Beteze Isabelle User manual

open architecture systems

beteze.org

assembly instructions for a manual

press for compressed earth bricks

Isabelle

© 2017 BETEZÉ No rights reserved

the technology and the

necessary tools

project goals

about Betezé

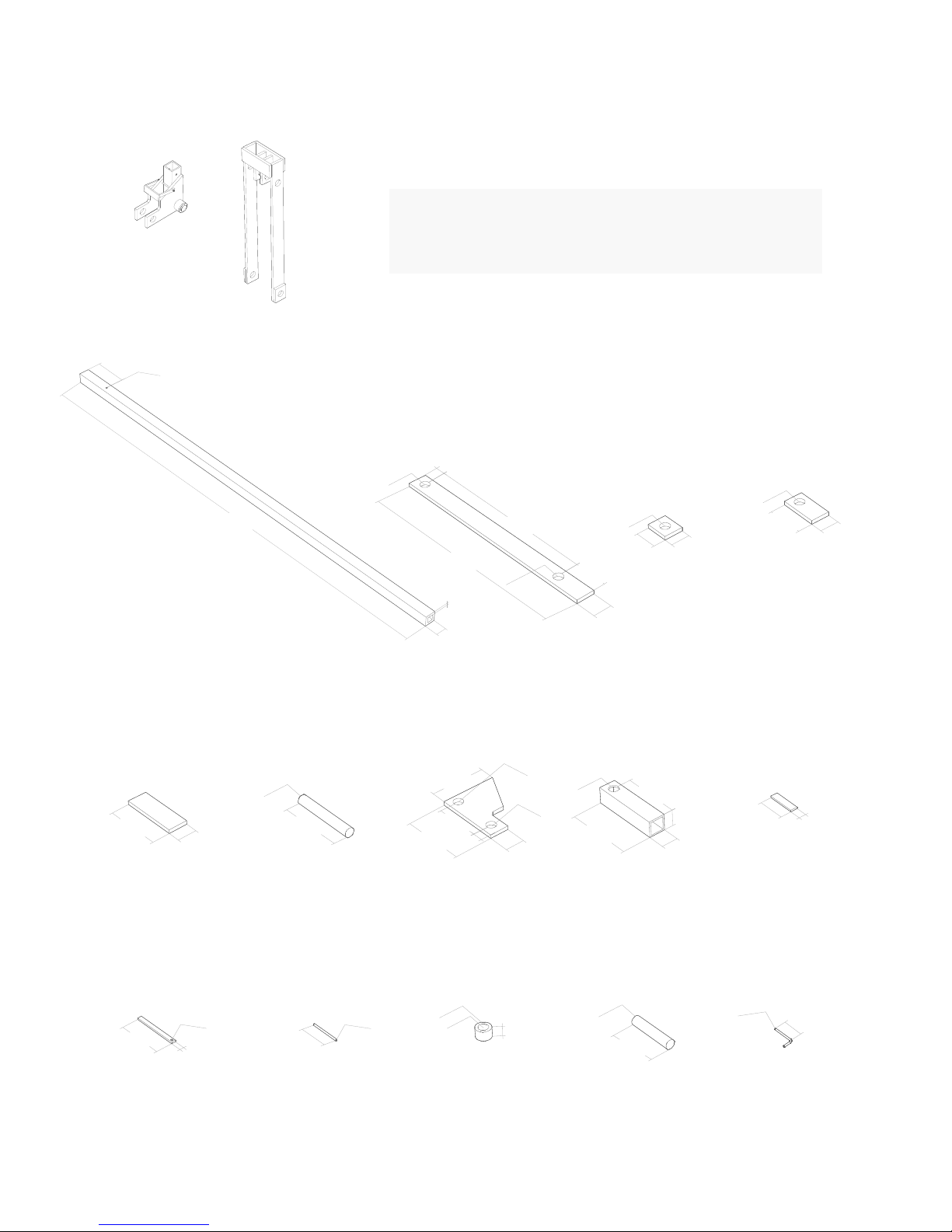

elements to assemble

structure

the reproduction of this machine requires some expertise in order to assure a

correct result. despite our efforts to simplify and optimize the designs we strongly

recommend only professional blacksmiths and welders take part in the the

assembling of the various pieces.

the material required to reproduce one of our machines are:

- band saw

- drill (up to 32mm)

- welding machine (or electrode)

- grinding machine with cutting discs and stone discs

we want to spread our knowledge on Compressed Earth Bricks (CEB) by distributing

assembling and usage manuals of different CEB machines. this distribution is to be

done for free! if you possess one of our manuals you will be able to assemble your

own proper press. make sure you read carefully all our annotations and follow the

instructions to assure the best possible results and to prevent you from taking any

risks.

with this press, which we named Isabelle, users will be able to make building bricks

290mm x 140mm by compressing a mix of sand, clay and (only if needed) some

lime, cement or other stabilizer.

we believe sharing knowledge is the best way of achieving an equitable development

in communities throughout the world and the cooperation between humans is

crucial for our growth as a society. it’s the way it should have always been.

to reach the final objective of reproducing the press Isabelle you will have to

produce 5 separate pieces to finally assemble them all together.

Isabelle is composed by

crank connecting

rod

piston

lid

+ + + + =

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

in the following pages you will find detailed 3D images of all the elements that conform

the different parts of the machine with accurate measurements so you can precisely

reproduce them in your own atelier with simple blacksmith and welding machinery.

we have decomposed the machine in order to make the assembling process easier

and more comprehensible. all measures are in millimetres (mm).

measurements

ALL PIECES MUST BE METICULOUSLY CUT IN ORDER TO ASSURE THE CORRECT

FUNCTIONING OF THE MACHINE

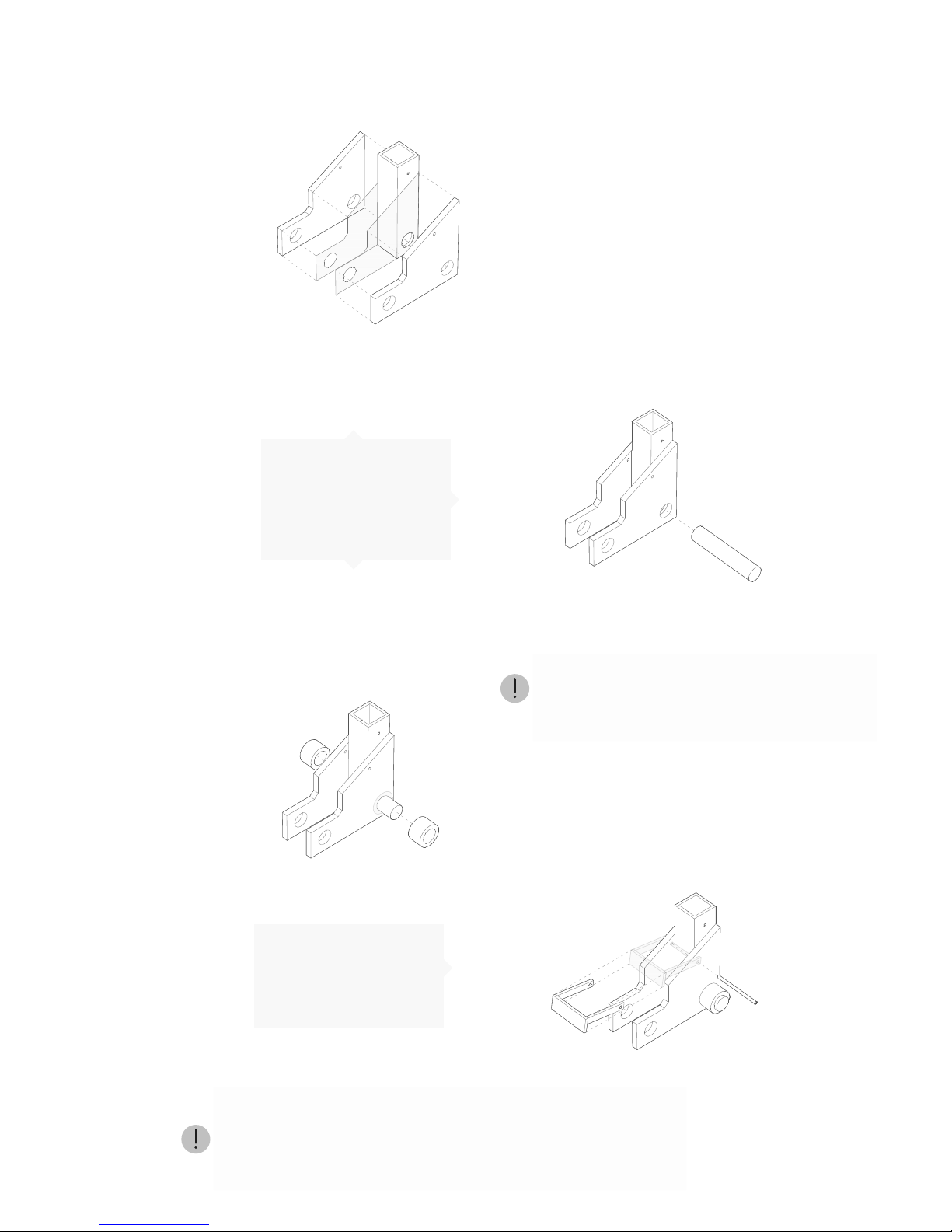

A_structure this piece is the machine’s skeleton and must be built with good

quality steel. pieces should be amongst the thickest of the whole

machine in order to resist the weight of the various parts that will

rest on it and the heavy compression process for the conformation

of the bricks.

A.1 x2

x2 x2 x1

x2 x2 x2

x1

A.3

A.6 A.7 A.8

A.5

A.4

A.2

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

pieces should have a thickness higher

than 5mm and thinner than 10mm

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

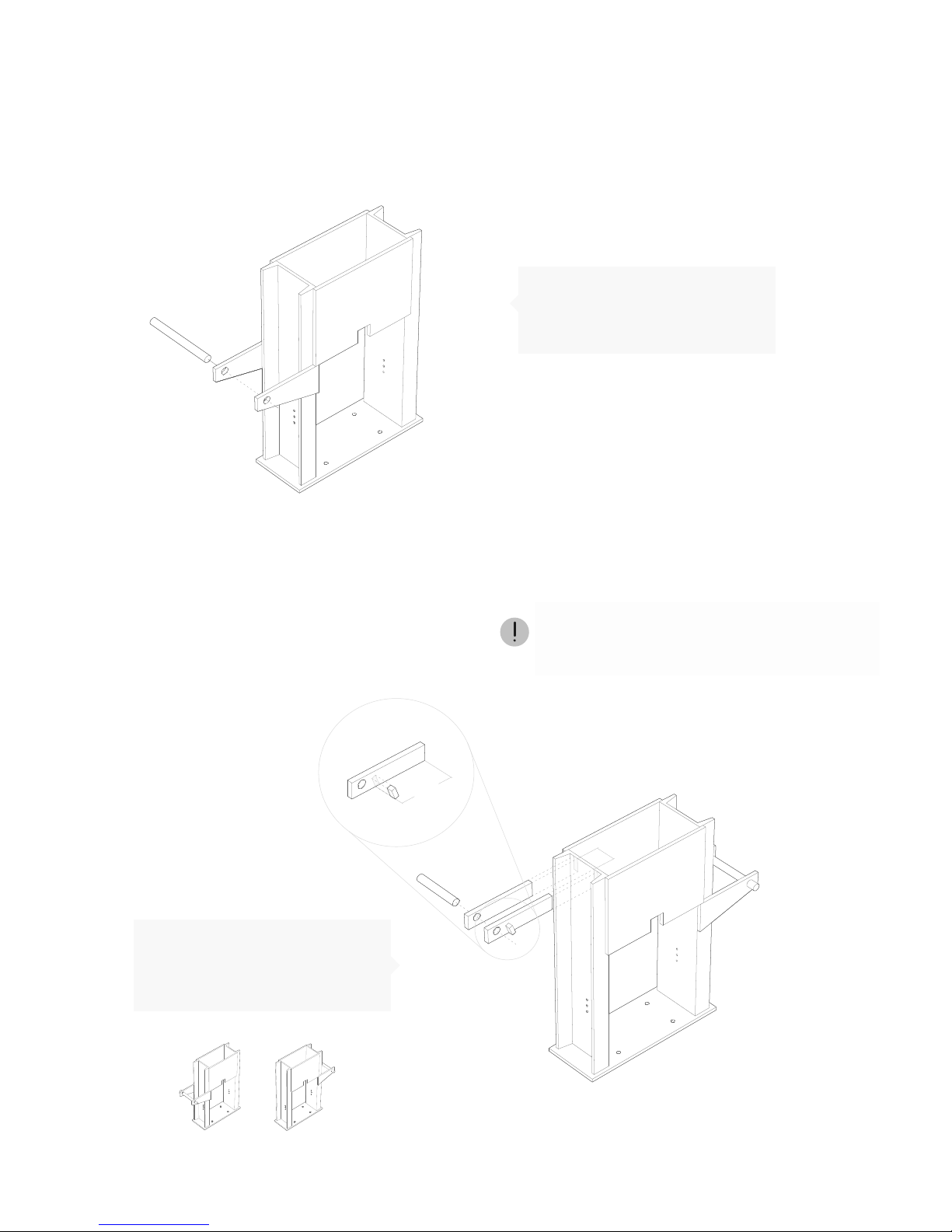

B_lid this part shall be resistant enough to bare hundreds

(actually thousands) of hits. make sure it won’t break any

time soon!

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

all pieces should have a thickness higher than 5mm

B.1

B.3 B.4 B.5

B.2x1

x2 x1 x1

x2

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

C_piston this piece is in charge of compressing the soil when the lever

is activated. It will undergo high compression and therefore it

has to be built according to all this measurements.

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

all pieces should have a thickness higher than 5mm

C.1

C.3 C.4

C.5 C.6

C.2x2

x1 x1

x1 x2

x2

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

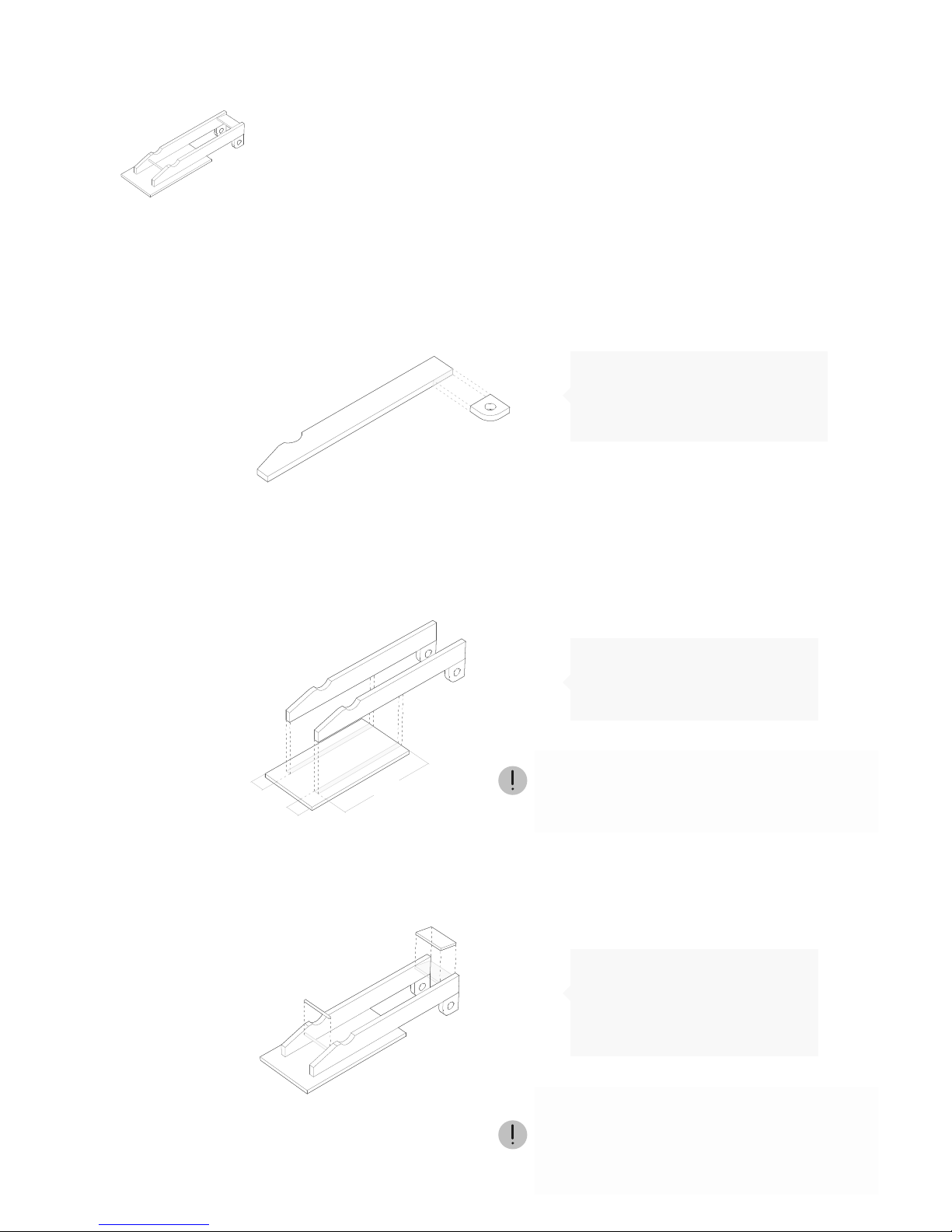

D_crank &

connecting rod

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

these pieces are in charge of transmitting the force applied

to the piston. therefore they’re designed to undergo heavy

traction forces.

all pieces should have a thickness higher than 5mm,

especially C.2 which, if possible should be 10mm

thick.

D.1 D.4

D.5 D.6 D.7 D.8 D.9

D.10 D.11 D.12 D.13 D.14

D.2 D.3x1 x2

x2 x1 x2 x1 x1

x2 x1 x2 x1 x1

x2 x2

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

200

192

41

167

756

64

112

608

32

64

64

126

64

66

188

210

220

64

190

230

196

56

94

60

90

15

105

160

32

251

130

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

32

Ø

50

Ø

32

Ø

32

Ø

32

Ø

25

Ø

152

240

310

135

40

135

40

90

30

20

30

10

50

75

80

50

50

50

460

50

352

306

160

270

290

270

130

290

140

90

25

25

290

25

25

110

51

30

40

195

15

6

Ø

6

Ø

6

Ø

40

1700

45

10

150

6

Ø

145

34

12

25

Ø

6

Ø

80

20

25

Ø

6

Ø

32

Ø

51

Ø

630

140

48

147

20

25

Ø

25

Ø

32

Ø

420

160

120

25

56

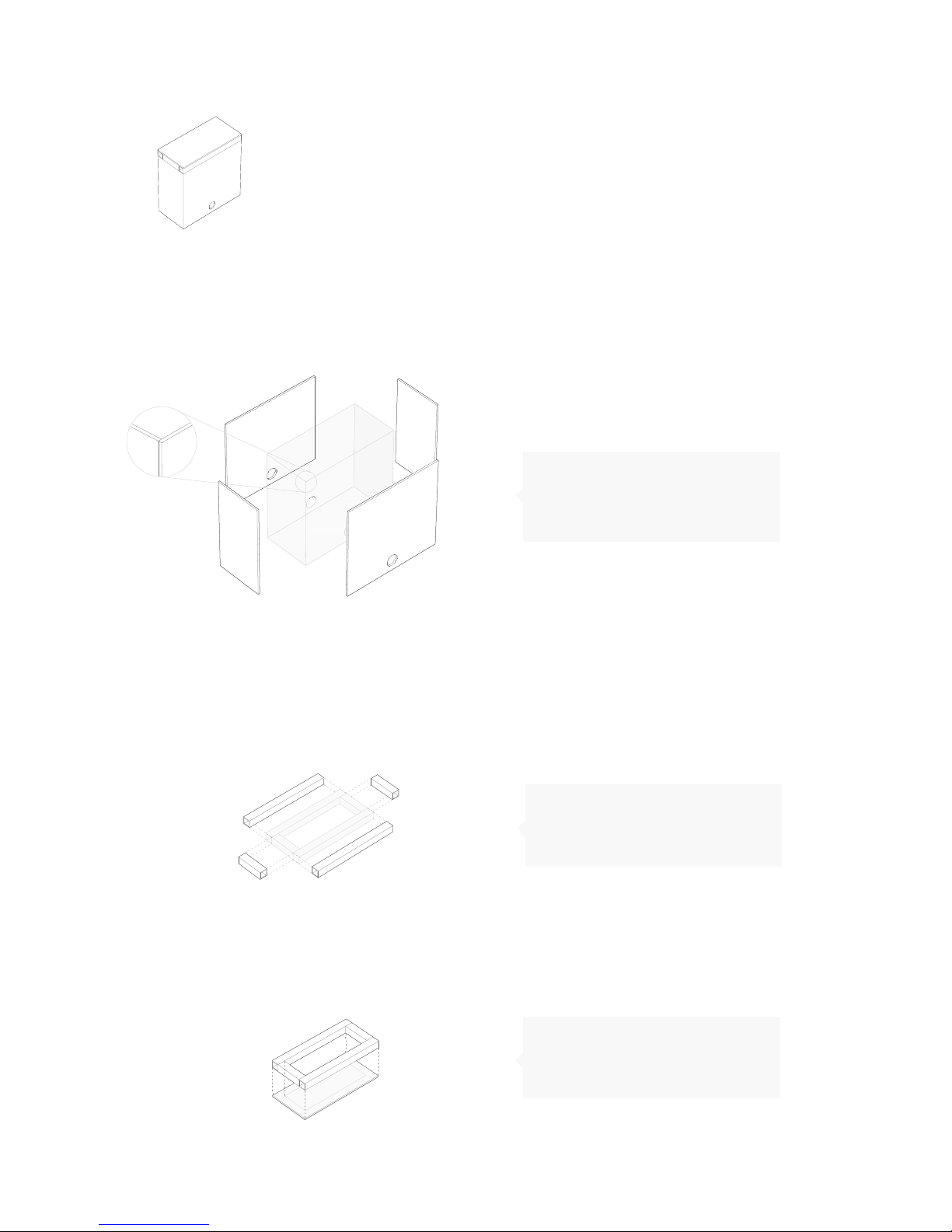

assemblage

ALL PIECES MUST BE METICULOUSLY ASSEMBLED IN ORDER TO ASSURE THE

CORRECT FUNCTIONING OF THE MACHINE

once you have faithfully reproduced the various elements that conform the machine

you will be able to start the assembling process detailed in the following pages.

dotted lines represent, schematically, the assembling movements and assembling

positions whilst grey ones indicate where the different pieces should be welded. all

measures are in millimetres (mm).

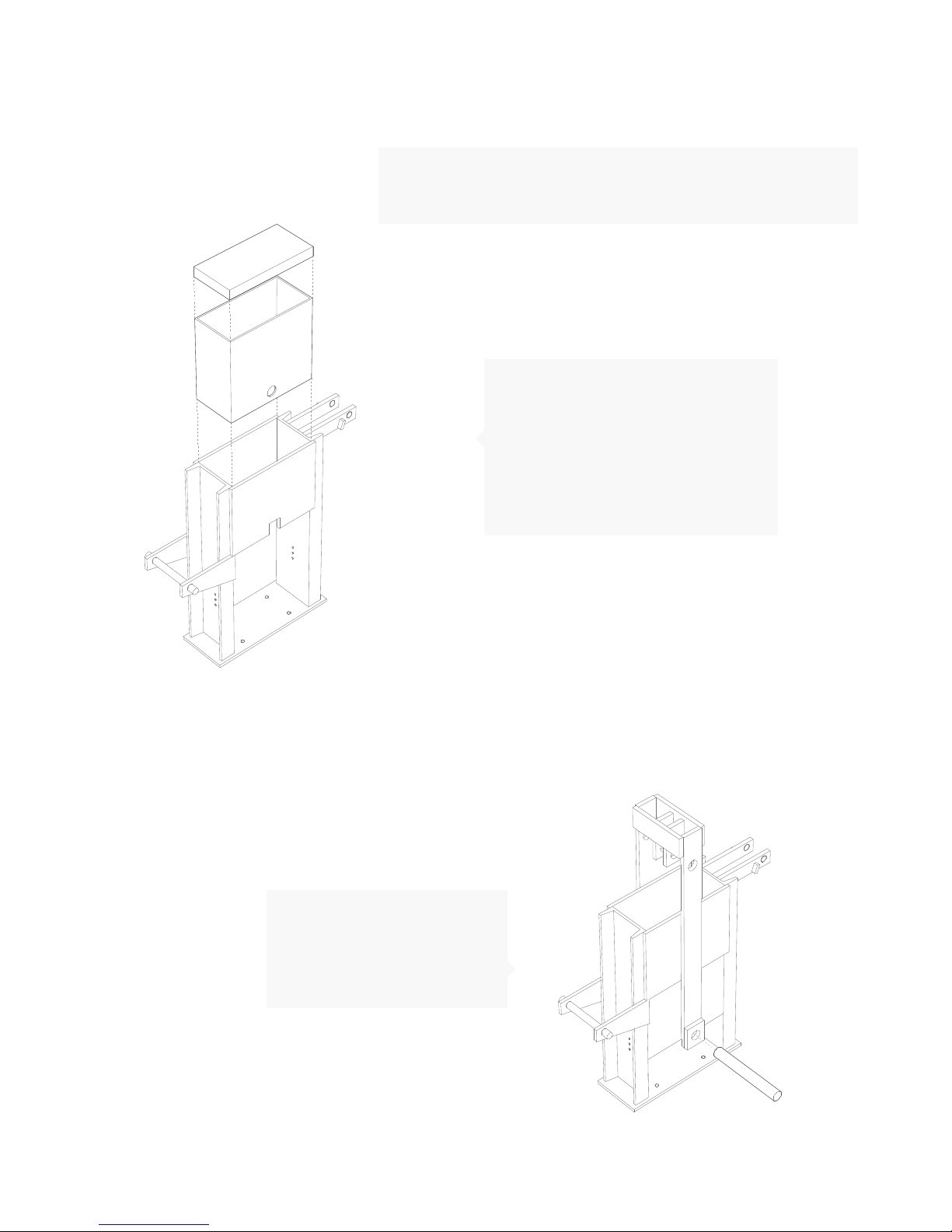

a_structure take into consideration that the piston will have to go up

and down very smoothly, so angles need to be perfectly

sharp and the structure walls completely perpendicular

to the base.

welding shall be done always on the outer part, leaving

the inside clear.

1 Weld pieces A.1, A.2 and A.3

making sure the pieces are well

centered to allow the piston to

move freely

2 add pieces A.4 to previous

step. pieces must be well aligned

to allow the correct insertion of

the correspondent rod as shown

on next step

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

3 insert rod A.5 and center it,

welding it to pieces A.4 around its

interior contact surface

4 add to structure pieces

conformed separately. make sure

they are aligned with the structure

NOTE: before welding to structure, join

together pieces A.6 and A.7

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

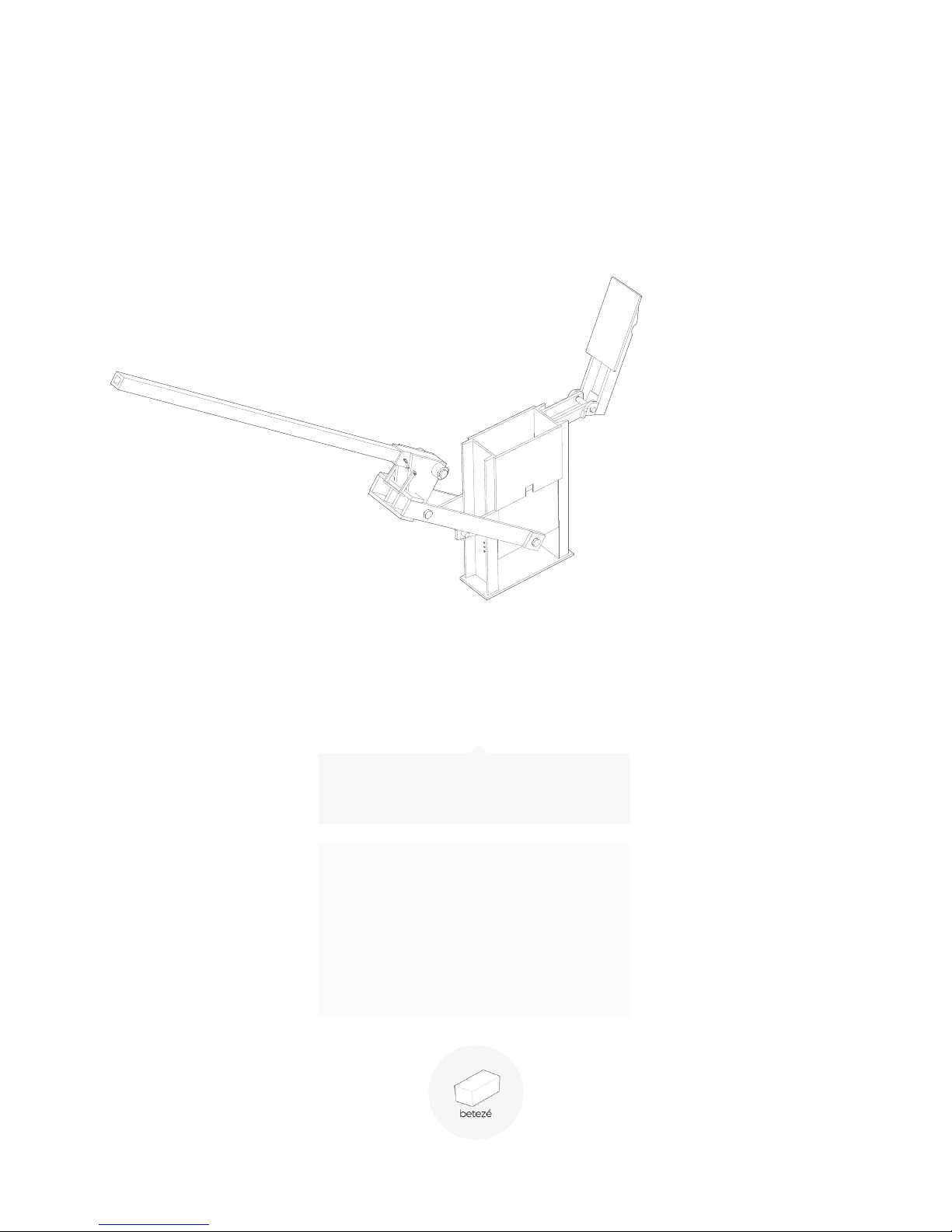

assemble the elements of the lid bearing in mind that it

will have to fit on top of the structure, and it should have

a smooth rotation. .

1 weld pieces E.2 and E.3

together ensuring they

describe a perfect 90º angle.

2 join pieces conformed in

previous step to piece B.1

3 Add pieces B.4 and B.5 to

strengthen the union and to

make the opening of the lid

easier

NOTE: pieces conformed in step 1 must be

completely parallel in order to allow the

lever to rotate correctly

NOTE: note: position the small rod to the

left of the indents, as shown in image. it

will help you to pull the lid whilst using the

machine.

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

b_lid

1 weld, as shown, pieces C.1

and C.2 following the detail

provided.

2 assemble pieces C.5 and

C.6 as shown

3 add to previous step pieces

A.3 ensuring they’re correctly

aligned

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

c_piston you are about to start probably the most critical stage of the

process so be warned to follow the instructions with extra

care. the most delicate step is ensuring all opposite sides are

parallel to each other.

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

1 Position pieces D.2 and

D.3 in their correct position

and completely parallel

2 weld, as shown, pieces

D.2, D.3, D.4 and D.5,ensuring

the holes are aligned amongst

them

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

d_crank &

connecting rod

make sure the vertical elements are situated in the correct

places and that they are perfectly parallel and vertical. if this

elements aren’t properly positioned it will limit the machine’s

performance by not letting the piston move up and down

resulting in the machine not functioning at all.

3 assemble pieces

D.7 and D.8, introduce

D.6 rod and then insert

pieces D.12 on both

sides

4 put together pieces

conformed in steps 5

and 6 by inserting D.11

through hole.

NOTE: weld to D.13. assure that whilst

welding both pieces can still rotate jointly

and severally.

NOTE: this piece will act as a safe that will be needed for the

machines correct functioning. weld piece from step 6 with

D.11 on its exterior contact suface. This element must have

freedom to rotate

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

130

MUNTATGE

BANCADA

BIEL·LA

PISTÓ

TAPA

30

170

57 57

260

39 39

58

290

291

1 assemble, as shown, structure,

piston and the piston’s cover.

before doing so, insert A.8 (x2) at any of

the holes done in the structure. this will

act as a stopper for the piston and also

will allow you to decide what amount

of compression you would like to apply

to the bricks

2 join rotating rod with the

piston through C.4 rod.

rest them on the structure.

it will make following steps

easier.

final

assembling

now that you have assembled all the different elements that

conform the Isabelle press it is time to put them all together in

order to be done with the process. The hard work is almost done

so take care during the following steps as they are still important

for the machine to function.

thoroughly daub the interior of the structure with dense car-oil

so the piston can easily slide up and down. this step will have be

repeated periodically during the usage of the machine.

3 join the crank to the rest

of the machine as shown on

image.

once put together, lock the

safe. this is very important for

to safety issues: if crank isn’t

secured, it can easily harm

people when manipulating

4 join lever with rest of

machine and pass D.14

through. this is another

important step to secure the

safety around the machine.

add the lid and pass B.5 rod

through to enable its rotation

now go enjoy your

Isabelle CEB press!

NOTE before adding any soil, make sure all

sliding and rotating elements are greased

and check if the machine moves correctly.

if any of the movements shows some

difficulties, check the machine manuals to

find the error.

if problems persist, do not hesitate to

contact us on our website.

www.beteze.org

Table of contents

Other Beteze Power Tools manuals

Popular Power Tools manuals by other brands

AEG

AEG POWERTOOLS BST 18 X Original instructions

Stiga

Stiga SCS 100 Li 20 S Operator's manual

Stanley

Stanley Genesis 07537 Instruction and service manual

Challenge Xtreme

Challenge Xtreme CSD36L.1 Original instructions

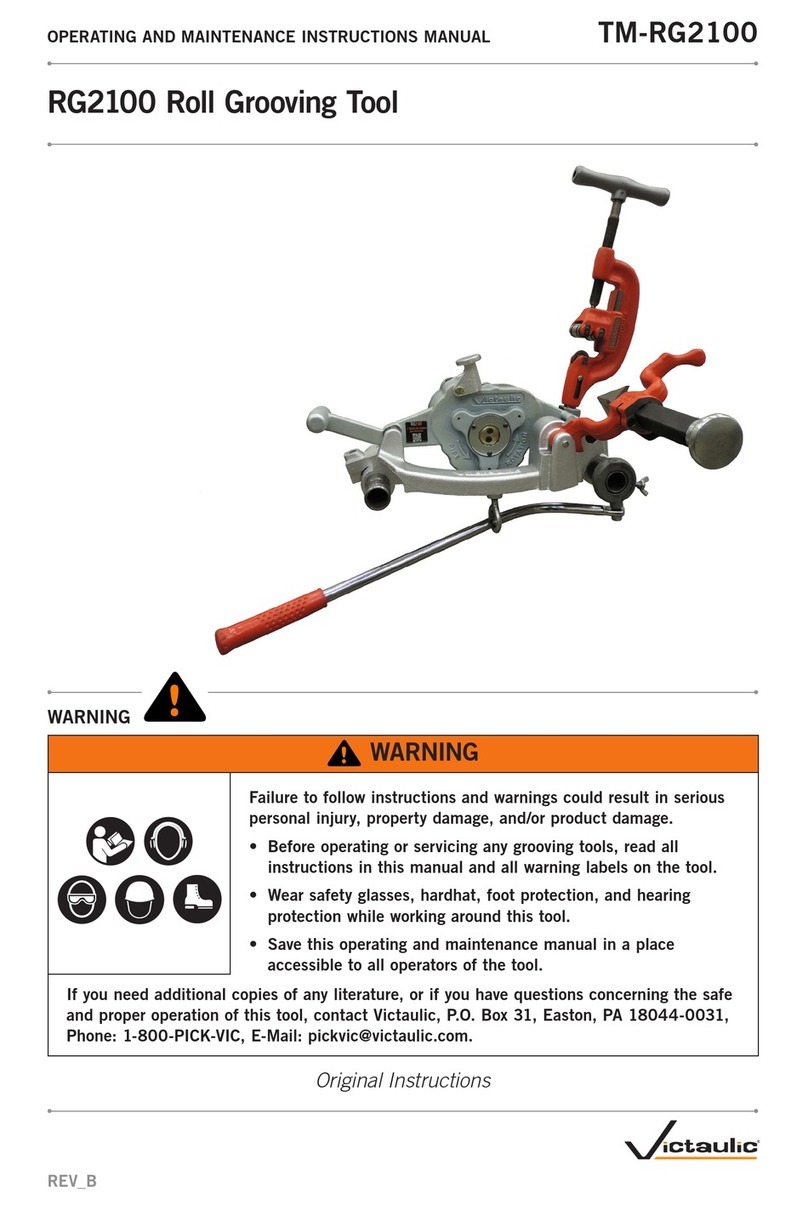

Victaulic

Victaulic RG2100 Operating and maintenance instructions

Husqvarna

Husqvarna Power Tools Price list

Crosby

Crosby IPH10 user manual

pellenc

pellenc FIXION 2 Translation of the original user guide

Atlas Copco

Atlas Copco EP7PTI55 HR10-MT Safety information

TorcUP

TorcUP TX LINK Series Maintenance Guide

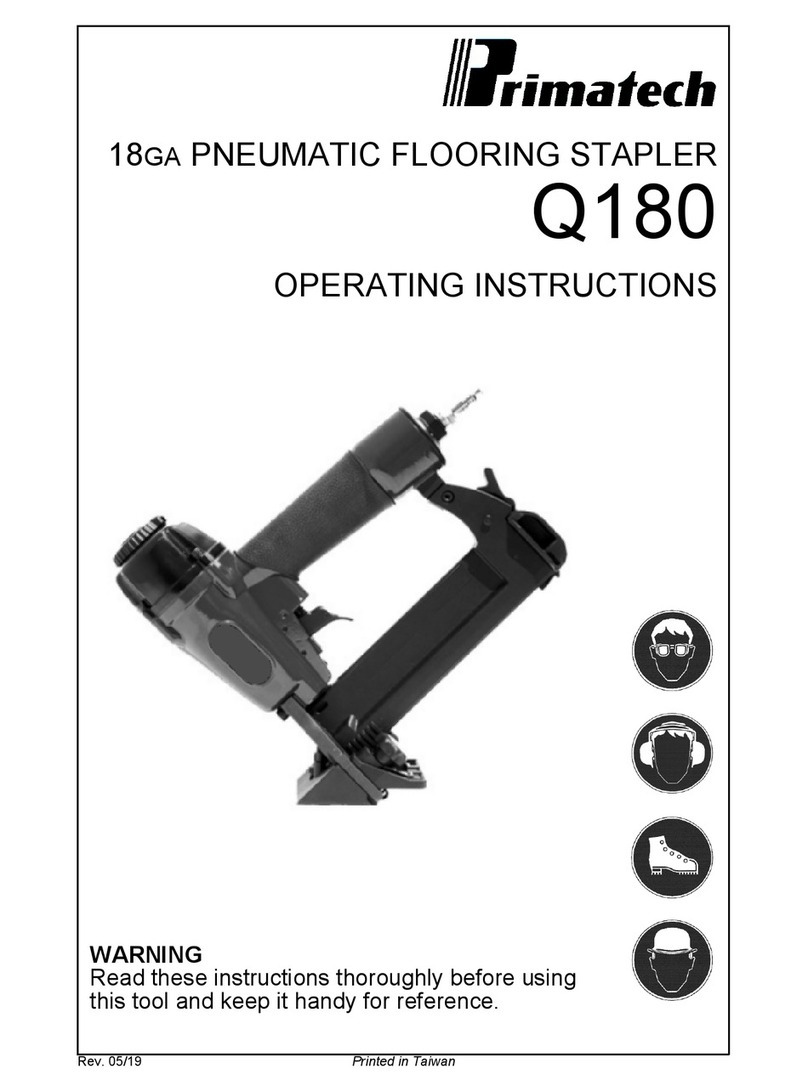

primatech

primatech Q180 operating instructions

XYZ Machine Tools

XYZ Machine Tools SMX 2500 Safety, installation, maintenance, service & parts list manual