BES Rehab Millie-Mova User manual

Installation instructions for the millie-mova

28th August 2014

1. Start - remove any felt or Nylon sliders

from the bottom of wooden leg chairs (not

applicable to front leg of metal chairs .

Bend the existing bends to align the frame

as shown, so that the arms about 10mm

inside the legs with the wheels parallel to

the front-back line of the chair.

.

.

.

Drill 4mm hole,

25mm deep, 35mm

above floor on

inside of leg wood

only)

Drill 1/4 inch hole

27mm above floor

2. Front legs wood - drill a horizontal 4mm

diameter hole 25mm deep on the inside of

each front leg, 35mm (for armchairs see

below*from the floor.

Front legs metal – drill the front legs 1/4

inch hole straight through, using the same

height (35mm - do not forget to allow for

the plastic plugs & rubber ferrules above

the floor as for the wooden chairs.

*NB – for armchairs check the pedal height

is suitable before drilling! See Hints and

Tips page 3.

Rear legs wood & metal - drill rear legs

straight through with a ¼ inch hole 27mm

above the floor. All holes should be exactly

horizontal and left and right holes should

be exactly in line with each other. NB. If

the rear legs are skewed or round that is

no problem – see Hints & tips page 3.

nut

washers

Left hand rear leg viewed from rear

lock-nut

3. Rear wheels - install rear wheels as

shown. Place the bolt through the hole

from the outside, add the nut and tighten

very firmly. Slip on the wheel, axle tube &

washers plus the lock nut. Tighten the lock

nut firmly but do not to deform the axle

tube . Cut bolts, if too long, and remove

sharp edges. Check that the chair is

“foursquare” on a flat surface. If it is not

quite foursquare then adjust the depth of

the holes for the front leg washers to

compensate (or put a washer in the

ferrules, if metal legs – see part 4.

bend to adjust here

wheels parallel

10mm gaps

front legs front legs

Installing the millie-mova system on a

chair is straight-forward in six easy

steps:

Please check the contents: 1 x millie-mova including 2 rear wheels with axle tubes & 2 pivots, 1 bag

containing, 2 bolts with nut, lock nut & 2 washers, 2 large screws, 2 shock cords, 2 eyes, 2 rubber washers

and 2 small screws. The kit for metal leg chairs will contain bolts for the front legs.

4. Front leg anti-slip washers - wooden chairs - these

are only really necessary where the chair will be used on

a hard floor such as vinyl, laminate or wood. NB. on a

deep carpet they may hinder movement. To compensate

for any unevenness caused by imperfect alignment of the

axle holes adjust the depth of the shallow hole for the

rubber washers. CAREFULLY drill a vertical hole 19mm

diameter approx.’ 2mm deep up into the centre of the

front legs AND a pilot hole for the screw. Insert the

washer into the hole and screw into the bottom of the

leg. Screw in until the head of the screw is recessed

slightly as shown. Metal legs (or if the wooden legs are

too thin - use rubber ferrules. Please ask us if these are

needed. The washers/ferrules provide vital chair stability

if leaned on from behind on hard floors and some carpets.

screw head 2mm recessed

Correct way up

pivot

5. Wooden chairs - locate the pivot into the front

frame hole and drive the screw in with a number

3”Pozidrive” bit (use a drill driver . Metal legs –

secure the V frame using a ¼ inch bolt, washer

and lock nut as shown below. Always use the

screws and bolts supplied so that the V frame does

not slip off the screw/nut. Substitute bolts must be

HT (High Tensile .

Pivot

Washer

and lock

nut

Metal leg chair

6. Shock cords - drill suitable pilot

holes (2mm dia in the underside

of the chair seat frame. Screw in

the eyes and thread the shock cord

into the eyes, tying a double knot

to secure (not on the eye, but as

shown . Thread the other end of

the cord through the hole in the

rear of the V frame and secure

with a single knot (do not tie

together . Adjust knots so that

cords are taking even strain with

the front wheels just above the

floor.

Tie a single knot to secure

Tie a double knot to secure

2

Hints and tips

If the chair has a low crossbar - If there is a crossbar lower than 100mm above

the floor then place the V frame in position to check that when the unit is fitted

that:

a. the front wheels are just above the floor (use a couple of coins under the

wheels as a gauge .

b. the front leg “lift” is sufficient before the pedal touches the floor (i.e. about

20mm

The 35mm pivot height may have to be increased to permit fitting. It may not be

possible to fit a millie-mova system if the crossbar is below 75mm.

If the bolt for the rear legs seems too short - If the

chair leg is too thick for the bolt then you can use a 14mm

drill to create a shallow hole for the bolt head to sit in. See

the picture here. You may have to use a screwdriver to hold

the bolt head from turning, so you can tighten the nut.

Round chair legs/non-vertical chair legs -

It is easy to fit the millie-mova to this type of chair

leg. The first step is to create a small flat vertical

area where the pivot is to be seated. Use a 13mm

flat wood drill as shown. The flat area should be

created holding the drill horizontally so that the flat

is vertical. This will permit the pivot or rear wheel

to sit correctly.

Rear Pedal if required for larger chairs and

armchairs) - Fit rear pedal as shown here using

bolt, washer and Nyloc. Tighten firmly, but not so

that it distorts the V frame. Only remove the black

edging if necessary. Please ask us if you require a

pedal. Armchairs should have legs at the back at

least 7.5 inches long (190mm .

To Use - Please refer to the Dos and Dont’s list

provided.

The millie-mova is used by pushing the rear end

of the device down nearly to the floor and

pushing or pulling the top of the chair backrest.

The maximum recommended weight is 130kg.

We hope the millie-mova system will be useful to

you. Any problems please contact us on 01202

240999.

Ski chairs - with a millie-mova system, the skis

are not needed and should be removed. Just

unscrew from the legs.

3

Skewed and/or non-vertical rear legs - drill

diagonally as shown. You may need to remove a

little of the leg at Ato avoid fouling the wheel.

Alternatively the wheel can be parallel to the leg

by drilling at a angle. This means the wheel will

not be vertical.

A

Correct fitting

arrangement

Table of contents

Popular Medical Equipment manuals by other brands

B. Braun

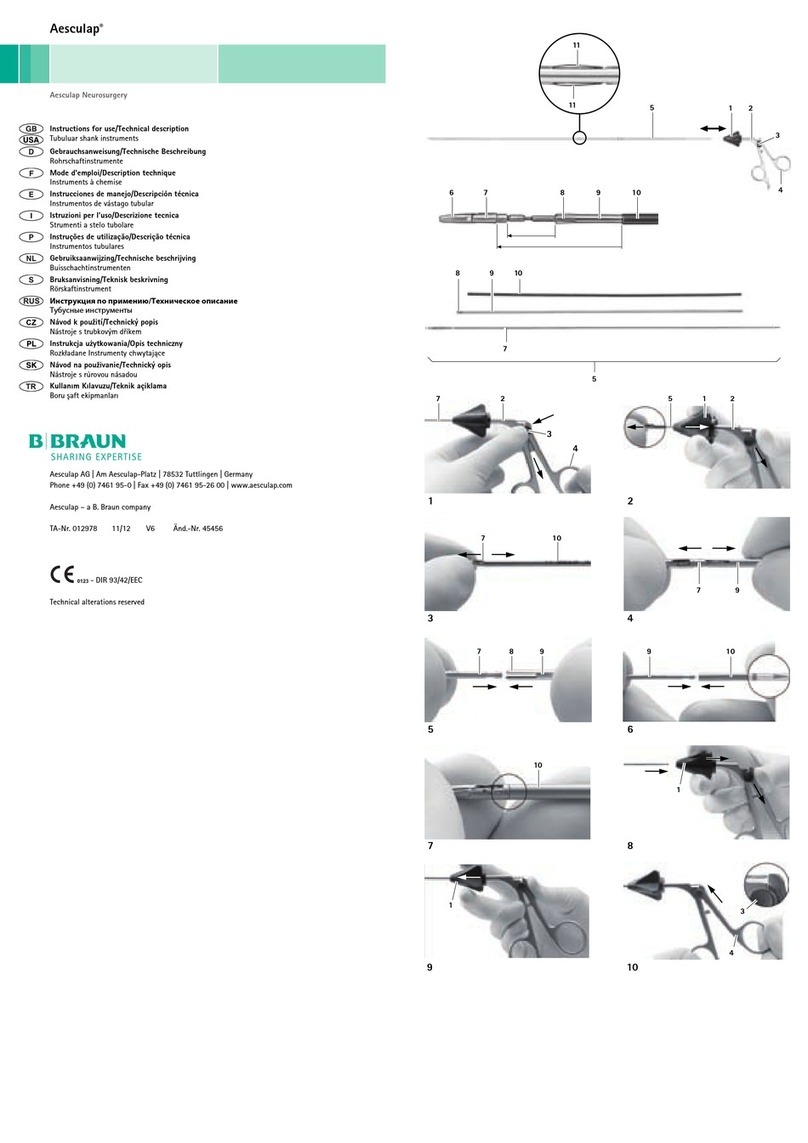

B. Braun Aesculap 012978 Instructions for use/Technical description

ArcFamily

ArcFamily ArcEquine user manual

Cooper Surgical

Cooper Surgical Mityvac Pearl Edge Bell Cup Instructions for use

BlueChip

BlueChip Adapt Pro Elite 9200 user manual

iSens

iSens i-Smart 300 VET Operator's manual

ARJO HUNTLEIGH

ARJO HUNTLEIGH FLOWTRON UNIVERSAL Instructions for use