BETE XA Series Operating instructions

Visit BETE.com for comprehensive spray nozzle tools, case studies and literature.

413.772.0846 sales@bete.com

1

TROUBLESHOOTING:

BETE XA NOZZLES

XA COMPONENTS

BETE XA nozzles consist of a body, a spray

set-up, hardware assemblies, and optional

mounting devices.

The body is the base

component. It contains the

connection ports for the

liquid and air supplies, a

connection for the spray

set-up, and may contain a

connection for a hardware

assembly.

The spray set-up consists of an air cap

and a uid cap. The air cap and uid cap

combination control the spray performance,

including ow rates and spray pattern.

Optional hardware assemblies allow

either shutoff or shutoff and clean-out of

the uid cap. Hardware assemblies may be

actuated manually (B, C, and D hardware)

or pneumatically (E or F hardware). Not all

bodies accept all hardware.

Mounting devices offer a method of holding

the nozzle in a xed location. They attach to

the uid cap.

Operation of the air cylinder of the E or F

hardware requires a minimum air pressure

of 30 psi to retract the rod. Failure to provide

sufcient air pressure is one of the most

frequent causes of poor nozzle performance.

The E or F hardware feature a built-in air

cylinder which allows liquid ow to be shut

off at the nozzle tip, resulting in precise,

intermittent application of liquid. When

air pressure is released a spring causes the

cylinder to return to the closed position.

For the F clean-out option, the pin pushes

accumulated material from the liquid orice

as it returns. The clean-out pin is not able

to remove material from the orices in the

air cap.

Standard seal materials limit the XA to use

at temperatures less than 400°F. Materials

allowing use at higher temperatures are

available by special request. All spray set-ups

t on all bodies. All spray set-ups may be

used with hardware, however the available

hardware is limited by the chosen body style.

The 00 and 03 bodies can accept all

hardware assemblies. Complete nozzle

assemblies initially sold with manual

The BETE XA series is a multi-component

air atomizing system. The XA system was

designed to allow the swift exchange and

replacement of caps, bodies and tips. The

system provides a wide range of spray

patterns and simplies maintenance. The XA

series assemblies may consist of anywhere

from 6 to 11 parts.

Please be certain to read all instructions

carefully before assembling or disassembling

the nozzle. Damage to these assemblies can

occur if these procedures are not followed.

OPEN

CLOSED

hardware (B, C, or D) may be upgraded in the

eld to automatic hardware (E or F).

The square 00 body with E or F hardware

requires two separate air lines and more

complex piping.

The 01 body features a consolidated air inlet

combining both the atomizing air and cylinder

air in a single line, resulting in simplied piping

layouts. The 01 body can be used only for

applications where the atomizing air pressure

is ABOVE 30 psi.

The 01 and 02 bodies simplify external air line

connections by xing the orientation of the air,

liquid and cylinder inlets.

The 01 and 02 bodies may only be used with the

E or F hardware.

The 02 body requires two separate air lines,

one to supply atomizing air and one to supply

operating air to the cylinder. The two air lines

allow the use of atomizing air at pressures both

BELOW and ABOVE 30 psi, while maintaining

the minimum 30 psi to the cylinder.

The 05, 06, 07, and 08 bodies do not accept any

hardware.

The XA10 and XA11 bodies have a built in

air-operated cylinder. This integral cylinder

provides a smaller prole for use where space

is limited.

1. Adequately size air and liquid lines

to maintain required pressures at each

nozzle. (consult air and water ow charts

on page 4)

16. During installation, ensure the liquid

and air supplies are connected to the

correct port. The words “LIQUID” and

“AIR” are

stamped on

the bodies

adjacent to the

correct port.

4. To maintain adequate air pressure (30

psig min) for cylinder operation, use the

02 body if atomizing air pressure to the

nozzle is expected to fall below 30 psi.

2. Each siphon nozzle must have a

separate liquid feed line from the

reservoir.

9. To maintain atomization during

startup and shutdown, always turn on

air rst and turn off air last.

10. Multiple nozzle

installations are especially

sensitive to line sizes and

lengths. Size air and liquid

lines generously and avoid

large numbers of nozzles

(no more than 6) on a single

branch.

11. Humidication requires

high air/ liquid ratios,

usually in the range of 2 to

4 SCFM per gallon per hour,

to produce droplets small

enough for evaporation.

14. For viscosities greater

than 150 cP, consider using

one of the EF setups.

6. Flush out air and liquid lines before

connecting nozzles to clear out loose

material which could cause pluggage.

7. Install air and liquid pressure gauges

close to the nozzle location(s) to allow

accurate control of pressures.

3. For extreme temperatures and a range

of chemicals, consult chart of options for

special gaskets, sealants and Loctite®

adhesives.

8. As a general rule avoid spraying

counter-current to reduce contamination

problems from process environments.

12. Maximum operating rate for air

cylinders is 3 cycles per second.

Maximum pressure is 125 psi.

13. In dirty process environments, a

purge air pipe surrounding the nozzle

can reduce contamination problems.

15. Whenever ow rate accuracy is

critical, a positive displacement metering

pump or ow controller should be used.

5. For severe chemicals and abrasive

liquids, consult factory for optional

nozzle materials.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

INSTALLATION TIPS

Visit BETE.com for comprehensive spray nozzle tools, case studies and literature.

413.772.0846 3

sales@bete.com 413.772.0846

2

SPRAY SET-UP BODY STYLES & SEALS HARDWARE ASSEMBLIES

*For extensions, A hardware is

standard; E and F hardware may

be provided on an application

specic basis. Loctite is a registered trademark of Henkel Corporation. BETE is a registered trademark of BETE Fog Nozzle, Inc.

Air Caps

ER

SF

SR

PR

PF

AD

EF

FF

XA 01

XA 03 Spray

perpendicular to

parallel inlets

Adapt-F

E

Replaceable E or

F Tip assembly

Rear

Gasket

XA 00 Standard

Fluid Cap

Front

Gasket

XA 02

XA 10

XA 11

XW

Mounting

Bracket

Thin Wall

Mounting Gasket

Thick & Thin

Wall Mounting

Adapter

Thin Wall

Mount

Lock Nut

Replaceable

E or F Tip

assembly

with small

o-rings

XA 10/11 Bodies:

Low prole

Built-in cylinder

XA10 – Separate

atomizing

and cylinder air inlets

XA11 – Combined

atomizing

and cylinder air inlet

XA 05 - Spray parallel to parallel inlets

XA 07 - Spray

perpendicular to

1/8” parallel inlets

XA 12

Spray parallel

to parallel

inlets. With

mounting

holes.

XA 08 -

Directional spray,

2 nozzle spray

set-ups

XA 06

(4-5 spray setups)

Parallel inlets

Rear

Gaskets

Large O-rings

E Air-operated Shut-off

D** Clean-out/Shut-off

C** Clean-out

B Shut-off

A End Plug

Seal Kit: 39572

Bushing

1/4 XA 01 PR 250 E 01 02

Sizes & Series

Body Styles

Air Cap Style Hardware Assemblies

Mounting Hardware

Extension Size

Combination Number

1/8”B, 1/4”B, 1/2”B - BSP 1/8”, 1/4”, 1/2” - NPT

00 01 02 03 05 06 07 08 10 11 12

PR FF AD XW PF EF SR SF ER A B C D E F

01 02 03

12”

SPRAY / SET-UP NUMBER

Before disassembling or reassembling, please review

the diagram on the left to make sure you have the parts

necessary to complete your choice of set-up.

These instructions are applicable to the 00 and 03 body

and hardware options A-D. For illustration, the gures are

shown with the 00 body and the C hardware option.

1. Attach gasket. Slide rear gasket onto A, B, C, or D

hardware until it rests on the shoulder behind the threads

(Figure 1).

2. Thread into body. Thread the hardware and gasket from

step 1 into the back of the 00 or 03 body. Snug the hardware

in place.

3. Attach uid cap. Slide front gasket onto uid cap until it

rests on the shoulder behind the threads. Screw the uid

cap into the body and tighten to 75 in-lb [8.5 Nm] (Figure 2).

4. Attach air cap. Rest the air cap on the uid cap and

secure it in place with the cap nut (Figure 3).

ASSEMBLY INSTRUCTIONS FOR A, B,

C AND D HARDWARE

!WARNING! The needle assembly can be severely damaged

if excessive torque is applied during disassembly or

reassembly.

1. Install bushing and o-rings. Slide relief bushing onto

cylinder rod with slotted side toward the cylinder body.

Slide the two larger o-rings onto the cylinder rod. Push the

bushing and the o-rings all the way down the rod (Figure

A).

2. Attach adapter. For 00 and 03 bodies only, slide the

adapter down the cylinder rod and thread it onto the

cylinder body.

3. Install rear gasket and connect hardware. Slide the rear

gasket down the cylinder rod, resting it on the shoulder

behind the threads of the cylinder (01 and 02 bodies) or the

threads of the adapter (00 and 03 bodies). `Insert cylinder

rod through body. HAND TIGHTEN into the body (Figure B).

4. Attach tip and small o-ring. Use supplied Loctite®

per manufacturer’s directions to coat threads on end of

cylinder rod as shown in Figure C. Screw tip to cylinder

rod. HAND TIGHTEN. Roll smaller o-ring onto tip (note that

the smaller o-ring may already be installed on the tip at

the factory). WARNING: Do not mar or gouge tip surface

when assembling; be sure to keep tip surface smooth.

5. Attach uid cap. Slide front gasket onto uid cap until it

rests on the shoulder behind the threads. Screw the uid

cap into the body and tighten to 75 in-lb [8.5 Nm].

6. Attach air cap. Rest the air cap on the uid cap and

secure it in place with the cap nut (Figure D).

ASSEMBLY INSTRUCTIONS FOR E

AND F AUTOMATIC HARDWARE

Replaceable Components and Gaskets

Seal Kit

Front Gasket

Rear Gasket

Body Seal

Cap Nut

Adapter

Thick & Thin Wall Mount

Adapter

Thin Wall Lock Nut

Thin Wall Mounting

Gasket

Mounting Bracket

E - Replacement Tip

F - Replacement Tip**

**Specify uid cap

Visit BETE.com for comprehensive spray nozzle tools, case studies and literature.

413.772.0846 sales@bete.com

3Visit BETE.com for comprehensive spray nozzle tools, case studies and literature.

413.772.0846 5

sales@bete.com 413.772.0846

4

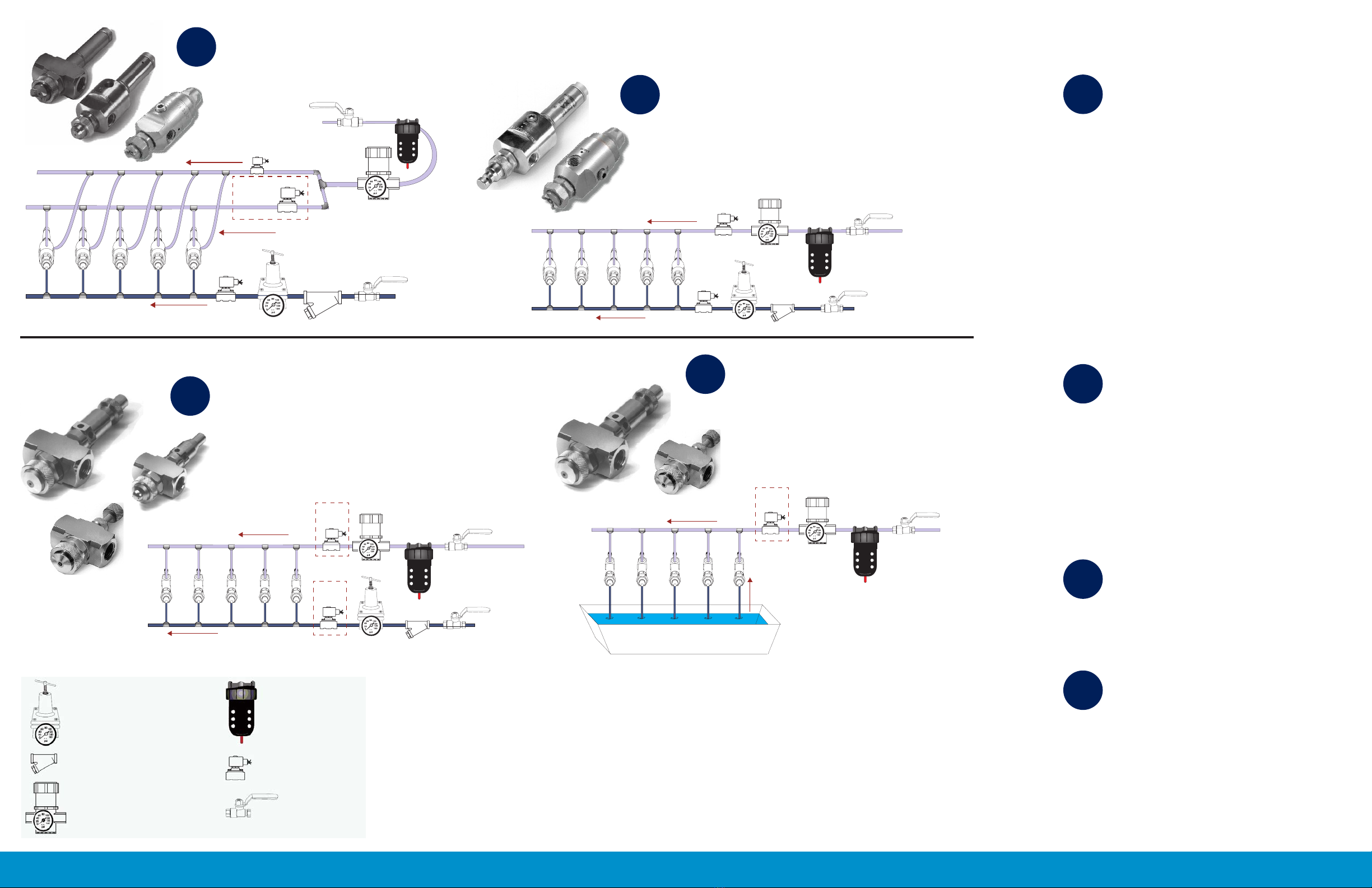

For Systems AA and BB

Liquid ow is shut off

in the nozzle with a

poppet valve operated

by an air cylinder

controlled by a 3-way

solenoid valve. The

00, 02, and 10 bodies

respond faster than the

01 and 11 bodies.

If you need assistance designing your XA system, please email or fax your

or 413-772-6729.

02 and 10 Bodies

Use a 3-way valve on the cylinder air line for

the fastest response. Use an optional 2-way

solenoid valve on the atomizing air line to

conserve air when the liquid ow is shut off.

Note that the atomizing air valve must open

before the 3-way cylinder air valve.

00 Body

The operation is the same as for the 02

body, but the piping is more difcult

because the location of the cylinder air

inlet is independent of the atomizing air

inlet. Flexible tubing may be used for some

applications.

An additional regulator is required for either

the 02 or 00 body if the atomizing air is to be

less than 30 psi.

AA

01 and 11 Bodies

Because this body has a single inlet for

cylinder and atomizing air, it requires only

one 3-way solenoid valve for control. The

response of the 01 body is slower than for

the 02 and 00 bodies because the liquid ow

doesn’t stop until the air has drained from the

line.

Atomizing air pressure must be greater than

30 psi to provide adequate cylinder pressure.

BB

00 Body

Liquid is fed under pressure to the 00 body,

which uses A, B, C or D hardware. Note that

systems similar to CC can be designed using

the 03, 05, 06, 07, and 08 bodies.

CC

00 Body

SR or SF set-ups siphon liquid from a

container to the

00 body, which uses A, B, C or D hardware.

Note that sytems similar to DD can be

designed using the 03, 05, and 07 bodies.

DD

LEGEND

Water Pressure Regulator Air Filter

Solenoid Valve

Manual Ball Valve

Water Strainer

Air Pressure Regulator

80

60

40

20

0

100

120

140

160

psi

80

60

40

20

0

100

120

140

160

psi

Cylinder Air Line

Atomizing Air Line

Liquid Line

3-Way Solenoid

Valve

2-Way Solenoid

Valve

OPTIONAL

Fastest Response - No Drips or Sputtering After Shutoff

00, 02 or 10 Body - E or F Hardware

Liquid Fed Under Pressure

80

60

40

20

0

100

120

140

160

psi

80

60

40

20

0

100

120

140

160

psi

Atomizing and

Cylinder Air Line

Liquid Line

3-Way

Solenoid

Fastest Response - No Drips or Sputtering

After Shutoff, Simplied Piping

01 or 11 Body - E or F Hardware

Liquid Fed Under Pressure

80

60

40

20

0

100

120

140

160

psi

80

60

40

20

0

100

120

140

160

psi

Atomizing Air Line

Liquid Line, Pressure Feed

2-Way

Solenoid

OPTIONAL

2-Way

Solenoid

OPTIONAL

Slow Response - Some Drips or Sputtering After Shutoff,

Simple Piping

00 Body - A, B, C or D Hardware

Liquid Fed Under Pressure

80

60

40

20

0

100

120

140

160

psi

Atomizing Air Line

Siphon Feed

Liquid Lines

Liquid Reservoir

2-Way

Solenoid

OPTIONAL

Slow Response - Some Drips or Sputtering

After Shutoff, Simple Piping

00 Body - A, B, C or D Hardware

Liquid Siphoned from Container

XA SYSTEMS

AA

BB

CC

DD

For Systems CC and DD

Using 00, 03, or 05

bodies, manual ball

valves or electric

solenoid valves control

the uid ow.

Visit BETE.com for comprehensive spray nozzle tools, case studies and literature.

WHAT YOU NEED TO

CONSIDER WHEN

DESIGNING YOUR XA

SYSTEM

FILTERS,

REGULATORS &

VALVES

WATER AND AIR FLOW DATA

• Conrm that the correct nozzle ow rate,

spray pattern, and operating pressures

have been selected and supplied for the

application, that the correct mounting

and accessory hardware such as thick

wall adapters and clean out needles

are installed on the nozzle and that the

correct number of nozzles is available.

• The header (for a multiple nozzle

installation) and supply lines should be

sized generously to prevent imbalance

between liquid and air pressures for each

nozzle and excessive pressure losses

along the header that could cause erratic

nozzle operation.

• Size the header to accommodate the total

ow to all the nozzles on the header.

Headers that are longer than 10 feet or

that have more than 10 nozzles may be

fed from both ends to minimize pressure

differences along their length.

• Be sure to account for the air pressure

according to the instructions on the chart

when sizing the air piping.

• The line supplying air to an automatic

cylinder can usually be 1/8” even when

multiple nozzles are used since the

volume ow of air to the cylinders is

very small.

• When the nozzles are supported by at

least one rigid pipe or wall, plastic tubing

often makes connections fast and easy,

but be certain the inside diameters of the

tubing to be used are as large as those in

the corresponding pipe size.

• Filters for the air and water lines should

be placed upstream of pressure regulators

and solenoid valves. Regulators and

pressure gauges should be placed as close

to the nozzles or header inlet as possible

to allow the regulator to respond rapidly

to pressure changes, especially when

the nozzles are being cycled on and off

automatically.

• Solenoid valves are generally installed

downstream of the pressure regulator

and as close to the nozzle as possible,

especially if they are to be used to cycle

the nozzles on and off.

• Automatic operation requires at least one

three-way valve so that air can escape

from the cylinder and allow the spring

to push the clean-out or clean-out/shut-

To determine the cubic feet per minute of

compressed air at any temperature and

pressure other than standard conditions, use

the equation:

(14.7 / p + 14.7) (460 + T / 520) (SCFM) = ACFM

Therefore, to determine the pressure drop for

inlet or average pressure other than 100 psi and

at temperatures other than 60°F, multiply the

values given in the table by the ratio:

(100 + 14.7 / P + 14.7) (460 + T / 520)

Where:

“P” is the inlet or average gauge pressure

in pounds per square inch, and, T is the

temperature in degrees Fahrenheit under

consideration.

Example: Suppose you need to supply two

XAPR300 nozzles with 60 psi water and 50 psi

air as shown in the diagram below.

Water

Total ow = (59 gph) x 2 / 60 = 1.96

gpm

Select 3/8” or larger pipe

Air

Total Flow = (4.6) x 2 = 9.2 scfm

Note that tabulated pressure losses will need to

be multiplied by

(100 + 14.7 / P + 14.7) = (114.7 / 50 + 14.7) = 1.77

to obtain losses at 50 psi. Select 3/8” or larger

pipe.

BETE recommends that lters be used on both

the air and liquid lines supplying XA nozzles

to minimize the potential for clogging. The air

lters supplied by BETE remove both water

and particulates and are equipped with an

automatic drain. The water lters remove

particulates larger than 100 mesh and can

be equipped with a quick ush drain valve to

remove accumulated deposits.

Liquid strainers for siphon setups should have

large areas to minimize pressure losses across

the strainer itself. It is also preferable to install

the strainer below the liquid level.

The standard liquid pressure regulators

supplied by BETE are the unbalanced type and

the downstream pressure may uctuate with

variations in inlet pressure regardless of the

pressure setting. The air regulators are the

relieving type and pressures can be set without

the air actually owing through the nozzles. In

addition these are less sensitive to variations in

upstream pressure.

If you have further questions, please do

not hesitate to call our customer service

department at 413-772-0846 or visit our website

at: www.bete.com.

off needle into place. Faster operation is

usually possible when you control the

cylinder separately using the 00, 02, or 03

body. Using the 01 body requires the air to

be exhausted from the larger atomizing

air supply piping to allow the cylinder to

return to the closed position.

• A complete XA system diagram with

lters, regulators and solenoid valves

is shown to the right and in the XA

Accessories brochure.

• You must correctly size the supply piping

to ensure that adequate air and water

are supplied to the nozzle. Correct size

is especially important in multi-nozzle

systems where differences in air and

water pressures from one nozzle to the

next can cause erratic operation.

• Several charts are included to help you

choose the correct pipe sizes.

Flow of air through schedule 40 steel pipe

For lengths of pipe other than 100 feet, the

pressure drop is proportional to the length.

Thus, for 50 feet of pipe, the pressure drop is

one-half the value given in the table; for 300

feet, three times the given value, etc.

The cubic feet per minute of compressed air at

any pressure is inversely proportional to the

absolute pressure and directly proportional to

the absolute temperature.

The pressure drop is also inversely proportional

to the absolute pressure and directly

proportional to the absolute temperature. .

Siphon System

Pressure System with XA02 Body