WAGNER Layer Check LC 1000 User manual

Other WAGNER Measuring Instrument manuals

WAGNER

WAGNER Rapid RH 4.0 EX User manual

WAGNER

WAGNER SprayPackE User manual

WAGNER

WAGNER TITANUS SUPER-SENS User manual

WAGNER

WAGNER L606 User manual

WAGNER

WAGNER L601-3 User manual

WAGNER

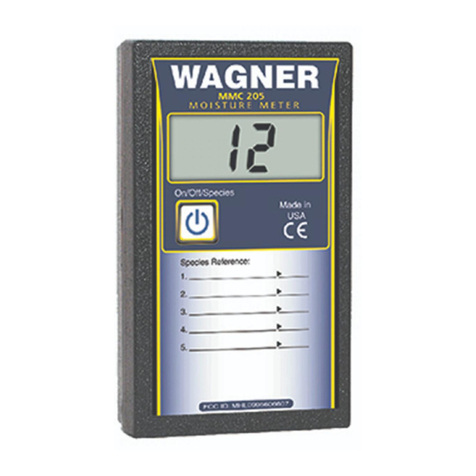

WAGNER MMC 205 User manual

WAGNER

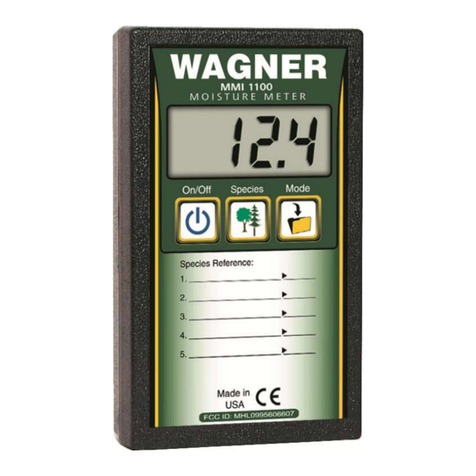

WAGNER MMI 1100 User manual

WAGNER

WAGNER Force Ten FDX User manual

WAGNER

WAGNER FORCE TEN User manual

WAGNER

WAGNER L622 User manual

WAGNER

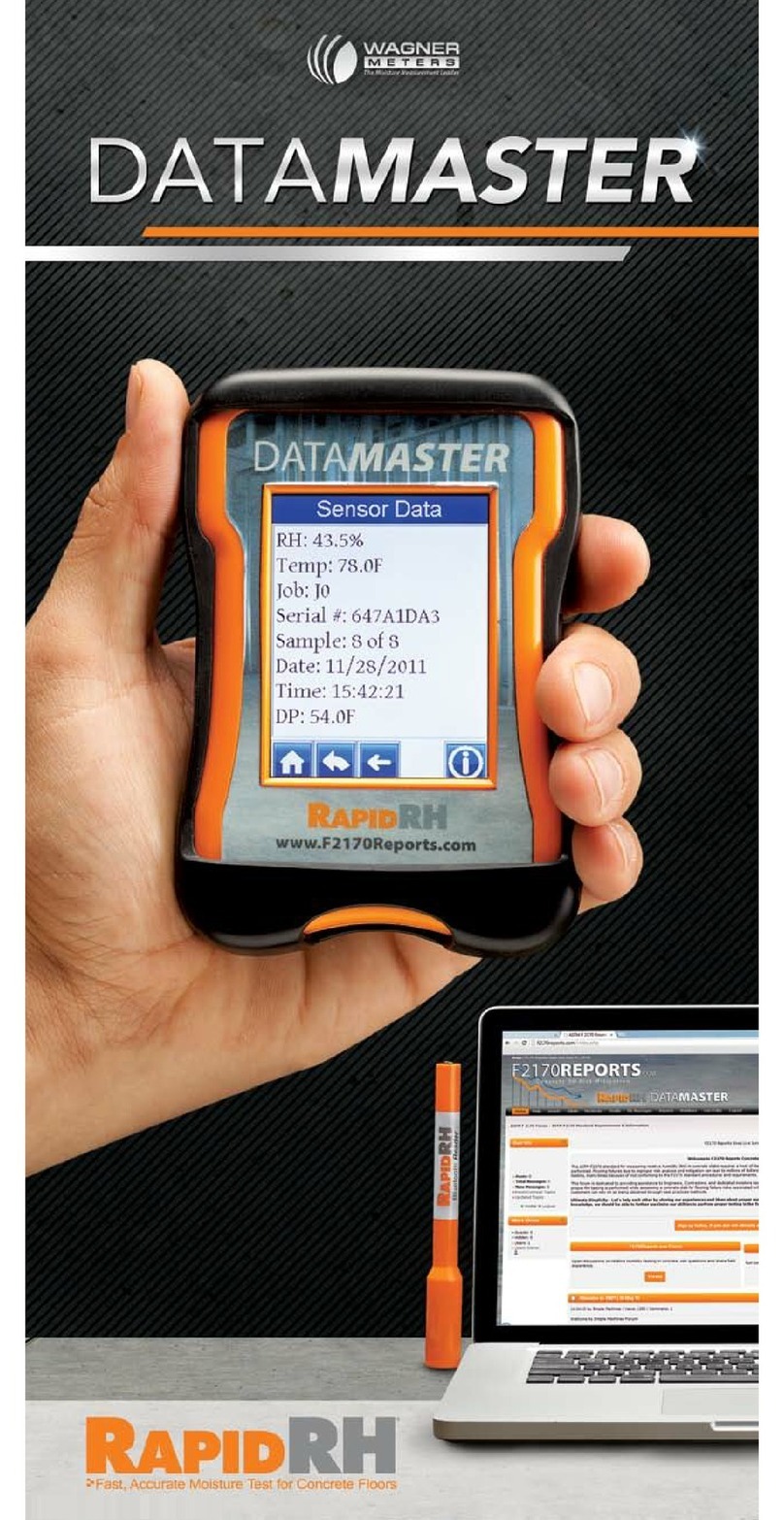

WAGNER Datamaster User manual

WAGNER

WAGNER Datamaster User manual

WAGNER

WAGNER C575 User manual

WAGNER

WAGNER FORCE DIAL FDL Series User manual

WAGNER

WAGNER RS 500 Operational manual

WAGNER

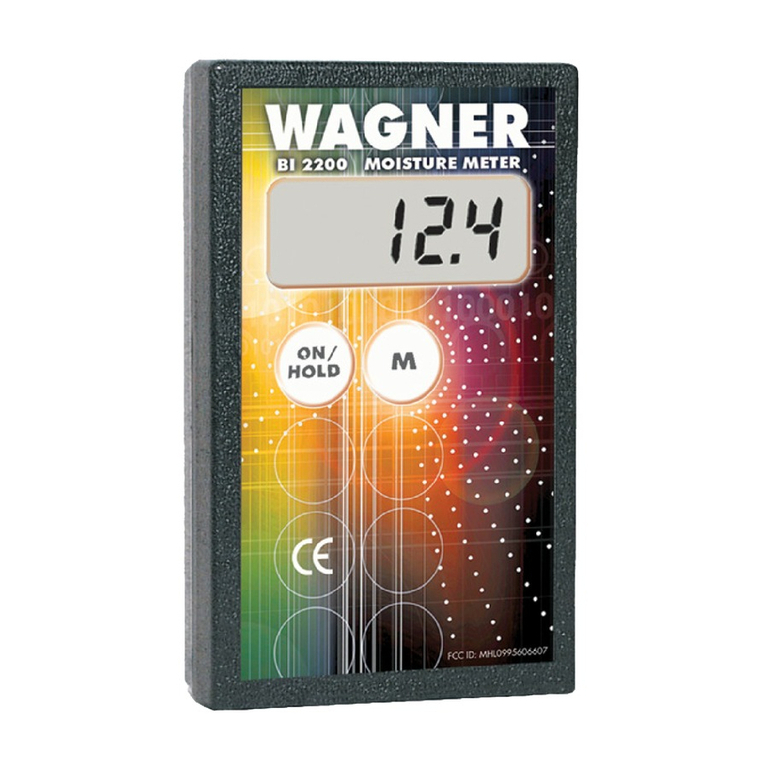

WAGNER BI 2200 User manual

WAGNER

WAGNER C575 User manual

WAGNER

WAGNER RAPID RH User manual

WAGNER

WAGNER FORCE DIAL FDL Series User manual