Graco SDX Operating instructions

Other Graco Paint Sprayer manuals

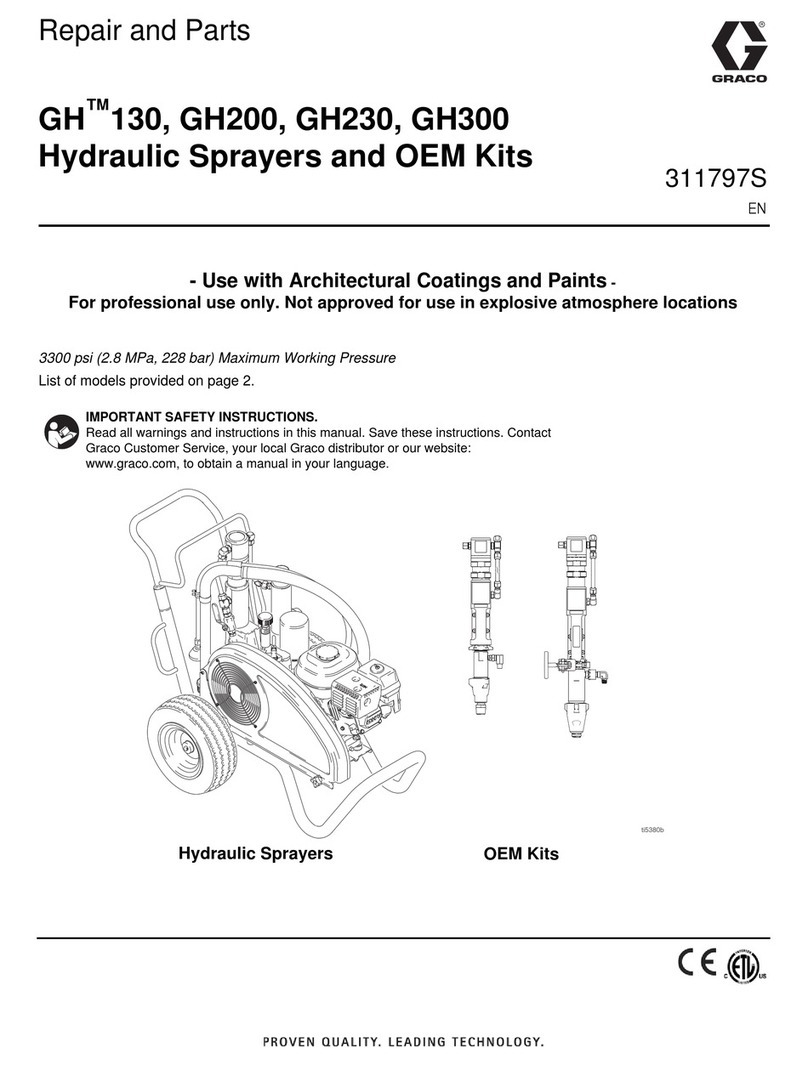

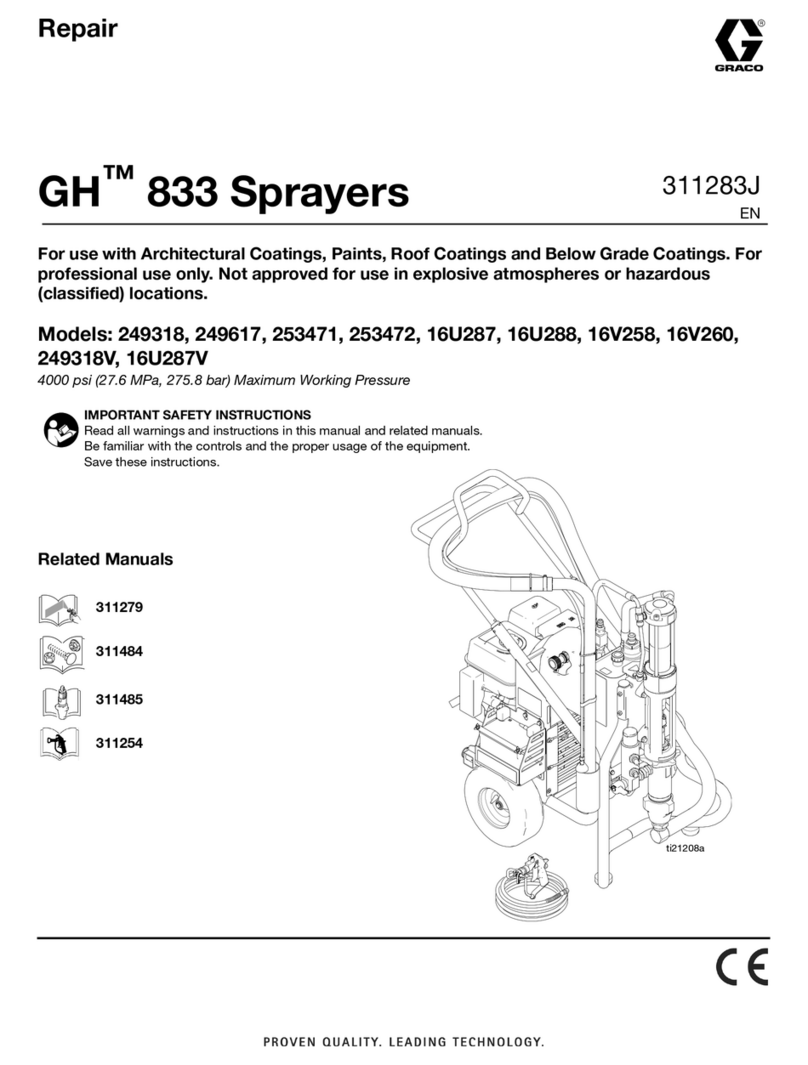

Graco

Graco 17C301 Guide

Graco

Graco ED 250 User manual

Graco

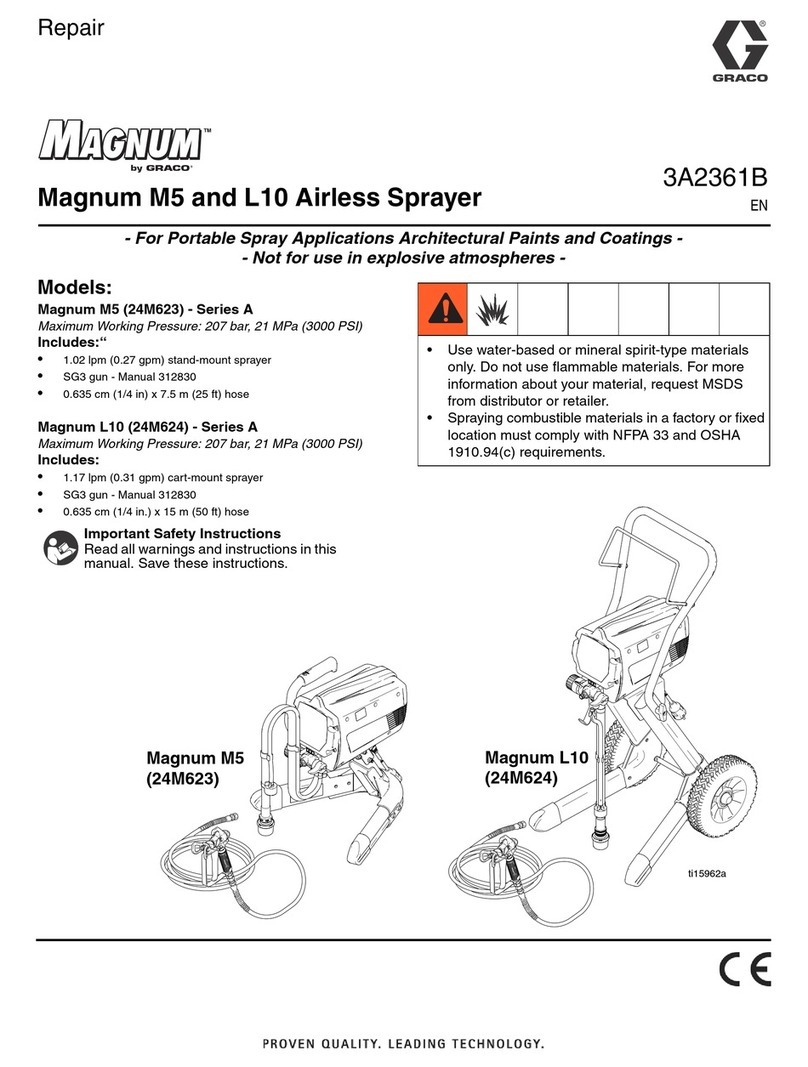

Graco 24M623 User manual

Graco

Graco C Series User manual

Graco

Graco 16U277 Instruction Manual

Graco

Graco Ultra Max II 695 Operation manual

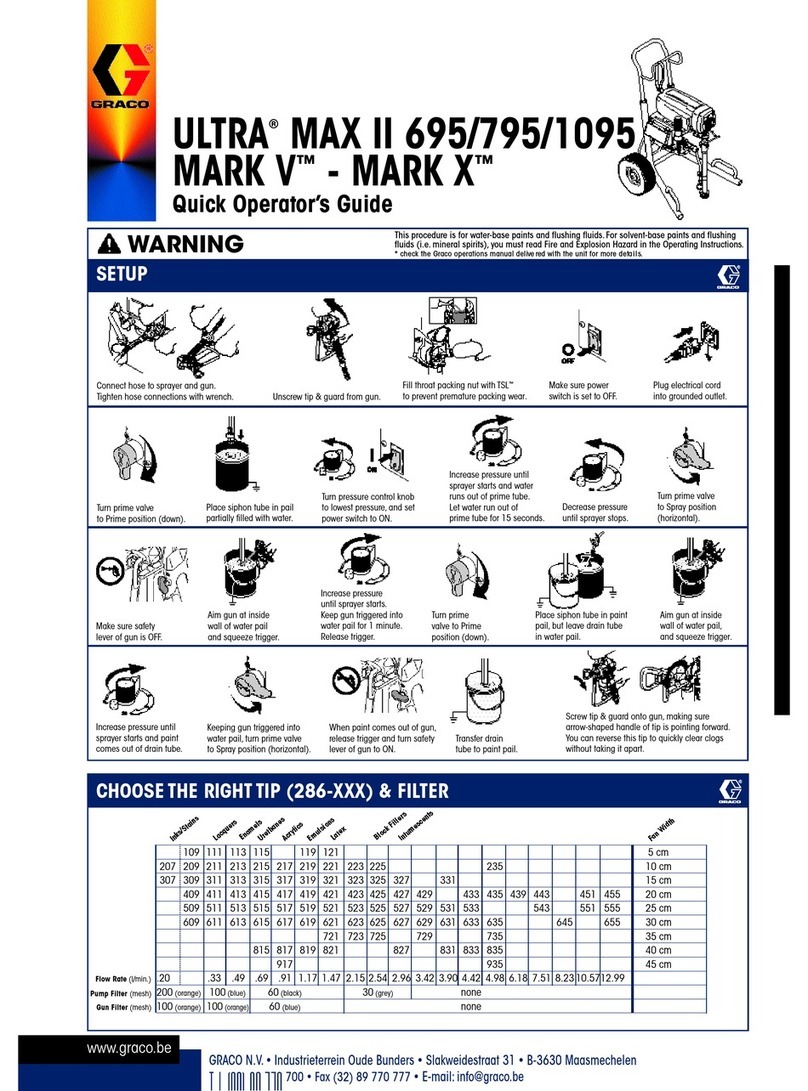

Graco

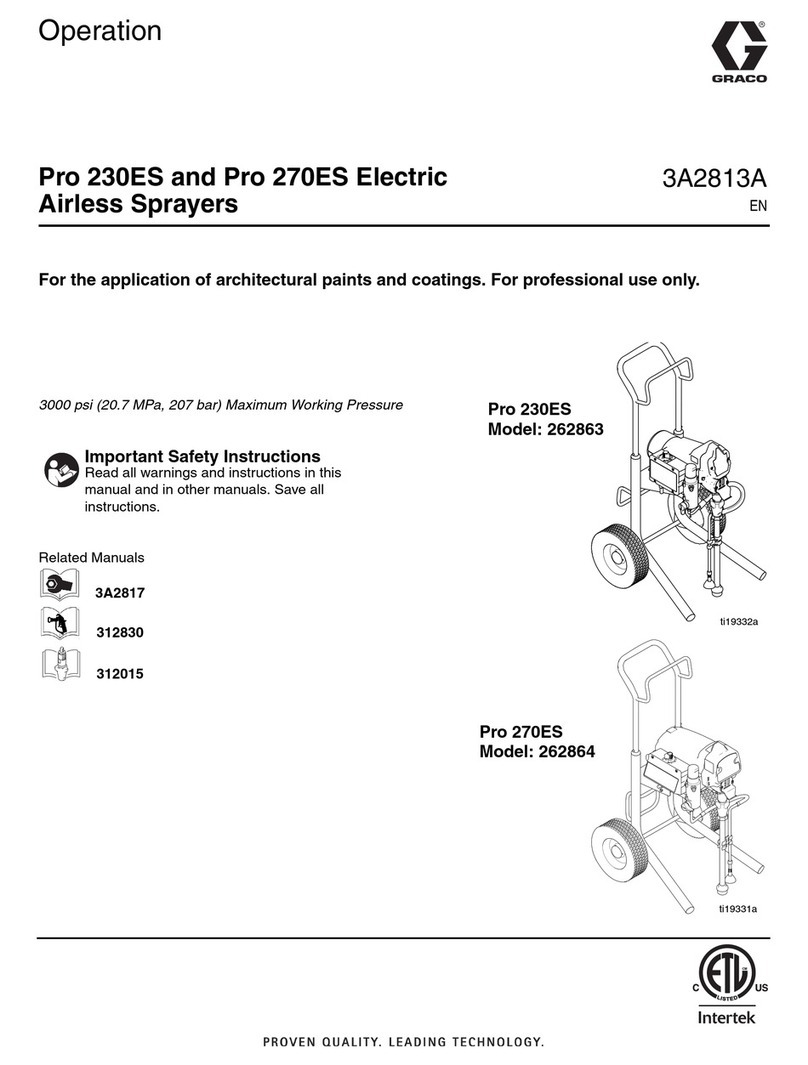

Graco Pro 230ES User manual

Graco

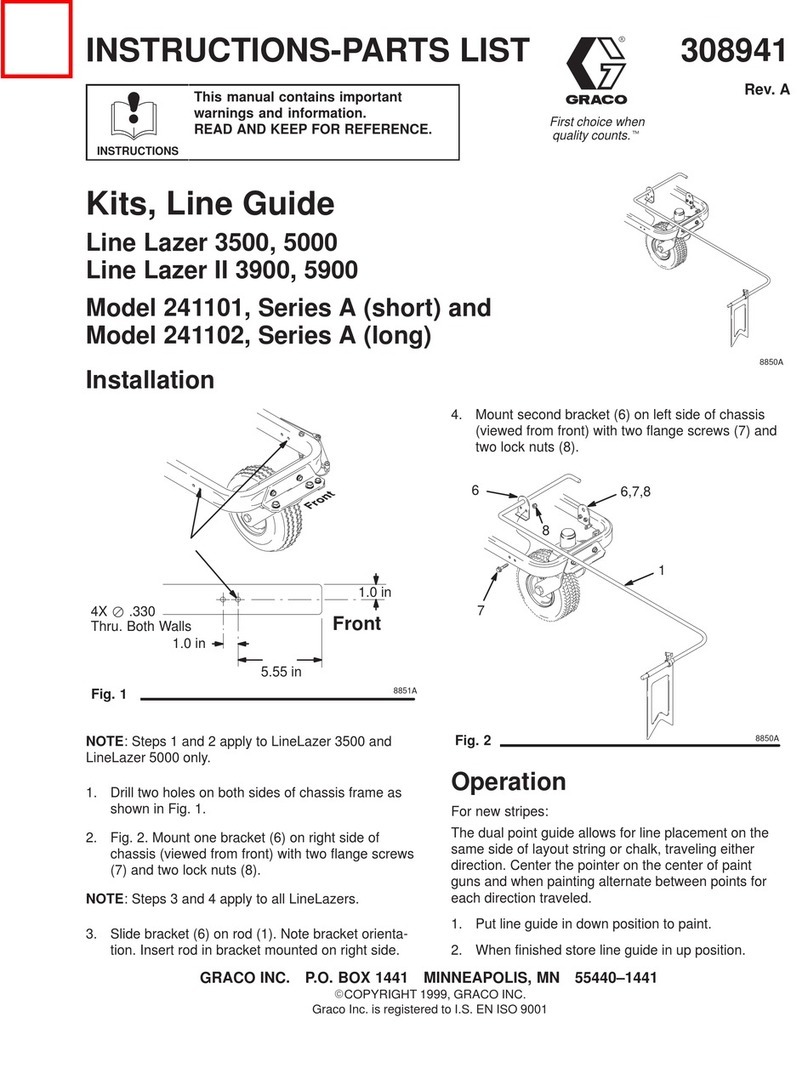

Graco Line Lazer 3500 Operation manual

Graco

Graco 307-896 Operation manual

Graco

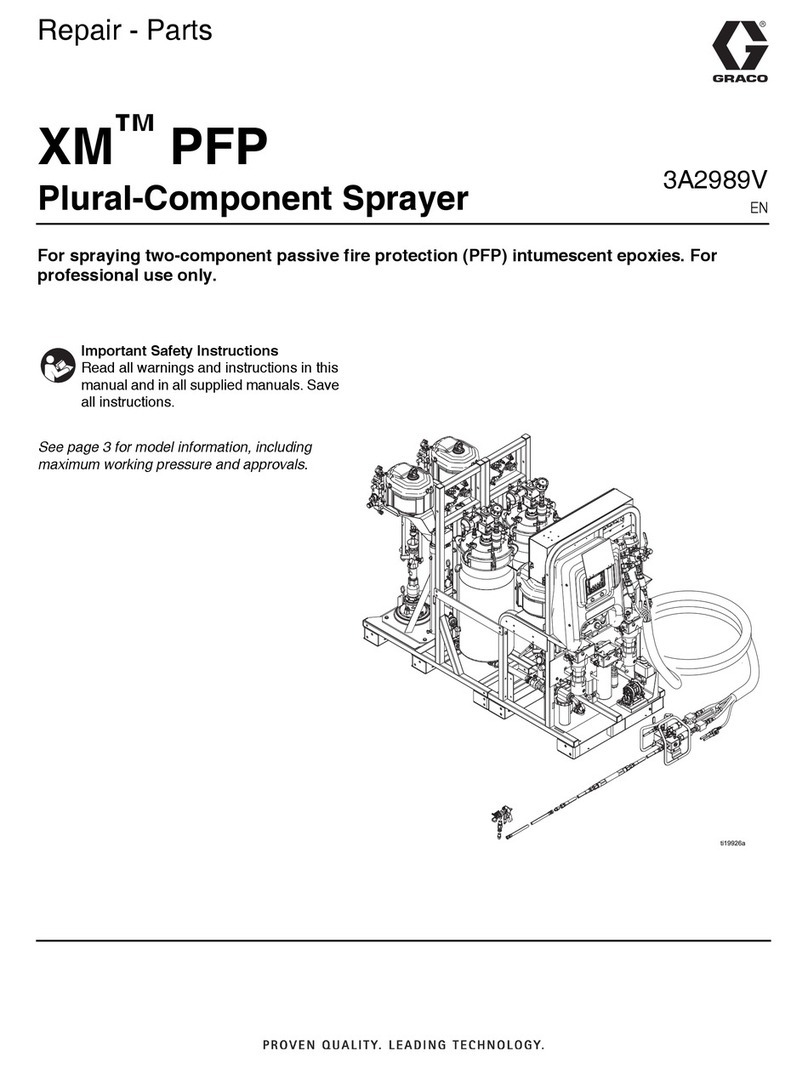

Graco XM PFP Use and care manual

Graco

Graco XP Guide

Graco

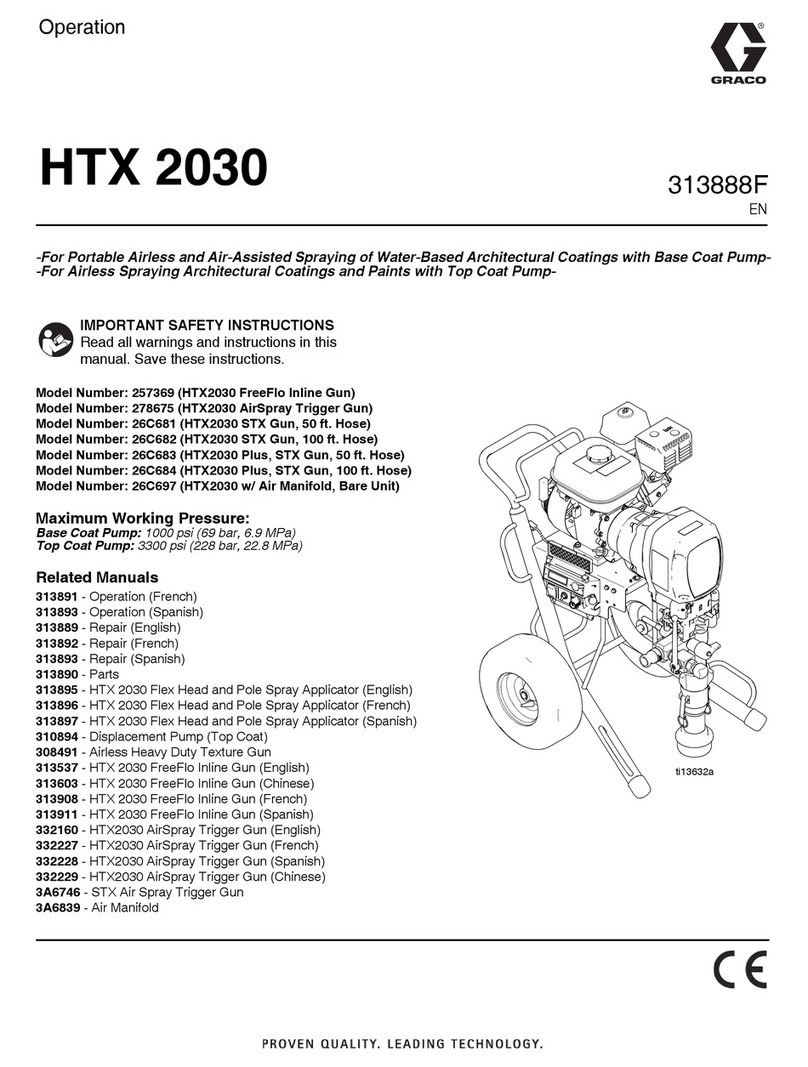

Graco 278675 Instruction Manual

Graco

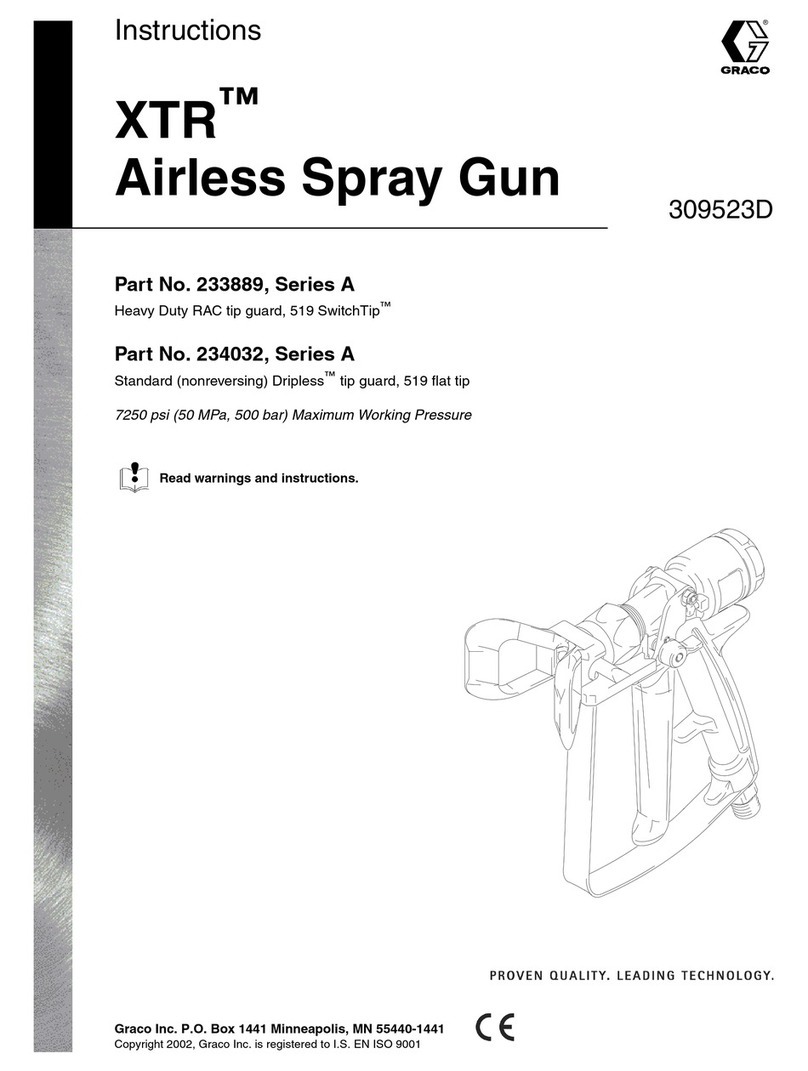

Graco XTR A Series User manual

Graco

Graco PT2500 User manual

Graco

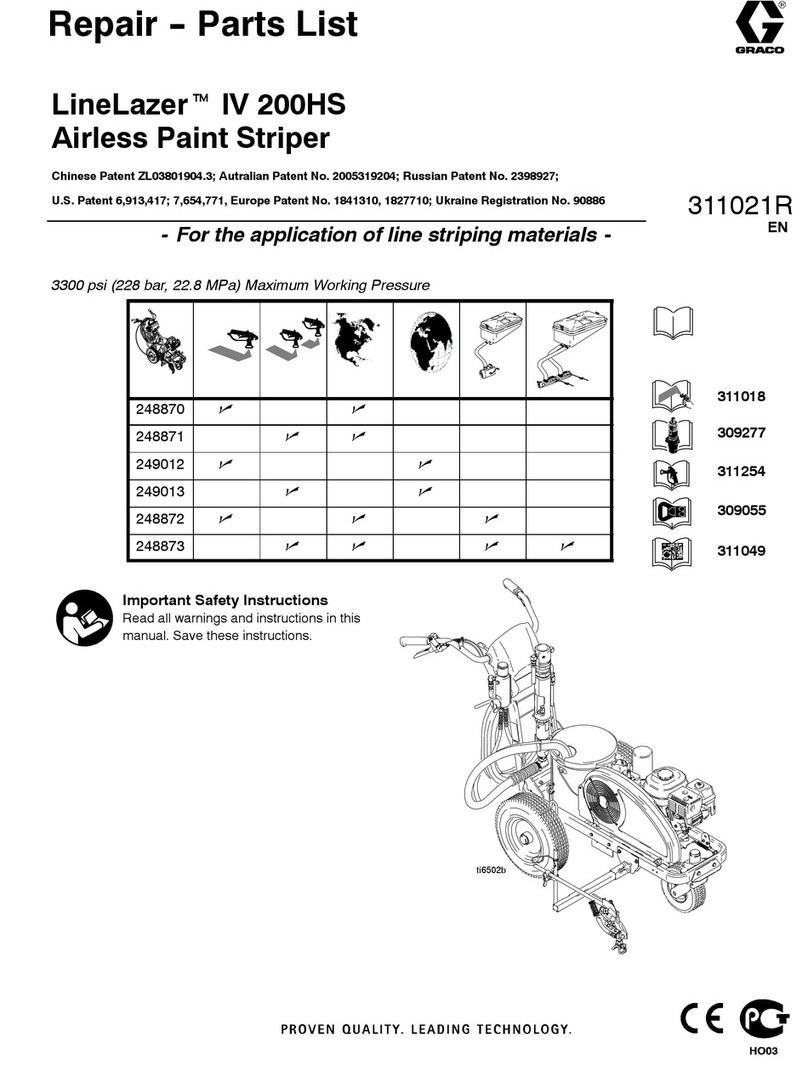

Graco LineLazer IV 200HS Use and care manual

Graco

Graco Pro Xp 3A2494D User manual

Graco

Graco 190ES 309063F Operating instructions

Graco

Graco 308-328 Operation manual

Graco

Graco 233889 User manual

Graco

Graco ultra max ii Operating instructions

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual