7

Installation

Unloading Units

1) Upon arrival all conveyors will be secured with wood blocks mounted to the trailer floor.All

wood blocks must be removed prior to moving the conveyors.

2) Warning: Conveyors must not be picked up utilizing forks on the rear of the unit. Failure to

adhere to this warning may cause damage to the main electrical panel on the back of the unit, or

the electrical connections coming into this panel. This damage will not be covered under war-

ranty.

3) To unload, the unit may be either manually pushed from the front of the conveyor, or by utilizing

a lifting strap placed around the rear frame of the conveyor and attached to a forklift. If using

the strap method, make sure that the strap does not come in contact with any electrical wiring

under the conveyor.

4) The steering actuator on the front axle of the conveyor has been disconnected for ease of

movement. When using either unloading method, someone must manually steer the front of the

unit to prevent damage to the front control panel.

Installation

Installation should only be performed by Best Diversified Installers or qualified personnel, and must be

completed in accordance with all applicable codes and regulations.

1) Locate and mark the center of the spur. Chalk a line from the dock leveler back approximately 50

feet. Measure 2 inches off each side of the centerline, this will give you your inside dimension on

track placement location, 5 inches off the center will give you your outside line placement. NOTE:

It might be helpful to cut 2, 4-inch blocks. Center these blocks on your chalk line at the front and

back of each piece of track, so that you have 2 inches on either side of the line. Then assemble the

track as instructed below.

2) Mark location for the front of floor track as shown on supplied application specific drawing (if you

do not have this drawing contact factory.)

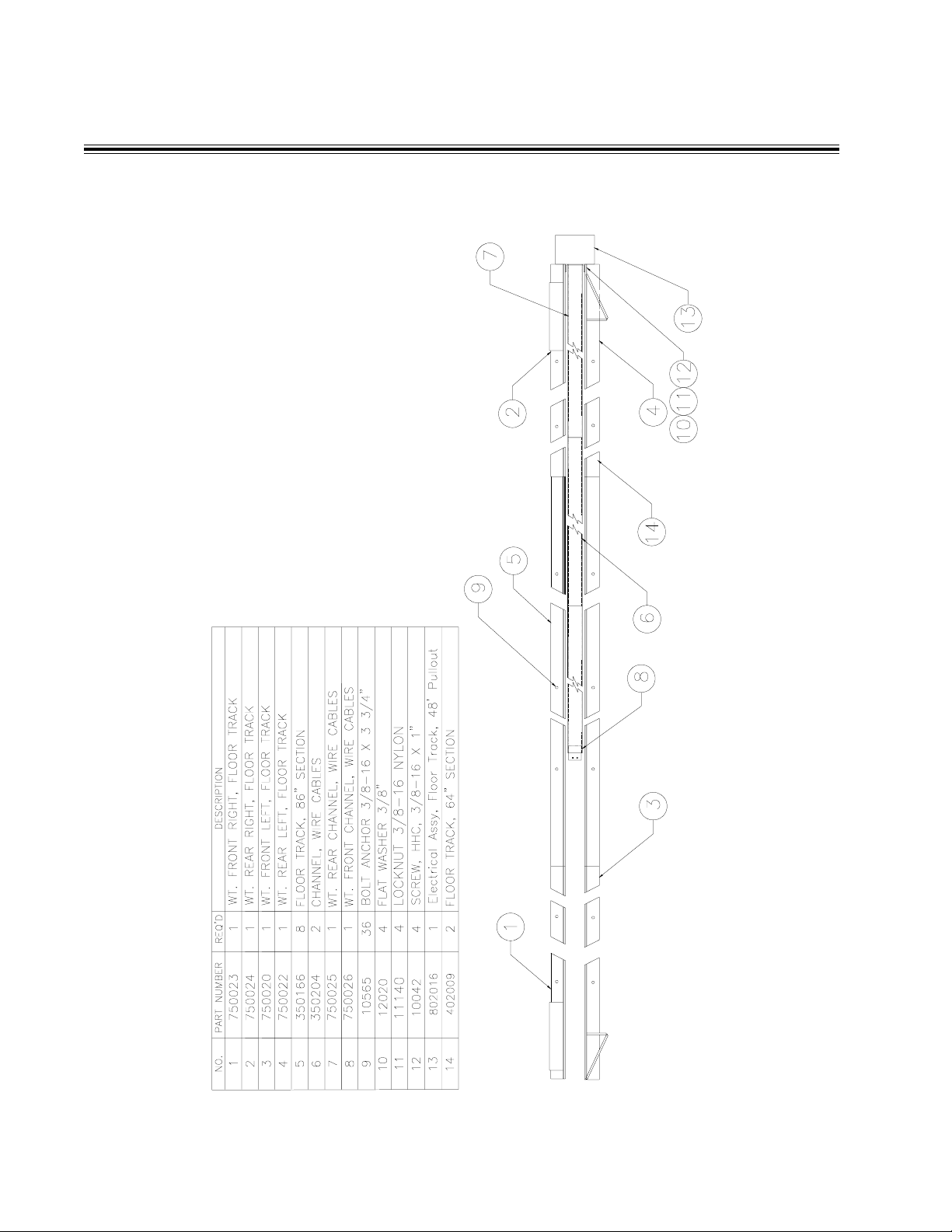

3) Locate and position the individual pieces of floor track as shown on drawingA.

4) Assemble the rear sections of floor track as shown in drawing B.

5) Position and anchor floor track starting with the front and aligning the inside edge with your 2-inch

measure out or utilize your cut blocks for this placement.

6) Pull 2 lengths of SO cable provided (16/8 and 14/4) thru flexible wire carrier.

7) Attach the included connection brackets to each end of the flexible wire carrier. These parts and

hardware are shown in Drawing C on page 13.

8) Feed both lengths of SO cable under rear wire cover (C channel illustrated in Drawing B, #7)

exposing approximately 10” at the rear of the floor track. Attach the flexible carrier to the wire

cover (C channel).

9) Install 2 cord grips (not included) in 7/8 holes of 8x6x5 junction box that is provided.

10) FeedApproximately 10” of the SO cables thru the cord grips and install junction box on floor

toward the rear of the floor track. Box should be held off the ground utilizing Uni-strut or some

other suitable material. This material is not included and will need to be provided by the installer.

11) Pull slack cable thru the opposite end of the flexible wire carrier.

12) Lay flexible wire carrier flat in the floor track.