Betamotor EVO 4t Instruction manual

WORKSHOP MANUAL

WORKSHOP MANUAL 2009

V

betamotor.com

INDEX

INTRODUCTION ...................................................................................................... 1

CHAPTER 1

LUBRICATION CIRCUIT

1 LUBRICATION CIRCUIT .......................................................................... 8

1.1 ENGINE OIL ..................................................................................................... 8

1.2 CHECKING THE ENGINE OIL LEVEL ............................... 9

1.3 CHANGING THE ENGINE OIL .................................................. 9

CHAPTER 2

ENGINE REMOVAL AND REFITTING

2 ENGINE REMOVAL AND REFITTING ................................. 12

2.1 ENGINE REMOVAL .............................................................................. 12

2.2 REFITTING THE ENGINE .............................................................. 19

CHAPTER 3

DISMANTLING

3 DISMANTLING ............................................................................................... 20

3.1 DRAINING THE OIL ........................................................................... 20

3.2 IGNITION ......................................................................................................... 21

3.3 CYLINDER HEAD ................................................................................... 21

3.4 CYLINDER ....................................................................................................... 24

3.5 FLYWHEEL ...................................................................................................... 24

3.6 OIL PUMP (LEFT-HAND CRANKCASE) ................... 25

3.7 CLUTCH ............................................................................................................. 26

3.8 PRIMARY TRANSMISSION ....................................................... 28

3.9 KICKSTART ..................................................................................................... 29

3.10 SHIFTING MECHANISM ........................................................... 29

3.11 OIL PUMP (RIGHT-HAND CRANKCASE) ......... 30

3.12 TIMING SPROCKET ........................................................................ 31

3.13 SPLITTING THE CRANKCASE ........................................... 31

3.14 GEARBOX AND SHIFTING MECHANISM .......... 32

3.15 CRANKSHAFT ........................................................................................ 33

CHAPTER 4

ASSEMBLY

4.1 RIGHT-HAND CRANKCASE ..................................................... 34

4.2 LEFT-HAND CRANKCASE .......................................................... 36

4.3 CLUTCH CASING ................................................................................... 37

4.4 GEARBOX AND SHIFTING MECHANISM ............. 39

4.4.1 Mainshaft ........................................................................................... 39

4.4.2 Layshaft ................................................................................................ 40

4.5 CRANK ASSEMBLY ............................................................................. 42

4.6 CLOSING THE CRANKCASE ................................................... 43

4.7 SHIFTING MECHANISM .............................................................. 44

4.8 TIMING SPROCKET ............................................................................ 46

4.9 OIL PUMPS ................................................................................................... 47

4.10 KICKSTART .................................................................................................. 50

4.10.1 Preassembly of kickstart shaft .......................... 50

4.10.2 Assembling the kickstart ........................................... 51

4.11 PRIMARY TRANSMISSION GEAR ................................ 51

4.12 CLUTCH .......................................................................................................... 52

4.13 FLYWHEEL .................................................................................................. 55

4.14 PISTON AND CYLINDER ......................................................... 56

4.14.1 Measurements and checks ................................... 56

4.14.1.1 Cylinder ....................................................................................... 56

4.14.1.2 Piston .............................................................................................. 56

4.14.2 Fitting ................................................................................................... 58

4.14.2.1 Studs ............................................................................................... 58

4.14.2.2 Piston .............................................................................................. 58

4.14.2.3 Cylinder ....................................................................................... 59

4.15 CYLINDER HEAD COVER ....................................................... 60

4.16 CYLINDER HEAD ................................................................................ 61

4.16.1 Checks ................................................................................................. 61

4.16.2 Fitting ................................................................................................... 62

4.17 VALVEGEAR ............................................................................................... 64

4.17.1 Pre-assembly of camshaft ....................................... 64

4.17.2 Fitting the valvegear ....................................................... 65

4.18 CLUTCH CASING ............................................................................... 68

4.19 IGNITION ...................................................................................................... 70

4.20 FINAL DETAILS ...................................................................................... 71

1

INTRODUCTION

betamotor.com

FOREWORD

This publication is addressed to the user of the motorcycle and to technical assistance staff. It

has been written with the objective of making known, and comprehensible, the operations

involved in the inspection, maintenance and repair of the motorcycle it deals with.

N.B. Read this manual carefully and from start to finish before carrying out any work on the engi-

ne. A good knowledge of all the components that make up the engine, and of all the procedures

to be followed during the various inspection and maintenance jobs, will help to prolong the life

of the engine.

The manual has been made as comprehensive as possible through the addition of diagramma-

tic illustrations that help clarify the subject at hand.

Note for information

Betamotor S.p.A. is committed to a policy of continuous improvement of its products. For

this reason it is possible that you will encounter slight differences between what is stated

in this manual and the vehicle on which you are about to carry out repair and/or mainte-

nance. Betamotor models are exported to numerous countries, where different rules apply

with respect to highway law and homologation procedures. Trusting that you will under-

stand, Betamotor S.p.A. therefore believes that it must reserve the right to make alterations

to its products and technical documentation at any time and without prior notice.

We respect and defend the environment.

Everything we do has repercussions for the the entire planet and its resources. In the in-

terests of the community, Betamotor wants its customers and technical assistance staff to

be aware of the need to adopt procedures for the use of the vehicle and for disposal of its

parts which fully comply with the applicable regulations in terms of environmental pollu-

tion and the disposal and recycling of waste.

SAFETY

Carbon monoxide

• Exhaust gases contain carbon monoxide (CO), which is a poisonous gas. Carbon monoxi-

de can cause loss of consciousness and lead to death.

• If the engine has to be started, make sure that the area is well ventilated. Never start the

engine in an enclosed space.

• Starting the engine in an enclosed space is permissible only if appropriate devices are

used for extracting the exhaust gases.

2

INTRODUCTION

betamotor.com

Petrol

• Petrol is highly flammable and in certain conditions can cause explosions.

• Keep heat sources, sparks and flames well away from the work area.

• Always work in a well-ventilated area.

• Never use petrol as a cleaning solvent. In general, avoid handling it if not strictly neces-

sary.

• Do not use petrol for cleaning components by means of compressed air.

• Keep it well out of the reach of children.

Engine oil

• Engine oil can cause skin diseases if it repeatedly comes into contact with the skin for

prolonged periods.

• If you come into contact with engine oil, wash the affected parts as soon as possible with

soap and water.

• If it comes into contact with the eyes, rinse with plenty of water and consult a doctor.

• If ingested, do not provoke vomiting, in order to avoid inhalation of the product. Consult

a doctor immediately. If it is thought that inhalation of the product has taken place, take

the person concerned urgently to hospital.

• Waste oil contains dangerous substances which are harmful to the environment. When

changing the oil, it is necessary to be equipped for disposing of the waste oil in accordan-

ce with the relevant law.

• Do not dispose of waste oil into the environment.

• Keep it well out of the reach of children.

Coolant

• In certain circumstances the ethylene glycol in coolant is flammable, and its flame is invisi-

ble. If ethylene glycol catches fire, the flame, although invisible, can cause serious burns.

• Avoid bringing coolant into contact with hot components. Such components could be

sufficiently hot to cause it to ignite.

• Coolant (ethylene glycol) can cause skin irritation and is poisonous if ingested.

• If coolant comes into contact with the skin, remove any contaminated clothing or foo-

twear immediately and wash promptly with soap and water. If it comes into contact with

the eyes, rinse with plenty of clean water and consult a doctor immediately. If ingested,

do not provoke vomiting, in order to avoid inhalation of the product. Give the affected

person clean water to drink, take them to hospital urgently and show the product to the

medical staff.

• In case of exposure to high concentrations of fumes, take the affected person into an

unpolluted environment and if necessary call a doctor.

3

INTRODUCTION

betamotor.com

• Do not remove the radiator filler cap when the engine is still hot. The coolant, being under

pressure, can spurt out violently and cause burns.

• Coolant contains dangerous substances which are harmful to the environment. When

changing the coolant, it is necessary to be equipped for disposing of waste oil/coolant in

accordance with the applicable law.

• Do not dispose of coolant into the environment.

• Keep it well out of the reach of children.

Hot parts

• The engine and exhaust system become very hot and retain heat for a considerable time,

even after the engine has been switched off. Wait for them to cool down before handling

these parts or working in areas adjacent to them. In addition, use insulating gloves.

WARNINGS

The information in this paragraph is important in order for the operations carried out on the

motorcycle to be performed without damaging the motorcycle itself.

• Before dismantling, clean the vehicle thoroughly.

• During dismantling, clean all parts and put them away in containers, following exactly the

order of dismantling.

• Always use special tools where necessary and whenever their use is specified.

• Always use adhesives, sealants and lubricants where specified. Follow the recommenda-

tions regarding their technical characteristics.

• Always replace parts such as gaskets, O-rings and safety washers with brand new parts.

• When loosening or tightening nuts or bolts, always start with the largest or from the cen-

tre. Always follow the recommended torque settings.

• Use only original Betamotor spare parts.

4

INTRODUCTION

betamotor.com

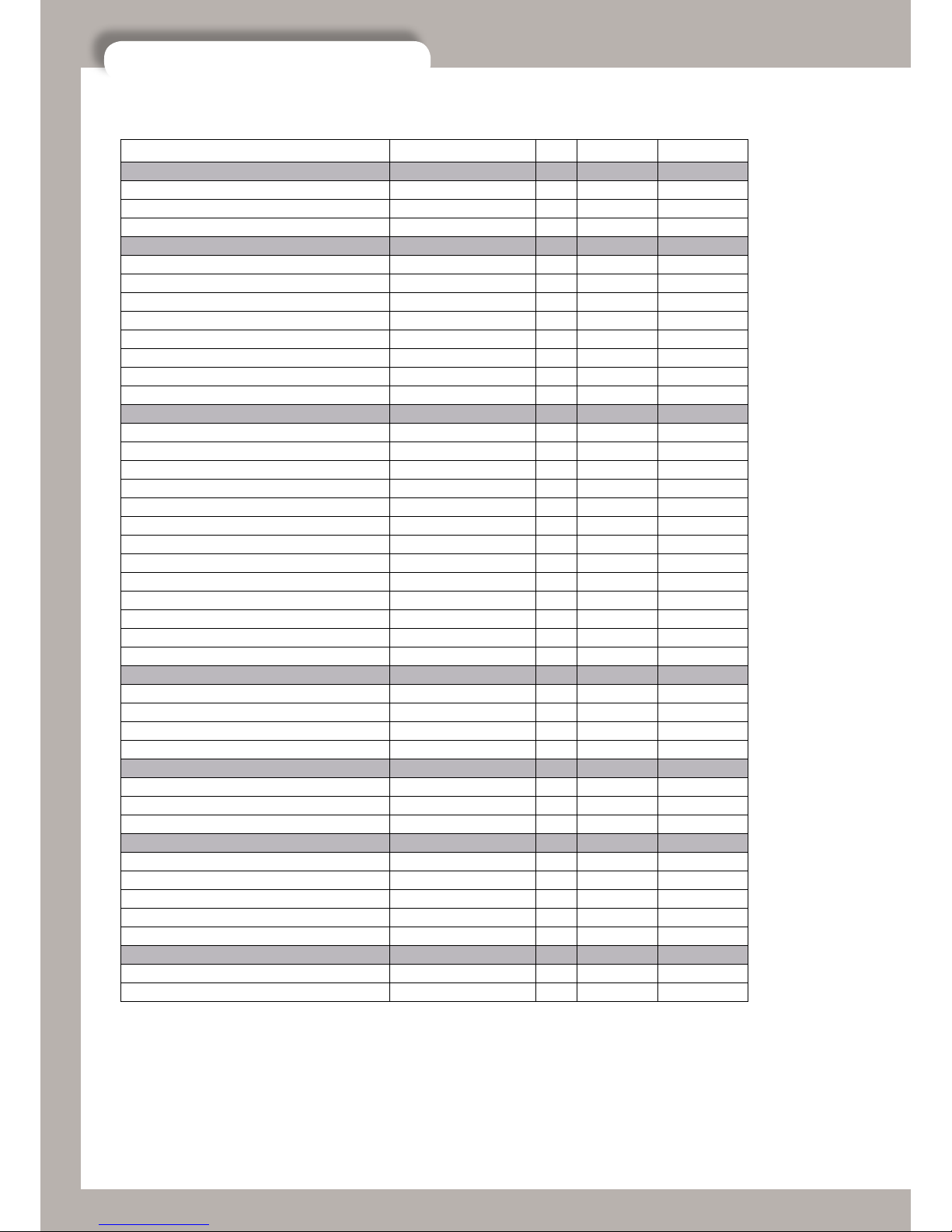

FIXING PART PCS THREAD LOCK TORQUE [NM]

ENGINE FIXING

Engine front fixing 10x1,5L127 [5.8] 1 25

Engine back fixing 10x1.25L100 [5.8] 1 30

Cylinder head fixing 8x1.25L55 [8.8] 1 30

FRAME PARTS

Engine arms to frame 8x1.25L16 [8.8] 4 25

Engine bumper (front fixing) 8x1.25L16 [8.8] 2 20

Engine bumper (back fixing) 8x1.25L20 [8.8] 2 30

Filter box support brackets 8x1.25L20s [10,9] 2 X 25

Footrest brackets 8x1.25L25 [8.8] 4 X 30

Engine retaining plates 6x1L50 [8.8] 2 15

Regulator support 5x0.8L8 [8.8] 2 5

Fixing screws for oil tank and regulator 5x0.8L12 [8.8] 1 5

SWING ARM

Swing arm to frame/engine 16x1,25L255 [5.8] 1 50

Shock absorber to frame 10x1,25L50 [8.8] 1 45

Shock absorber to lever 10x1,25L45 [8.8] 1 45

Lever to swing arm 10x1.5L75 [10,9] 1 45

Connecting rods to lever 10x1.5L125 [10.9] 1 45

Connecting rods to frame 8x1,25L42 [10,9] 2 30

Stand to swing arm 6x1L20 [8.8] 2 X 10

Sliding block chain tightener to swing arm 8x1.25L12s [8.8] 1 10

Chain tightener spring fixing 5x0.8L20 [8.8] 1 5

Chain guide shoe rubber (upper) 6x1L35 [8.8] 1 10

Chain guide shoe rubber (lower) 5x0.8L8 [8.8] 1 5

Sprocket cover 5x0.8L8 [8.8] 2 5

Pipe fastening clamps 5x0.8L6 [8.8] 2 5

FRONT FORK

Triple fork clamp (fixing tubes) 6x1L25 [8.8] 10 10

Handlebar to triple fork camps 8x1.25L30 [8.8] 2 30

Fork adjusting ring nut Speciale 1 25

Head tube nut 18 125

HANDLEBAR DEVICES

Throttle control 4x0.7L12 [8.8] 2 3

Clutch master cylinder 4x0.7L12 [8.8] 2 3

Brake master cylinder 5x0.8L15 [8.8] 2 3

BRAKES

Front brake caliper (upper) 8x1.25L55 [8.8] 1 X 23

Front brake caliper (lower) 8x1.25L35 [8.8] 1 X 23

Rear brake master cylinder to frame 6x1L16 [8.8] 2 12

Brake pedal 8x1.25L20 [8.8] 1 X 10

Brake disk cover 4x0.7L14 [8.8] 2 3

EXHAUST

Silencer to frame (upper) 6x1L25 [8.8] 1 10

Silencer to frame (lower) 6x1L10 [8.8] 1 10

FASTENING BOLT TORQUE SETTINGS - FRAME

5

INTRODUCTION

betamotor.com

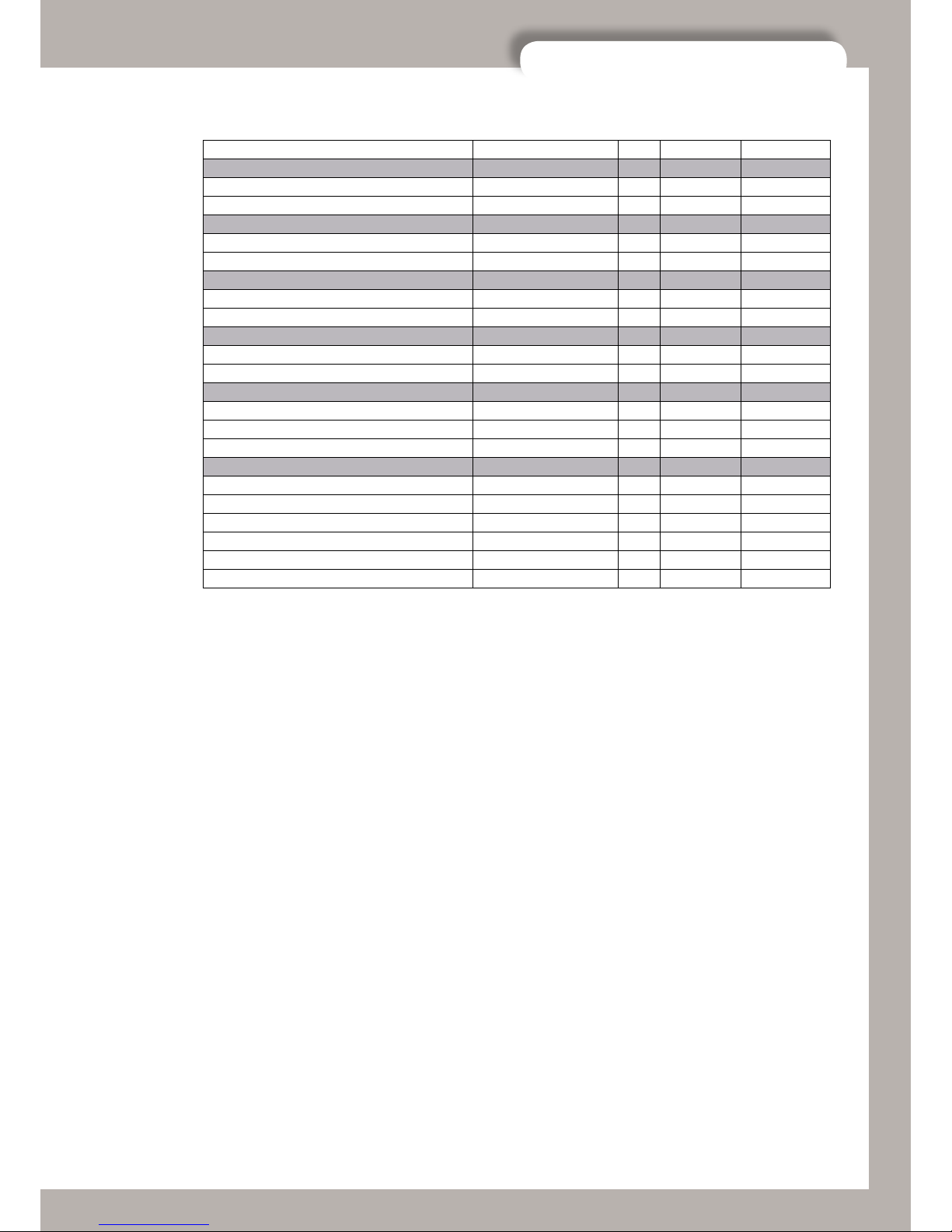

FIXING PART PCS THREAD LOCK TORQUE [NM]

AIR FILTER BOX

Air filter box to frame 5x0,8L12 4 5

Filter case cover 5x0,8L12 2 5

COOLING

Radiator to silent block 6x1L10 [8.8] 2 10

Electric fan to radiator 6x1L20 [8.8] 4 10

ELECTRICAL EQUIPMENT

Coil retaining screws 5x0.8L25 [8.8] 2 5

Lights switch 4x0,7L14 [8.8] 2 3

FRONT WHEEL

Front wheel pin 18x1,5 [5.8] 1 50

Disc brake 6x1L25 [8.8] 4 X 10

REAR WHEEL

Rear wheel pin 16x1.5 [5.8] 1 80

Disc brake 6x1L16 [8.8] 4 X 10

Sprocket 8x1.25L33 [8.8] 4 X 23

PLASTICS / TANK

Front mudguard 6x1L16 [8.8] 4 10

Rear mudguard 5x0.8L8 [8.8] 5 5

Headlight mask (upper) 5x0,8L20 [8.8] 1 5

Headlight mask (lower) 5x0,8L30 [8.8] 1 5

Tank panels 5x0,8L8 [8.8] 4 5

Front disc cover (lower screw) 5x0,8L16 [8.8] 1 5

6

INTRODUCTION

betamotor.com

ASSEMBLY COMPONENT QTY THREAD LOCK TORQUE (NM)

VALVEGEAR GROUP

Valve adjuster covers Bolt M6x16 4 10

Camshaft sprocket Screw M6x10 2 10

Water pump cover Screw M6x20 3 10

Carburettor flange Bolt M6x16 2 10

Exhaust flange Screw M6x15 4 10

Movable guide Bolt TTLIC M6x12 1 X 10

Camchain tensioner Bolt M6x16 2 8

Water circuit bleed screw Screw M6x12 1 8

Water circuit drain screw Screw M6x12 1 8

Rocker spindle plug M16x1 2 10

Valve adjuster locknut Nut M6x0.75 4 11

Cylinder head cover Bolt M6x35 4 10

Bolt M6x25 2 10

Bolt M6x55 4 10

Head – Cylinder Bolt M6x25 1 10

CRANKSHAFT GROUP

Crankshaft half, clutch side Nut M18x1.5 1 150

Crankshaft half, flywheel side Nut M14x1.5 1 120

TDC locking bolt Special bolt M8 1 25

CRANKCASE GROUP

RH crankcase – LH crankcase Bolt M6x45 2 10

Bolt M6x60 9 10

RH crankcase – Clutch casing Bolt M6x25 7 10

Bolt M6x55 1 10

Bolt M6x30 2 10

Selector drum bearing retaining bolt Bolt M6x10 2 X 10

Flywheel cover Bolt M6x30 5 10

Bolt M6x35 2 10

Clutch cover Screw M6x20 4 10

Head – Cylinder – Crankcase Stud M10x1.25 4 X 30

Nut M10x1.25 4 30

Oil drainplug M16x1.25 1 20

Oil level plug M16x1.5 1 10

Retaining plate Corteco Special screw M4x8 2 X 3

Oil circuit jet M5x0.75 2 6

IGNITION/STARTING GROUP

Pickup retaining bolt Bolt M6x12 2 8

Stator retaining screw Screw M5x25 3 6

Ramp Bolt M6x20 2 X 8

Kickstart pivot retaining bolt Bolt M8x20 1 25

Sparkplug M10x1 1 10-12

GEARCHANGE GROUP

Detent cam Bolt M6x35 1 X 10

OIL PUMP GROUP

Cover, oil pump LH Screw M6x14 2 10

Cover, oil pump RH Screw M6x20 1 10

Screw M6x15 1 10

Pivot, oil pump idler gear Screw, shallow, M6x25 1 X 10

Intake filter cover, output oil pump M20x1.5 1 15

Intake filter cover, scavenge oil pump M20x1.5 1 15

FASTENING BOLT TORQUE SETTINGS - ENGINE

7

INTRODUCTION

betamotor.com

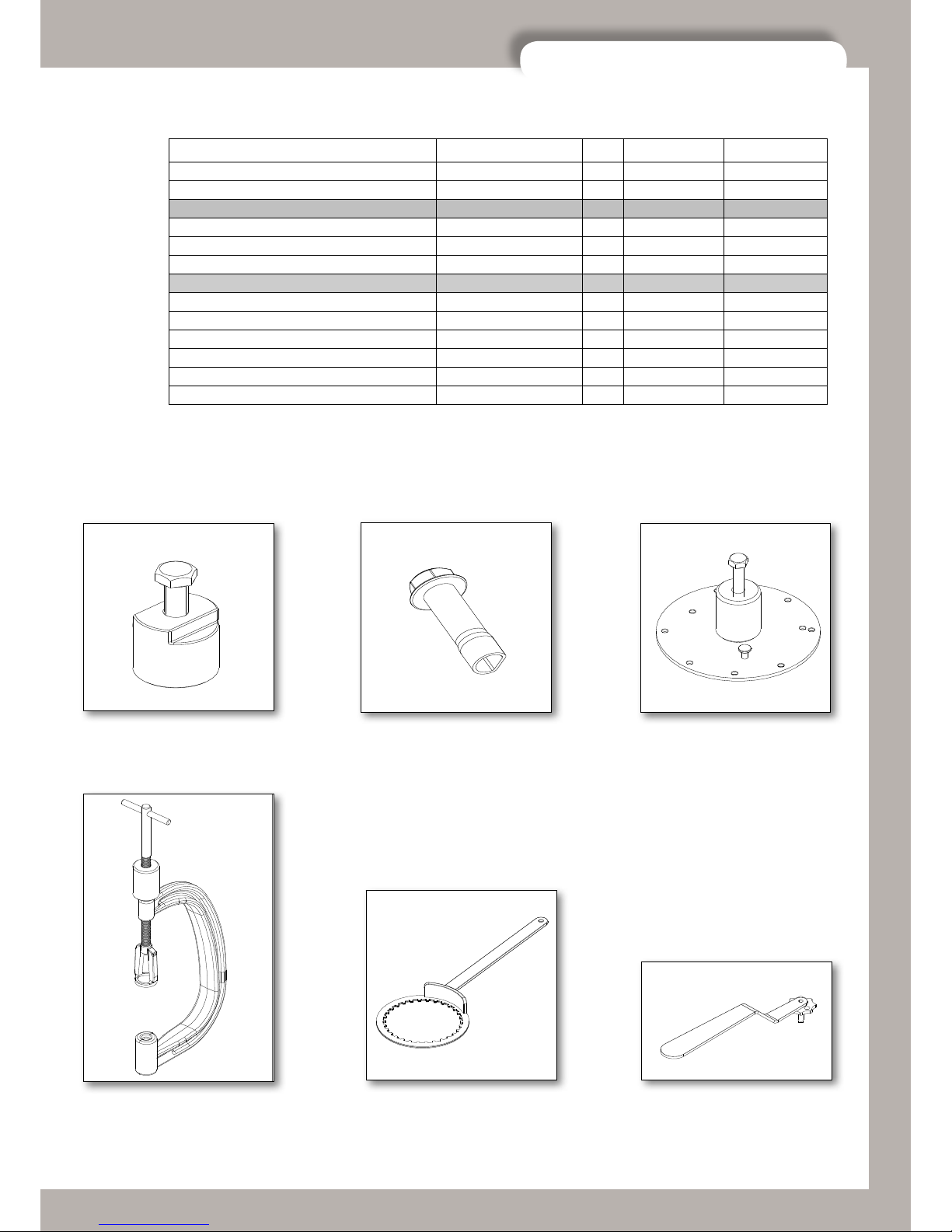

01.00040.000

Flywheel extractor

01.00041.000

Key for water pump shaft

01.00042.000

Crankcase splitter

01.00043.000

Valve spring fitting tool

01.00044.000

Inner clutch hub locking tool

01.00045.000

Carburettor adjusting

spanner

ASSEMBLY COMPONENT QTY THREAD LOCK TORQUE (NM)

Filter cover, output oil pump Screw M6x20 3 10

Oil pressure relief valve Special bolt M12x1.25 1 20

CLUTCH GROUP

Pressure plate Bolt M6x16 6 10

Clutch centre Special nut M14x1.25 1 90

Clutch actuator body. Bolt M6x16 3 10

FRAME – ENGINE

Swing-arm bolt Nut M16 1 90

Stay RH Bolt M8 2 25

Stay LH Bolt M8 2 25

Engine mounting bolt, front Bolt M10 1 25

Engine mounting bolt, lower Nut M10 1 25

Mounting bolt, cylinder head Nut M8 1 30

SPECIAL TOOLS

8

LUBRICATION CIRCUIT

betamotor.com

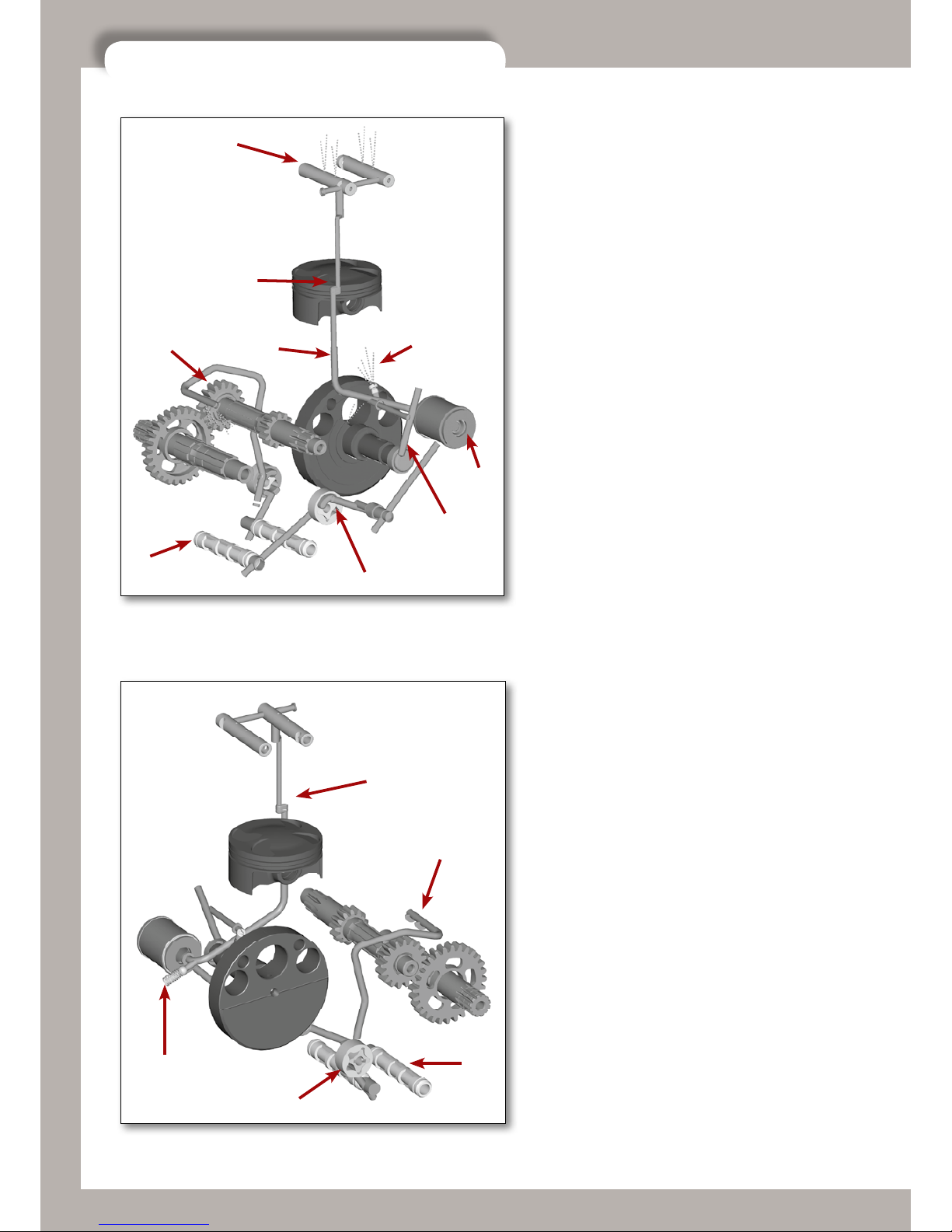

1 LUBRICATION CIRCUIT

The output oil pump (1) draws in oil from the area

at the base of the gearbox through its own mesh

oil filter (2) and then sends it to the paper oil fil-

ter (3). From here the oil, starting from the bypass

valve (4), is directed in three different directions:

by means of a jet (5) it lubricates the piston pin

and takes heat from the crown of the piston; and it

passes through two pipes, one of which (6) takes it

to the crankshaft to lubricate the roller bearing on

the crankpin; the other (7), whose flow is regulated

by a calibrated hole in the cylinder base gasket (8),

feeds the valvegear (9). The oil then returns to the

base of the crank chamber from the piston, the con-

rod assembly and the cylinder walls, and is drawn

in by the scavenge pump (10) through the mesh

filter (11). It is pumped through special jets (12)

and lubricates the transmission gears. The oil in the

cylinder head, however, returns to the base of the

gearbox passing through the timing case and the

inner clutch casing.

1.1 ENGINE OIL

Use only fully synthetic oils of a reputable brand

(BARDAHL XTC60 15W50).

9

8

75

3

6

1

2

12

8

4

10

11

12

9

LUBRICATION CIRCUIT

betamotor.com

1.2 CHECKING THE ENGINE OIL LEVEL

The engine oil level must be checked when the en-

gine is warm. Run the engine for several minutes

and then switch it off. Place the bike on a flat surfa-

ce in such a way that it is perfectly vertical.

Wait a few minutes and then check the oil level in

the sightglass located in the clutch casing (right-

hand side of the engine). The level must be betwe-

en the limits indicated in the picture.

If necessary, remove the oil filler plug and top up

the level.

N.B. Running the engine with too little oil causes ex-

cessive wear to the engine components.

1.3 CHANGING THE ENGINE OIL

N.B. At each oil change, the mesh filters must be cle-

aned and the paper filter replaced.

N.B. The oil change must be carried out when the

engine is at working temperature. Be careful not to

scald yourself with the hot oil.

After the engine has reached operating temperatu-

re, switch the bike off and stand it upright.

Unscrew the oil drainplug and let all the oil flow out

into a drain pan. Thoroughly clean the magnet on

the drainplug to get rid of the metallic impurities

that it has collected.

MAX

MIN

10

LUBRICATION CIRCUIT

betamotor.com

Unscrew the plug in the left-hand casing and use

pliers to extract the filter. Clean it carefully and blow

it through with compressed air. Check for damage

to the O-rings, and replace them if necessary. Refit

all the parts and tighten the plug to 15 Nm.

Carry out the same procedure for the output mesh

filter, for which the access is via the right-hand en-

gine casing.

11

LUBRICATION CIRCUIT

betamotor.com

Position a container under the bike, near the cover

for the paper filter, and unscrew the bolts on the

filter cover.

Then extract the paper filter using pliers. Check the

condition of the O-ring too, and replace it if neces-

sary.

Change the filter and refit the cover, tightening the

three M6x20 bolts to 10 Nm.

Refit the oil drainplug, tightening it to 20 Nm, and

refill with 0.81 of engine oil (BARDHAL XTC60

15W50).

N.B. If the engine has been opened up for an internal

inspection, the quantity of oil to put in is 0.9 litres.

Finally, tighten the oil filler plug (A) to 10 Nm.

A

12

ENGINE REMOVAL AND REFITTING

betamotor.com

2 ENGINE REMOVAL AND REFITTING

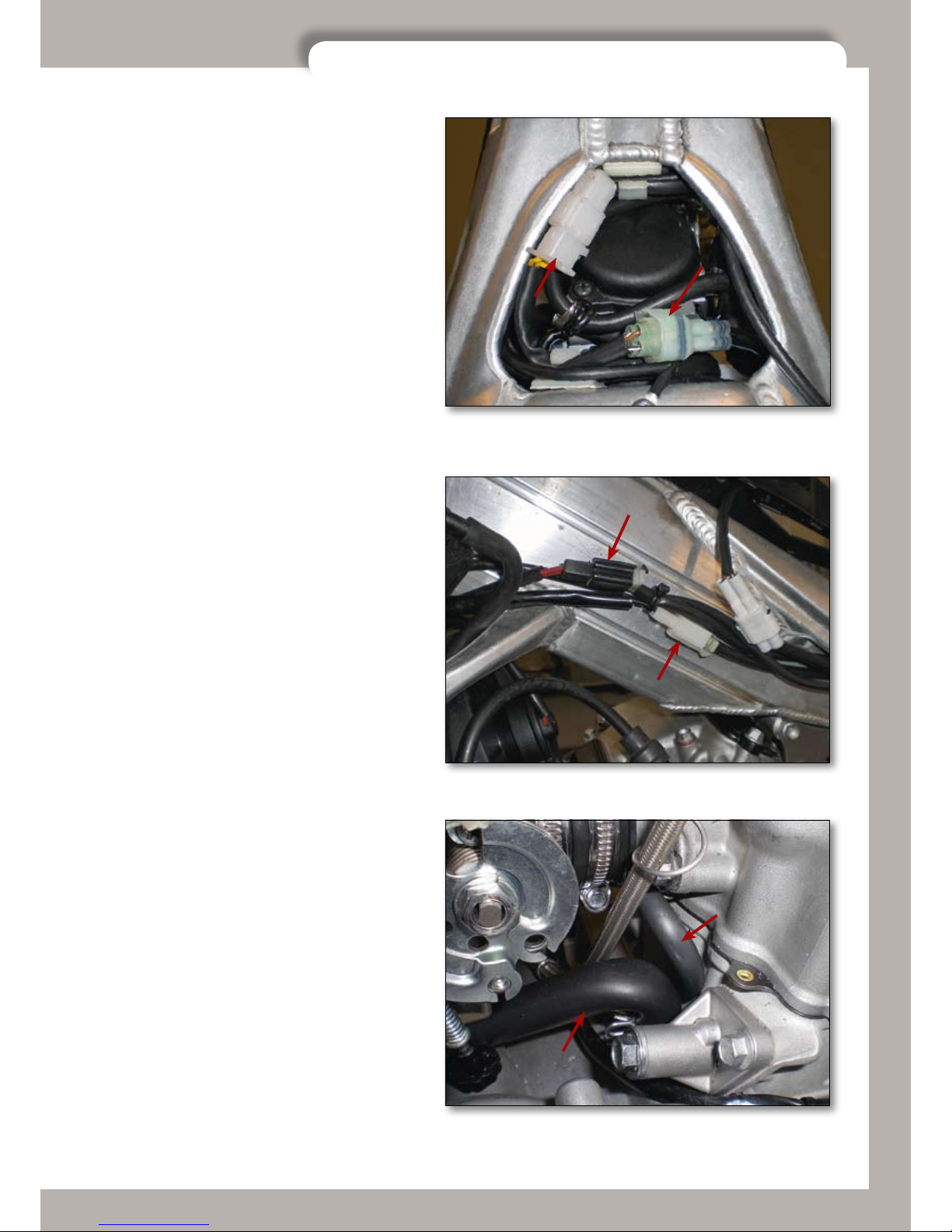

2.1 ENGINE DISASSEMBLING

Deeply clean the whole bike and position it on a

steady stand.

Disassemble front fender.

Disassemble silencer.

Unhook the two springs located in front of the en-

gine head (A). Then disassemble the exhaust col-

lector (B).

Disassemble the bumper.

B

AA

13

ENGINE REMOVAL AND REFITTING

betamotor.com

Disconnect the electrical connectors A and B loca-

ted over the carburettor.

Disassemble left panel and disconnect connectors

C and D of the electric fan and bulb.

Disconnect the coil from radiator and unplug the

pipe from the spark plug.

Disconnect oil vapour hose (E) and Hot Start hose

(F).

B

C

F

D

E

A

14

ENGINE REMOVAL AND REFITTING

betamotor.com

Make sure that the fuel petcock is closed (lever

in position “C”).

Disassemble the rear brake oil tank by un-

screwing the fixing screw.

Loosen the carburettor fixing clamp.

This manual suits for next models

1

Table of contents

Other Betamotor Motorcycle manuals