BERTHOLD TECHNOLOGIES LB 379 User manual

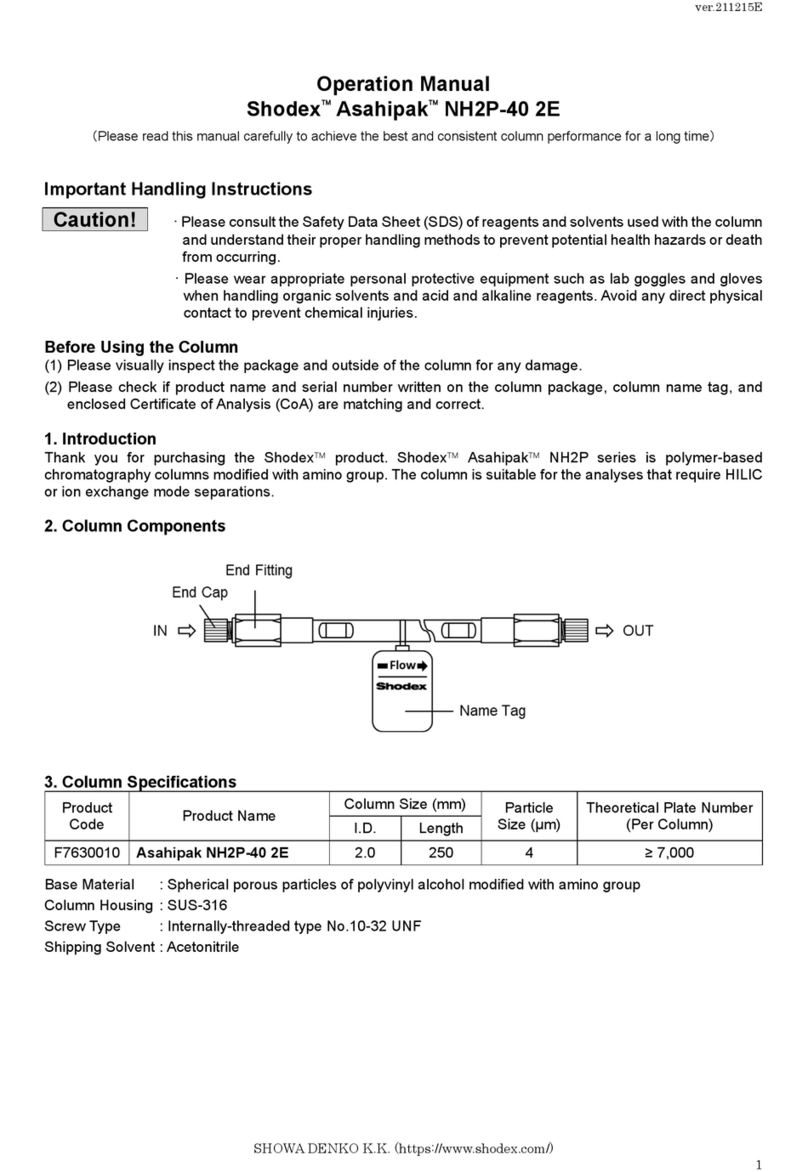

Measuring Path

LB 379 and LB 3602 / 3603

Operating Manual

40437BA2

Rev. No.: 00, 12/2016

LB 379

2

LB 379

3

Contents

OPERATING MANUAL .....................................................................1

40437BA2......................................................................................1

REV. NO.: 00, 12/2016 ..................................................................1

1OVERVIEW...........................................................................6

1.1 The Principle of Measurement ................................................................ 6

1.2 The Measurement Device........................................................................ 8

1.3 Device Configuration (Operating Modes)................................................ 9

1.3.1Setting the Detector Code..................................................................9

1.3.2Measuring Path Dimension .................................................................9

1.4 Measuring Paths and Sources............................................................... 10

1.4.1Measuring Path LB 379 .................................................................... 10

1.4.2Measuring Paths LB 3602/3603......................................................... 11

1.4.3Radioactive Sources ........................................................................ 12

1.5 Detector................................................................................................ 12

2INSTALLATION...................................................................13

2.1 Installation of the Measuring Path........................................................ 13

2.1.1Safety Instructions.......................................................................... 13

2.1.2Selection of Measuring Site .............................................................. 14

2.1.3Installation Instructions for PTFE lined Measuring Paths (LB 379)........... 16

2.1.4Installation of the Resistance Thermometer Pt 100 .............................. 16

3WATER COOLING IN THE MEASURING PATH LB 379 .........17

3.1 Cooling Water Requirement.................................................................. 17

4ELECTRICAL CONNECTIONS ...............................................18

4.1 Detector................................................................................................ 18

5TECHNICAL DATA...............................................................19

5.1 Measuring Path LB 379......................................................................... 19

5.2 Measuring Path LB 3602/3603:............................................................ 20

5.3 Pressure Equipment Directive 2014/68 / EU........................................ 21

6RADIATION PROTECTION ..................................................22

6.1 Emergency Instructions........................................................................ 25

6.1.1Checking the Crystal-Multiplier Assembly ........................................... 26

7APPENDIX..........................................................................28

7.1 Table 1: Absorption Coefficients ........................................................... 28

7.1.1Temperature Coefficients ................................................................. 29

8DENSITY OF WATER AS A FUNCTION OF THE TEMPERATURE30

9DIMENSIONAL DRAWINGS.................................................31

9.1 Measuring Path LB 379 with DIN Flange............................................... 31

9.2 Measuring Path LB 379 with ASA Flange............................................... 32

9.3 Measuring Path LB 379 with Threaded Connector................................. 33

9.4 Measuring Path LB 3602/03 ................................................................. 34

10 ATEX CERTIFICATE ............................................................35

11 INDEX................................................................................42

LB 379

4

LB 379

5

Safety Summary

Electrical Shock Hazard

Disconnect power to ensure that contact with energized part is avoided during installation and

servicing.

Specific Warnings

Never change the installation or the parameter settings without a full knowledge of the rele-

vant part of this manual, the connected controller and the process, if it is controlled by this

measuring device.

Radiation Protection Instructions

This measuring system uses radioactive sources. The radiation protection information in this

operating manual and the relevant statutory provisions must be strictly observed.

At least one screw on the access openings to the radioactive sources on the measuring path

is sealed. Do not open any sealed screws. A damaged seal must be repaired immediately by

a representative of the manufacturer.

Sources that are not in use must be kept in a secure place and protected against access by

unauthorized persons.

LB 379

6

1Overview

The radiometric density measuring system offers the possibility to measure the density of

liquids, suspensions, slurries and bulk goods. The measurement can be carried out directly

in a product line. The measurement is independent of variations in pressure or viscosity,

and on the flow rate of the product.

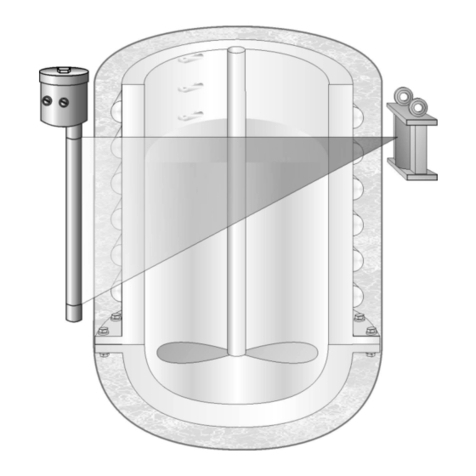

1.1The Principle of Measurement

The density measurement utilizes as a measuring effect the attenuation of gamma radia-

tion passing through the product being measured. The residual radiation picked up by the

detector (scintillator) is a measure of the density of the product being measured.

The attenuation of radiation takes place in accordance to the following law:

Figure 1: Principle of measurement

I = radiation picked up by the detector

Io = unattenuated radiation

µ = mass attenuation coefficient (absorption coefficient in cm2/g

= density of absorbing material in g/cm3

d = thickness of absorbing material in cm

The intensity of the radiation arriving at the detector is also dependent on the distance

between source and detector. As in the case of light, the function involved is a square

function, i.e. doubling the distance reduces the radiation intensity to ¼ if all other condi-

tions remain unchanged.

In the measuring paths LB 379 and LB LB3602/3603, source, measurement pipe and de-

tector are combined into one unit. This ensures a fixed geometry and a constant distance.

Under these conditions, the radiation arriving at the detector is only dependent on the

density of the material to be measured.

An activation of the product being measured, or of the pipe used for the measurement by

the gamma radiation is completely excluded.

With the isotopes 241Am and 244Cm the absorption is dependent, in addition to the density,

on the atomic number of the absorber. It increases with increasing atomic number (see

Figure 2), so that with the substances occurring in practice we can almost always assume

that a higher atomic number can also be equated with a higher absorption coefficient. Due

to this relationship, very high measurement accuracies can be achieved for products con-

taining substances with a high atomic number (e.g. hydrochloric acid, milk of lime, sulfuric

acid, etc.), with the measuring paths LB 379 and LB 3602/3603, which are equipped with

one of these isotopes.

d

oeII **

*

d

Io I

Radiation

source Detector

LB 379

7

Figure 2: Absorption coefficients

With 244 cm, the atomic number has a significant influence on the absorption coefficient.

This isotope is incorporated in the measuring paths LB 3602/3603. These measuring paths

are used to measure materials with high atomic number at very low concentrations. These

measuring paths are not type approved.

This dependence of the absorption coefficient on the atomic number has a positive effect

if, for example, in a solution of sodium chloride in water, where the salt content is to be

determined, contaminations by hydrocarbons may occur, for example by sugar or cellulose,

in varying proportions. The lower absorption coefficient of the impurity results in a lower

influence on the measurement result.

An adverse effect is obtained if, for example, the density of a hydrocarbon mixture is to be

determined, which contain impurities by a substance having a high atomic number, such

as chlorine. In this case we get significant changes in the absorption of the radiation even

with low fluctuations in the chlorine content, so that a density change is simulated, which

in reality does not exist.

0,01

0,1

1

10

100

0 5 10 15 20 25 30 35

Absorption coefficient µ

Atomic number Z

Cs - 137 (662 keV)

Am - 241 (60 keV)

Cm 244 (18 keV)

Co -60 (1,3 MeV)

LB 379

8

1.2The Measurement Device

The radiometric density measuring system can be used to measure the density of

liquids

suspensions

solids and

bulk goods

The measurement can be performed directly on a product line and is independent of fluc-

tuations in pressure and viscosity, as well as in the flow velocity.

Specific device configurations and calculations allow you to adapt the density measuring

system to local conditions and the conditions of the product being measured.

The measuring device generally comprises the following components:

a) the measurement path with

- radioactive source

- through pipe for the product to be measured

- detector

b) the evaluation unit

c) the connection cable

d) the resistance thermometer Pt 100 (optional)

The detector's supply voltage and

the measurement signal and im-

portant information (high-voltage

setting, detector temperature,

product temperature with con-

nected Pt 100, etc.) are transmitted

from the detector to the evaluation

unit via the connection cable be-

tween the detector and evaluation

unit.

Figure 3: Measuring arrangement

a) c)

d)

b)

BERTHOLD

LB 444 - 1 V 1.0

Density -Meter etc.

enter

clear run

RADIOACTIVE

LB 379

9

1.3Device Configuration (Operating Modes)

The evaluation unit can be used for different tasks.

Density measurement without temperature compensation (TC)

Density measurement with temperature compensation

via Pt100 or

density measurement with temperature compensation via current input

Suspension measurement with any carrier liquid

solid density and liquid density are known

with or without TC

Suspension measurement with water as the carrier liquid

solid density is known

with water temperature compensation, the density of the water and

the concentration of the solid material are taken into account for temperature

compensation

Mass flow measurement without TC (in connection with a volume flow meter)

Mass flow measurement with TC via Pt 100 (in connection with a volume flow

meter)

Measurement modes

Continuous measurement

Discontinuous measurement

Batch operation via keyboard (press <run> button)

Batch operation via digital input

1.3.1 Setting the Detector Code

Internal device parameters are adjusted to suit the used scintillator size by setting

the detector code. The correct detector code is set at the factory and a change is

not normally required. A table with the detector codes to be used is found below:

Measuring Path Detector Code

LB 379 2

LB 3602/3603 manual

For the measuring path LB 3602/3603 you must set the HV working point to manually

fixed value. If the value is not known you must evaluate the value by a plateau measure-

ment. The plateau measurement is descriped in the manual LB 474 respectively LB 444.

The HV working point must be entered in the evaluation unit at the mid of the plateau

curve.

1.3.2 Measuring Path Dimension

Input of the measuring path dimension in the evaluation unit:

Measuring

Path without

Liner with

PTFE - Liner With

Rubber - Liner

LB 379 6.8 6.0 5.8

LB 3602/3603 5.1 - -

Dimensions in cm

LB 379

10

1.4Measuring Paths and Sources

1.4.1 Measuring Path LB 379

The measuring path LB 379 includes the following components in a compact unit:

The radioactive source (1), isotope Am-241, with an activity of 1,110 MBq (30 mCi) and

3,700 MBq (100 mCi) or in exceptional cases 11,000 MBq (300 mCi).

The measuring path is no longer type approved for a source activity of 11,100 MBq (300

mCi).

Am-241 is particularly suitable for determining the concentration of components having a

high atomic number (iron, nickel, HCl, etc.) in a carrier liquid having a low atomic number.

The energy is 60keV, the half-life 433 years.

The radiation source is installed in a stainless steel coated lead shield (2). The collimator

(3) allows the unattenuated exit of the useful radiation only in the direction of the product

pipe.

The radiation is shielded by the lead shielding (2) and by the case even if the pipeline is

empty, so that no additional protective measures are required.

In non-lined measuring paths, the product pipe DN 65/PN 10 (4) is made of stainless steel

1.4571 or 1.4401. The material number is stamped on the flange or on the pipe. Stainless

steel 1.4301 is used for lined pipes. A lining made of PTFE (Teflon) can be supplied to

protect the pipes against aggressive products. To protect the pipes from abrasive wear, we

recommend using a lining made of soft rubber. For use in the food industry, a product pipe

with threaded ends DN 65 according to DIN 11851 can be supplied instead of the flanged

pipe. No lining is possible with this design. The detector (scintillation counter) LB 4451 (5)

is located in the upper part of the measuring path. It is explosion-proof.

LB 379

11

1.4.2 Measuring Paths LB 3602/3603

This measuring path is constructed similarly to the measuring path LB 379. It is comprised

of the following components:

a) Radiation sources (1)

Isotope 244Cm

Activity: max. 7400 MBq (200 mCi)

Half-life: 17.8 years

Energy of the emitted -radiation:

about 18-22 keV

b) Product pipe (2): DN 50/PN 10

Material: Polypropylene

c) Detector (3): Detector

in the measuring path LB 3602

LB 4491-05-0x-Gd-E

Ex-protection: EEx de II CT6

Figure 4: Measuring path LB 3602/3603

The measuring path LB 3602 can be used in potentially explosive areas

or

with the measuring path LB 3603 detector LB 5491-05-0x-2

Do NOT use the measuring path LB 3603 in potentially explosive areas.

The measuring paths LB 3602/3603 are not type approved.

IMPORTANT:

The measuring pipes and the lining should be checked at least once a year for damage and

leaks. If damage is suspected, the Radiation Protection Officer and the manufacturer or

the local agent must be informed immediately.

LB 379

12

1.4.3 Radioactive Sources

Radioactive sources for industrial applications are generally "enclosed radioactive materi-

als" which are tightly welded into a sturdy stainless steel capsule, so that the radioactive

sub-stance cannot leak out. Contamination is therefore excluded. Moreover, for physical

reasons, any activation of the product being measured by the emitted gamma radiation is

not possible.

The following sources can be used for these measuring paths:

Radiation source Measuring path Energy of radiation Half-life

Am-241 LB 379 60 keV 433 years

Cm-244 LB 3602/3603 about 18 keV 17.8 years

Please note the Radiation Protection Guidelines in Chapter 6.

1.5Detector

A scintillation counter is used as a detector.

The detector converts the gamma radiation picked up into electrical pulses. The count rate

transmitted to the evaluation unit is proportional to the radiation intensity received.

The detector is equipped with an automatic drift compensation which automatically corrects

component aging and temperature influences, ensuring a high long-term stability of the

measuring system.

The power supply of the detector is carried out via the fail-safe connection circuit of the

LB 444 evaluation unit.

The detector itself includes a fail-safe connection circuit to which a resistance thermometer

Pt 100 can be connected for measurement of the product temperature.

The detector assembly in a sturdy stainless steel housing protects the instrument against

normal ambient pollution in industrial applications.

The detector must not be subject to heavy mechanical stress or vibrations.

For more information on its function see chapter Fehler! Verweisquelle konnte nicht

gefunden werden..

The ambient temperatures must not exceed 50°C; otherwise adequate cooling has to be

provided.

LB 379

13

2Installation

The measuring path with the radioactive source is delivered in a box in compliance with

the regulations concerning the transportation of radioactive substances.

Take the shielding out of the box just prior to installation. Until then, store it in a location

that is guarded against unauthorized access.

Work is performed according to the instructions and under the supervision of the Radiation

Safety Officer. It has to be ensured that the lock of the shielding is closed and secured, so

that no unshielded radiation can exit. Make sure the shielding is not tampered with or

damaged.

Very important: Please read the Radiation Protection Guidelines in chapter Radi-

ation Protection and observe them strictly!

2.1Installation of the Measuring Path

2.1.1 Safety Instructions

2.1.1.1 Measuring Path LB 379

1. The max. pressure in the measuring path must not exceed 10 bar.

2. You have to check whether the resistance of the pipe material and the liner is suitable

for the intended application. The exact material name is stamped on the flange or on

the pipe.

3. The instructions and regulations of the type approval certificate must be observed.

4. Do not open the sealed screws.

CAUTION:

A damaged measuring path must be disassembled immediately.

Please inform immediately:

a) the manufacturer or their local agent

b) the competent supervisory authority.

LB 379

14

2.1.1.2 Measuring Path LB 3601

1. The permissible operating pressure of the product pipe made of polypropylene de-

creases with increasing temperature. The following values must not be exceeded:

Temperature max. pressure in kp/cm2

20 10

30 10

40 6.2

50 5

60 3.6

70 2.2

80 1.2

90 0.8

2. You have to check whether the material of the product pipe is suitable for the intended

application.

3. Do not open the sealed screws.

CAUTION:

A damaged measuring path must be disassembled immediately.

Please inform immediately:

a) the manufacturer or their local agent

b) the competent supervisory authority.

2.1.2 Selection of Measuring Site

When selecting the installation site, please keep in mind:

a) The pipeline must always be completely filled at the measuring site with the product

to be measured during the operation.

b) Corrosion, abrasion or wall deposits must not occur at the pipeline walls. This hazard

is least likely with installations on vertical pipes.

c) Gas bubbles in the product falsify the results. This risk can be avoided or at least

reduced by:

Performing measurements under fairly high pressure (see 2.1) (installation in

pressure pipes, at the foot of a standpipe).

If no air bubbles are to be expected in the product, the suction side of the pump

should preferably be used for installation to exclude air bubbles which might oc-

cur as a result of damaged pump seals.

Measurements on horizontal pipelines should be performed using horizontal irra-

diation to reduce errors caused by deposit formation and gas bubbles (see Figure

50).

LB 379

15

Figure 5: Installation on a horizontal pipeline with gas bubbles and debris

Extensions of the pipeline should be avoided. If they are unavoidable, they should always

be performed only on vertical lines.

Pipe extensions may be made at the measurement point only if

a continuous flow of product is ensured over the entire pipe cross section. Par-

ticularly with highly viscous products this will not always be the case. Usually,

the product flows only in the center. However, the measurement covers the entire

diameter of the product in the path or radiation. Therefore, the measurement

result is not representative.

no gas bubbles are present in the path of radiation.

suspension measurements are not carried out directly behind a pipe-bend, for

there the material will not be distributed homogeneously.

The distance from the bend must be the larger

the higher the flow rate

the bigger the difference between liquid density and solid density

d) Measuring system installed outdoors have to be protected from rain and direct sun-

shine by a canopy.

Figure 6: Canopy roof for protection against sun and rain in outdoor installations

Gas bubbles

Debris

LB 379

16

e) The pipeline must not be subject to heavy vibrations as this could damage the de-

tector. Vibration dampers have to be installed, if necessary.

f) Samples have to be taken for calibration of the measurement. A sampling point has

to be provided in the direct vicinity of the measuring site.

2.1.3 Installation Instructions for PTFE lined Measuring

Paths (LB 379)

Lined parts must not be welded, soldered or burned as this can destroy the plastic material.

The flanges of all parts are provided with protective plates, so that the sealing surfaces are

not damaged during transport and storage. The protective plates should not be removed

until immediately before installation. If plates are taken off for control purposes, they have

to be attached again in any case.

No further seals are required between the sealing surfaces; however, possibly when at-

taching a sealing surface to a flange made of metal, glass, carbon or ceramic, if that flange

is not plane-parallel. This PTFE seal, which should be about 5 mm thick, can then absorb

tensions and inhomogeneities as a resilient sealing element.

The screws should be tightened to a torque of 45 Nm. The sealing surface may get de-

formed if the screws are tightened too much during installation of pipe parts.

During commissioning of a line system the flange screws should be retightened once more

to the specified torque after reaching the final temperature.

Pipeline parts may be disassembled only at max. 40°C so that the sealing surfaces are not

damaged.

If a flange connection leaks, although all screws are tightened, NO LONGER TIGHTEN but

loosen the screws on the side opposite the leak and tighten the other side. If the leak

persists, examine the sealing surfaces for grooves or chips which may be the cause of the

leak. If the impressions or damage are no deeper than about 15% of the flange thickness,

these can be removed with fine emery cloth.

2.1.4 Installation of the Resistance Thermometer Pt 100

A temperature measurement must be carried out such that the measured temperature is

fairly equal to the product temperature at the density measuring site. The resistance ther-

mometer must not obstruct the path of radiation.

If the resistance thermometer cannot be installed in the pipeline, it may also be mounted

on the outside of the pipeline.

The pipeline with the mounted resistance thermometer must be provided with temperature

insulation over a length of 1 - 2 m to ensure that the surface temperature of the pipeline

at the temperature measuring point is fairly equal to the product temperature. Neverthe-

less, it may happen, especially with plastic pipes or lined pipelines that very rapid temper-

ature changes occur in the product to be measured will lead to temperature-induced

measurement errors. The change in density is detected by the measurement without time

delay; however, the necessary temperature correction is delayed due to the inertia of the

temperature measurement. This influence can be reduced by operating the measuring de-

vice with the greatest possible time constant.

LB 379

17

3Water Cooling in the Measuring Path

LB 379

The detector is allowed to reach a maximum temperature of 50°C. If significant heating

may occur caused by the product to be measured and/or by a higher ambient temperature,

the water cooling which is included in the measuring path LB 379 has to be used.

No water cooling is provided for the measuring path LB 3601.

3.1Cooling Water Requirement

Water should preferably be used as cooling medium, because air does not ensure adequate

cooling at high temperatures. The water must be clean to avoid the buildup of dirt particles

in the cooling jacket which would have an adverse effect on the cooling efficiency.

The minimum cooling water requirement Qmin can be calculated for the measuring path

LB 379 using the following formula:

W

UT

TT

313 10*75.9*)323(5.5*)323(

Q114

4

Pr

min

Qmin = cooling water requirement in l/h

TPr = product temperature

TU= ambient temperature

TW= cooling water inlet temperature

Example:

Product temperature TPr: 393 K (120° C)

Ambient temperature TU: 353 K (80° C)

Cooling water inlet temperature TW: 293 K (20° C)

hl /3.19

293313 10*75.9*)323353(55.5*)323393(

Q1144

min

Water must enter from below and exit at the top. Thus, the cooling jacket is always

filled with water, ensuring good thermal insulation.

The connection cables used have to be able to withstand higher ambient temperatures!

If there is a risk that the cooling water can freeze, the water cooling system has to be

emptied or antifreeze has to be added to the cooling water.

LB 379

18

4Electrical Connections

4.1Detector

Switch off the evaluation unit before connecting the detector.

Open the screws and remove the connection box cover to expose the connection area.

For intrinsically safe installations, connect the detector to the potential equalization bar of

the installation. The detector is connected to the evaluation unit via a 2-wire cable with

approx. 8…10 mm diameter and a cross-section

of 1 mm². A screen cable may be used in instal-

lations with extremely strong electrical interfer-

ences. The screen may be placed only on one

side of the detector.

Figure 7: Cable connections to the detector

For intrinsically safe installations, the per-

missible inductivities and capacities of the

connection cable have to be observed in ac-

cordance with the Ex test certificate.

Please observe the maximum cable lengths be-

tween evaluation unit and detector. They are

listed in chapter 5.

When installing the connection cable, make sure that water cannot get into the connection

box via the cable. At ambient temperatures >70°C, the installed cable has to be protected

to prevent exceeding of the temperature limits of the cable. After connecting, make sure

that the terminal compartment is carefully closed and the cable conduit properly sealed.

If a resistance thermometer is connected, pass the cable coming from the Pt 100 through

the second cable conduit to the terminals 3and 4.

For installations in hazardous areas, the special requirements of the cable and to

the preparation of the lines have to be observed.

The detector LB 44... has to be used for installation in hazardous areas. Detector

LB 54.. may only be used for non-hazardous applications.

The evaluation unit must always be installed outside the hazardous area.

A special transmission technique ensures interference suppression. Nevertheless, the cable

should not be installed together with power cables.

4

3

2

1

5

LB 444

PA

Pt 100

LB 47x

LB 379

19

5Technical Data

5.1 Measuring Path LB 379

License no. BW/19/78

Detector LB 4450 Scintillation counter with NaI (Tl) crystal 44/5.

With drift compensation.

Ex-protection: II 2 G EEx de IIC T6 or

II 2 G EEx ib d IIC T6

Temperature range: Operating temperature: - 20 °C to + 50 °C (253 to 323 K).

Water cooling for higher temperatures

Storage temperature: - 40 °C to + 60 °C

Radioactive sources: 241Am activity: 1110 to 3700 MBq (30 to 100 mCi) in the high-

security version (special form)

Measuring pipe: ND 65, NP 10, material: stainless steel 1.4571 or 1.4401, in

lined pipes: 1.4301

Connections: Flanges according to DIN 2576 or threaded connector SC 65

to DIN 11851.

Measuring pipe with optional rubber or PTFE lining (only pos-

sible with flange version).

Product temperature: Measuring pipe without lining: -190°C to +260°C (80 to 560

K).

Measuring pipe with rubber lining: -30 to +80°C (243 to 353

K);

Measuring pipe with PTFE lining: -190°C to + 260°C

(80 to 560 K)

Housing: Stainless steel, material 1.4301

Protection type: IP 65

Weight: approx. 18 kg

Connection cable: 2-wire, shielded, with 2 x 1.0 mm2

Cable length detection - evaluation unit 1000 m.

LB 379

20

5.2Measuring Path LB 3602/3603:

Detector LB 4491-05-0x-Gd-E (measuring path LB 3602)

Ex-protection: II 2 G EEx de IIC T6

Scintillation counter with NaI(Tl) crystal 44/5

Detector LB 5491-05-0x-2 (measuring path LB 3603)

Ex-protection: no

Scintillation counter with NaI(Tl) crystal 44/5

Housing: Stainless steel housing with integral junction box, material:

1.4301

Protection type IP 65

Temperature range: Operating temperature for the detector:

-20 to +50°C (253 to 323 K);

Storage temperature:

-40 to +65°C (233 to 338 K);

Measuring path LB 3602/3603:

Measuring pipe

material: Polypropylene

Flanges: DN 50/PN 10 similar to DIN 2576

Radioactive sources: 244Cm activity: 370 to 7400 MBq (10 to 200 mCi) in the high-

security version (special form)

Connection cable: 2-wire, shielded, with 2 x 1.0 mm2

Cable length detection - evaluation unit 1000 m.

Weight: approx. 11 kg

This manual suits for next models

2

Table of contents

Other BERTHOLD TECHNOLOGIES Measuring Instrument manuals

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 124 Scint Series User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Uni-Probe LB 490 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 567 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES FlowStar2 LB 514 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 444 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Junior LB 9509 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 480 User manual