BERTHOLD TECHNOLOGIES LB 444 User manual

Density

Meter

LB 444

Id. No 32816BA2

Rev. No.: 04 22.04.03

04/03 347 LB 444

I

Table of Contents

Page

1. OVERVIEW.................................................................................................... 1

2. SYSTEM DESCRIPTION ................................................................................. 2

2.1 Use and Function ................................................................................ 2

2.2 Instrument Configuration (Operating Modes) .......................................... 2

2.3 The Principle of Measurement ............................................................... 3

2.4 Measuring Configuration ...................................................................... 4

3. INSTRUMENT DESCRIPTION ......................................................................... 5

3.1 Radioactive Source ............................................................................. 5

3.2 Shieldings.......................................................................................... 6

3.2.1 Shielding Types LB744... with Manually Operated Lock............................. 6

3.2.2 Shieldings with Pneumatically Operated Lock and Shutter Switch.............. 7

3.2.3 Shieldings for Installation in a Container with Manually Operated Lock....... 8

3.2.4 Shieldings for Installation in a Container with Pneumatically Operated Lock

and Shutter Switch ............................................................................. 9

3.3 Detector .......................................................................................... 10

3.4 Evaluation Unit LB 444 ...................................................................... 10

3.4.1 General Description........................................................................... 10

3.4.2 Display............................................................................................ 11

3.4.3 Keypad Function ............................................................................... 11

3.4.4 Softkeys.......................................................................................... 11

3.4.5 Menu Structure ................................................................................ 11

4. SOFTWARE FUNCTIONS AND SYSTEM CONFIGURATION ............................. 17

4.1 General Data.................................................................................... 17

4.2 Operating Mode ................................................................................ 18

4.3 Parameter ....................................................................................... 19

4.4 Product Data .................................................................................... 22

4.5 Calibrate ......................................................................................... 23

4.6 Live Display ..................................................................................... 26

4.7 Service Menu ................................................................................... 26

4.8 Mass Flow........................................................................................ 26

5. INSTALLATION ........................................................................................... 27

5.1 General Safety Precautions ................................................................ 27

5.2 Installation ...................................................................................... 28

5.2.1 Installation on Pipelines ..................................................................... 28

5.2.2 Installation in a Container .................................................................. 30

5.2.3 Water Cooling Installation .................................................................. 32

5.2.4 Cooling Medium ................................................................................ 33

5.2.5 Installation of Resistance Thermometer Pt 100...................................... 34

5.2.6 Installation of Evaluation Unit ............................................................. 34

5.3 Electrical Connections........................................................................ 35

5.3.1 Detector .......................................................................................... 35

5.3.2 Evaluation Unit LB 444 ...................................................................... 36

6. GETTING STARTED...................................................................................... 38

6.1 Quick Installation Overview ................................................................ 38

6.2 Getting Started................................................................................. 39

04/03 347 LB 444

II

6.2.1 Basic Settings .................................................................................. 41

6.2.2 Calibration ....................................................................................... 42

6.3 Measurement ................................................................................... 44

6.4 Error Messages................................................................................. 45

6.4.1 Error Messages Reset ........................................................................ 45

6.4.2 Error Messages during Operation ........................................................ 45

6.4.3 Error Messages during Calibration ....................................................... 45

6.4.4 Error Messages during Measurement ................................................... 46

6.5 System Start/Stop ............................................................................ 48

7. TEMPERATURE COMPENSATION ................................................................. 49

7.1 Temperature Measurement ................................................................ 49

7.2 Monitoring the Temperature Signal...................................................... 49

7.3 Function of Temperature Compensation ............................................... 50

7.4 Temperature Compensation in Suspensions .......................................... 50

7.5 Calculation of Temperature Coefficients................................................ 50

7.6 Calculation of Square Temperature Coefficient ...................................... 52

7.7 Reference Temperature ..................................................................... 53

7.8 Temperature Coefficient Calculation without Table Values ....................... 53

8. CALIBRATION ............................................................................................. 55

8.1.1 Calibration Modes ............................................................................. 55

8.1.2 One-Point Calibration ........................................................................ 57

8.1.3 Two and Multi-Point Calibration........................................................... 59

8.1.4 Correction of Analysis Values.............................................................. 60

8.1.5 Checking the Calibration .................................................................... 62

8.2 Radiating Interference Detection ......................................................... 63

8.3 Automatic Measuring Time Switchover ................................................. 64

8.4 Measurements of Suspensions ............................................................ 65

8.4.1 Calculating the Density of Individual Components.................................. 68

8.5 Correcting the Results: Addition and Multiplication................................. 69

8.5.1 Additive Constant ............................................................................. 69

8.5.2 Multiplication Factor .......................................................................... 70

9. TECHNICAL DATA ....................................................................................... 71

9.1 Evaluation Unit LB 444 ...................................................................... 71

9.2 Detectors......................................................................................... 72

10. SERVICE INSTRUCTIONS ............................................................................ 74

10.1 General Safety Precautions ................................................................ 74

10.2 Evaluation Unit LB 444 ...................................................................... 74

10.3 Shielding and Source......................................................................... 76

10.4 Service Menu ................................................................................... 77

10.4.1 Overview ......................................................................................... 77

10.4.2 Service Menu ................................................................................... 78

10.4.3 Plateau Check .................................................................................. 79

10.5 Detector .......................................................................................... 82

10.5.1 Checking the Crystal-Multiplier Assembly ............................................. 82

10.6 Replacing the Evaluation Unit LB 444................................................... 84

11. RADIATION PROTECTION ........................................................................... 85

11.1 Basics and Guidelines ........................................................................ 85

11.2 Shielding Installation Safety Instructions.............................................. 87

11.3 Radiation Dose Calculations................................................................ 87

04/03 347 LB 444

III

11.4 Emergency Instructions ..................................................................... 89

12. APPENDIX .................................................................................................. 90

12.1 Absorption Coefficients ...................................................................... 90

12.2 Temperature Coefficients ................................................................... 91

12.3 Density of Water as a Function of the Temperature................................ 92

12.4 Setup Protocol.................................................................................. 93

13. DIMENSIONAL DRAWINGS ......................................................................... 95

13.1 Detectors......................................................................................... 95

13.2 Detectors with FM Certificate .............................................................. 97

13.3 Mounting Device 90° for Pipe Diameter 88.9...304 mm ................................ 98

13.4 Mounting Device 90° for Pipe Diameter 21.3...76.1 mm ............................... 99

13.5 Mounting Device 30 / 45 ° ................................................................100

13.6 LB 444 ...........................................................................................101

14. EX- CERTIFICATES FOR EVALUATION UNIT .................................................. 1

15. EX-CERTIFICATE FOR THE DETECTORS ......................................................... 4

04/03 347 LB 444

IV

List of Figures

Page

Figure 1: Principle of measurement ......................................................... 3

Figure 2: Measuring system mounted on a pipeline.................................... 4

Figure 3: Shielding container type LB744 ................................................. 6

Figure 4: Shielding container type LB 744x with pneumatic locking drive ...... 7

Figure 5: Shielding for installation in a container ....................................... 8

Figure 6: : Pneumatic locking mechanism, not Ex-protected........................ 9

Figure 7 Shutter switch for ex-protected area ........................................... 9

Figure 8: Front Panel LB 444 ................................................................ 10

Figure 9: Softkeys functions ................................................................. 12

Figure 10: Function keys...................................................................... 13

Figure 11: Installation on a horizontal pipeline ........................................ 28

Figure 12: Outdoor installation ............................................................. 29

Figure 13: Installation on S or U-shaped measuring path.......................... 29

Figure 14: External installation of shielding and detector .......................... 30

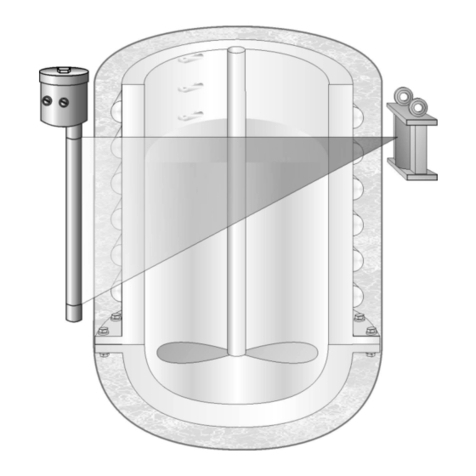

Figure 15: Installation in a container ..................................................... 30

Figure 16: Installation in a container with horizontal flow ......................... 31

Figure 17: Installation in a container with vertical flow ............................. 31

Figure 18: Installation of water cooling .................................................. 32

Figure 19: Required amount of cooling water .......................................... 33

Figure 20: Cable connections at detector................................................ 35

Figure 21: Terminal connection evaluation unit (rear panel)...................... 36

Figure 22: Rear view of shielding container type LB 744. .......................... 39

Figure 23: Locking mechanism with knurled nut ...................................... 40

Figure 24: Locking mechanism with spring pin ........................................ 40

Figure 25: Influence of absorption coefficients on one-point calibration....... 58

Figure 26: One-point calibration with additional calibration points .............. 58

Figure 27: Example of multi-point calibration.......................................... 59

Figure 28: Response ........................................................................... 64

Figure 29: Density of suspensions ......................................................... 65

Figure 30: Conversion scheme.............................................................. 67

Figure 31: Plateau curve...................................................................... 80

Figure 32: Assembly of scintillation counter ............................................ 82

04/03 347 LB 444

V

Operating Manual Density Meter LB 444

Revision History

No. Date Comments

04 22.04.03 Atex certificates, LB 4430

04/03 347 LB 444

VI

Safety Summary

Electrical Shock Hazard

Disconnect power to ensure that contact with energized part is avoided during installation

and servicing.

Specific Warnings

Never change the installation or the parameter settings without a full knowledge of the

relevant part of this manual, the connected controller and the process, if it is controlled

by this measuring device.

Radiation Protection Instructions

This measuring device utilizes radioactive sources. Local regulations controlling the use of

radioactive sources must be followed. This is the law.

Installation, dismantling, relocation, maintenance, testing involving the radioactive

source or its shielding have to be performed by persons specifically licensed. Radioactive

sources which are not in use have to be stored at a save place which is tamperproof.

04/03 347 LB 444

VII

04/03 347 LB 444

1

1. Overview

The Density Meter LB 444 is designed for density measurements of liquids, suspensions,

pulps and bulk materials. Measurements can be carried out directly in a product line or in

a container.

The density measuring system LB 444 utilizes the radiometric measurement method, i.e.

the attenuation of Gamma radiation passing through the product being measured.

Typically, the measuring system is installed at the measurement location using appropri-

ate installation devices. If you have any questions, please contact the supplier.

Radiometric measuring systems utilize radioactive substances which are manufactured

in compliance with official regulations and which are protected by suitable shieldings.

When handled properly, any hazards to personnel due to radioactive substances can be

ruled out. As prescribed by law, these measuring facilities may be operated only by spe-

cifically licensed persons with sufficient expertise and training.

The hardware and software of the LB 444 system makes it easy to adapt the system to

rather different measuring geometries and measuring tasks. Therefore, the settings and

parameters of the measuring instrument have to be defined with care for the respective

measuring task when taking the system into operation. Important parameters may not

be changed later, in order not to compromise the reliable operation of the system. The

system should be taken into operation and settings changed only by persons who know

how to work with the instrument. Therefore, all users should read these operating in-

structions carefully. We recommend documenting all settings in a setup protocol.

Before starting any work, please read this operating manual carefully!

04/03 347 LB 444

2

2. System Description

2.1 Use and Function

The radiometric density measuring system can be used to measure the density of

•liquids

•suspensions

•pulps and

•bulk goods.

Measurements can be carried out directly in a product line or in a container. They are not

affected by pressure and viscosity fluctuations or the flow rate of the product.

Special instrument configurations and calculations allow you to adapt the density meas-

uring system to the local situation and the conditions of the product being measured.

2.2 Instrument Configuration (Operating Modes)

•Density measurement without temperature compensation (TC)

•Density measurement with temperature compensation

−via Pt 100 or

−via current input

•Suspension measurement with any carrier liquid

−Solid density and liquid density are known

−with or without TC

•Suspension measurement with water as carrier liquid

−Solid density is known

−with water temperature compensation the density of the water and the

solids concentration are taken into account for temperature compensa-

tion

•Mass flow measurement without TC (in connection with a volume flow meter)

•Mass flow measurement with TC via Pt 100 (in connection with a volume flow

meter)

•Backscatter measurement (density measurement in containers where no instal-

lations are possible)

•Measurement modes

•continuous measurement

•discontinuous measurement

−Batch operation via keyboard (press <run> button)

−Batch operation via digital input

04/03 347 LB 444

3

2.3 The Principle of Measurement

The density measurement is based on the irradiation method. It utilizes the physical law

of the attenuation of gamma radiation passing through the product being measured. The

resulting measurement effect is the ratio I/I0between the untenanted radiation I0and

the radiation I which is attenuated by the product being measured. The remaining radia-

tion picked up by the detector (scintillation counter) represents the density of the product

being measured. Figure 1 illustrates the principle of measurement. The radiation is at-

tenuated according to the following formula:

I = I0 * e - µ' * ρ* d

I = Radiation picked up by the detector

I0= Untenanted radiation

µ= Mass attenuation coefficient (absorption coefficient) in cm2/g

ρ= Density of absorbing material in g/cm3

d = Thickness of absorbing material in cm

Figure 1: Principle of measurement

The intensity of the radiation picked up by the detector is also dependent on the distance

between source and detector. As in the case of light, the function involved is a square

function, i.e. doubling the distance reduces the radiation intensity to ¼ if all other condi-

tions remain unchanged.

Assuming a constant distance between source and detector and a fixed measuring path,

the radiation picked up by the detector is only dependent on the density of the material

being measured.

Contamination of the product being measured or the pipeline wall by gamma radiation is

not possible at all.

d

Io I

Source Detector

04/03 347 LB 444

4

2.4 Measuring Configuration

Measuring systems for density, concentration and mass flow measurements typically

comprise the following components:

•Radioactive source (a)

•Shielding container (b)

•Detector (c)

•Evaluation unit LB 444 (d)

•Mounting device (e)

•Connection cable (f)

•Resistance thermometer Pt 100 (option) (g)

•Cooling jacket for detector (option)

The detector’s power supply and the measuring signal (pulses) are transmitted via the

cable connected between detector and evaluation unit.

Figure 2: Measuring system mounted on a pipeline

Different configurations and mounting devices may be required, depending on the meas-

uring tasks, the condition of the product being measured and the containers.

Figure 2 shows a basic setup in a pipeline with Pt 100 resistance thermometer and a 90°

mounting device for density, concentration and mass flow measurement.

45° and 30° mounting devices are available to extend the measuring path.

U or S-shaped measuring paths may be used for smaller pipeline diameters. Measure-

ments in containers are also possible (see 5.2.2).

EG&G BERTHOLD

enter

clear run

BERTHOLD

LB 444 - V 2.10

Density -Met er etc.

enter enter

enter

clear run

347

a, b

e

g

c

e

f

04/03 347 LB 444

5

3. Instrument Description

3.1 Radioactive Source

Radioactive sources for industrial applications are always “encapsulated radioactive sub-

stances” which are tightly welded into a sturdy stainless steel capsule, so that the radio-

active substance cannot leak out. Contamination is therefore ruled out. Moreover, any

activation of the product being measured by the sources used is not possible for physical

reasons.

The following sources can be used for these measuring configurations. 241Am, 60Co, 137Cs.

The following isotopes are primarily used for density measurements:

60Co has a relatively high energy of 1.17 and 1.33 MeV, respectively. It is used for den-

sity measurements over very long distances and/or if the radiation has to pass through

very thick pipe or vessel walls. Its half-life period is 5.27 years.

137Cs is the isotope most frequently used for density measurements. Its energy of 0.660

MeV is sufficient to penetrate commonly used pipe and container walls. Due to the lower

energy, the measuring effect is better than with Co-60. Also, the shielding costs for a Cs-

137 source are lower than for a Co-60 source. The half-life period of Cs-137 is approx.

30 years.

Am-241 is ideally suited for measurement of the concentration of components with high

atomic order (iron, nickel, HCl, etc.) in a carrier medium with low atomic order. Its en-

ergy is 60 keV and its half-life period 433 years.*

Please note the Radiation Protection Guidelines in Chapter 11!

*According to NBS, half-life is defined as: Time for the activity of any particular radioisotope to be reduced to

half its initial value.

04/03 347 LB 444

6

3.2 Shieldings

Typically, the source is firmly installed into the working shielding which includes a radia-

tion exit channel to release the active beam towards the detector. The active beam can

be shielded during transport, installation and servicing.

The shielding function must be checked every six months!

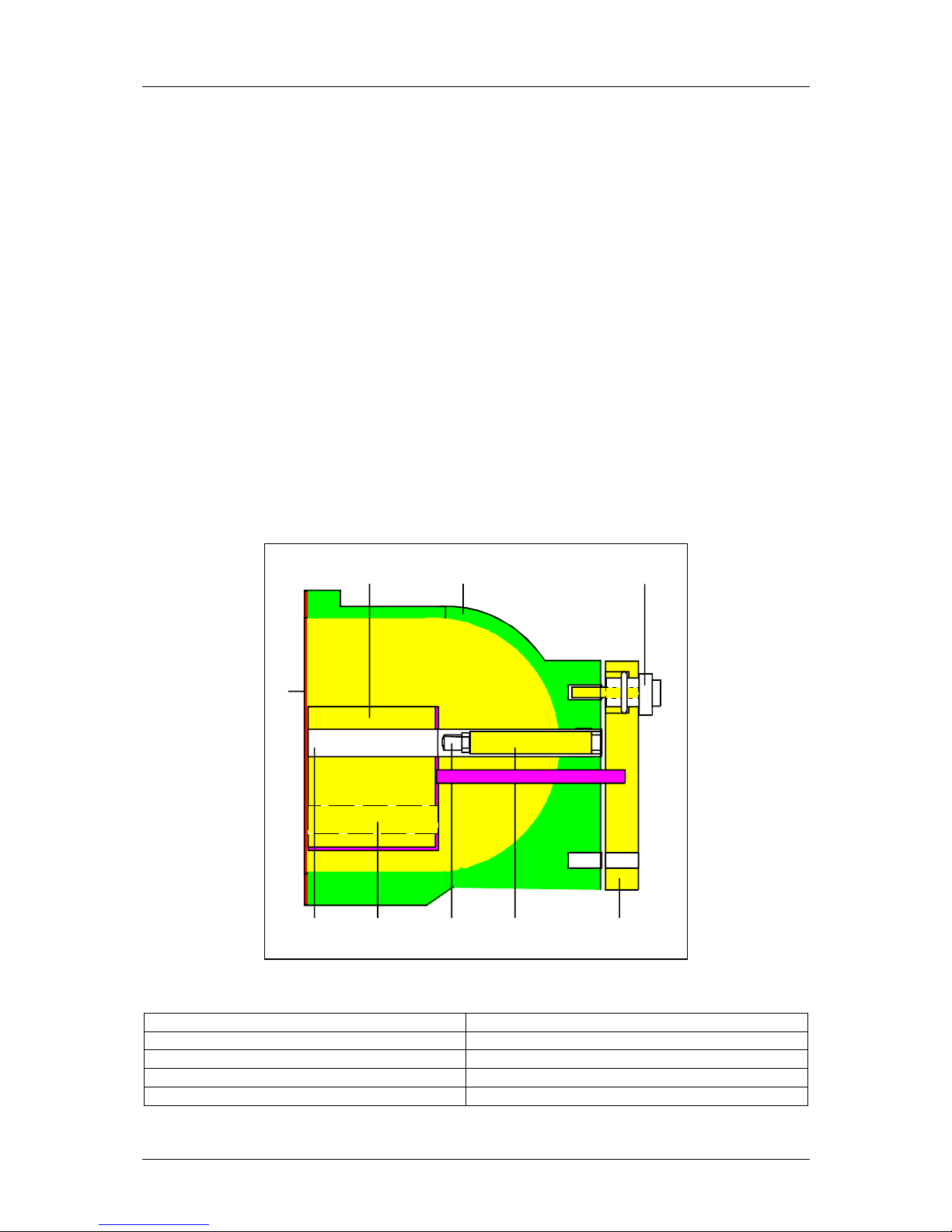

3.2.1 Shielding Types LB744... with Manually Operated Lock

The shielding consists of a cast iron or stainless steel outer shell filled with lead, except

for an exit port blocked by a lead filled moveable shutter. The shutter mechanism con-

sists of a rotatable lead filled cup connected to the outside of the housing by means of a

shaft, secured to a handle. The lead filling of the cup has a cylindrical hole. At one dis-

tinct and defined position of the handle, the hole and source holder are aligned, allowing

the radioactive beam to reach outside via a steel cover plate.

This is the “on” position of the device. At all other shaft positions, the beam exit is

blocked by the lead in the cup. The handle which indicates the open or closed condition

of the shutter can be secured in either position against unauthorized manipulation. Ac-

cess to the source holder is prevented by the handle in both the open and closed posi-

tions.

2 1 7

8

Pb

3 3.1 4 5 6

Figure 3: Shielding container type LB744

1 Shell 4 Radiation source

2 Moveable shutter 5 Source holder

3 Radiation exit channel, “OPEN” 6 Locking lever

3.1 Radiation exit channel, “CLOSED” 7 Lock

8 Cover plate

04/03 347 LB 444

7

3.2.2 Shieldings with Pneumatically Operated Lock and

Shutter Switch

NOTE: Option not available in the USA.

A pneumatic lock with switch contacts indicating the position of the lock is available as a

special version.

The pressurized air moves the shutter to the OPEN position. If the pressurized air is

turned off or in case of failure the moveable shutter is turned back to the CLOSED posi-

tion by the spiral spring.

Pressurized air:

min. 4*105 Pa (4 kp/cm2)

max. 7*105 Pa (7 kp/cm2)

Shutter switch:

IP 65

max. 250 V,

40 VA, 1 A

Air quality

clean, as usual for pressurized

air tools, oil free

Temperature range:

-5 to + 60°C

CAUTION-

RADIOACTIVE

MATERIAL

Throttle

valve

Pressurized air

connection

Spring unit

Drive

Shutter

switch

Figure 4: Shielding container type LB 744x with pneumatic locking drive

Do not open spring unit. DANGER!

The pneumatic drive is equipped with a throttle valve. The valve must be set

such that the shielding’s opening and closing process takes at least 2 s; other-

wise the shielding may get damaged!

04/03 347 LB 444

8

3.2.3 Shieldings for Installation in a Container with

Manually Operated Lock

The shielding consists of a lead-filled

steel pipe, with a guide tube for the ra-

dioactive source installed in the center.

The radiation exit channel is located in

an angle of 90° or 45° relative to the

longitudinal axis.

After taking off the covering cap which is

secured by a lock you may open the

knurled screw and, using the stay bar,

move the radioactive source forward

(OPEN) or back (CLOSED).

Locking

mechanism

Covering cap

Lead

Source position

CLOSED

Steel pipe

Protection pipe

Source position

OPEN

Radiation exit

channel

45°

90°

Figure 5:

Shielding for installation in a container

04/03 347 LB 444

9

3.2.4 Shieldings for Installation in a Container with

Pneumatically Operated Lock and Shutter Switch

NOTE: Option not available in the USA.

A shielding with a pneumatic lock and

shutter switch is available as a special

version. The pressurized air moves the

source lever to the OPEN position. If the

pressurized air is turned off, or in case

of failure, the spring installed in the

pneumatic cylinder moves the source

back to CLOSED

Pressurized air:

min. 1*105 Pa (1 kp/cm2)

max. 6*105 Pa (6 kp/cm2)

Air quality

clean, as usual for pressurized

air tools, oil free

Closed

Open

Switch CLOSED

Switch OPEN

Cover cap

Connection for

pressurized air electr. signal

OPEN/CLOSED

Figure 6: : Pneumatic locking mecha-

nism, not Ex-protected

Shutter switches signal the position of the

sources.

Two versions are available:

a) Version for use in areas not endan-

gered of explosion:

2 Reed contacts max. 250 V, 40

VA

1 x for OPEN, 1 x for CLOSED.

b) Version for use in the areas endan-

gered of explosion:

1 proximity switch for position

CLOSED.

It has to be connected to a fail-safe power

supply.

Figure 7 Shutter switch for ex-protected

area

See the drawings which are part of the

documentation for detailed information on

the construction and function of the shield-

ing type used.

Closed

Open

Switch flag

Cover cap

C

onnec

ti

on

f

or

pressurized air electr. signal

OPEN/CLOSED

Proximity

switch

04/03 347 LB 444

10

3.3 Detector

A scintillation counter is used as detector.

The detector converts the gamma radiation picked up into electrical pulses. The count

rate transmitted to the evaluation unit is proportional to the radiation intensity received.

The detector is equipped with an automatic drift compensation which automatically cor-

rects component aging and temperature influences, ensuring a high long-term stability of

the measuring system.

The power supply of the detector is carried out via the fail-safe connection circuit of the

LB 444 evaluation unit.

The detector itself includes a fail-safe connection circuit to which a resistance thermome-

ter Pt 100 can be connected for measurement of the product temperature.

The detector assembly in a sturdy stainless steel housing protects the instrument against

normal ambient pollution in industrial applications.

The detector must not be subject to heavy mechanical stress or vibrations.

For more information on its function see chapter 1.

The ambient temperatures must not exceed 50°C; otherwise adequate cooling has to be

provided (see also chapter 5.2.3).

3.4 Evaluation Unit LB 444

3.4.1 General Description

The evaluation electronics is

designed as a 19" module. It

includes the microprocessor-

controlled evaluation elec-

tronics and the power supply

for the required operating

voltage. A 32 bit microproc-

essor featuring a menu-

structured software specially

designed for density meas-

urements is used for signal

processing.

enter

clear run

BERTHOLD

LB 444 - 1 V 1.0

Density -Meter more

enter enter

enter

clear run

LCD display

Softkeys

Function keys

Figure 8: Front Panel LB 444

Table of contents

Other BERTHOLD TECHNOLOGIES Measuring Instrument manuals

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 567 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES FlowStar2 LB 514 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 480 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 124 Scint Series User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Uni-Probe LB 490 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 379 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Junior LB 9509 User manual