircraft and repaired. If

the stabilizers are down, raise the stabilizers (using auxiliary hand pump)

before towing the stairway unit.

1.2.4.1 | Operating Auxiliary Hand Pump

The auxiliary hand pump provides emergency hydraulic power for

operating the stairway, A-frame and stabilizers in case the engine-

NOTE:

Stairway should be raised to

service height before adjusting

A-frame height.

NOTE:

The A-Frame ratchet does not

have to be locked in ratchet

stop for normal operation. It

is intended as a safety device

in the event of cylinder failure.

The ratchet assembly (dogs)

must operate freely and be

in with the ratchet bars on

the A-Frame for normal safe

operation.

NOTE:

The side panel locks are on

the platform oor and can be

released by foot.

Passenger Stairway PS-813B/E Boeing | 18

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

powered hydraulic pump is disabled. The hand pump is located near the

hydraulic control valve and is equipped with an extension handle. It is

operated by moving the handle back and forth repeatedly.

1.2.4.2 | Raising Stairway or A-frame Using Hand Pump

1. Hold STAIRWAY or A-FRAME control valve handle in UP position.

Pump hand pump until stairway or A-frame is at desired height.

2. Move control handle to DOWN position. Pump hand pump until

mechanical ratchet lock engages.

1.2.4.3 | Lowering Stairway or A-frame Using Hand Pump

1. Raise stairway or A-frame approximately 1 in. to clear ratchet.

2. Raise ratchet release handle.

3. Move control valve handle to DOWN position. Pump hand pump

until stairway or A-frame is at desired height.

4. Lock stairway or A-frame in position by releasing ratchet handle.

1.2.4.4 | Operating stabilizers Using Hand Pump

1. To raise stabilizers, hold STABILIZER control valve handle in UP

position. Pump hand pump until stabilizers are fully raised.

2. To lower stabilizers, hold STABILIZER control valve handle in DOWN

position. Pump hand pump until stabilizers are fully lowered.

NOTE:

The battery charger functions

best when set at the 15 Amp.

Deep Cycle/12 Volt/ Automatic

positions.

Passenger Stairway PS-813B/E Boeing | 19

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

1.3 SPECIFICATIONS

AND CAPABILITIES

1.3.1 | General Specifications

DIMENSIONS

Overall Length (less tow bar) 297 in. (7544 mm)

Overall Width 99 in. (2515 mm)

Overall Height (stairway not collapsed) 146 in. (3708 mm)

Maximum Platform Height 228 in. (5790 mm)

Minimum Platform Height 96 in. (2440 mm)

Tow Bar Length 86.25 in. (2191 mm)

Wheelbase 147 in. (3734 mm)

Platform Dimensions

Length 84 in. (2135 mm)

Width 72 in. (1830 mm)

Step Dimensions

Width 48 in. (1220 mm)

Depth 12 in. (305 mm)

Rise 7.5 in. (190 mm)

Railing Height 35 in. (890 mm)

1.3.2 | Capacities

Hydraulic Reservoir 10 U.S. gal. (38 liter)

Caster (ea.) 3700 lb. (1678 kg)

Wheels and Tires

Tires 4:00 x 8 in. soft solid

rubber

Rims 8 in. x 3.75

1.3.3 | Engine Specifications

Manufacturer Honda

Model/Serial No. GX240/GCBJT1218977

Type

4-stroke, OHV, single

cylinder, air-cooled,

gasoline-fueled electric

start

Bore 3.0 in.

Stroke 2.3 in.

Displacement 16.5 cu. in.

Horsepower (bhp), Max 7.9 @ 3600 RPM

Passenger Stairway PS-813B/E Boeing | 20

SECTION 1 - PROCEDURES, SPECS & CAPABILITIES

Torque (ft. lb.), Max 13.4 @ 2500 RPM

Fuel Tank Capacity 1.40 US gallons

Engine Oil Capacity 1.2US quarts

1.3.4 | Hydraulic System

HYDRAULIC PUMP

Manufacturer/Serial No. Gresen/Dana X1017 00411

Model MGG20010BC1B3

Displacement 0.218 cu. in./rev (3.57 cc/rev)

Rated Flow per 1000 RPM 0.95 GPM (3.6 liter/min)

Max. Rated Pressure (cont.) 2000 psi (138 bar)

Auxiliary Hand Pump

Manufacturer Star Hydraulics

Model PDA-2

Type Double-acting, hand-operated

Displacement 1.5 cu. in./cycle (2 strokes/cycle)

Handle Load 39 lb. per 1000 psi

Cylinders

Stairway Cylinder Part # 204497 Double-acting, 2.5 in. (63.5 mm)

bore, stroke 163.13

A-frame Cylinder Part # 204219 Double-acting, 3.5 in. (88.9 mm)

bore, stroke 24”

Stabilizer Cylinder Part # 204074 Double-acting, 2 in. (50.8 mm) bore,

8 in. (203 mm) stroke

Pressure Relief

Type Adjustable, part of hydraulic control

valve

Recommended Setting 1500 psi (104 bar)

Filters

Return Line 10-micron, spin on canister

Suction Line 25 GPM ow, 100 mesh strainer

Hydraulic Oil Mobil DTE-13

Table of contents

Other STINAR Lifting System manuals