Betstco FHM FH-FFM Series Application guide

www. Betstco.com

541-895-3083 M-F 7am-4pm PST

83371 Melton Rd, Creswell OR 97426

FH-FFM Forestry Mulcher Series

GeneralSafety Informa�on

E

nsure all potenal operators read this manual thoroughly before using the machine

S

afety: Ensure tractor and machine is stopped & keys out of ignion before set-up/maintenance

S

afety: Failure to follow good safety standards could result in severe injury oreven death

M

isuse: This machine is designed for use with compact tractors, and should be used only for the

i

ndicated purpose. We do not take responsibility if the machine is used for any one

p

urpose. Children must not operate the machine under any circumstance.

M

odifica�on: Do not modify equipment in anv way. This may impair the operaon and overal

s

afety of the machine.

T

ractor requirements: Use only with compact tractors within power range specied.

M

isuse transport: Do not use machinery to transport personnel or livestock.

C

ondi�on: For the safety of personnel and opmum performance of the machine, you should

c

heck the condion of the machine and the tractor before starng. Before use check all nuts and

b

olts are ght.

S

pa�al awareness: Always check the operang area is safe before starng machinery.

O

perator clothing: The operator should not wear loose clothing while operang machinery.

S

afety wear: Always use appropriate ear protecon when running a tractor and machinery

E

nsure you are wearing protecve gloves when servicing and using machinery.

B

ystander safety: Ensure bystanders keep away from the machine when it is in use. Do not

t

ouch moving parts when the machine is at work.

P

ublic places: When traveling on the road/public places, always keep the PTO turned o

M

aintenance: Always keep the machine maintained and in a good state. Where necessary

r

epair or replace any defecve parts. Do not modify the machine.

S

harp objects: Pay aenon to the sharp/pointed parts while servicing the machine.

S

afety guards: All protecve parts should be in good condion before operang machinery.

S

afety signs/s�ckers: Keep all safety signs clean and legible. Replace anywhich are missing or

i

llegible. If a component with safety sign(s) is replaced, make sure new safety sign(s) are

a

ached in the same locaons.

O

pera�ng speeds: Machinery and PTO should be operated at the recommended speed at all

mes.

S

afety awareness: Good safety requires that you familiarise yourself with various safety signs,

t

he type of warning and the area, or parcular funcon related to that area.

A

lertness: Never consume alcohol or drugs these can hinder alertness/coordinaon. Consult

your doctor about using this machine while taking prescripon medicaons.

WARNING! WE SHIP ALL OUR MACHINES DRY. THIS IS A SAFTEY PRECAUTION

AND ALSO PREVENTS OIL OR GAS FROM LEAKING DURING TRANSPORTATION.

Machinery Pre-Use Checks

'brake in' period as we like to call it, we always recommend checking over the ma-

chine.

• Tighten/Check any bolts and nuts securing blades.

• If your machine has belts, check the tension and adjust the belts or the pulleys

necessary.

• Apply greese to greese points if necessary.

Tractor Pre-Use Checks

pins are used on the linkage mountaing pins.

• Be sure to add extra weights to the front of the tractor or add wheel weights if

required.

-

remove the key.

the tractor.

Running/Opera�ng Checks

-

ery.

Post-Use Regular Checks

• Check blades, belts and wearing parts. Be sure they are not damaged and blades

WARNING! WE SHIP ALL OUR MACHINES DRY. THIS IS A SAFTEY PRECAUTION

AND ALSO PREVENTS OIL OR GAS FROM LEAKING DURING TRANSPORTATION.

READ MANUAL BEFORE OPERATING

DO NOT OPERATE OR PERFORM MAINTENANCE ON YOUR

FORESTRY MULCHER WITHOUT READING AND

UNDERSTANDING THIS ENTIRE MANUAL FIRST.

IF THIS MANUAL IS LOST OR IFY OU HAVE ANY QUESTIONS,

CONTACT FARMER-HELPER OR YOUR DEALER BEFORE YOU

PROCEED.

Understand the written instructions, rules and safety precautions:

•The written instructions rules and safety precautions are outlined

in this operation and safety manual.

• Check the rules and regulations at your location. The rules

include employer’s work safety regulations and local government

guildelines and restrictions for safe operation of the equipment.

Perform application training with operator:

•Conduct feld instruction with a trained Operator. Application

training should include complete vehicle safety, operation

training, complete mulching safety and application training.

• Know and understand your work conditions; hazards should be

reviewed and terrain surveyed at this time as well as with all new

work sites.

• Verify that the machine is in complete safe working order and

prepared for your application.

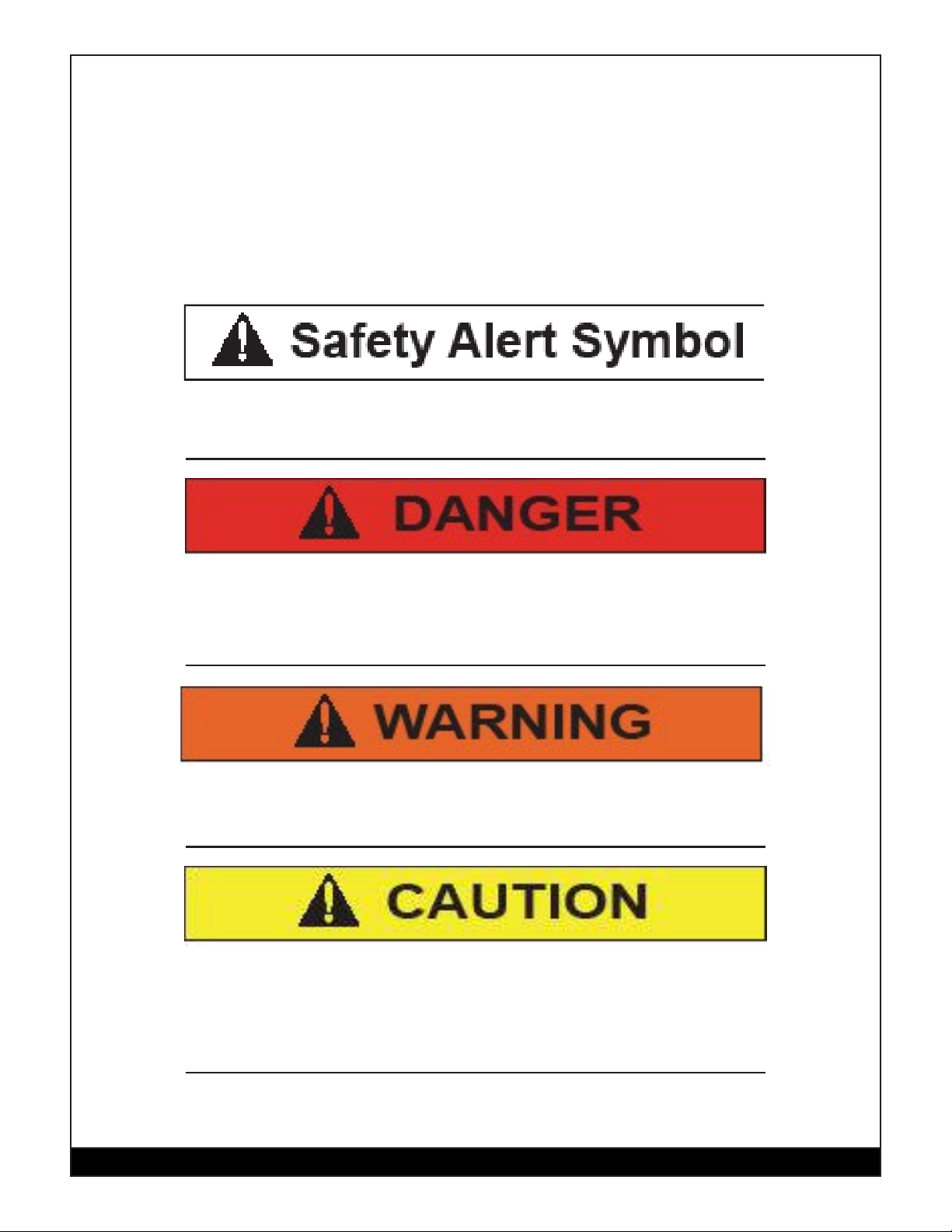

1. SAFETY

1.1 General

The forestry mulcher is designed to process heavy organic material

such as branches, stumps, heavy timber and brush.

1.2 Safety Instructions

This symbol is used throughout this manual to call attention

to safety procedures.

The word DANGER indicates an immediate hazardous

situation, which if not avoided, will result in death or serious

injury.

The word WARNING indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

The word CAUTION preceded with a safety alert symbol

indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

The word CAUTION without a safety alert symbol means

there is possiblity of a hazards that can result in equipment

damage.

Indicates information or a company policy that relates

directly or indirectly to the safety of personnel or protection

of property.

SAFETY FIRST

With any piece of equipment, new or used, the most

important part of its operation is SAFETY! FARMER-HELPER

Inc.

encourages you and your employees to familiarize

yourselves with your new equipment and to

STRESS SAFE OPERATION!!

Prior To Operation:

•Read the owner’s manual in its entirety and follow all safety

procedures.

•Check all grease points per the owner’s manual

•Inspect all fasteners for tightness with power off.

•Manually turn rotor to inspect tool bolts with engine off.

•Check gearbox oil (PTO models) for proper level per owner is

manual.

Obey all safety labels on the forestry mulcher. They are

provided for your protection. If any labels are removed,

damaged, or made unreadable in any way, call your FARMER-

HELPER dealer for a replacment.

1.3 Safety Regulations

Tag the engine operating area

to show that the machine is

being serviced. Use

lockout/tagout procedure

(29CFR 1910.147) during any

inspection or maintenance.

Stop action and read and

observe the operation and

safety manual in its entirety

following all safety

procedures before

operating or performing

maintenance.

Wait until all machine

components have completely

stopped before touching them.

Perform maintenance only

after the carrier has been

shut-off.

DO NOT EXIT CAB

while

rotor is still turning.

Danger fl ying objects; stay

back 300 ft (90m) from the

machine as long as the engine

is running.

Keep Safe Distance

Keep Hands and Feet clear of

rotor.

Hydraulic fl uid under

pressure. Use safe operating

procedures at all times.

Do not operate the Mulcher

without all guards in place.

Side and rear access panels

must be installed prior to

running.

Secure lifting cylinder with

locking device before getting

in hazardous area.

Insert safety lock before

getting in hazardous area.

Attach support before getting

into hazardous area.

Keep suffi cient distance

away from electrical power

lines.

1.4 FARMER-HELPER Forestry Mulcher – Description and

Applications

Forestry

Orchard Removal

Land Clearing

Transfer Stations

Stump Grinding

ROW Maintenance

Yard Waste Process

Forest Fire Prevention

Brush and Slash Piles

The versatile forestry mulcher was designed for shredding woody

materials. The forestry mulcher excels at processing yard waste,

land preparation and slash reduction. It has multiple uses for

farmers, parks, golf courses, loggers, land clearing companies,

ranchers, foresters and silvaculturists.

The mulchers fixed tools are designed to withstand daily brush

shredding, land clearing, and stump grinding operations.

The forestry mulch shreds material into a fine particle size by

going over the shredded material until the desired texture is

achieved.

If left on the ground the shredded material is beneficial to the soil.

On steep slopes the output from the mulcher is ideal for interim

erosion control.

1.5 Operational Safety The Work Area:

For the sake of this manual, the front of the mulcher is the side with

the rotor exposed. The rear has defection chains. For crawlers and

rubber tire machines, when the mulcher is mounted on the front of

the machine, the front of the mulcher is facing the same forward

direction. If mounted on the rear, the front of the mulcher is facing

away from the rear of the carrier. Mounting for excavators and

other boom-type installations may vary but references to the front

and rear of the mulcher remain the same

1.6 The Hazard Zone

FLYING DEBRIS OR OBJECTS AND FALLING OBJECTS CAN

CAUSE SERIOUS INJURY OR DEATH

Improper operation and failure to follow safety precautions

can cause serious injury or death. All personnel must be

clear of the hazard zone while the Mulcher is in operation.

The Hazard Zone is illustrated in Figure 1.1 on the following page. All

personnel should be kept clear of this zone while the mulcher is

operating.

The shaded area in the Hazard Zone must be considered OFF LIMITS

TO ALL INDIVIDUALS! The operator should follow the PRECAUTIONS

below before and during operation of the mulcher.

Hazard Zone Precautions

•It is the OPERATORS RESPONSIBILTY to ensure that NO ONE

ENTERS THE HAZARD ZONE!

WARN all persons in the area of the HAZARD ZONE

•STAY ALERT for outsiders entering the work area who may not

be aware of the HAZARD ZONE.

•Land clearing operations generally involve other machinery and

people on the site. MAINTAIN an AWARENESS of all working

traff c within 150 ft (45 m) (to each side) and 300 ft (90 m) (in

front and behind) of the Mulcher operation.

Figure 1.1

)ft (90 m300 300 ft (90 m)

Carrier

Mulcher

Excavator

300 ft (90 m)

300 ft (90 m)300 ft. (90 m)

ft (90 m)300

1.7 Dangerous Locations

FLYING DEBRIS OR OBJECTS AND FALLING OBJECTS CAN

CAUSE SERIOUS INJURY OR DEATH

Improper operation and failure to follow safety precautions

can cause serious injury or death. All personnel must be

clear of the hazard zone while the Mulcher is in operation.

DANGER EXISTS MOST PROMINENTLY IN FRONT OF AND

BEHIND THE MULCHER.

Pieces of wood and rock can project from the mulcher. This condition is

dangerous. This will occur when the mulcher is raised high enough to

allow material to escape.

FOLLOW THESE PRECAUTIONS:

•NEVER allow anyone to enter the Safety Zone of the

mulcherwhile it is in operation.

•INSPECT the Carrier and mulcher daily for damaged or missing

def ection chains and flaps

Be especially CAREFUL when:

•When the mulcher is being raised up and out of the material that

it is working in.

•When the mulcher is lowered into new material.

•CLOSE the hydraulic trap door (if equipped) while pull-working to

better contain material. This also increases the fineness of the

shredded product.

(See section 5.2, Mulcher Operation – Pull-working).

1.8 Urban Precautions

A STEP-UP of SAFETY PROCEDURES and PRECAUTIONS is

required when working:

•Near streets

•Near highways

•In parks, on golf courses or other inhabited areas

•Near buildings

ESTABLISH SAFETY PARAMETERS THAT FIT THE SITE:

•String colored warning tape to secure the work area.

•Place signs warning of mowing zone (if working along side of

highway) 1,000 ft (300 m) (minimum) before edge of Hazard

Zone is breached.

•Utilize a traffic director when the hazard zone impinges on

pedestrian or vehicular traffic.

•Erect barriers

2.0 OPERATIONAL SAFETY/ THE OPERATOR

2.1 Sound Levels/ Hearing Protection

HEARING PROTECTION MUST BE USED IN THIS AREA!

Take the following precautions:

•Always keep doors and windows of carrier closed.

•Use ANSI S3.19-1975 approved hearing protectors with a noise

reduction rating (NRR) of 25dB (A)

•Ear muffs

•Ear plugs (disposable or reusable)

2.2 Dust Protection

Prolonged and excess exposure to dust can cause

complications of your Respiratory System. Prolonged and

excess exposure to dust can cause chronic and acute health

problems.

Take the following precautions:

•Keep the door shut and windows of carrier closed.

•Utilize a NIOSH approved respirator with replaceable filters rated

for dust collection.

2.3 Protection from Flying or Falling Objects

BE ALERT of the possibility of projectiles exiting the machine.

Falling brush, branches, and trees also present a potential

hazard to the operator. As illustrated in Section 1

2.4 Avoid Power Lines

Serious injury or death can result from contact with electric

lines. Never move any part of the equipment or the tree it's

carrying, closer than 3 meters plus twice the line insulator

length to an electric line. Use a signal person to guide

operator. Use shrouds or insulators as necessary.

BE AWARE OF THE DIRECTION THAT TREES ARE FELLING!

ALWAYS DIRECT AWAY FROM POWER LINES!

2.5 Operator Protection

FLYING DEBRIS OR OBJECTS AND FALLING OBJECTS CAN

CAUSE SERIOUS INJURY OR DEATH

•Install minimum of 1/2” thick (1.25cm) Lexan™

Polycarbonate cab windows.

•Install approved FOPS falling Object Protection.

•Replace damaged or missing Polycarbonate windows or

falling object protection components.

Improper operation and failure to follow safety precautions

can cause serious injury or death. All personnel must be

clear of the hazard zone while the mulcher is in operation.

Take the following precautions!

The following precautions are recommended for operator protection.

Additional guarding may be required to protect the carrier, such as

belly pans or skid plates, etc. Always follow safety regulations and

certifications for your specific industry. Check with the manufacturer of

your carrier for recommended operator protection.

For PTO Carriers:

•A 1/2” (1.25cm) thick polycarbonate or equal, should be installed

in place of or outside of the cab glass between the operator and

the mulcher.

•A steel mesh screen of 2” (5cm) maximum openings and 1/4”

(.6cm) diameter wire is recommended outside of the cab

between the mulcher and the operator to protect Polycarbonate

from scratches.

For Forestry Prime Movers with Enclosed Cab:

•A 1/2” (1.25cm) thick polycarbonate or equal, should be installed

in place of or outside of the cab glass between the operator and

the mulcher.

•A steel mesh screen of 2” (5cm) maximum openings and 1/4”

(.6cm) diameter wire is recommended outside of the cab

between the mulcher and the operator.

For Excavators and Boom type Carriers with Enclosed Cab: •

Front of cab facing boom should have a 1/2” (1.25cm) thick

polycarbonate or equal, should be installed in place of or outside of

the cab glass between the operator and the mulcher. • A steel

mesh screen of 2” (5cm) maximum openings and 1/4” (.6cm)

diameter wire is recommended outside of the cab between the

mulcher and the operator to protect Polycarbonate from scratches.

For Mini-Track Loads and Skidsteers:

•Do not operate without enclosed cab.

•Cab door should have a 1/2” (1.25cm) thick polycarbonate or

equal, should be installed in place of or outside of the cab glass

between the operator and the mulcher.

•A steel mesh screen of 2” (5cm) maximum openings and 1/4”

(.6cm) diameter wire is recommended outside of the cab

between the mulcher and the operator to protect Polycarbonate

from scratches.

Take the following precautions!

•Make sure that the carrier vehicle has proper protection between

the operator and the mulcher. This will protect the operator as

well as the carrier control area. • Wear ANSI approved

protective eyewear such as: Safety Glasses, Goggles, Face

shield.

•Wear an ANSI approved hard hat.

•Wear appropriate ear protection.

•Steel toe shoes are an excellent safeguard for anyone on or

around machinery.

2.6 Stopping the Rotor Before Exiting the Carrier

Contact with moving rotor can cause serious injury or death. Do

not exit the vehicle before the rotor stops.

To stop rotor:

1. Lower the engine speed to

Idle

2. Shut off the mulcher circuit

3. Push the rotor into the ground

or other debris until rotor stops

If there is no place to stop the

rotor, wait for the rotor to stop

before exiting the cab.

3.0 CARRIER VEHICLE PREPARATION/MAINTENANCE

3.1 Shielding • Shielding is essential for protecting the Carrier and the

operator. All parts of the carrier closest to the mulcher are most

susceptible to damage.

•Use appropriate material as brush guards.

•The operator area should be protected as noted in Section 2.5

•Shielding must allow good access to service machine, clean and

remove debris.

3.2 Carrier Vehicle Preparation/Maintenance

AVOID INJURY OR DEATH

•Shut-off the engine. Put carrier in depressurized state.

•Wait until all machine components have completely stopped

before touching them.

•Use lockout/tagout procedure (29CFR 1910.147) during any

inspection or maintenance.

•Secure lifting cylinder with locking device before entering a

hazardous area.

•Insert safety lock before entering a hazardous area.

•Attach support before entering a hazardous area.

Refer to the Safety Section in this manual for more information.

3.3 Carrier Clean-up • Periodic removal of debris and dust from the

carrier vehicle is essential to continued successful operation and

FIRE PREVENTION.

•Open all compartments and remove all flammable debris such

as leaves, twigs, pine needles, wood chips, dust and any leaking

or spilt oil or fuel.

•Upon discovery of oil or fuel leaks, repair and clean up

immediately. Oil attracts dust and creates a fire hazard by

insulating lines causing excess heat generation. Inspect and

clean all dust from fittings and lines.

•Provisions should be made for removal of shredded wood

buildup between hoses, lift arms, lines, and other “nooks and

crannies.”

•A blower should be used to knock the dust and wood chips off

the entire carrier at least twice per day, wherever permissible by

the carrier manufacturer.

•Clean the radiator as required to avoid overheating.

•Use water only if it can dry thoroughly before operating. Dust

clings to anything wet and a wet radiator can quickly restrict air

flow.

•Contain and dispose of any petro-chemical runoff through a

licensed processing facility.

•Do not dispose of petro-chemical runoff into municipal waste.

•Do not use high pressure washer directly on electrical contacts.

Be careful using high-pressure washers, which may bend

and split the radiator fins.

This manual suits for next models

1

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

SNOWJOE

SNOWJOE SunJoe 24V-SS12-XR Operator's manual

Velleman

Velleman PEREL GIKLED03 user manual

SPYKER

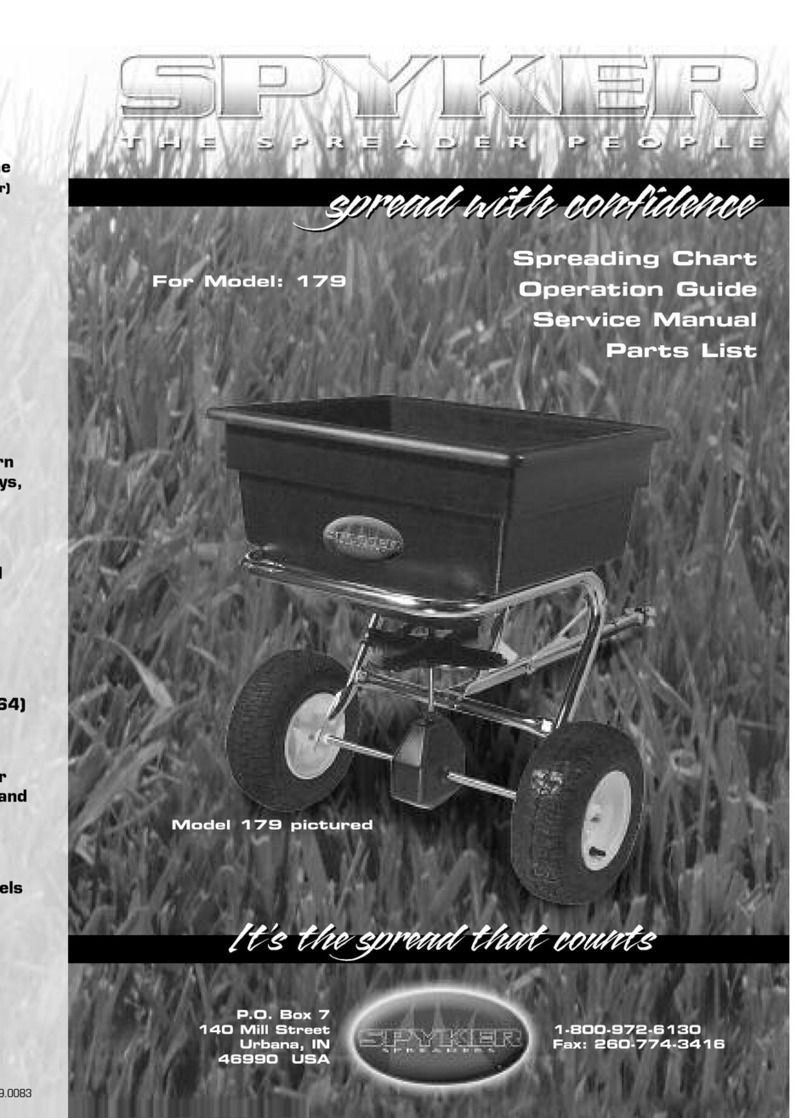

SPYKER 179 Operation guide service manual parts list

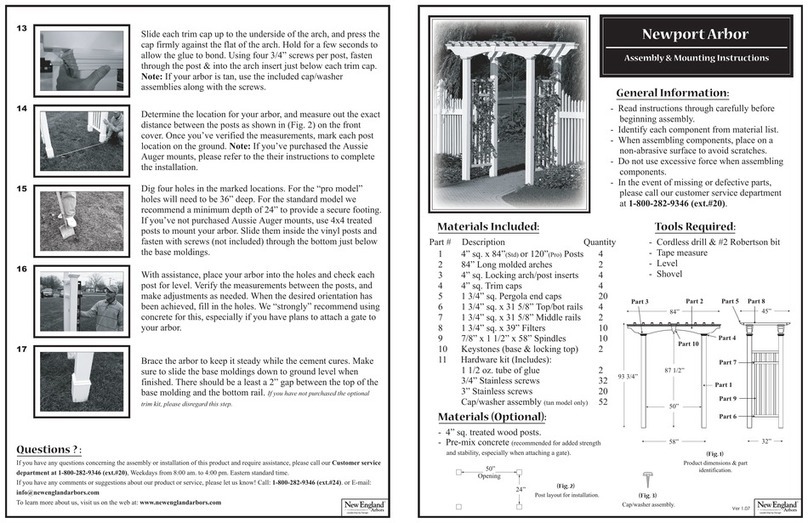

New England Arbors

New England Arbors Newport Arbor Assembly and mounting instructions

Vermeer

Vermeer 504 PRO Operator and maintenance manual

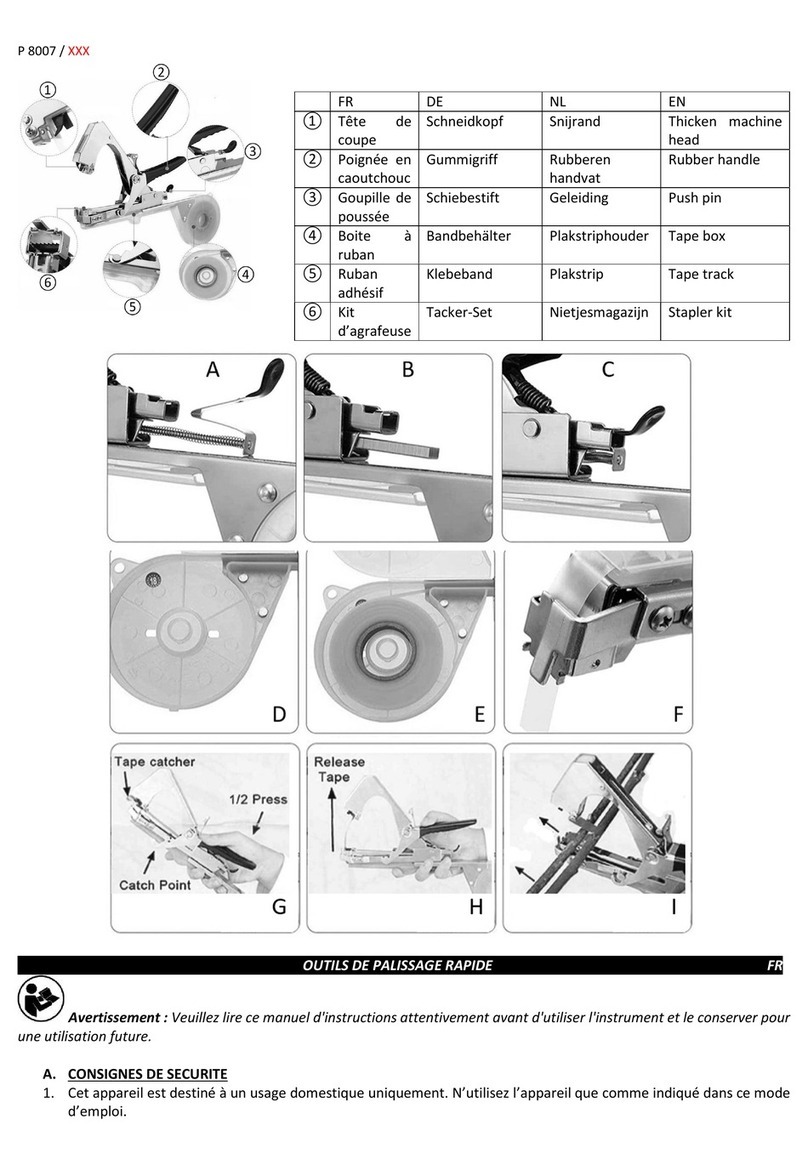

CAPTELEC

CAPTELEC P 8007 / Series quick start guide