ENGLISH

INDEX

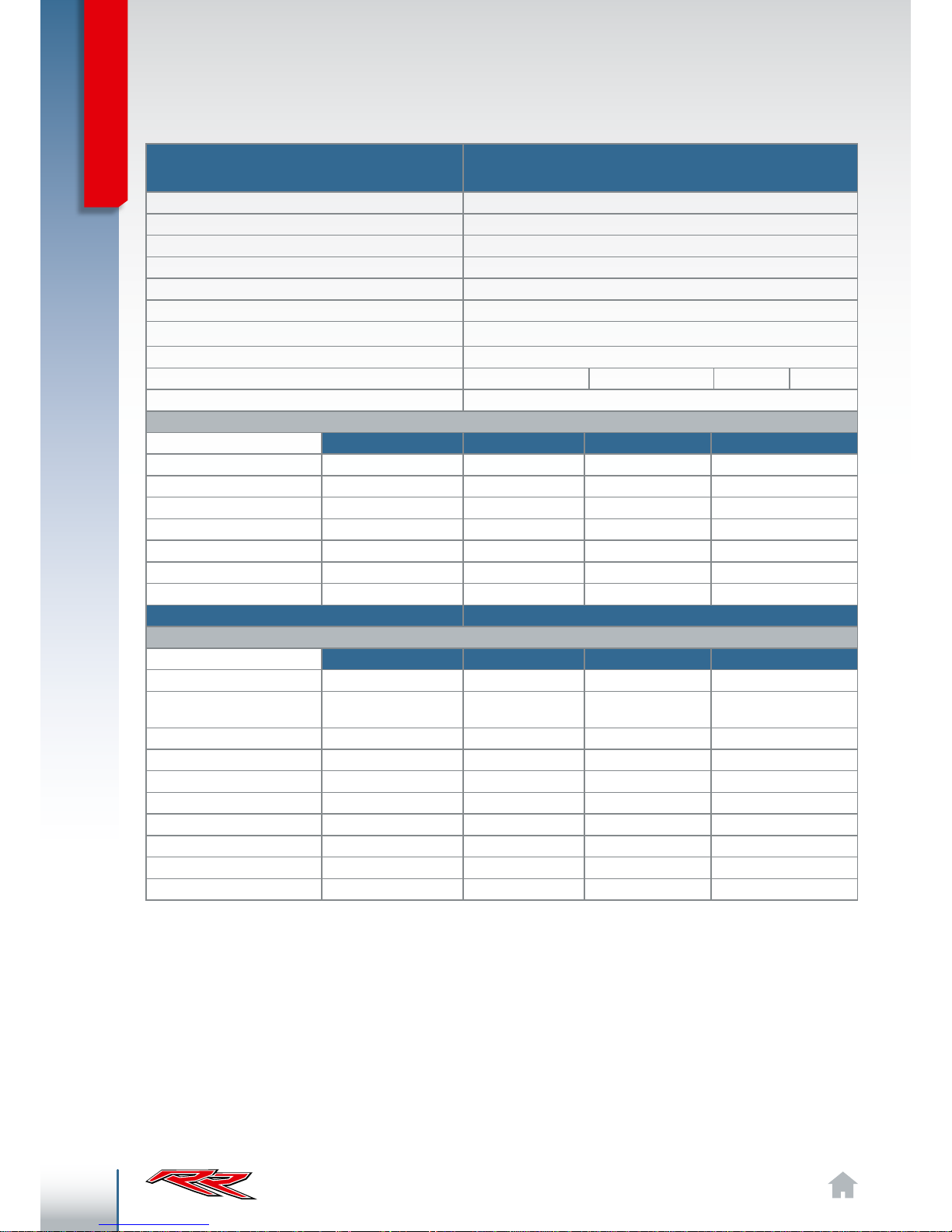

Table of tightening torques of engine components 127

Engine/frame table of tightening torques 129

Recommended engine maintenance 130

Recommended lubricants and liquids 130

2.5 ASSEMBLY OF INTERNAL GEARBOX AND GEARSHIFT 59

2.6 CLOSING ENGINE BLOCK 62

2.7

BLOCKING THE CRANKSHAFT AT THE TOP DEAD

CENTRE AND TIGHTENING THE NUT ON THE LEFT

SIDE OF THE CRANKSHAFT

63

2.8 EXTERNAL GEARSHIFT 64

2.8.1 Checking the complete drive shaft 64

2.8.2 Assembly of external gearshift 66

2.9 KICK STARTER 66

2.9.1 Checking kickstarter shaft unit and assembly 66

2.9.2 Assembly of kickstart device 68

2.10 ELECTRICAL STARTER UNIT AND MAIN GEAR 69

2.10.1 Checking electrical starter device elements 69

2.10. 2 Coupling ignition and primary gears to the motor 70

2.11 OIL PUMPS: CONTROL AND REASSEMBLY 72

2.11.1 Assembly of low pressure pump 74

2.11.2 Assembly of high-pressure pump and control gear 75

2.11.3 Checking and assembly of pressure control valve 75

2.11.4 Checking and assembly of oil pumps control gears 76

2.11.5 Paper oil filter insertion 77

2.11.6 Checking and coupling countershaft 78

2.12 CLUTCH UNIT 80

2.12.1 Checking clutch basket, roller bearing and

internal centre bearing 80

2.12. 2 Checking clutch discs 81

2.12. 3 Checking springs 82

2.12. 4 Checking inner hub 82

2.12. 5 Checking thrust bearing device 83

2.12. 6 Assembly of clutch unit 83

2.13 COOLANT PUMP 86

2.13.1 Checking pump unit and disassembly 86

2.13. 2 Assembly of pump unit 87

2.14 ASSEMBLY OF COMPLETE CLUTCH COVER 88

2.15 CHECKING AND COUPLING OF TIMING CHAIN,

FIXED AND MOBILE GUIDES 90

2.16 IGNITION SYSTEM 90

2.16.1 Checking ignition system 91

2.16. 2 Coupling ignition system to crankcase 91

2.17 THERMAL UNIT 94

2.17.1 Checking piston, pin bolt, and piston rings 94

2.17. 2 Checking the cylinder 96

2.17. 2.1 Assembly clearance 96

2.17. 3

Cylinder head: disassembly and checking auxiliary

devices

97

2.17. 3.1

Lubrication jets and centring pins 97

2.17.3.2

Finger follower/shafts unit 98

2.17.3.3

Shims (calibrated discs) for valve play adjustment 99

2.17. 4 Cylinder head: disassembling and

checking valve units 100

2.17. 4.1 Springs 101

2.17.4.2 Valve guides, valves and seats 101

2.17.4.3 Valve stem seal and lower stop washer 103

2.17. 5 Cylinder head: checking cylinder head body 103

2.17. 6 Checking camshafts 104

2.17. 7 Checking camshafts support 105

2.17. 8 Cylinder head: insertion of inner cup and

valve stem seals 106

2.17. 9 Cylinder head: assembly of valve unit 107

2.17.10

Cylinder head: repositioning calibrated discs,

assembly of finger follower shafts and finger

followers and coupling the spark plug

108

2.17.11 Cylinder head: Insertion of oil jets, centring pins and

spark plug O-ring 109

2.17.12 Piston: application of compression and

oil-scraper rings 110

2.17.13 Application of piston to cylinder 111

2.17.14 Application of piston-cylinder coupling to crankcase 113

2.17.15 Coupling head to cylinder 115

2.17.16 Coupling camshafts to cylinder head and phasing 116

2.17.17 Valve play 119

2.17.18

Checking and coupling of hydraulic tensioner to engine

121

2.17.19 Coupling cylinder head cover gaskets and

cylinder head cover 123

2.18 COUPLING PINION AND BREATHER NOZZLE 124

2.19 RELEASING CRANKSHAFT 124

2.20 COUPLING OIL CAPS 125

2.21 COUPLING GEARSHIFT LEVER 126