Beton Trowel BTCS500 User manual

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

1/20

INSTRUCTION MANUEL

SLAB SAW

BTCS500

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

2/20

Use this guide along with the parts lists attached to locate and identify components of

your trowel. When ordering replacement parts, be sure to provide the model number

and serial number from the trowel.

Copyright

© Copyright 2011 by Beton Trowel.

Contact

BETON TROWEL

Nijverheidsstraat 11

1840 Londerzeel

BELGIUM

www.betontrowel.com

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

3/20

BETON TROWEL NV

Nijverheidsstraat 11

B-1840 Londerzeel

Declares that this product :

Floor Saw BTCS500

Chris Livingston

Managing Director

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

4/20

Foreword

Quality assurance / machine break in

The machine is the product of extensive engineering development designed to give long life

and unmatched performance. The trowels are shipped fully assembled, and only require

filling with fuel and a brief check of lubricant levels in preparation for operation.

You can help ensure that your trowel will perform at top levels by observing a simple routing

on first use. Consider that your new trowel is like a new car. Just as you would break in a

new car to the road or any new machine to the job, you should start gradually and build up to

full use. Learn what your machine can do and how it will respond. Refer to the engine

manufacturer’s manual for run-in times. Full throttle and control may be used after this time

period, as allowed by material. This will serve to further break in the machine on your specific

application, as well as provide you with additional practice using the machine.

We thank you for the confidence you have placed in us by purchasing a

Beton Trowel machine and wish you many years of satisfied use.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

5/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

6/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

7/20

2 General description of the BTCS500

Any modification, which could lead to a change in the original characteristics of the

machine,

may be done only by Saint-Gobain Abrasives S.A. who shall confirm that the machine is still

in

conformity with the safety regulations. Saint-Gobain Abrasives S.A. keeps the right of

making

technical or design modification without prior

notification.

2.1 Short description

The Floor Saw BTCS500 you have chosen, is used for small repair works in concrete and

asphalt,

for cutting induction loops and installing cables as well as for cutting expansion joints. It

can

be

used for either wet or dry cutting operations. Being of small construction, it can be

transported

in

a car or van. The water container is enclosed in the frame. All component parts on

the BTCS500

are

assembled to a high quality standard, ensuring long life, reliability and

a minimum

of

maintenance. Special types of blades are available for asphalt, green concrete,

cured

concrete

(reinforced or not) as well as for industrial cement

flooring.

Made of jig welded open profile steel, the BTCS500 is stable but at the same time,

easily transportable.

The one-piece blade guard fully protects the operator and his working environment. It

is

firmly fixed to the main frame but can be opened by rotation to change

blades.

A manually operated hand wheel mechanism enables graduated depth setting. Turning

the

hand wheel clockwise or anti-clockwise will lower or raise the cutting

blade.

The pivoting frame , hinged on the rear axle, is supporting the engine, the blade

shaft

assembly, and the protecting guards. Four heavy-duty belts drive the

blade.

The precisely manufactured blade shaft is fitted into two heavy-duty self-aligning pillow

block

bearings, including grease nipples. A four-belt taper lock pulley is fitted on one end. The

shaft

is

reduced to 25,4mm at the other end, allowing an inner flange complete with dowel

pinholes

to

be

fixed.

The steel belt guard is bolted to the mainframe of the machine. It is covering the four

drive

belts and pulleys for protection of the environment while the machine is running. The pointer

allows the operator to make precise cut

easily.

The Honda GX390 engine is connected to an emergency shut down switch on the

board

of

the machine. This allows an immediate stop of the machine in case of danger. The

water

cooling system is composed of a 70 litres water tank, a water tank tap and two water

nozzles

on the blade guard ensuring adequate flow of water to both sides of the

blade.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

8/20

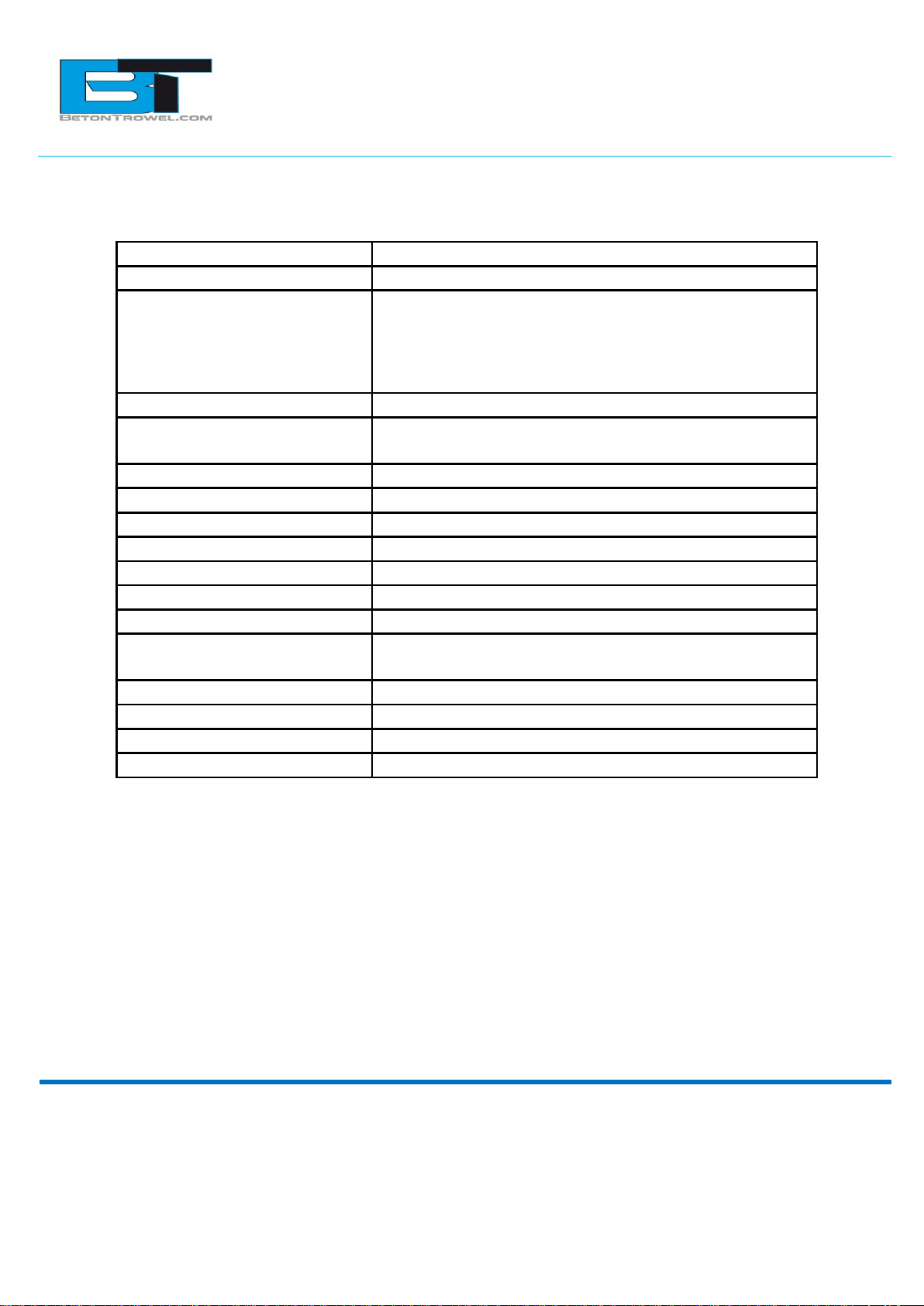

2.3 Technical data

Engine

Honda GX390, 4 strokes, 1 cylinder, 13HP

(9,6kW)

Fuel

Automotive unleaded gasoline

Oil

Honda 4-Stroke, or equivalent high detergent, premium quali

t

y

motor oil certified to meet or exceed U.S. au

t

omobile

manufacturer’s requirement for service classification SG, SF. (SG

,

SF designated on the oil con

t

ainer)

.

SAE 10W-30 recommended

Starter

Manual pull

chord

Air

filter

Dual type (machine type 99277, 99556, 99557, and

99558)

Cyclone type (machine type

99939)

Max. blade

diameter

500

mm

Bore

25,4

mm

Max. cutting depth

mm

190

mm

Flange

diameter

115

mm

Blade shaft

speed

2600

min

-1

Driving

belts

4

Water

tank

70

l

Machine

dimensions

(length x width x

height)

1088x580x925mm

Weight

140

kg

Max. operating

weight

220

kg

Sound pressure

level

89 dB (A) following ISO EN

11201

Sound energy

level

105 dB (A) following ISO EN

3744

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

9/20

3 Assembly and commissioning

Before beginning the work with the BTCS500, you have to assemble some

parts.

3.1 Tool assembly

Only use professional blades with the BTCS500

.

A blade with a maximum diameter of 500 mm can be fitted. All tools used must be selected

with

regard to their maximum permitted cutting speed for the machine’s maximum permitted

rotation

speed.

Before mounting a new blade, switch the machine

off.

To mount a new blade, follow these

steps:

Turn the wheel until the cutting head is in the raised

position.

Loosen the screw maintaining the blade guard with the 19mm wrench, and turn it

open.

Loosen the hexagonal nut, which holds the removable outer flange with the 36mm

wrench.

Remove the outer

flange.

Clean the flanges and blade shaft and inspect for

wear.

Mount the blade on the shaft ensuring that direction of rotation is correct. Wrong direction

of

rotation blunts the blade

quickly.

Replace outer blade

flange.

Tighten hexagonal nut with spanner supplied for this

purpose.

Close the blade

guard.

The blade bore must correspond exactly to the blade shaft. Cracked or damaged bore

is

dangerous for the operator and for the

machine.

3.2 Water cooling system

Fill the water tank with clean

water.

Open water-tap (note that handle on water-tap should be in line with

water-flow).

Ensure that water is flowing freely in the circuit and delivered adequately to both sides of

the

blade, as insufficient water supply may result in premature failure of the diamond

blade.

In case of frost, empty the water cooling

system

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

10/20

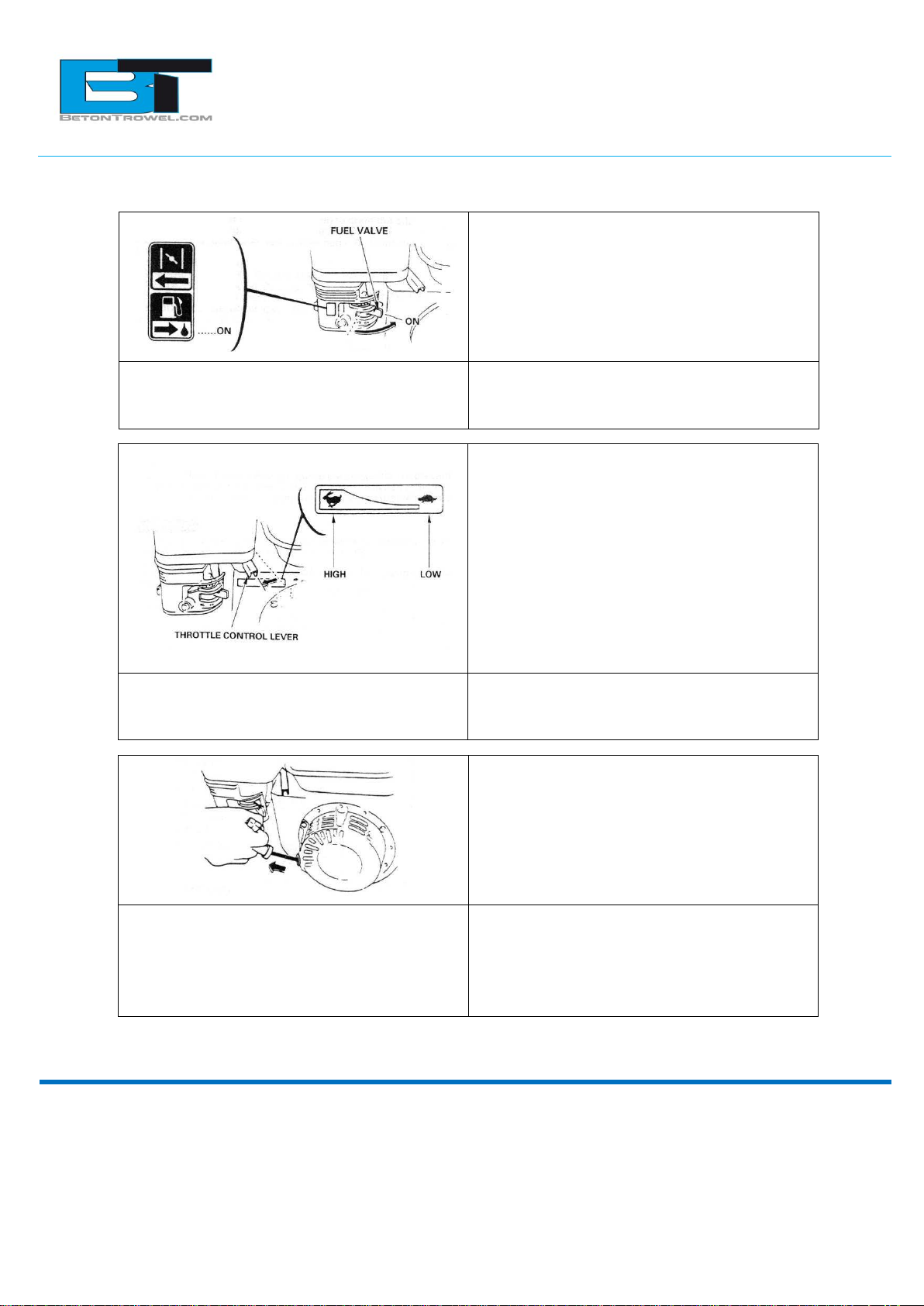

3.3 Starting the machine

Make sure the blade is raised clear up the ground before starting the

machine.

Turn the fuel valve to the ON

position.

Move the choke lever to the CLOSED

position.

NOTE: do not use the choke if the engine

is

warm or the air temperature is

high.

Move the throttle control lever slightly to

the

left.

Put the engine switch on ON, and make

sure

the emergency switch on the board of

the

machine is in the correct

position.

Pull the starter grip lightly until you

feel

resistance, then pull

briskly.

CAUTION: Do not allow the starter grip to

snap

back against the engine. Return it gently

to

prevent damage to the

starter.

As the engine warms up, gradually move

the

choke lever to the OPEN

position.

Position the throttle control lever for

the

maximum engine

speed.

To stop the engine, move the throttle control lever fully to the right, then turn the engine

switch

to

the OFF position. Turn the fuel valve to the OFF

position

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

11/20

4 Transport and Storing

Take the following measures in order to transport and store the BTCS500

securely

4.1 Securing for transport

Before transporting the

machine:

Remove the

blade.

Empty the water

tank.

Raise the guide-a-cut in its upright

position.

Raise the cutting frame to its highest position using the

handwheel.

4.2 Transport procedure

The machine can be moved on a flat surface using its wheels. Use the metal hook located

on

the board of the machine over the motor to move the machine with a

crane.

4.3 Long period of inactivity

If the machine is not going to be used for a long period, please take the following

measures:

Completely clean the

machine.

Loosen the drive

belts. Grease

the threaded

shaft.

Possibly

change the motor

oil.

Empty

the water

system.

The storage site must be clean, dry and at a constant

temperature

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

12/20

5 Operating the BTCS500

5.1 Site of work

Before you start working, please check the following

points:

Remove from the site anything, which might hinder the working

procedure.

Make sure the site is sufficiently well

lit.

Make sure you have a continual adequate view of the working area so you can intervene

in

the working process at any

time.

Keep other staff out of the area, so you can work

securely.

5.2 Cutting method

5.2.1 Preparing your

cut

Before starting the

machine,

Draw a line on the floor over the cutting

length.

Make sure you have filled the engine tank with fuel, and the water tank with water. No

petrol

is supplied with the

machine.

The engine is shipped with oil. Check oil level before starting. Top up if

required.

Make sure you have mounted the correct blade as recommended by the

manufacturer

depending on the material to be worked, the working procedure (dry or wet cut) to be

carried

out, and the efficiency

required.

Make sure that the flanges securely hold the diamond

blade.

Make sure that the blade is not touching the floor before

starting.

Roll the machine until the blade is over the

line.

Lower the guide-a-cut so it touches the

line.

5.2.2 Cutting the

floor

You can now start the

engine.

To make your

cut,

Turn the depth hand wheel until the blade slightly touches the

floor.

Open water valve to control the amount of water required for the type of blade, using 15

to

25l/min for wet and 1-2l/min for dry cutting, dust control. Check for minimum water

level

regularly.

turn the hand wheel to lower blade into the

cut.

Once the required depth of cut is reached, push the machine forward with steady and

gentle

pressure and follow the line with the pointer. The feed speed must be adjusted

depending

on the material being cut, and depth of

cut.

At the finish of the cut, raise the blade out of the cut by turning the hand wheel, switch

off

the

engine and shut-off the

water

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

13/20

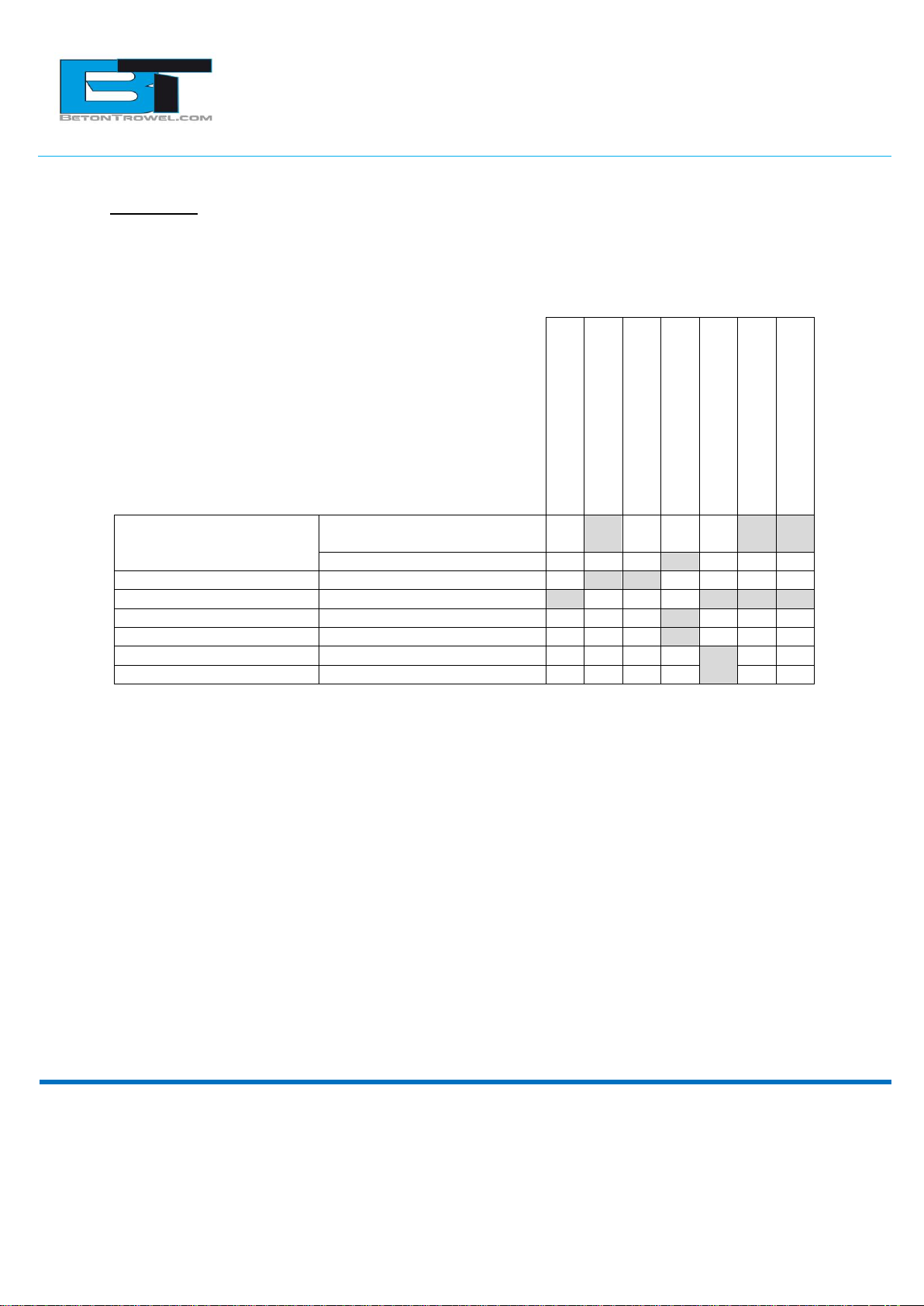

After one hour of work

Begin of the day

During the changing of the tool

End of the day

Every week

After a fault

After a damage

Whole machine

Visual control (general aspect,

watertightness)

Clean

Flange and blade fixing devices

Clean

Belts tension

Control

Water hoses and nozzles

Clean

Depth screw

Grease

Engine housing

Clean

Reachable nuts and screws

Tighten up

6 Maintenance and service

ATTENTION : to perform maintenance on the machine, always switch it off. Always wear a

face

mask and safety goggles while performing the maintenance of

machine

6.1 Maintenance of the machine

To ensure a long-term quality from the cutting with the BTCS500, please follow the

maintenance

plan below:

Adjustment and replacement of the

belts

After one hour of work, the belts heat and stretch. Therefore, you have to re-tension

them.

To adjust the belts, firstly remove the belt guard by unscrewing the 2 nuts. Loose the 2 bolts

at

the back of the engine-plate and shift the engine by using the screw on the back of the plate

to

retighten the

belts.

To replace the belts, move the engine completely down by unscrewing the screw at the back

of

the engine-plate. Adjust the belts and retighten them using the screw at the back of the

engine plate.

Always use a matched set of belts. Do not replace single belts. After controlling or

retightening

the belts, reassemble the belt guard on the frame of the

machine.

Lubrication

The BTCS500 uses life-lubricated bearings. Therefore, you don’t need to lubricate

them at

all.

Grease the depth screw every

day.

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

14/20

Cleaning of the

machine

Your machine will last longer if you clean it thoroughly after each day of

work

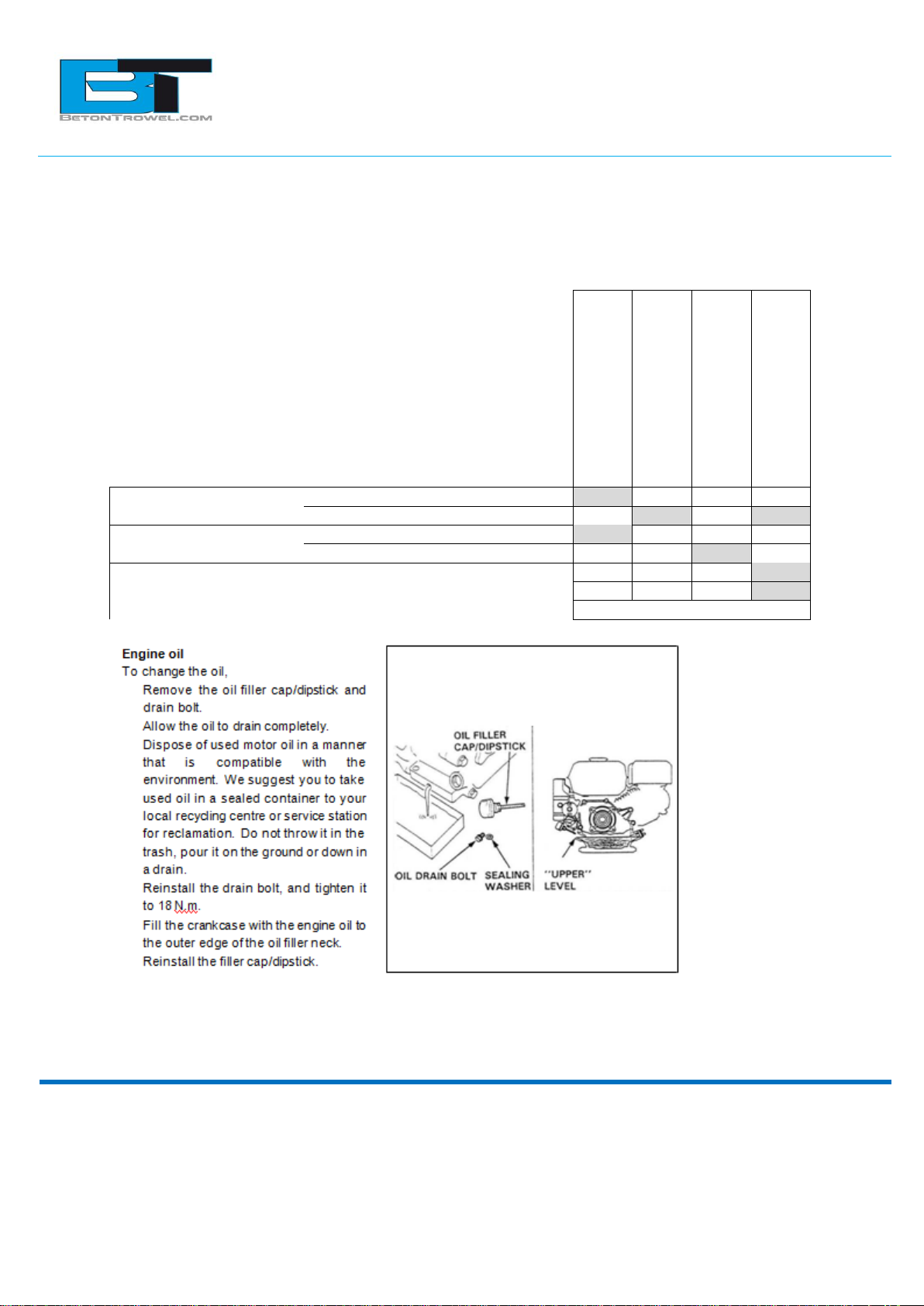

6.2 Maintenance of the engine

Each use

First month or 20 hours

Every 3 months or 50 hours

Every 6 months or 100 hours

Engine oil

Check level

Change

Air cleaner filter

Check

Clean

Fuel strainer cup Clean

Spark plug Check-Clean

Fuel line Check (Replace if necessary)

Every 2 years

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

15/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

16/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

17/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

18/20

8. PARTS

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

19/20

Beton Trowel nv

Nijverheidsstraat 11

1840 Londerzeel/Belgium

Tel: +32 (0)52 315 350 - Tel: +32 (0)52 315 351

Fax: +32 (0)52 303 739

E-mail: info@betontrowel.com

BE 0821.249.312

www.betontrowel.com

BNP FORTIS:

ING:

BE81 0015 9813 5624

BE

-

GEBABEBB

BBRUBEBB

Pag.

20/20

Table of contents