Healthmark Flexible Inspection Scope User manual

Instructions for Use: Flexible Inspection Scope Kit-USB

Brand Name of Product

Flexible Inspection Scope Kit - USB

Generic Name of Product

Flexible Inspection Scope Kit - USB

Product Code Number(s)

FIS-007U, FIS-007USK, FIS-007UB, CT-101, CT-102

Intended Use

For visually inspecting items.

Range of Applications for Product

Enhance visual inspection by providing lighted magnification, image capture and the

option for documentation in hard-to-see crevices, channels, and lumens in areas of

instruments that are not visible to the unaided eye.

Key Specifications of Product

Flexible Inspection Scope- FIS-007U

•CT-101 1.9 mm OD and 110 cm length

•CT-102 1.06 mm OD and 110 cm length

•Optical

oResolution format:

oCT-102 1.06 mm—40,000 or 200 x 200 pixels

oCT-101 1.9 mm —160,000 or 400 x 400 pixels

oField of View: 120° in air

oAngle of view: 0°

USB Control Module: Control Module housing Camera processor and LED

illumination:

•Dimensions: 5.25 in x 3.90 in x 1.85 in

•Weight: 1.20 lbs

•Digital Inspection Scope Connection

•Illumination Control- LED in the Control Module

•Power Cycle

•USB Camera Cable

•Easily change from small and large diameter scopes

Light Settings:

There are four light settings operated by one button.

Blinking Light (Indicates transmitting video data):

•Splash proof (IPX5 Rating).

•No external power needed.

Flexible Inspection Scope Software Requirements:

•Compatible with Windows 10 Operating systems

•USB Flash Drive includes Software.

Shipping & Storage

Shipping Conditions &

Requirements

N/A

Storage Conditions

Storage and transport

Humidity: 10 to 100 %rh (condensing)

Temperature: -20 to 60 °C

Pressure: 600 to 900 hPA

Normal Operation

Humidity: 0 to 100 %rh (condensing)

Temperature: 5 to 40 °C

Packaging Contents

N/A

Shelf Life

Warranty: one-year from date of purchase.

Instructions for Using Product

Description of

Use(s)

For visually inspecting items.

Preparation for

Use

Unpacking Flexible Inspection Scope:

Carefully inspect for shipping damage. If there is any damage contact the shipping carrier and Heatlhmark

customer service 800-521-6224 immediately.

USB Control Module: (Fig 1)

1. Digital Inspection Scope Connection

2. Illumination Control

3. Power Cycle

4. USB (Type C) on the right side of the box

Figure 1

Flexible Inspection Scope™: (Fig 2)

•CT-101 1.9 mm O.D. and 110 cm length

•CT-102 1.06 mm O.D. and 110 cm length

Large 1.9mm Small 1.06mm

Figure 2

Flexible Inspection Scope™Features

Light/Illumination Settings: (Fig 3)

•5 light settings

oLight on control indicats setting level

3

2

1

4

oFifth setting is OFF

•Press light button to advance to next setting

•Fifth setting turns the light OFF

Figure 3

Power Cycle Button

Press button to RESET camera (Fig 4)

Figure 4

1. Flexible Inspection Scope™Plug (Fig 5)

Contains camera video connection as well as LED Light for illumination.

Figure 5

2. Flexible Working Length (Fig 6)

The portion of the Flexible Inspection Scope™ that is inserted into an item during visual inspection.

The measuring scale markings on the Flexible Working Length are in centimeters (accuracy = ± 0.5

cm).

1

Figure 6

3. Distal Camera (Fig 7)

Distal portion of Flexible Inspection Scope™ that contains the camera lens.

Figure 7

SOFTWARE INSTALLATION:

Note: This section is done only once when connecting the scope to the computer for the first time.

•System Requirements: MS Windows version 10

•Install the Flexible Inspection Scope™ Software from the USB flash drive on a computer

Note: If you have any IT policies that may block this installation, please contact your IT team to give access

to Healthmark scope viewer to install.

1. Insert the USB Flash drive into your computer, and double click on the Healthmark Scope Viewer installer

package to begin installation.

2. The Welcome to the Healthmark Scope Viewer Setup Wizard screen pops up and click on Next

2

3

3. Next click on the first tab Typical or setup type of your choice, click Next

4. Click Install and wait for installation to complete

5. Next, Click Finish.

STARTING SOFTWARE & CONNECTING SCOPE TO PC:

(Fig 8) 1. Open the Windows PC viewer software

2. Connect the Control Module to PC using USB Cable

3. Plug the Flexible Inspection Scope into the Control Module

4. In the viewer software, click Settings and Select USB Video Device, click on the desired

resolution, select the preferred Video Output Format, and then Click OK

5. Press the Power Cycle Button

Figure 8

6. Now you can start using the scope.

Verifing Operation

Following the steps listed below will ensure the proper use and performance of the Flexible Inspection Scope.

The Flexile Inspection Scope can be checked for normal operation by connecting it as described in the

Startup section of this IFU.

Normal operation includes:

•An image appearing on your computer monitor or HDMI Monitor

•A blinking light on Control Module near the Power Cycle button indicates the image feed is

transmitting

•White light will emit from the distal end of the Digital Inspection Scope

•An LED light on the control module top panel indicates the light intensity of the device.

Using Software

Healthmark Scope Viewer Software (Fig 9)

1. Capture button: Captures a Reference Image and saves it to the Reference Image folder

2. Main Image window: Displays the image from the camera

3. Reference image window: Displays a reference image

4. Clear button: Removes the image from the Reference image window

5. Open Reference Image button: Allows you to select a reference image from the Reference

Image folder

6. Settings button: Click to select the video camera and resolution settings

7. File Location Button: Click to change location where captured images are being saved

8. File Location Window: Shows the file path where captured images are being saved currently

9. Capture Image button: Captures images and adds them to the File Location selected by the user

(as shown in the File Location Window)

10. Capture Video button: Click to record video. Click again to stop recording video

11. File Prefix: Type in text that you would like included in the file name of Captured Images

Figure 9

Selecting Video Device or Camera

Follow the directions below to select the video device or camera used to capture images using the Flexible

Inspection Scope™ Viewer Software. (Fig 10)

1. Click Settings button in the lower left of the Scope Viewer software to display a list of video

devices or cameras being detected by your computer

2. Select a device for capturing images using the Scope Viewer

a. The example below shows a webcam and USB Video Device in the Settings box. Select the

USB Video Device for the Flexible Inspection Scope™

b. You can also select your preferred Video Output Format from the dropdown box

3. Click OK to view the selected Video Device

Figure 10

Capturing Still Pictures

Follow the instructions for capturing still pictures from the Main Image Window.

Select the Capture Image button. (Fig 11)

Figure 11

Note: When an image is captured, “Image Captured” in red text will flash on the lower portion of the screen

and a new file will appear in the Files Location.

Capturing Video Images

Follow the instructions below for capturing video from the Main Image Window.

1. Select the Capture Video Button (Fig 12)

Figure 12

2. When the video is recording “Recording…” in red text will appear toward the bottom of the

software window

3. To stop recording, click Stop Capture (Fig 13)

Figure 13

1

2

3

Setting File Prefix

Following the steps below allows you to create a file prefix that will appear after the underscore of image file

names save to the File Location specified by the user.

1. Click the field next to File Prefix

2. Enter the characters that you would like to be included in the file name (Fig 14)

Figure 14

Setting Location for Saved Files

Following the steps below allows you to set the file location of saved images using the Scope Viewer

software.

1. Click the File Location button

2. Select the file location you want to save captured images (Fig 15)

Figure 15

Displaying Reference Image

There are two ways to display a still image in the Reference Image Window on the Scope Viewer software.

1. To display an image currently being displayed in the Main Image Window, click the Capture button

Note: The images will be saved in a file folder titled Reference Images in the designated File Location that

the user specified in the File Location field. (Fig 16)

Figure 16

2. To display a saved image in the Reference Image Window from your File Location:

a. Click the Open Reference Image button

b. Select the file you want to display

c. Click the OK Button, to display the image in the Reference Image Window. (Fig 17)

Figure 17

Switching to a Different Flexible Inspection Scope™ on the Control Module:

1. Press the Power button on the Control Module once

2. Disconnect the current Flexible Inspection Scope from the Control Module

3. Repeat the steps in the “STARTING SOFTWARE & CONNECTING SCOPE TO PC” procedure

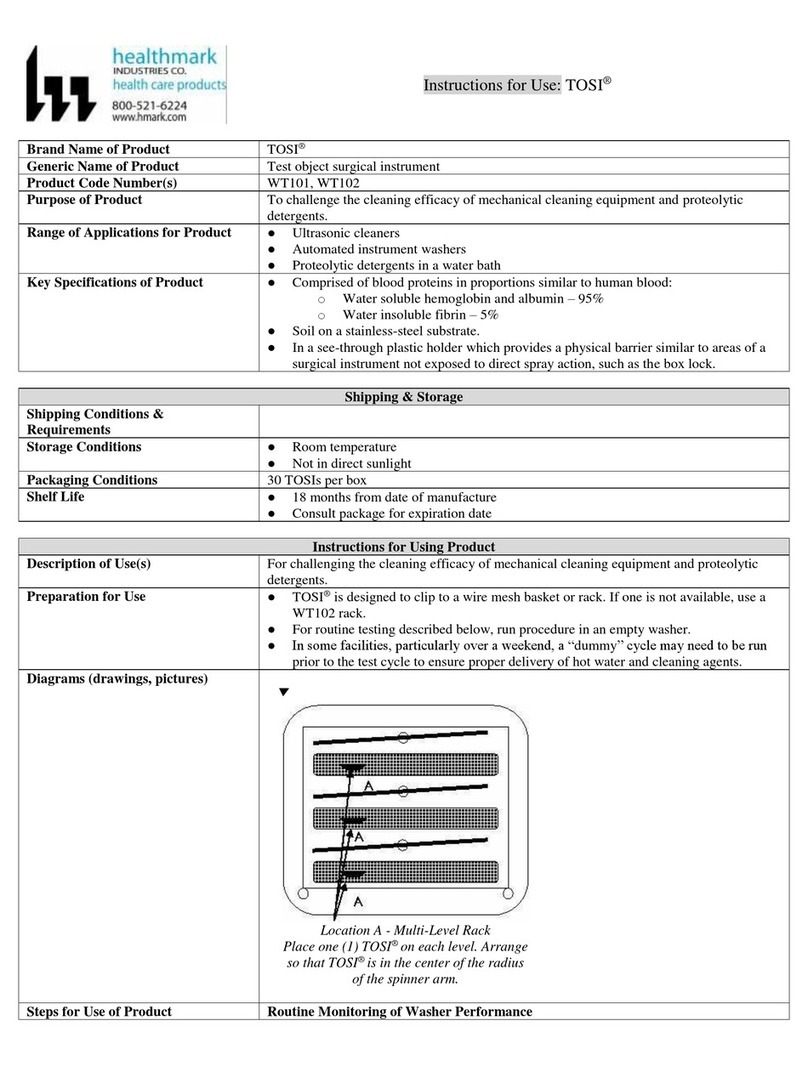

Diagrams

(drawings,

pictures)

Inserting Scope in Item

Figure 1

Rotating Device to Avoid Obstacle

Figure 2

Steps for Use of

Product

Performing Inspection

Following the steps listed below will ensure the proper use and best performance of the Flexible Inspection

Scope™. Follow the steps prior to inspection.

1. Grasp the Flexible Inspection Scope™ near its distal end and gently insert the Flexible Working

Length into the intended item, as shown in (Fig 1 above)

2. Adjust light with the Illumination button on the Control Box for ideal lighting

3. Use short advancements while keeping your fingers close to the device’s opening.

a. View the monitor while inserting into the item

b. If an obstruction hinders the path of the Flexible Inspection Scope™, gently attempt to

manipulate or rotate it to avoid the obstacle (Fig 2 above)

4. Once the Flexible Working Length has reached the end of the area you are inspecting, retract the

scope slowly while looking for debris or damage

5. When switching between control boxes, power off the control box that is in use, then disconnect the

Flexible Inspection Scope from the control box

6. If the HDMI control box is in use, power off the control box and disconnect the Borescope Catheder

along with the power adapter

Interpretation of

Test Results

N/A

Contraindications

of Test Results

N/A

Documentation

N/A

Special Warnings

and Cautions

•To ensure operator safety, read and understand this IFU before using the Flexible Inspection

Scope™

•Do not attempt to use the Flexible Inspection Scope™if it appears to be damaged

•The Flexible Inspection Scope™is not sterile as supplied. The user must follow the protocol for

cleaning and disinfecting, or sterilizing described in the instructions for Cleaning and Disinfecting

or Sterilizing section

•Do not attempt to service any part of this product

•The Flexible Inspection Scope™emits visible light energy from its distal end when powered on.

Avoid looking directly at this emitted light or directing it toward others

•Do not bend the Flexible Inspection Scope™ to a radius less than 0.50 in (12.7 mm). This may

cause damage

•Do not apply excessive force to the Flexible Inspection Scope™. Applying excessive force to the

Flexible Inspection Scope™ can result in damage

oIf you feel resistance or an obstruction hinders its path, you may gently attempt to

manipulate or rotate the scope to avoid the obstacle

oYou may also slowly withdraw it a short distance any try advancing again

Disposal

This can be disposed of the same as standard electrical products. Follow your local regulations for disposal

of electrical components.

Reprocessing Instructions

Point of Use

N/A

Preparation for

Decontamination

N/A

Disassembly

Instructions

Disconnect the Flexible Inspection Scope™ from the control module prior to cleaning/disinfecting.

Cleaning –

Manual

Cleaning Between Uses:

Wipe down the Flexible Inspection Scope™with a compatible wipe. Follow the manufacturer’s Instructions

for Use for appropriate wipe usage. See Chemical Copatibility Chart for approved cleaning agents click here:

The Flexible Inspection Scope™is made of the same material as other common endoscopes. Any Wipe,

solution, or low temperature (≤ 60 °C [140 °F]) method intended for the reprocessing of endoscopes is likely

compatible with the Generation II Flexible Inspection Scope™Catheters if used according to the product

labeling.

Solution Containing (Flexible Inspection Scope Only)

Alcohol Ethoxylates

Neutral or Near-Neutral pH Detergents

Enzymatic Cleaning Solutions

Enzymatic Detergents

Sodium Borated, Decahydrate

Tetrapotassium Pyrophosphate

Flexible Inspection Scope™ has a fluid ingress protection rating of IPX7 (Waterproof) and can withstand

immersion in fluid up to 1 m in depth for up to 30 minutes.

Control Module USB has a fluid ingress protection rating of IPX5 (Water resistant) and can withstand a

sustained, low pressure water jet spray for up to three minutes.

•

Note: (Do NOT soak). Control Module and cables are not waterproof and should not be immersed.

Cleaning –

Automated

N/A

Disinfection

Control Module and Cables

These may be cleaned with alcohol based disinfectant wipes.

Compatible agents (wipes and solutions) for disinfecting Flexible Inspection Scope™ and Control

Module:

•Hydrogen Peroxide

•Isopropyl Alcohol (IPA)

•Sodium Hypochlorite (Bleach)

•Ortho-Phenylphenol

•Quaternary Ammonium.

High Level Disinfection (Flexible Inspection Scope™ Only)

•Select only the disinfecting solutions listed in the compatible disinfecting methods

•Follow all recommendations regarding health hazards, dispensing, measuring, and storage from the

manufacturer of the cleaning and disinfecting agents

•Soak the Flexible Inspection Scope™in the selected disinfecting solution per the solution

manufacturer’s Instructions for Use

•Rinse the Flexible Inspection Scope™with critical (sterile) water, again, following the instructions

of the disinfecting solutions manufacturer

Reprocessing Chemical Compatibility Chart click here:

Drying

Flexible Inspection Scope™ Only

•Dry with a sterile, non-linting wipe or sponge

•Ensure the distal tip and proximal end are dried

Note: Air drying could leave deposits on the optical surfaces, which could result in a degraded image.

Maintenance,

Inspection, and

Testing

•(Prior to use), carefully inspect the external surfaces of the Flexible Inspection Scope™and any

accessories to ensure they are smooth and free of any wear or damage, such as protrusions or sharp

edges

•Flexible Inspection Scopes™ have no user:

oServiceable parts

oMaintenance beyond cleaning.

•Refer all service or replacement needs to Healthmark Industries

•Light leaks may be common and possibly noticeable when inspecting the flexible portion of the

Flexible Inspection Scope™

oThis does not have an effect on its function, but it should be monitored for light output

oIf the image on your monitor is too dark to visualize, this may be caused by damaged light

fibers and may require repair or replacement of the Flexible Inspection Scope™

Troubleshooting and Servicing

Condition

Appearance

Cause

Correction

No Image

Main image Window is

black

The Inspection Scope

was not connected to

computer when the

software was opened

Unplug USB

Connection on Camera

Cable and plug in again

No Image

Main image Window is

black

1.USB Video Device

not selected, or

without the scope

connected

2.Check HDMI

Monitor “Input”

Selection

If no image, to the

"Settings" Tab and

select USB Video

Device

No light

No light when scope

pointed at surface

No power to light

source or power

connections are not

secure.

1.Check the Camera

Cable connections

and make sure the

computer is powered

on

2.HMDI is “ON”

Low Light

•No image or very

dark image.

•Weak light pattern

when scope pointed

at surface

Light setting too low

Cycle through light

intensity levels/settings

until a clear image is

obtained

Low light

•No image or very

dark image.

•Weak or light

pattern when scope

pointed at surface

Broken light fibers in

scope

Replace Flexible

Inspection Scope™

•Decide if the scope

is no longer

adequate for use

•Recommendation is

when 10% of the

image or

illumination has

been degraded/lost

to replace the scope

No image or distorted

image

No image or heavily

distorted, cracked

appearance

Broken image sensor

and/or internal cables

1.Press Power Cycle

button

2.Replace Flexible

Inspection Scope™

Overly bright image

White-out type

reflection

Light intensity is too

bright

Cycle through light

intensity levels/settings

until a clear image is

obtained

Blurry image or overly

bright image

Distorted image. Light

often reflective and

image appears brightly

colored

Debris or film on lens.

Wipe off end of

Flexible Inspection

Scope™with non-

Linting wipe

Image does not capture

When you click the

Capture Button, the

still image or video is

not captured

The File Location path

may have changed, or

the folder names does

not exist.

Set up a new Windows

File Loc folder

Rapidly takes pictures

automatically

“Pictured Captured”

keeps flashing and

Image files are created

rapidly

PC’s internal camera is

selected as the video

device is Settings

Disable the PC’s

internal camera

Reassembly

Instructions

N/A

Packaging

N/A

Sterilization

Do Not autoclave the Flexible Inspection Scope™.

See the Chemical Compatibility Chart click here:

Low Temperature Sterilization Systems (Flexible Inspection Scope Only)

Ethylene Oxide (EtO)

STERRAD®100S System (Standard)

STERRAD® NX System (Standard, Advanced)

STERRAD®100NX System (Standard)

STERIS®Liquid Chemical Sterilization Systems

STERIS V-PRO®Low Temperature Sterilization

Systems (Non-Lumen Cycle)

Storage

Storage and transport

Humidity: 10 to 100 %rh (condensing)

Temperature: -20 to 60 °C

Pressure: 600 to 900 hPA

Normal Operation

Humidity: 0 to 100 %rh (condensing)

Temperature: 5 to 40 °C

Additional

Information

N/A

Related

Healthmark

Products

N/A

Other Product

Support

Documents

ProSys™ Brochure, ProSys™ Price List

Reference

Documents

N/A

Customer Service

Contact

Healthmark Industries Company, Inc.

18600 Malyn Blvd.

Fraser, MI 48026

1-586-774-7600

healthmark@hmark.com

hmark.com

2021-07-29 Suzanne Latta

This manual suits for next models

5

Table of contents

Other Healthmark Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual