BES MDU12i Installation and operation manual

Instruction Manual

For

MDU12i

12 port Intelligent Mains Distribution Unit

DOC32 Page 2 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 3 of 41 Issue 2 30 NOV 17

Contents

1.0 Description

2.0 Installation

3.0 Operation

4.0 Connections

5.0 Indication

6.0 Characteristics

Appendix A Web server HTML page description

Appendix B SNMP trap setup and register description

Appendix C Telnet command line interface description

DOC32 Page 4 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 5 of 41 Issue 2 30 NOV 17

1.0 Description

The DEM Intelligent Mains Distribution Unit [iMDU] is a meter grade 12 outlet power

distribution product housed within a 1U 19” sub-rack.

The main function of the product is to distribute a single phase mains power supply to 12

socket outlets while monitoring voltage, current, power and energy usage to a

meter grade accuracy of ± 1%. Additionally the product can monitor external environmental

conditions, temperature or humidity, contact inputs, 0-5VDC analogue inputs and control

voltage free contact outputs. The product is controlled remotely over an Ethernet network

using the integrated web server, SNMP registers or Telnet command interface. The product

provides the following features:

Single phase 16A capable ± 1% accuracy metering.

Monitoring of VRMS, IRMS, kW, kWh, Power factor, kVA, kgCO2, BTU/h, kJ/h and

frequency measurements.

Ethernet port [IEEE 802.3 with full 10/100Base-T network compatibility].

High-speed MODBUS RS485 port for local daisy-chaining of up to 31 iMDU slaves.

Temperature sensor bus [8x chained] + Humidity/Temperature sensor port.

External GPIO contact monitoring inputs x8.

External GPIO 0-5VDC analogue inputs x2.

External GPIO voltage free N.O. 1A @ 48VAC/DC relay output x2.

12 socket outlets with 16A N.O. switching and fuse blown monitoring.

USB Type ‘A’ port with 1A @ 5VDC power output.

Remote monitoring and configuration [HTML webserver, SNMP registers and Telnet

command interface].

Physical layout

The product is enclosed within a 1U 19” sub-rack with a mains inlet/outlet, illuminated front

panel mounted isolator switch, 12x IEC outlets and main interface connectors on the rear

panel and USB port, 12x fuses and power/fuse blown LED indication on the front panel.

The product is made up of a ‘Control’ PCB assembly which consists of a front panel

removable processor and mains power supply PCB that plugs into (hot swappable) a fixed

rear mounted meter and interface PCB.

DOC32 Page 6 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 7 of 41 Issue 2 30 NOV 17

2.0 Installation

Installation should be performed by a suitably competent person.

The MDU12i (iMDU) is designed to be mounted in a 19” rack. The rear of the unit must be

supported within the rack. The unit is supplied with an inlet connector for the user and wiring

instructions. The unit has an earth stud at the rear of the unit and must be connected to

earth.

The unit ratings are shown at the rear of the unit. The unit must be protected by a suitably

rated 16A MCB or fuse.

The unit is supplied with 5 amp HRC fuses in each outlet fuse holder. The maximum rating

for each outlet is 10 amps provided a suitably rated HRC fuse is fitted in the front panel

mounted fuse holder.

Make all connections before applying power to the unit and switching on.

To ensure isolation, the illuminated front panel switch must be in the off position with the

green light extinguished. Disconnect from the supply before making or changing connections

to the IEC outlets or connected equipment.

Control card

The control card is designed to be hot swappable from the front panel as a security against

system failure or future upgrade. The main parts of the system are located on this card eg.

CPU, SMPS.

Control card change

Ensure the new card has the ‘keep outlet status enabled’ option set (enquire with the factory

if confirmation is required )

Undo the two hex head screws securing the card to the front panel and gently withdraw the

card.

Warning, at this point the outlets will remain live but the outlet status indication will

be lost! The front panel mounted illuminated switch will remain lit at all times power is

supplied to the unit. Do not leave the unit with the card removed and do not insert anything

other than a control card into the aperture.

Insert the new card into the aperture and card guides. Push home until the front plate is

against the front panel. Fuse indication and all functions should reappear at this point.

Replace the hex head screws and tighten.

DOC32 Page 8 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 9 of 41 Issue 2 30 NOV 17

3.0 Operation

The iMDU product is energised when supplied with AC power. On power application, and if

configured to do so, the system will sequentially switch each socket outlet ON starting at

socket 1 and ending at socket 12 at a pre-defined sequence period (default 0.5 seconds)

illuminating the optical power indicator associated with each socket. Should a fuse be

ruptured (blown) on any outlet the corresponding optical fuse blown indicator shall also

illuminate.

The system will continually collect data from the meter and store this for access via the Web

server, SNMP registers, Telnet command interface or Modbus requests.

MODBUS connection.

The iMDU product may be configured as a ‘Master’ and connected to up to thirty-one other

iMDU’s, via a 2 wire RS485 interface, that are configured as ‘Slaves’ to allow the master

iMDU to collect measurements from the slaves.

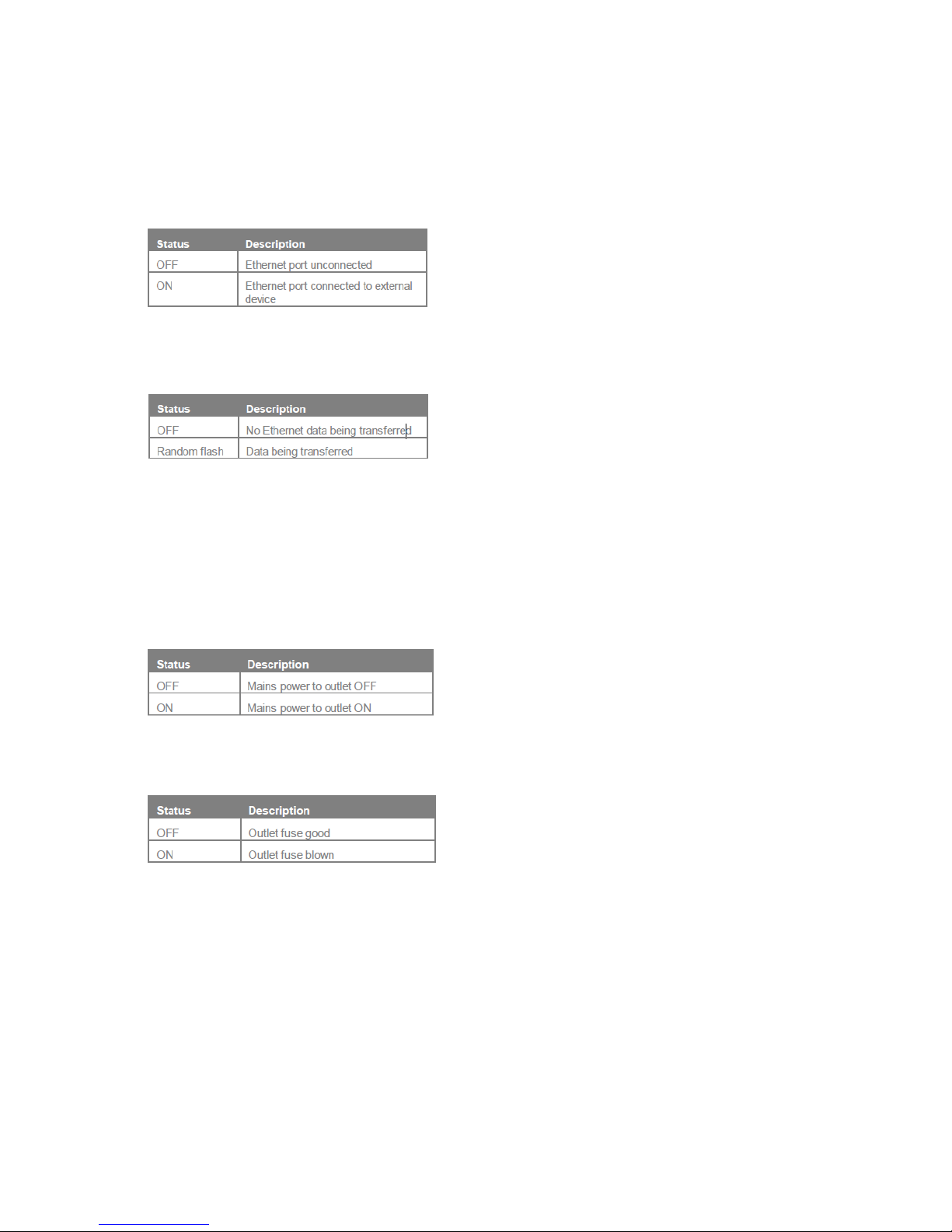

Ethernet connection

The iMDU product may be connected to a PC or laptop using a cross-over CAT5 Ethernet

cable or to a router using a straight through CAT5 Ethernet cable. The GREEN LED on the

Ethernet connection port indicates that the product is connected to a valid device, the

YELLOW LED indicates data traffic to/from the unit.The product, as default, is configured for

DHCP [Dynamic Host Configuration Protocol] which allows a connected Ethernet router to

assign an IP address to the product for Ethernet communication. DHCP may be configured

using the ‘Network Configuration’ button within the Web server, see Appendix A ‘Web server

HTML page description’ for more information.

Web server access

The iMDU product supports full HTTP access of the internal HTML web pages using any

standard internet browser ie. Internet Explorer, Firefox, Google Chrome etc. Please see

Appendix A ‘Web server HTML page description’ for more information on

accessing this service.

SNMP register access

The iMDU product can be provided with a MIB [Management Information Base] for use with

any SNMP manager. This MIB outlines all the accessible registers, there type and

description. The file is called ‘iMDU_Vxxx.mib’. For more information please look at the MIB

file. Please see Appendix B ‘SNMP trap setup and register description’ for more information.

Telnet command line access

The iMDU product supports a selectable Telnet command line interface that allows

anexternal user to access system information and control socket status. See Appendix C

‘Telnet command line interface description’ for more information.

DOC32 Page 10 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 11 of 41 Issue 2 30 NOV 17

Connections

External connections (Rear panel)

Ethernet Port - 8way RJ45 right-angle socket.

GPIO port - 15way ‘D’ type right-angle socket.

MODBUS port - 2x 4way RJ11 right-angle socket.

DOC32 Page 12 of 41 Issue 2 30 NOV 17

Temperature sensor and humidity sensor port - 4way RJ11 right-angle socket.

Mains outlets - 12x C14 IEC outlets.

External connections (Front panel)

USB port - 1x USB type ‘A’ socket.

DOC32 Page 13 of 41 Issue 2 30 NOV 17

5.0 Indication

External optical indication (rear panel)

Ethernet connection indicator - GREEN L.E.D indicator, mounted on Ethernet port.

Ethernet data indicator - YELLOW L.E.D indicator, mounted on Ethernet port.

External optical indication (front panel)

Front panel mounted switch with integral indicator. Green light is lit when switch is on and

mains applied.

Outlet power indicator - 12x GREEN 3mmD L.E.D indicator, located next to fuse.

Fuse blown indicator - 12x RED 3mmD L.E.D indicator, located next to fuse.

DOC32 Page 14 of 41 Issue 2 30 NOV 17

This page is intentionally blank

DOC32 Page 15 of 41 Issue 2 30 NOV 17

6.0 Characteristics

AC Characteristics

Mains input 115/230VAC 50-60Hz

Mains input protection Transient suppression (LIVE - NEUTRAL)

Mains power consumption 15W

Maximum load 16A

DC Characteristics

USB Supply output 5VDC @ 1A max.

USB Supply protection 1A Current limit

Ethernet port

Compatibility IEEE 802.3 10/100/1000Base-T (Auto-negotiated to

10 or 100Mb)

Protocols TCP/IP, HTTP, SNMP, XML, DHCP, SMTP, Telnet

MODBUS port

Compatibility RS485 115.2kbps, 8 data bits, no parity, 1 stop bit

Protocol MODBUS RTU

Digital temperature sensor [x8]

Temperature range 0 to +125 °C

Accuracy (Temperature Error) 0°C to +85°C = ±0.5 °C nominal

85°C to +125°C = ±1.0 °C nominal

Resolution +0.0625 °C

Sensor supply voltage 3.3VDC

Sensor interface I2C 3.3V [TTL/CMOS] logic

Humidity sensor [x1]

Humidity range 0-100% Relative humidity

Response Time 8 Seconds in slow moving air @ 25ºC

Stability < 0.5% RH per year

Accuracy ± 2.0% RH, 0-100% RH non-condensing @ 25ºC

Non-linearity < 1% RH Typical

Repeatability ± 0.1% RH

Resolution 0.04 %RH

Temperature range 0 to +125ºC (32 to +254.9°F)

Response Time 5 to 30 seconds

Accuracy ±0.4 °C nominal

Repeatability ± 0.1 °C

Resolution 0.01 °C

Sensor supply voltage 3.3VDC

Sensor interface I2C 3.3V [TTL/CMOS] logic

DOC32 Page 16 of 41 Issue 2 30 NOV 17

GPIO inputs

Contact type Voltage free normally open or closed

Contact resistance 2Kohm max.

Contact de-bounce time 50mS

GPIO analogue inputs

Analogue input voltage 0-5V (6V max.) 1023 bits @ 15.244mV per bit

Analogue measurement period 100mS

GPIO control output 1

Output type Voltage free Solid State Relay (SSR)

Output capability 48VDC @ 1000mA max.

GPIO control output 2

Output type Voltage free Mechanical Relay (SPDT)

Output capability 48VDC @ 1000mA max.

General timings

Temperature & humidity measurement rate 1000mS default (software programmable)

General parameters

Login name & password ‘admin’ default (HTML programmable)

DOC32 Page 17 of 41 Issue 2 30 NOV 17

Appendix A. Web server HTML page description

Web server HTML page description

The iMDU HTTP web server service provides a set of HTML pages that can be viewed

within any HTML compatible web browser [ie. Internet Explorer, Firefox, Google Chrome

etc.].

Logging into the web server

The HTTP service provides Domain Name Service [DNS] resolution so that the iMDU IP

address does not need to be known, entering ‘iMDUSNMP’ into the browsers URL bar will

contact the web server and initiate the authentication process to allow entry into the iMDU

system. The following authentication screen will be displayed:

At this point the operator may enter the system as a User, Administrator or Factory operator.

The default User name and Password for the default administrator account is ‘Admin’ and

the default User name and Password for the factory account is ‘factory’, both are case

sensitive. New accounts may be configured under the ‘Configuration’ tab settings, see later

in this appendix.

User account

A User account prevents access to the all configuration options and most other operations

that could compromise iMDU SNMP operation.

Administrator account

An Administrator account allows the operator to re-configure any aspect of the iMDU

configuration. This configuration includes re-naming of the iMDU customer name, location,

outlet equipment names and changes to default parameters. The Administrator also has

access to buttons that allow the iMDU to turn individual outlets ON/OFF and reset currently

stored energy levels etc.

DOC32 Page 18 of 41 Issue 2 30 NOV 17

Factory account

As the Administrator account but allows access to the config.htm page

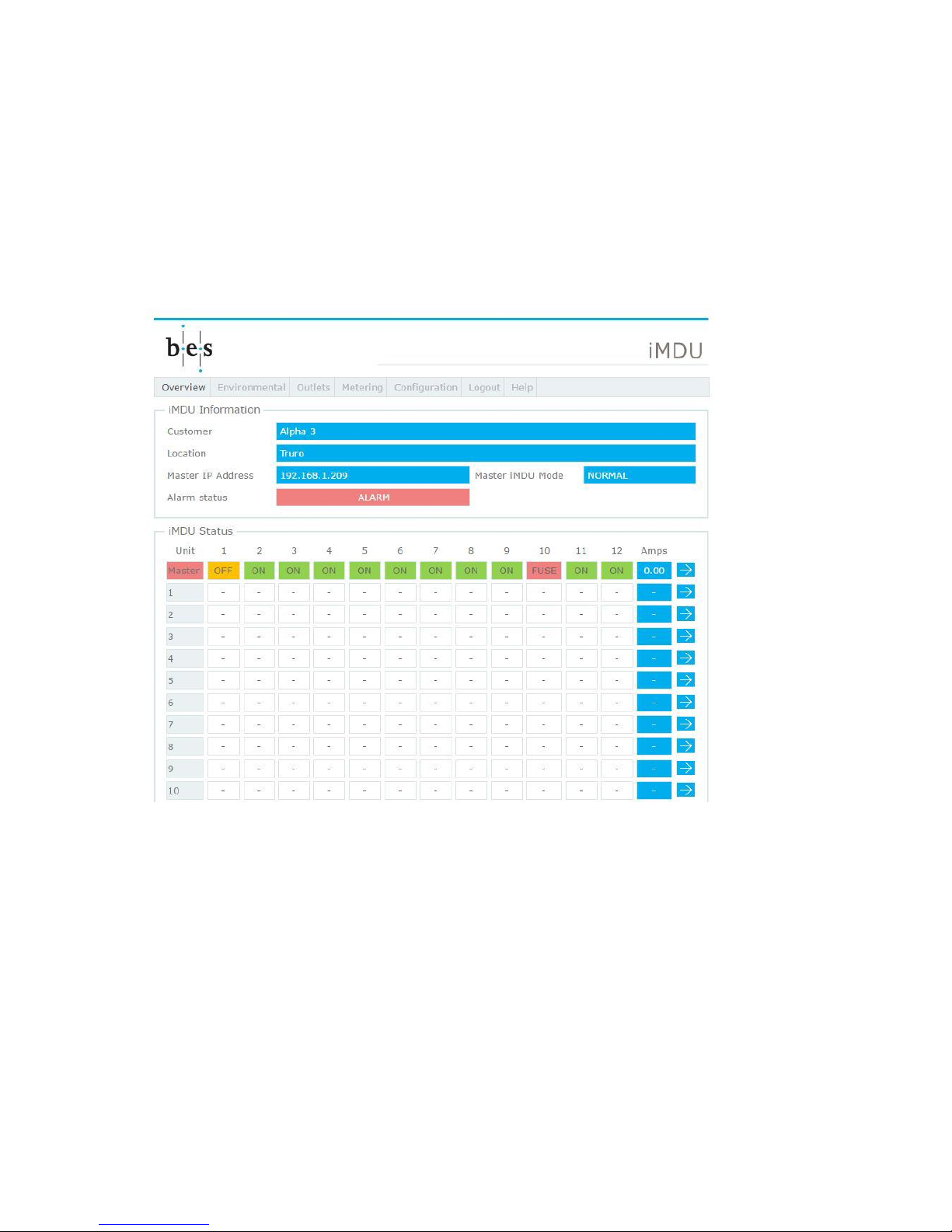

Overview page

After successful authentication the operator is presented with the initial Overview page which

provides an overview of all master and slave iMDU units. The following screen shot shows a

master only unit with an alarm condition:

The iMDU Information provides an overview of the customer and location to which the iMDU

belongs, its IP address, the mode of operation (NORMAL, MASTER or SLAVE) and the

alarm status.

Below this an overview of the master and connected slave units outlet status and meter

current. Clicking on the arrow next to the status line takes the user to the Outlets page for

this particular unit.

DOC32 Page 19 of 41 Issue 2 30 NOV 17

Environmental page

Clicking on the Environmental button the operator is presented with the environmental

status page for the currently selected master or slave which contains details of any humidity

probe or temperature probes connected to the unit, the eight [8] contact inputs, the two [2]

Analogue to Digital Converter (ADC) levels and the two [2] General Purpose Outputs (GPO)

contact outputs.

The following screen shot shows the top of the page with a humidity probe connected and

contacts 1&2 OPEN:

The humidity probe status box provides the temperature and humidity output from any

connected humidity probe along with location name and check boxes and threshold levels to

configure alarms against these parameters. Please see later topic for alarm setup.

The temperature probe status box(s) provide the temperature output from up to eight

temperature probes along with location name and check boxes and threshold levels to

configure alarms against these parameters. Please see later topic for alarm setup.

The contact status boxes provide the status (OPEN or CLOSED) of the contact inputs along

with location name and check boxes to configure alarms. Please see later topic for alarm

setup.

DOC32 Page 20 of 41 Issue 2 30 NOV 17

The following screen shot shows the bottom of the page showing the two ADC channels and

the two GPO outputs:

The ADC Input status boxes show the input voltage measured from the ADC a name and

check boxes and threshold levels to configure alarms against these parameters. Please see

later topic for alarm setup.

The GPO Output status boxes provide the status (OPEN or CLOSED) of the contact outputs

along with name and check boxes to configure alarms. Please see later topic for alarm

setup.

Table of contents

Popular Measuring Instrument manuals by other brands

Compressed Air Alliance

Compressed Air Alliance POM200x00 user manual

Nikon

Nikon ARROW ID 7000 VR instruction manual

TechnipFMC

TechnipFMC Smith Meter JB10 S1 manual

WAGNER

WAGNER Layer Check LC 1000 Translation of the Original Operating and Manual

Hach

Hach HQ1110 Basic user manual

ION

ION TITAN 875 user manual