BERTHOLD TECHNOLOGIES LB 480 User manual

1

g/l

Time

000 10:30 11:

00

1

1

:

30

1

2

:

: 0

0 1

2

:

3

0

User’s Manual

Id. No. 54733-10BA2L

Rev. No.: 03 02.2017

Embedded Soft. from Rev. 1.00.00

Device Description from Rev. 01

Process Control detect and identify

LB 480

Level measurement

SENSseries LB 480

54733-10BA2L

1 – 4 02.2017

Volume 1-3

General Information

Dear customer Thank you for purchasing the measuring system SENSseries

LB 480 by BERTHOLD TECHNOLOGIES.

The scope of supply also includes this User’s Manual. Keep this

User’s Manual on hand for reference at any time.

Please observe the warnings and safety instructions given in this

User’s Manual to rule out personal injury and property damage.

They are identified by the following symbols: DANGER, WARNING,

CAUTION or IMPORTANT. In Volume 1, "Meaning of Other Symbols

Used in this Documentation" you find an overview of the hazards to

be observed and instructions on how to deal with these hazards.

Please read this User’s Manual prior to installation to get familiar

with the product.

If you do encounter problems despite careful study of the User’s

Manual, please do not hesitate to contact us.

Your BERTHOLD team

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 5

Volume 1-3 Table of Contents

Volume 1 Safety Manual

1About this User’s Manual..................................................1 – 13

1.1 Typographical Conventions.......................................1 – 13

1.2 Meaning of Other Symbols Used in this

Documentation ........................................................1 – 14

1.3 Meaning of Warning Signs on Detectors and

Source Shieldings .....................................................1 – 14

1.4 Terms Used in this User’s Manual .............................1 – 15

1.5 General Information .................................................1 – 16

2Proper Use ........................................................................1 – 17

3Qualification of Personnel .................................................1 – 19

3.1 Persons with a General Knowledge...........................1 – 19

3.2 Experts .....................................................................1 – 20

3.3 Authorized Persons..................................................1 – 20

4Transport and Assembly....................................................1 – 21

5Explosion Protection..........................................................1 – 23

5.1 Declaration of Conformity ........................................1 – 25

5.2 General Information .................................................1 – 26

5.3 Improper Use............................................................1 – 26

5.4 Safety Instructions ....................................................1 – 27

5.5 Application Range and Technical Data ......................1 – 28

5.6 Installation................................................................1 – 34

5.7 Ex – Concept ............................................................1 – 40

5.8 Maintenance and Visual Inspection...........................1 – 49

5.9 ATEX Certificate .......................................................1 – 55

5.10 IECEx Certificate .......................................................1 – 65

5.11 FM Certificate...........................................................1 – 81

Inhaltsverzeichnis

54733-10BA2L

1 – 6 02.2017

Table of Contents Volume 1-3

6Electrical Installation ......................................................... 1 – 87

7Functional Safety .............................................................. 1 – 91

7.1 Scope....................................................................... 1 – 91

7.2 Use........................................................................... 1 – 92

7.3 Other Applicable Documents and Records ................ 1 – 93

7.4 Detector Identification .............................................. 1 – 93

7.5 Project Planning........................................................ 1 – 94

7.6 Device Behavior during Operation........................... 1 – 100

7.7 Installation and Wiring............................................ 1 – 100

7.8 Commissioning....................................................... 1 – 101

7.9 Periodic Inspections ................................................ 1 – 102

7.10 Repair..................................................................... 1 – 103

7.11 Functional Safety Data Sheet LB 480....................... 1 – 104

7.12 Attachments........................................................... 1 – 106

7.13 Functional Safety Certificate ................................... 1 – 108

8Visual Inspection............................................................. 1 – 111

9Radiation Protection ....................................................... 1 – 113

9.1 General Information and Guidelines ....................... 1 – 113

9.2 Mounting the Shielding.......................................... 1 – 115

9.3 Testing the Shutter Mechanism .............................. 1 – 118

9.4 Safety Measures ..................................................... 1 – 119

9.5 Protection against Theft.......................................... 1 – 119

9.6 Accidents, Loss, Damage, Fire, Theft....................... 1 – 120

9.7 Shielding and Source.............................................. 1 – 122

9.8 Leak Test ................................................................ 1 – 123

10 Source Replacement ....................................................... 1 – 129

10.1 Radiation Exposure during Source Replacement...... 1 – 129

10.2 Point Source Replacement on Rotary

Cylinder Shielding................................................... 1 – 131

10.3 Rod Source Replacement........................................ 1 – 135

10.4 Point Source Replacement on LB 744x Shieldings.... 1 – 140

11 Source Disposal .............................................................. 1 – 145

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 7

Volume 1-3 Table of Contents

Volume 2 Installing SENSseries

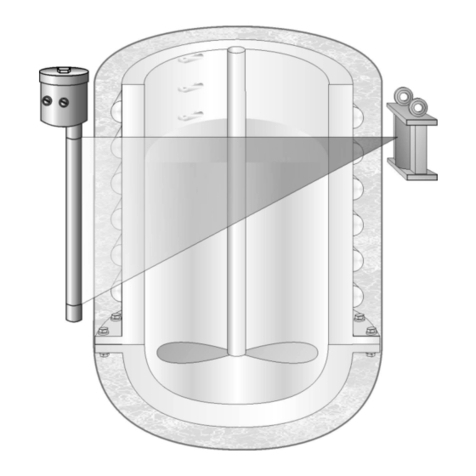

1System Description..........................................................2 – 151

1.1 Measuring System ..................................................2 – 151

1.2 SENSseries Hardware ..............................................2 – 154

1.3 Measuring Principle ................................................2 – 157

1.4 Measuring Arrangements .......................................2 – 158

1.5 Technical Data........................................................2 – 162

1.6 Detector Codes ......................................................2 – 166

1.7 Nomenclature of the SENSseries LB 480..................2 – 167

2Installation ......................................................................2 – 171

2.1 Transport to the Installation Site .............................2 – 173

2.2 Source Detector Arrangements...............................2 – 175

2.3 Detector Protection ................................................2 – 177

2.4 Detector Assembly..................................................2 – 180

2.5 Water Cooling........................................................2 – 187

2.6 Shielding ................................................................2 – 189

3Electrical Installation........................................................2 – 217

3.1 Cable Entries ..........................................................2 – 217

3.2 Terminals................................................................2 – 219

3.3 Connecting the Detector ........................................2 – 223

4Repair, Maintenance and Upkeep ...................................2 – 227

4.1 Safety Instructions ..................................................2 – 228

4.2 Replacing the Complete Detector ...........................2 – 229

4.3 Replacing the Electronics Module ...........................2 – 231

4.4 Replacing the Crystal-Multiplier Assembly

(for CrystalSENS).....................................................2 – 234

4.5 Checking the Detector............................................2 – 235

4.6 Customer Service....................................................2 – 238

4.7 Repair, Return Shipping ..........................................2 – 239

5Technical Information .....................................................2 – 241

5.1 TI LB 480 Level .......................................................2 – 241

5.2 TI LB 480 TowerSENS..............................................2 – 276

6Accessories .....................................................................2 – 289

6.1 Cable glands ..........................................................2 – 289

6.2 Limit Switches for Pneumatics.................................2 – 292

54733-10BA2L

1 – 8 02.2017

Table of Contents Volume 1-3

Volume 3 Operation with

HART®Communicator

1HART®Communication .................................................. 3 – 301

1.1 HART® Protocol ..................................................... 3 – 301

1.2 General Information on the

HART®Communicator ........................................... 3 – 301

1.3 Connection, Power On and Power Off of the

HART®Communicator ........................................... 3 – 302

1.4 Working with the HART®Communicator ............... 3 – 302

1.5 Archiving Parameter Sets........................................ 3 – 303

2Menu Structure .............................................................. 3 – 307

2.1 Information on the Menu Structure ........................ 3 – 307

2.2 Menu Overview ...................................................... 3 – 308

2.3 Start Menu ............................................................. 3 – 313

2.4 Live Display.......................................................... 3 – 314

2.5 Device Config....................................................... 3 – 316

2.6 Setup .................................................................... 3 – 316

2.7 Quick Start ........................................................... 3 – 317

2.8 Quick Start, Step 1................................................. 3 – 317

2.9 Quick Start, Step 2................................................. 3 – 318

2.10 Quick Start, Step 3................................................. 3 – 319

2.11 Sensor Configuration .......................................... 3 – 322

2.12 Date & Time ......................................................... 3 – 323

2.13 Sensor Settings.................................................... 3 – 324

2.14 Config Slave Detectors........................................ 3 – 327

2.15 Signal Condition .................................................. 3 – 328

2.16 Signal Parameter ................................................. 3 – 329

2.17 Reading Range..................................................... 3 – 330

2.18 Signal Dependency.............................................. 3 – 331

2.19 Source Exchange.................................................. 3 – 333

2.20 Cal Parameter....................................................... 3 – 335

2.21 Cal Points.............................................................. 3 – 337

2.22 Cal Settings .......................................................... 3 – 341

2.23 Product Conditions.............................................. 3 – 343

2.24 Calc Comp Factor ................................................. 3 – 349

2.25 Adapt Calibration ................................................ 3 – 350

2.26 Adjust Lower Point.............................................. 3 – 351

2.27 Adjust Upper Point.............................................. 3 – 353

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 9

Volume 1-3 Table of Contents

2.28 I/O Setup ..............................................................3 – 354

2.29 Current Output ....................................................3 – 355

2.30 Digital Output......................................................3 – 357

2.31 Level Threshold Settings.....................................3 – 359

2.32 Temp. Threshold Settings ...................................3 – 360

2.33 Digital Input .........................................................3 – 361

2.34 HART Interface.....................................................3 – 362

2.35 Service ..................................................................3 – 363

2.36 PMT.......................................................................3 – 364

2.37 Sensor Temperature ............................................3 – 365

2.38 Test .......................................................................3 – 366

2.39 Test Settings ........................................................3 – 366

2.40 I/O Test Settings ..................................................3 – 369

2.41 Plateau..................................................................3 – 370

2.42 Plateau Measurement .........................................3 – 371

2.43 Plateau View ........................................................3 – 372

2.44 Plateau Information ............................................3 – 372

2.45 Meas Parameter...................................................3 – 373

2.46 Meas Data ............................................................3 – 373

2.47 Meas Settings ......................................................3 – 374

2.48 Meas Readings.....................................................3 – 375

2.49 Access ...................................................................3 – 376

2.50 Identification........................................................3 – 378

2.51 Location ................................................................3 – 378

2.52 Device Information..............................................3 – 379

2.53 Device Revision....................................................3 – 380

2.54 Diagnostic ............................................................3 – 381

2.55 Operating Status .................................................3 – 382

2.56 Ext dev status ......................................................3 – 382

2.57 Device Variables Status.......................................3 – 383

2.58 Config Change Status..........................................3 – 383

2.59 Lock Device Status...............................................3 – 383

2.60 Error Status ..........................................................3 – 384

2.61 Log ........................................................................3 – 387

2.62 Error Log...............................................................3 – 387

2.63 Modification Log .................................................3 – 388

3Getting Started via the HART®Communicator .............. 3 – 389

3.1 Steps for Getting Started ........................................3 – 389

4Quick Guide to Calibration..............................................3 – 391

54733-10BA2L

1 – 10 02.2017

Table of Contents Volume 1-3

5Calibration...................................................................... 3 – 393

5.1 Preparing Calibration.............................................. 3 – 394

5.2 Calibration with Quick Start.................................... 3 – 396

5.3 Ensuring the Function of the Measurement ............ 3 – 402

6Functional Processes ....................................................... 3 – 405

6.1 Multidetector Operation ......................................... 3 – 405

6.2 Plateau Measurement............................................. 3 – 406

6.3 Master Reset .......................................................... 3 – 408

7Explanations ................................................................... 3 – 411

7.1 Background............................................................ 3 – 411

7.2 Conditions for Empty Calibration............................ 3 – 413

7.3 Linear and Exponential ........................................... 3 – 415

7.4 Multi-point calibration ............................................ 3 – 417

7.5 Radiation Interference Detection............................. 3 – 420

7.6 Time Constant........................................................ 3 – 423

7.7 Software Versions................................................... 3 – 424

8Error Handling ................................................................ 3 – 429

8.1 Error Handling Modes............................................. 3 – 429

8.2 Device Response to Errors....................................... 3 – 430

8.3 Trouble Shooting.................................................... 3 – 437

8.4 Reset...................................................................... 3 – 438

8.5 Operation Modes during Measurement .................. 3 – 438

8.6 Error Reset.............................................................. 3 – 438

8.7 Fault Current.......................................................... 3 – 439

9Setup Protocol ................................................................ 3 – 441

1

g/l

Time

000 10:30 11:

00

1

1

:

30

1

2

:

: 0

0 1

2

:

3

0

Volume 1 Safety Manual

54733-10BA2L

1 – 12 02.2017

Volume 1

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 13

Volume 1 1 About this User’s Manual

1

1About this User’s Manual

1.1 Typographical Conventions

The symbols and typefaces used in this User’s Manual have the fol-

lowing meaning:

The term BERTHOLD TECHNOLOGIES is used in this User’s Manual

for the company BERTHOLD TECHNOLOGIES GmbH & Co. KG.

Please observe the warnings and safety instructions given in this

User’s Manual to rule out personal injury and property damage.

They are identified by the following symbols: DANGER, WARNING,

CAUTION or IMPORTANT.

Indicates a direct threat of danger. The consequences will

be death or most severe personal injuries.

Indicates a possibly dangerous situation. If the situation is not

avoided, death or serious bodily injury could result.

Indicates a possibly dangerous situation. If the situation is not

avoided, minor or moderate bodily injury could occur.

Indicates a situation which could result in material damage if the

instructions are not observed.

IMPORTANT

Paragraphs marked with this symbol provide important information

on the product and on handling the product.

Tip

Includes application tips and other helpful information.

prompts you to carry out an action.

1, 2, 3, … identifies items in a graphic.

• identifies enumerations.

italic typeface highlights important information.

bold typeface indicates commands or menu items.

bold italic identifies user entries.

54733-10BA2L

1 – 14 02.2017

1 About this User’s Manual Volume 1

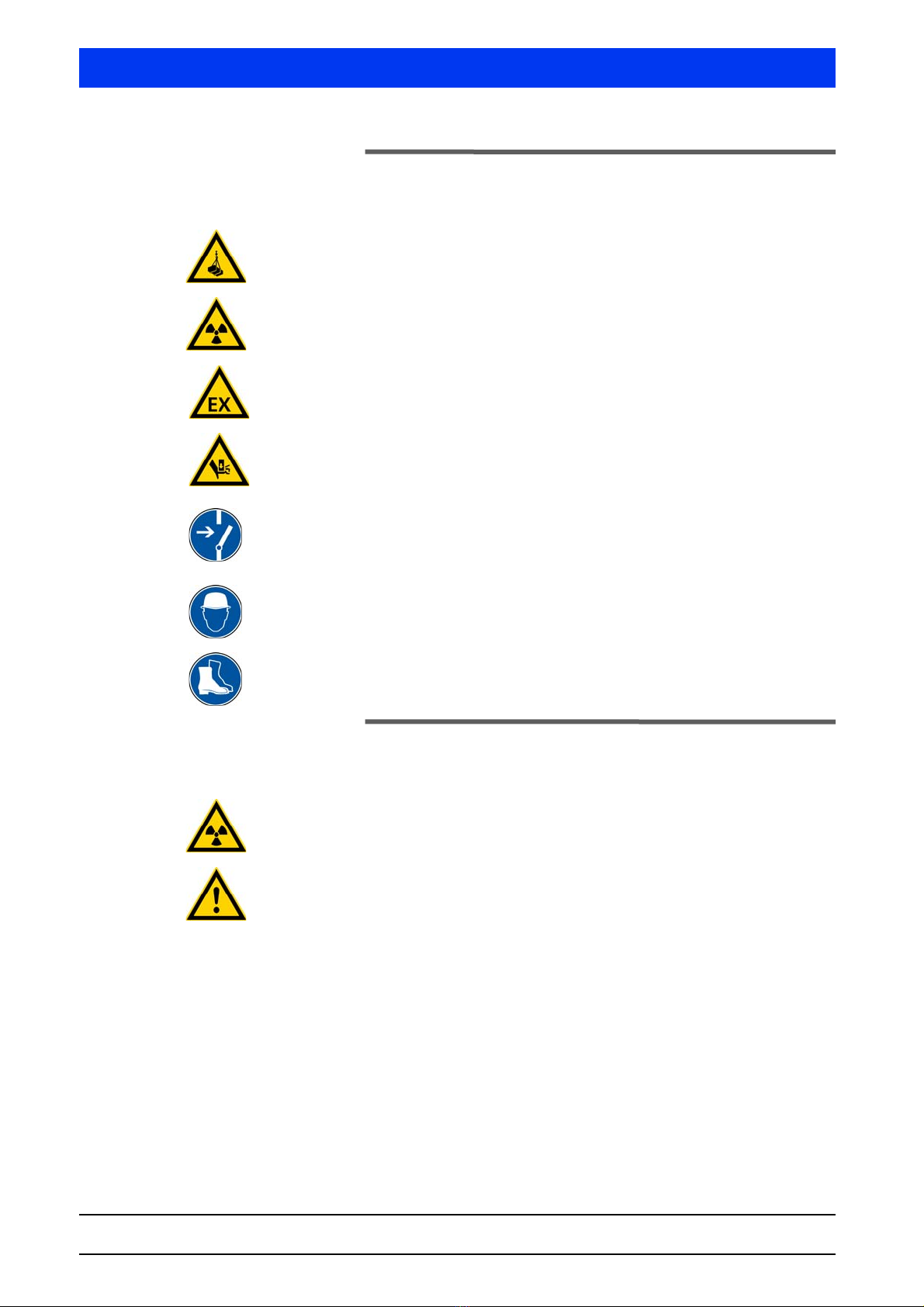

1.2 Meaning of Other Symbols Used in this

Documentation

Warning: Do not step or stand under a suspended load.

Warning: Radiation

Warning: Ex-protection

Warning: Risk of crushing

Requirement: Switch off power

Requirement: Wear a hardhat

Requirement: Wear safety shoes

1.3 Meaning of Warning Signs on Detectors

and Source Shieldings

Warning: Radiation

This warning is located on the source shielding.

Warning: Please read the User’s Manual prior to installation

This warning is located on or in the terminal compartment of the

detector.

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 15

Volume 1 1 About this User’s Manual

1

1.4 Terms Used in this User’s Manual

CrystalSENS Standard point detector version in the SENSseries LB 480.

UniSENS Standard rod detector version in the SENSseries LB 480.

SuperSENS Highly sensitive detector with large volume polymer scintillator 150

x 150 mm for large pipe or tank diameter.

Tow e rS EN S Rod detector with an especially large potential measuring length. In

contrast to multi-detector configurations, only one detector is

required here.

NaI detector NaI = sodium iodide crystal = scintillator

Scintillation detectors are very sensitive probes for gamma radia-

tion.

Isotope Substance of the radiation source, e.g. Cobalt 60 (Co-60) or Cesium

137 (Cs-137).

Count rate Value for the number of pulses standardized to one second.

Background The count rate caused by the natural environmental radiation.

Cps Unit for the count rate: Counts per second.

Factory setting In the factory setting, all parameters are preset with default values.

In most cases, this makes calibration of the detector a lot easier.

Nevertheless, a calibration must always be carried out.

mSv Milli-Sievert: The unit indicates the dose rate (dose equivalent).

mrem Milli-rem (roentgen equivalent in man): traditional unit for the dose

rate (100 mrem = 1 mSv).

MBq Mega Becquerel: The unit indicates the activity of a source. Each Bq

corresponds to one disintegration per second, i.e. 1 MBq equals one

million disintegrations.

mCi Milli-Curie: Traditional unit for the activity of a source

(1 mCi = 37 MBq).

ATEX Atmosphère explosive: is used as a generic term for the ATEX Prod-

uct Directive 94/9/EC and the ATEX Workplace Directive 1999/92/

EC. The directives contain provisions for equipment and compo-

nents for use in explosion hazardous areas.

FM Factory Mutual: an American industrial property insurance company

that, among other things, issues certifications in the field of explo-

sion protection.

54733-10BA2L

1 – 16 02.2017

1 About this User’s Manual Volume 1

CSA Canadian Standard Association: sets norms and standards that are

important for Canada (and America), among other things, the

Directive for Explosion Protection and Low Voltage.

PMT Photomultiplier or only multiplier: converts the flashes of light gen-

erated by the radiation in the detector into electrical signals.

HV HV = High voltage

The multiplier is operated at high voltage, so that flashes of light

can be converted into electrical pulses.

The high-voltage control allows for measurements that are stable to

temperature and aging. Each multiplier has a slightly different sen-

sitivity, and must therefore be operated at a different high voltage.

active / passive (Source / Sink) Depending on the detector type, the current output can be config-

ured as a current source or current sink. The following terms are

used interchangeably:

• Current source: active / Source Mode

• Current sink: passive / Sink Mode

1.5 General Information

The most important safety measures are summarized in this vol-

ume. It supplements the appropriate provisions which the staff in

charge is obliged to follow.

Please pay attention to:

– the national safety and accident prevention regulations

– the national assembly and installation directions (for example,

EN 60079)

– the generally accepted engineering rules

– the information on transport, assembly, operation, service,

maintenance in this User’s Manual

– the safety instructions and information in this User’s Manual

and the enclosed technical drawings and wiring diagrams

– the parameters, limit values and the information on operating

and ambient conditions on the type labels and in the data

sheets

– the labels on the device

Depending on the field of application, the corresponding chapters

have to be taken into account.

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 17

Volume 1 2 Proper Use

1

2Proper Use

The measuring system SENSseries LB 480 is a detector which,

depending on its design, can be used for different measurement

tasks:

– Level measurement

– Monitoring limit values

– Density measurement

The measurement system is designed for the continuous monitoring

and detection of levels and limit levels of liquids and bulk solids in

bins, or to determine the density of liquids in tanks and pipes. The

proper use is defined in the project planning stage by BERTHOLD

TECHNOLOGIES, the system delivered may be used only for this

purpose.

If the detector is used in a way which is not provided for during the

project planning stage and which is not described in the User’s Man-

ual, then the detector's protection is compromised and the guaran-

tee claim becomes invalid.

BERTHOLD TECHNOLOGIES only accepts liability for / guarantees

the correspondence of the systems of the SENSseries LB 480 to its

published specifications. The detectors of the SENSseries may only

be installed in an undamaged, dry and clean condition. Alterations

and modifications to the system components are not allowed.

Repairs to the detector may only be made if expressly authorized

by the operating manual.

Conformity to standards The standards and guidelines the SENSseries complies with are

itemized in the CE conformity declaration.

54733-10BA2L

1 – 18 02.2017

2 Proper Use Volume 1

Warning about misuse The following use is inappropriate and has to be prevented:

– Use under other conditions and prerequisites than those speci-

fied by the manufacturer in his technical documents, data

sheets, operating and assembly instructions and other specifi-

cations.

– The repair of detectors that are used in explosion hazardous

areas by persons who were not authorized by BERTHOLD

TECHNOLOGIES.

– Using the device in a damaged or corroded condition.

– Operation with open or inadequately closed cover.

– Operating with inadequately tightened adapters and cable fit-

tings.

– Operation without the safety precautions provided by the man-

ufacturer.

– Manipulating or bypassing existing safety installations.

Maintenance The measuring system of the SENSseries LB 480 may only be

installed, serviced and repaired by trained persons (see chapter 3.2,

page 1-20).

Repair Spare parts for detectors used in the Ex-area may be assembled

only by the BERTHOLD TECHNOLOGIES service or by persons

authorized by BERTHOLD TECHNOLOGIES. If this is not possible,

you must replace the entire detector or return it to the manufac-

turer for repair.

Parameter settings Never change the parameter settings without a full knowledge of

this User’s Manual, as well as a full knowledge of the behavior of the

connected controller and the possible influence on the operating

process to be controlled!

Sources and shieldings This measuring system uses radioactive sources. The radiation pro-

tection instructions in this User’s Manual and the relevant statutory

provisions are to be observed strictly, see also chapter 8, "Visual

Inspection", page 1-111.

SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG 1 – 19

Volume 1 3 Qualification of Personnel

1

3Qualification of Personnel

At different parts in this User’s Manual, reference is made to per-

sonnel with certain qualifications who can be entrusted with differ-

ent tasks during the installation, operation and maintenance.

These three groups of people are:

1. Persons with a general knowledge, see chapter 3.1.

2. Experts, see chapter 3.2.

3. Authorized persons, see chapter 3.3.

The following chapters explain the meaning of these terms and the

prerequisites for the particular group of people.

IMPORTANT

All work on and with the measurement systems SENSseries LB 480

must be performed by persons having at least a general knowl-

edge; they must always be guided by an expert or an authorized

person.

3.1 Persons with a General Knowledge

Persons with a general knowledge are e.g. technicians or welders

who can undertake different tasks during the transportation,

assembly and installation of the measuring systems SENSseries

LB 480 under the guidance of an authorized person. This can also

refer to construction site personnel. The persons in question must

have experience in the transportation and assembly of heavy com-

ponent parts.

Persons working with Ex devices must in addition have knowledge

on how to work with these devices, for example, that the devices

must not be subject to mechanical damage (blow, etc.).

IMPORTANT

Persons with a general knowledge must always be guided by a

trained expert at the very least.

When dealing with radioactive substances, a Radiation Safety Offi-

cer must also be consulted.

54733-10BA2L

1 – 20 02.2017

3 Qualification of Personnel Volume 1

3.2 Experts

Experts are persons who have sufficient knowledge in the required

area due to their specialist training and who are familiar with the

relevant national health and safety regulations, accident prevention

regulations, guidelines and recognized technical rules. Expert per-

sonnel must be capable of safely assessing the results of their work

and they must be familiar with the content of this User’s Manual.

3.3 Authorized Persons

Authorized persons are those who are either designated for the cor-

responding task due to legal regulations or those who haven been

authorized by BERTHOLD TECHNOLOGIES for particular tasks.

When dealing with radioactive materials, a Radiation Safety Officer

must also be consulted.

Table of contents

Other BERTHOLD TECHNOLOGIES Measuring Instrument manuals

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 379 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 444 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Uni-Probe LB 490 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 567 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Junior LB 9509 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES FlowStar2 LB 514 User manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES LB 124 Scint Series User manual