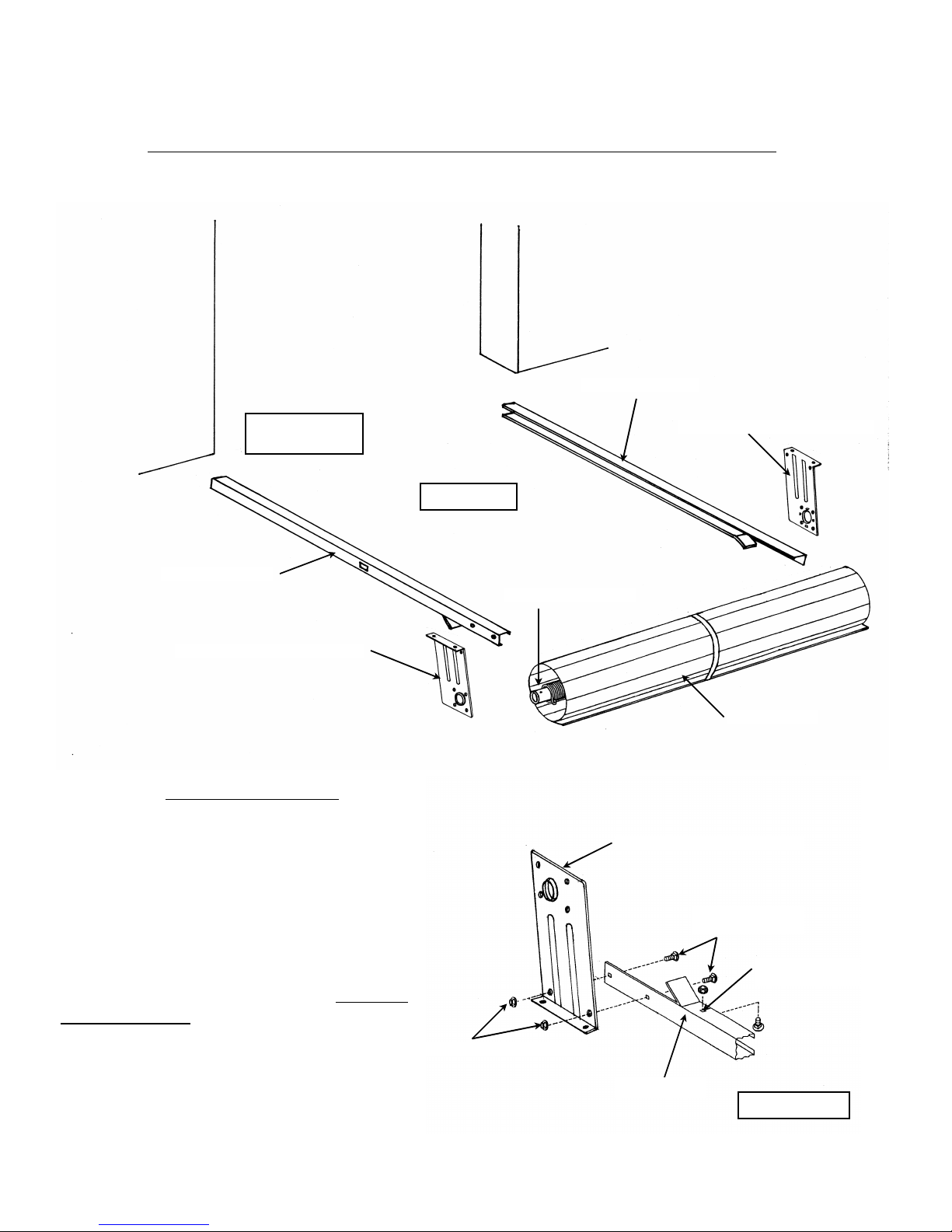

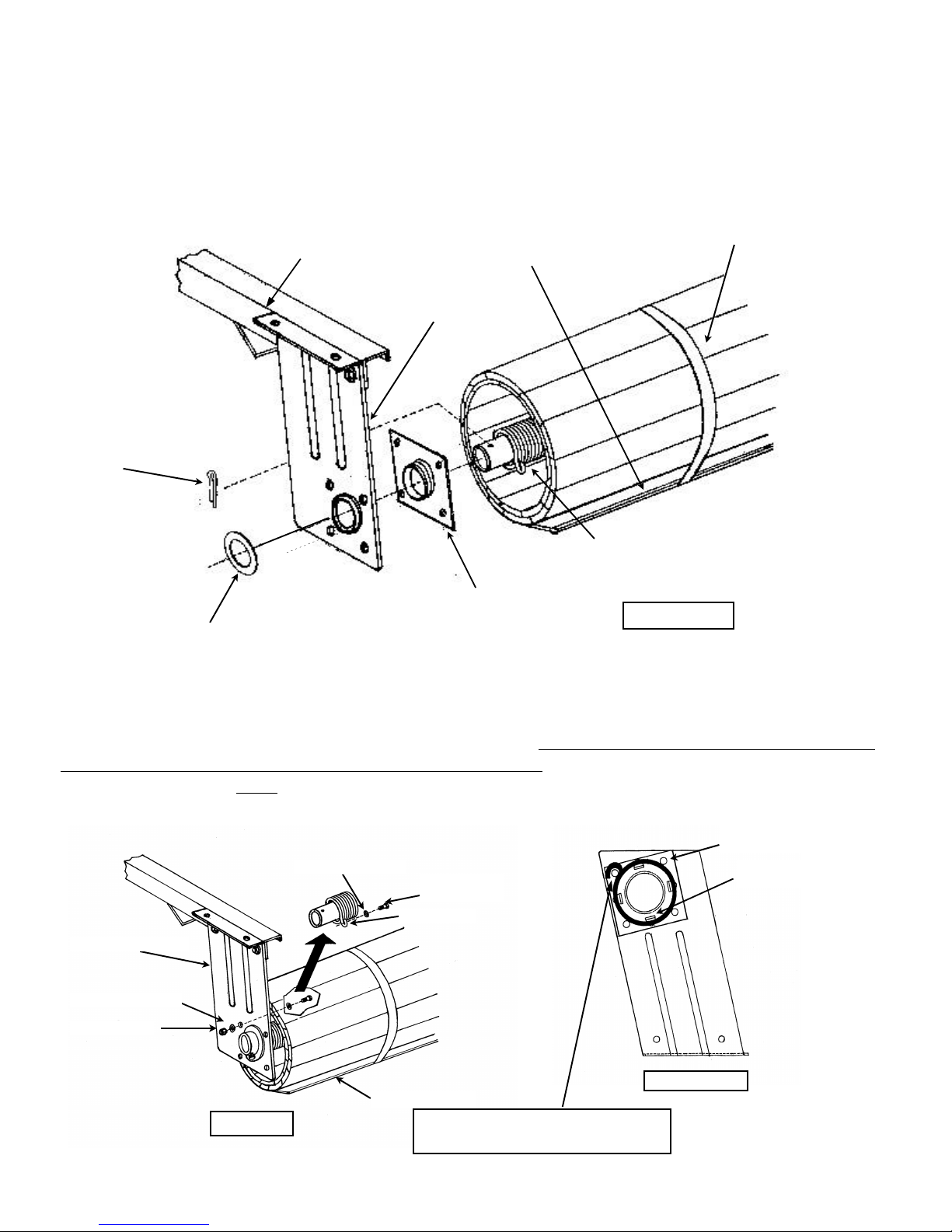

STEP 10. INSTALLING OPTIONAL TENSION ADJUSTER

Slide DOOR TRACK ASSEMBLY with DOOR BRACKET onto AXLE ASSEMBLY. (TENSION

ADJUSTER is factory assembled with DOOR BRACKET.) Attach spring to TENSION

ADJUSTER into the offset hole with a 5/16” x 3/4” bolt and washer. Slide large WASHERS

onto AXLE. Install 1/8” diameter x 2-1/2” COTTER PINS through holes provided in AXLE.

Install 1/4” diameter BALL LOCK PINS through (1) hole into TENSION ADJUSTER.

Return to steps 6, 7, 8, & 9.

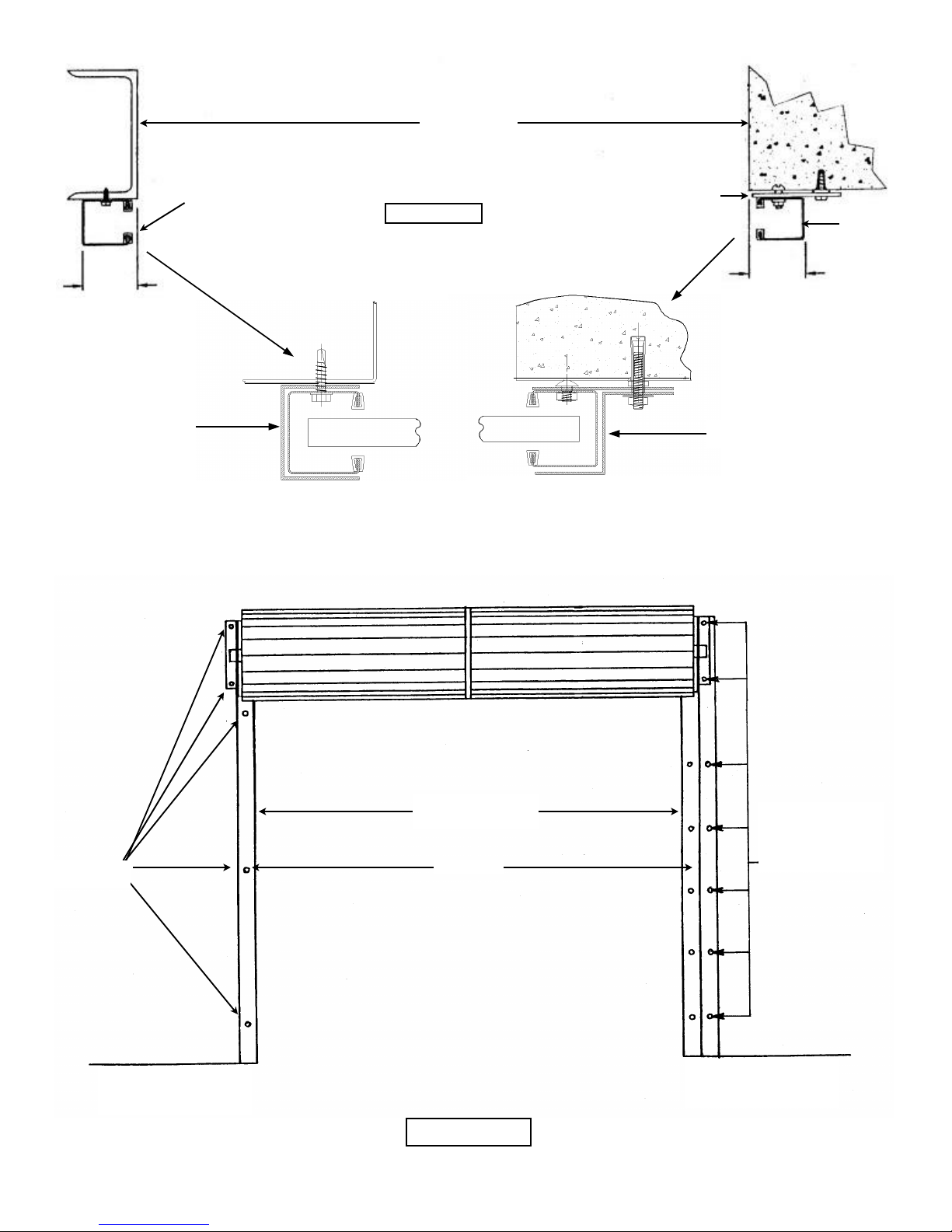

STEP 11. ADJUSTING SPRING TENSION USING TENSION ADJUSTER

Doors with openings 9’0” wide or less use

only one tension adjuster located on the left

side with left door bracket assembly. Right

side will be installed with a standard right

door bracket assembly.

WARNING

SINCE SPRINGS ARE UNDER EXTREME TEN-

SION. NEVER REMOVE SPRING FASTENERS.

KEEP A SECURE HOLD ON THE DOOR AND

BOTTOM BAR WHEN ANY TENSION ADJUST-

MENTS ARE MADE OR WHEN DOOR STOPDS

ARE NOT SECURELY ATTACHED THE DOOR

ROLL WILL TRY TO UNROLL RAPIDLY AND

CAN CAUSE SEVERE INJURY.

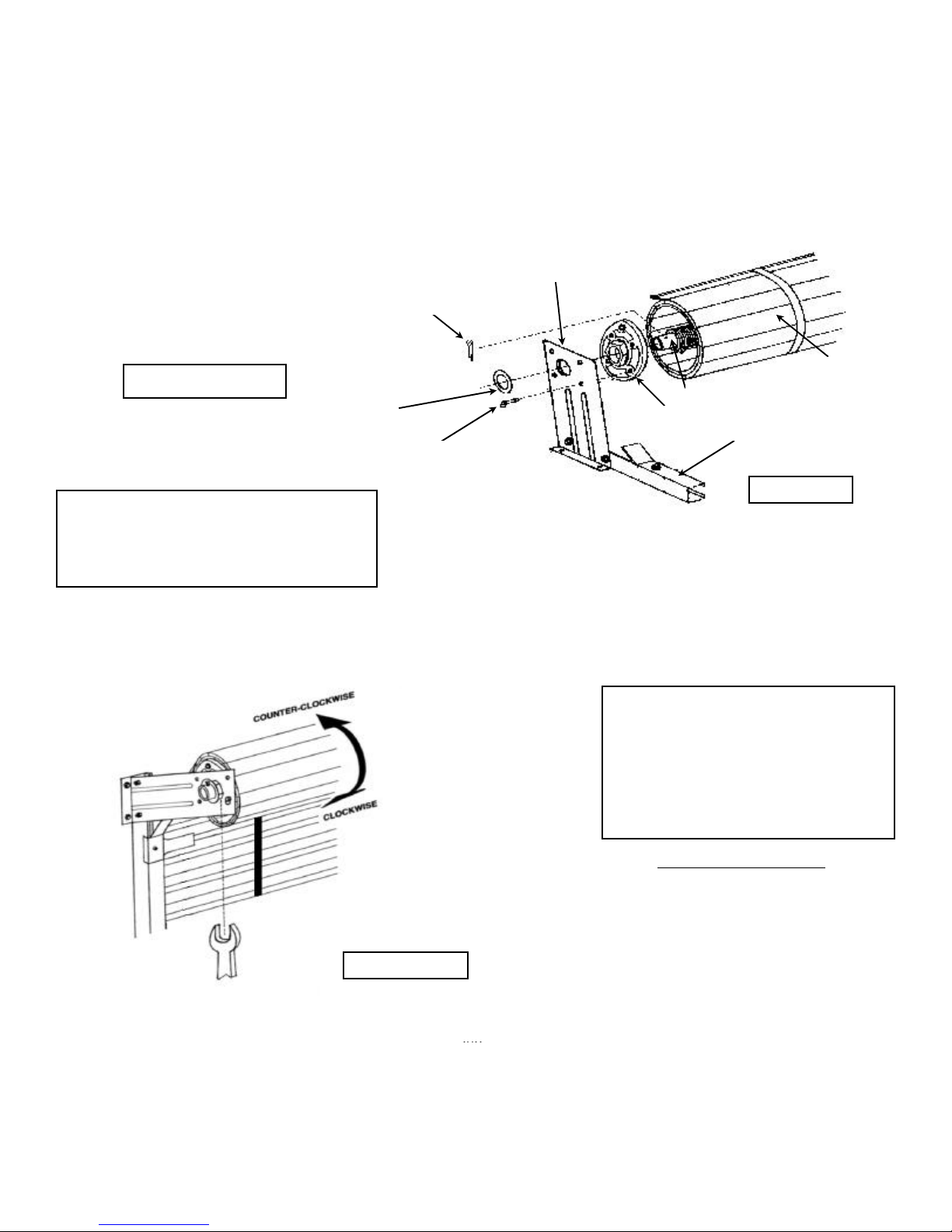

ADJUSTING TENSION

Place 1-3/4” wrench or channel lock

pliers onto 1-3/4” hex of TENSION

ADJUSTER. Hold that position to

retain tension. Remove ball lock pin.

Turn TENSION ADJUSTER to next

hole alignment in TENSION

ADJUSTER. To increase tension,

turn wrench counter-clockwise or

turn clockwise to decrease tension.

Replace ball lock pin. Retry DOOR

for proper tension. Repeat operation

until tension is satisfactory to the

customer. Install a 5/16” x 3/4” hex

head bolt through bracket into

TENSION ADJUSTER.

DOOR BRACKET

SEE STEP 8 FOR PRE-

TENSION OF DOOR SPRING

1/8” DIA. X 2-1/2” LG. COTTER PIN

2” I.D. X 3” O.D.WASHER

1/4” DIAMETER BALL LOCK PIN DOOR TRACK

FIGURE 10

TENSION ADJUSTER (Pre-assembled to bracket)

DOOR AXLE ASSEMBLY

DOOR CURTAIN

FIGURE 11

Page 8 12/31/03