BETTCHER INDUSTRIES Whizard UN-84 Guide

OPERATING INSTRUCTIONS AND SPARE PARTS LISTS

UN-84 UNIVERSAL

DRIVE MOTOR

For Use With All

Current Electric

Whizard Trimmers

MANUAL #163835

Issued : November 15, 1995

TMC#755

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Information in this document is subject to change without notice.

No part of this document may be reproduced or transmitted in any form or any

means, electronic or mechanical, for any purpose, without the express written

permission of Bettcher Industries, Inc.

Written permission to reproduce in whole or part is herewith granted to the legal

owners of the Whizard UN-84 Universal Drive Motor with which these Operating

Instructions have been supplied.

Operating Instructions in other languages are available on request. Additional

copies of Operating Instructions are available by calling or writing the local

Representative or by contacting :

BETTCHER INDUSTRIES, INC.

6801 State Route 60

Birmingham, Ohio 44889

U.S.A.

Telephone : 1-440-965-4422

(In The U.S.A.) : 1-800-321-8763

Fax : 1-440-965-4900

The Information Provided In These Operating Instructions

Are Important To Your Health, Comfort And Safety.

For Safe And Proper Operation, Read This Entire

Manual Before Using This Equipment.

Copyright 1999 By Bettcher Industries, Inc.

All Rights Reserved

Original Instructions

Page i

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Table Of Contents

SECTION 1.0 Machine Specifications 1

SECTION 2.0 Designated Use 2

2.1 Warning 2

2.2 Recommended Operation 3

SECTION 3.0 Function 4

3.1 Machine Functions 4

3.2 Safety Recommendations And Warnings 4

SECTION 4.0 Safety Features 6

SECTION 5.0 Installation 6

5.1 Space Requirements 6

5.2 Installation 8

5.3 Connecting The Power 8

SECTION 6.0 Instructions For Operation 9

6.1 Fault Detection And Correction 10

6.2 Instructions on Safety For Personnel 11

SECTION 7.0 Maintenance 12

SECTION 8.0 Spare Parts List 13

8.1 Handpiece Hanger 13

8.2 Motor Assembly 14

8.3 Top View of 115V Motor with Schematic 16

8.4 Top View of 230V Motor with Schematic 18

SECTION 9.0 About These Operating Instructions 21

9.1 Other Languages 21

9.2 Document Identification 21

9.3 Software And Duplication 21

SECTION 10.0 Contact Addresses And Phone 22

Page ii

OPE

R

INST

R

SE

C

The

indu

s

p

rod

u

The

W

has

b

(UK

)

Volt

a

with

In a

d

745

a

and

89/3

9

Tri

m

Gen

e

Pow

e

R

ATING

R

UCTIONS

C

TION 1.0

Bettche

r

-B

s

try, desig

n

u

ction and

W

hizard U

N

b

een tested

)

Ltd, ET

L

a

ge Direct

i

the follow

i

•EN 5

0

•EN 5

0

•EN 6

0

d

dition, thi

s

a

nd HD 40

0

UL763.

9

2/EEC

p

m

mers or W

h

e

ral UN-84

We

Ov

e

e

r Require

m

Model

1

Model

1

M

AC

H

ilt Univers

n

ed with th

e

yield effici

e

N

-84 Mot

o

by an ind

e

L

Albury,

C

i

ve 73/23/

E

i

ng standar

d

0

081-1

0

082-1

0

335-1

s

product

a

0

.1 and als

o

This pro

d

p

rEN/TC15

3

h

izard Mo

d

Motor Dri

v

ight:

e

rall Size:

m

ents :

1

63023:

1

63554:

B

ETT

C

INDU

S

H

INE SP

E

al Drive

M

e

highest p

o

e

ncy.

o

r Assembl

y

e

pendent a

n

C

ranleigh,

S

E

EC and E

M

d

s :

•IE

C

•IE

C

a

lso confor

m

o

conforms

d

uct is al

s

3

/WG2/N1

6

d

ular Trim

m

v

e Informa

t

24

l

22"

(53

0

115 VA

230 VA

C

HER

S

TRIES, INC.

Page 1

E

CIFICAT

I

M

otor is hi

g

o

ssible sta

n

y

Unit desc

n

d certifie

d

S

urrey, En

g

M

C 89/33

6

C

801

C

335-1

m

s with t

h

with Ame

r

s

o in con

f

6

.5E whe

n

m

ers.

t

ion :

l

bs. (10.9 k

g

High x 11

"

0

mm) x (2

8

C / 1 Phas

e

C / 1 Phas

e

I

ON

S

g

hly effect

i

n

dards for s

c

ribed in th

i

d

body, Inc

h

g

land and

c

6

/EEC whi

c

h

e followin

g

r

ican stand

a

f

ormity w

i

n

used

w

g

)

"

Wide x 7

-

8

0mm) x (1

e

/ 60 Hz

e

/ 50 Hz

MO

R

i

ve for use

afety, ergo

n

i

s Operatio

n

h

cape Test

c

omplies

w

c

h include

s

g Swiss st

a

a

rds USD

A

i

th Machi

n

w

ith Whi

z

-

1/2" Deep

90mm)

6 Am

p

3 Am

p

O

DEL U

N

-8

4

R

ev. Octobe

r

in the me

a

n

ometry a

n

n

Instructi

o

ing Servic

e

w

ith the Lo

w

s

conformi

t

a

ndards IE

C

A

, ANSI 3.

3

n

e Directi

v

z

ard UN-

8

p

s

p

s

4

MOTOR

r

17, 2011

a

t

n

d

o

n

e

s

w

t

y

C

3

4

v

e

8

4

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 2

SECTION 2.0 DESIGNATED USE

2.1 Warning

WARNING

WHIZARD TRIMMERS ARE USED FOR REMOVAL

OF FAT AND TISSUE, THE RECOVERY OF LEAN MEAT

FROM FAT AND AS AUNIVERSAL CUTTING TOOL

IN THE MEAT INDUSTRY. ANY USE IN APPLICATIONS OTHER

THAN THOSE FOR WHICH THE WHIZARD TRIMMERS HAVE BEEN

DESIGNED AND BUILT MAY RESULT IN SERIOUS INJURIES.

WARNING

THE MANUFACTURER ASSUMES NO LIABILITY FOR ANY

UNAUTHORIZED DESIGN CHANGES, MODIFICATIONS, OR USE OF

PARTS NOT SUPPLIED BY THE MANUFACTURER

OR

THE USE OF PARTS NOT DESIGNED FOR USE

ON THE SPECIFIC MODEL

AND

INCLUDES CHANGES IN OPERATING PROCEDURES

MADE BY THE OWNER OR ANY OF HIS PERSONNEL.

THE USE OF PARTS OTHER THAN THOSE LISTED IN THE PARTS

LIST OF THIS MANUAL MAY CAUSE BLADE LOCK-UP RESULTING

IN AN UNSAFE OPERATING CONDITION.

FOR SAFE AND PROPER OPERATION, READ ENTIRE

MANUAL BEFORE USING THIS EQUIPMENT.

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 3

2.2 Recommended Operation

The Whizard UN-84 Motor Drive Assembly has been designed for use with the

following Whizard Trimmers :

Model Modular Model

350 Trimmer 350M Modular Trimmer

360 Trimmer 360M Modular Trimmer

500 Bone Trimmer 500M Modular Bone Trimmer

500MA Modular Angle Bone Trimmer

505 Bone Trimmer 505M Modular Defatting Machine

505MA Modular Angle Defatting Machine

520 Bone Trimmer

564 Modular Bone Trimmer

620 Bone Trimmer 620M Modular Bone Trimmer

620MA Modular Angle Bone Trimmer

625 Fat Trimmer 625M Modular Fat Trimmer

750 Trimmer 750M Modular Trimmer

754M Modular Trimmer

850 Defatting Machine 850M Modular Defatting Machine

850MA Modular Angle Defatting Machine

880-B Primal Fat Shaper (Beef) 880B-M Modular Primal Fat Shaper (Beef)

880-S Primal Fat Shaper (Swine) 880S-M Modular Primal Fat Shaper (Swine)

1850 Defatting Machine 1850M Modular Defatting Machine

1880 Primal Fat Shaper 1880M Modular Primal Fat Shaper

1000 Fat And Lean Trimmer 1000M Modular Fat And Lean Trimmer

1300 Primal Fat Shaper 1300M Modular Primal Fat Shaper

1400 Ham Finisher 1400M Modular Ham Finisher

1500 Skinning Machine 1500M Modular Skinning Machine

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 4

SECTION 3.0 FUNCTION

3.1 Machine Functions

This universal motor drive unit features a 1/3 HP motor which will drive all

current electric Whizard Trimmers with all the advantages, the power, and with all

the performance to improve your yields and profits.

A vertical motor drives a flexible shaft. The flexible shaft drives a rotating blade

in the handpiece via a gear and pinion. The force to cut through meat and fats is

now provided by the drive motor and no longer by the worker. Forces applied by

the worker are greatly reduced and limited to guiding the rotating knife blade.

The design locks the handpiece in the hanger and shuts the motor off when the

handpiece is placed in the hanger.

The motor will not start if the handpiece is in the hanger. An emergency slap-stick

stops the unit.

The handpiece has no metal to metal contact with the motor.

3.2 Safety Recommendations And Warnings

WARNING

ALWAYS TURN OFF THE MOTOR AND PLACE THE HANDPIECE IN

THE HANGER BRACKET. NEVER LAY THE HANDPIECE DOWN ON

THE WORKSTATION OR LET IT HANG FREE BY THE FLEX SHAFT

CASING. NEVER PLACE THE HANDPIECE IN THE HANGER WHILE

THE BLADE IS STILL REVOLVING.

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 5

3.2 Safety Recommendations And Warnings (Continued)

WARNING

ALWAYS DISCONNECT THE POWER

AND REMOVE THE TOOL FROM THE

FLEX SHAFT PRIOR TO SERVICING.

WARNING

IF AT ANY TIME THIS MACHINE DOES NOT APPEAR TO OPERATE

NORMALLY OR EXHIBITS AMARKED CHANGE IN

PERFORMANCE, IT SHOULD BE IMMEDIATELY SHUT DOWN AND

TAGGED AS "UNSAFE" UNTIL SUCH TIME AS PROPER REPAIRS

ARE MADE THE MACHINE AGAIN OPERATES NORMALLY.

WARNING

AVOID USE OF THIS MACHINE IN STANDING WATER.

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 6

SECTION 4.0 SAFETY FEATURES

The sealed enclosure is extremely water resistant with only one small vent hole.

Switch mechanism is located on top of the motor and is completely enclosed under

the motor cover for protection from moisture.

Bottom mounted extra long on/off switch rod.

Strain relief design allows motor to be free-swinging.

The machine has an interlock on the handpiece hanger that prevents hanging the

handpiece while the motor is running or turning the motor on while the handpiece

is in the hanger. The motor will shut off automatically if the handpiece is placed

into the hanger.

SECTION 5.0 INSTALLATION

Correct installation is extremely important to achieve maximum efficiency for

both the Whizard Trimmer unit being used and the operator. Incorrect installation

may possibly hamper the operator's movements and cause undue wear or damage

to the flex shaft and flex shaft casing parts of the unit.

5.1 Space Requirements

CAUTION

IT IS STRONGLY RECOMMENDED THAT ASAFETY CABLE OR CHAIN BE

INSTALLED THROUGH THE SUPPORT YOKE AND AROUND AFIXED

OVERHEAD STRUCTURE.

A 3/4" diameter pipe should be fastened to an overhead beam with the pipe

centerline 12 inches (300mm) to the right of the operator's shoulder for a right-

handed operator (or 12 inches (300mm) to the left of the operator's shoulder if the

operator is left-handed). Pipe centerline for Small Tool Models should be 12

inches (300mm) back from the front edge of the table and 15 inches (380mm)

back from the front edge of the table for the Large Tool Models (see Figure 1).

The pipe should be long enough to provide vertical clearance between the motor to

the casing adapter and the top of the table surface. Actual clearance dimensions

vary between Whizard tools -see listing of tools as illustrated in Figure 1. (Table

top height may be set differently based on operator height and the height of the

meat product on the table).

The yoke should be rigidly mounted and parallel to the work station.

OPE

R

INST

R

5.1

I

E

For

f

W

Mod

e

350/

3

360/

3

500/

5

505/

5

520

564

M

620/

6

625/

6

750/

7

754

M

850/

8

880/

8

1000

/

1300

/

1400

/

1500

/

1850

/

1880

/

R

ATING

R

UCTIONS

Space R

e

MPROPER

L

E

FFORT

&

f

urther detail

s

W

hizard Tri

m

Bettch

e

e

l

3

50M

3

60M

5

00M/500M

A

5

05M/505M

A

M

6

20M/620M

A

6

25M

7

50M

M

8

50M/850M

A

8

80M-B&S

/

1000M

/

1300M

/

1400M

/

1500M

/

1850M

/

1880M

e

quirement

s

L

Y

HUNG

M

D

ECREAS

E

s

on the ergo

n

m

mer Ergono

m

e

r Industries

a

A

28"

28"

A

28"

A

40"

28"

28"

A

28"

28"

42"

42"

A

42"

42"

42"

42"

42"

42"

42"

42"

INCOR

R

B

ETT

C

INDU

S

s

(Contin

u

CA

M

OTORS

M

E

IN

MOBI

L

EFFICIEN

C

n

omic design

m

ic Manual.

C

a

t the contact

F

B

12"

12"

12"

12"

12"

12"

12"

12"

15"

15"

15"

15"

15"

15"

15"

15"

15"

15"

R

ECT

CO

R

C

HER

S

TRIES, INC.

Page 7

u

ed)

UTIO

N

M

AY

RESU

L

L

ITY.

INC

R

C

Y

MAY

O

consideratio

n

C

opies may

b

locations list

e

F

igure 1

R

RECT IN

C

N

L

T

IN

EXC

E

R

EASED

F

A

O

CCUR.

n

s to the wor

k

b

e obtained b

y

ed in

t

he bac

k

C

ORRECT

A

= Dista

n

Casing A

d

Product

B = Dista

n

MO

R

E

SSIVE

OP

E

A

TIGUE

&

L

k

station, ple

a

y

making the

k

of this man

u

n

ce from M

o

d

apter to C

e

n

ce Out fro

m

O

DEL U

N

-8

4

R

ev. Octobe

r

E

RATOR

L

OSS

OF

a

se refer to th

request to

u

al.

o

tor to

e

nter Line

o

m

Table To

p

4

MOTOR

r

17, 2011

e

o

f

p

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 8

5.2 Installation

Install the motor in the proper position as shown and described in Section 5.1.

Install the flex shaft assembly to the motor disconnect by lifting the disconnect

collar and inserting the adapter end of the casing into the disconnect body.

It may be necessary to rotate the casing assembly to align the square drive of the

flex shaft with the square hole in the motor shaft adapter.

Release the disconnect collar to secure the casing to the motor assembly. The flex

shaft casing assembly should swivel freely.

5.3 Connecting The Power

Connect the motor power cord to the prescribed voltage on the motor nameplate.

The motor must be connected to a ground. Use only approved type connector.

WARNING

ELECTRICAL SHOCK MAY OCCUR!

USE ONLY 3WIRE GROUND TYPE CONNECTOR.

THIS MUST BE CONNECTED TO APLANT GROUND

VIA ASUITABLE GROUNDED THREE CONDUCTOR

RECEPTACLE. AVOID USE OF THIS MACHINE

IN STANDING WATER.

Refer to the Wiring Diagrams in Section 8.0

OPE

R

INST

R

SE

C

The

flipp

of h

han

d

On/

O

catc

h

the s

On/

O

Re

m

you

eith

e

The

tripp

han

g

hold

e

R

ATING

R

UCTIONS

C

TION 6.0

hanger is

d

er and the

m

anging th

e

d

piece from

O

ff Proced

u

h

with one

w

itch kno

b

O

ff Proced

u

m

ove the ha

n

pull the h

a

e

r running

a

mo

t

or can

ing the ha

n

g

er to prev

e

e

r until cat

c

I

NST

R

d

esigned t

o

m

otor turn

e

e

handpiec

e

the hange

r

u

re : Re

m

finger as

y

b

clockwise

u

re With D

i

n

dpiece fro

a

ndpiece o

u

a

t the time

o

be turned

o

n

ger flipper

.

e

nt dulling

c

h drops in

B

ETT

C

INDU

S

R

UCTIO

N

o

hold the

e

d off. Th

i

e

with the

r

in order to

m

ove the

h

y

ou pull th

e

to start the

i

sconnect

C

m the han

g

u

t. The Q

u

o

f engagem

o

ff by tur

n

.

Turn the

m

the blade

o

place.

C

HER

S

TRIES, INC.

Page 9

N

S FOR O

P

handpiece

i

s feature i

s

blade rot

a

start the

m

h

andpiece

fr

e

handpiec

e

motor.

C

asing Ass

e

g

er, lifting

t

u

ick Disco

n

ent or with

n

ing the sw

i

m

otor off

b

o

n the flip

p

Fi

g

Ha

P

ERATIO

N

with the b

s

to discou

r

a

ting and

m

otor.

f

rom the h

a

e

out. Wit

h

e

mbly (Mo

d

t

he metal c

n

nect can

b

the motor

o

itch knob

c

b

efore plac

i

p

er. Push

g

ure 2

ndpiece i

n

MO

R

N

lade facin

g

r

age the un

s

requires r

e

a

nger, lifti

n

h

your oth

e

d

ular Trim

m

c

atch with

o

b

e used wi

t

o

ff.

c

ounterclo

c

i

ng the han

d

the handp

i

n

Han

g

er

O

DEL U

N

-8

4

R

ev. Octobe

r

g

toward t

h

s

afe practi

c

e

moving t

h

n

g the met

a

e

r hand, tu

r

m

ers Only)

o

ne finger

a

t

h the mot

o

c

kwise or

b

d

piece in t

h

i

ece into t

h

4

MOTOR

r

17, 2011

h

e

c

e

h

e

a

l

r

n

:

a

s

o

r

b

y

h

e

h

e

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 10

6.1 Fault Detection And Correction

Problem Probable Cause Remedy

Motor Will

Not Run

No power to motor

Check line voltage.

Make sure line voltage

matches motor spec.

plate

Bad power cord or plug

Check voltage at cord

to switch point. Refer

to Sections 8.3, 8.4,

and/or 8.5 for proper

schematic

Loose wire connections Tighten loose

connections

Bad circuit breaker

(230V Only)

Try reseting breaker or

replace breaker if

defective (refer to

Section 8.4)

Bad switch Check switch and

replace if defective

Motor Noisy Bad bearing in motor Remove and replace

Handpiece

Vibration

Machine not installed

correctly in relation to

operator position

Check installation

procedures in Section

5.1

Flex shaft/motor adapter

worn Replace adapter

(Part Number 143077)

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 11

6.2 Instructions On Safety For Personnel

WARNING

NEVER PLACE THE HANDPIECE IN THE HANGER WHILE THE

BLADE IS STILL REVOLVING.

WARNING

ALWAYS TURN OFF THE MOTOR AND PLACE THE HANDPIECE IN

THE HANGER BRACKET.

WARNING

ALWAYS DISCONNECT POWER AND REMOVE THE TOOL FROM

THE FLEX SHAFT CASING PRIOR TO SERVICING.

WARNING

IF AT ANY TIME THIS MACHINE DOES NOT APPEAR TO OPERATE

NORMALLY, OR EXHIBITS AMARKED CHANGE IN

PERFORMANCE, IT SHOULD BE IMMEDIATELY SHUT DOWN AND

TAGGED AS "UNSAFE" UNTIL SUCH TIME AS PROPER REPAIRS

ARE MADE AND THE MACHINE AGAIN OPERATES NORMALLY.

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 12

SECTION 7.0 MAINTENANCE

Make sure the motor unit pivots freely in the yoke. Check that the pivot bolts and

pivot sleeve bearings are in good condition. If required, clean pivots and change

the sleeve bearings.

Check to make sure the power cord connector is tight in the bell cap. Tighten as

required.

Periodically check the condition of the flex shaft casing to motor disconnect.

Make sure the balls move freely and the casing rotates freely in the disconnect.

OPE

R

INST

R

SE

C

8.1

R

ATING

R

UCTIONS

C

TION 8.0

Handpie

c

IT

E

1

2

3

4

5

6

SPA

R

c

e Hange

r

E

M DESC

1

HAN

G

2

BOLT

3

FLAN

4

LATC

H

5

WAS

H

6

NUT

B

ETT

C

INDU

S

R

E PARTS

RIPTION

G

ER/CATC

H

G

ED SPAC

H

H

ER

C

HER

S

TRIES, INC.

Page 13

LIS

T

H

ASSEMB

L

ER

3

PAR

NUM

B

L

Y 1436

7

1431

9

1222

7

1436

7

1202

8

1236

0

MO

R

T

B

E

R

QTY.

USED

7

9 1

9

9 1

7

5 1

7

1 1

8

0 1

0

9 1

O

DEL U

N

-8

4

R

ev. Octobe

r

4

MOTOR

r

17, 2011

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 14

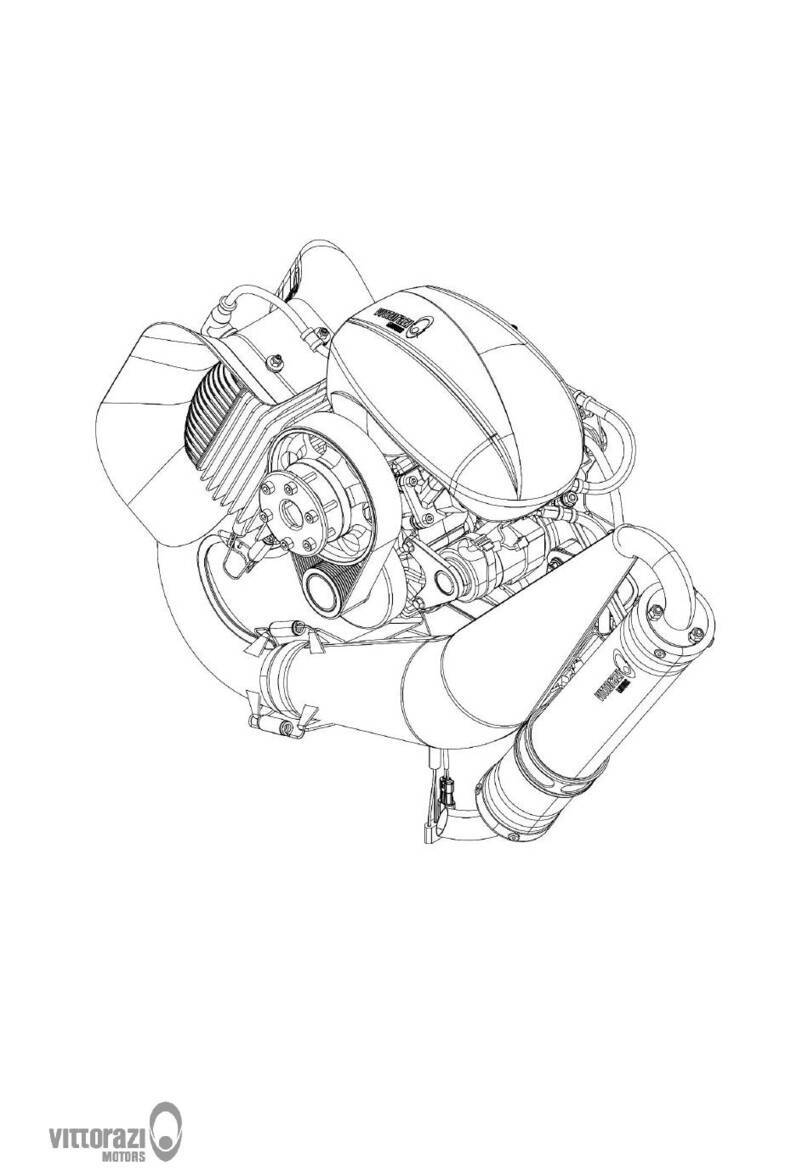

8.2 Motor Assembly

15

24

16

19

28 22

4

2

3

26

187

23

17

25

13

14

34

14

20

21 22

12

11 9 108

2

56

27

2932

3233

31 30

1

COMPLETE MOTOR ASSEMBLY

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 15

8.2 Motor Assembly (Continued)

ITEM DESCRIPTION

115 VOLTS

1 PHASE

60 HZ

230 VOLTS

1 PHASE

50 HZ

P/N QTY P/N QTY

1 COMPLETE MOTOR ASSEMBLY 163023 1 163554 1

2 END BELL ASSEMBLY

(INCLUDES SWITCH ROD BUSHING) 143074 1 163900 1

3 SWITCH ROD BUSHING 143125 REF. 143125 REF.

4 MOTOR 163057 1 163058 1

5 LOCK WASHER 120220 4 120220 4

6 BOLT 120576 4 120576 4

7 FLEX SHAFT/ MOTOR ADAPTER 143077 1 143077 1

DISCONNECT ASSEMBLY

INCLUDES ITEMS; 8 THRU 12 163190 1 163190 1

8 DISCONNECT BODY 143112 1 143112 1

9 DISCONNECT COLLAR 143113 1 143113 1

10 BALL 143114 2 143114 2

11 SPRING 121610 1 121610 1

12 RETAINING RING 122025 1 122025 1

13 SLEEVE BEARING 121751 2 121751 2

14 MOTOR SUPPORT YOKE 143161 1 143161 1

15 HANGER ASSEMBLY

(SEE HANDPIECE SECTION FOR

DETAIL)

143691 1 143691 1

16 PIVOT BOLT 143117 1 143117 1

17 PIVOT INTERLOCK BOLT 143674 1 143674 1

18 SWITCH ROD 143132 1 143132 1

19 E-RING 122024 1 122024 1

20 LIMIT SWITCH ASSEMBLY 173660 1 173661 1

21 SWITCH CAM 185767 1 185767 1

22 SPRING PIN 120166 2 120166 2

23 SHUT-OFF PIN 143675 1 143675 1

24 FLIPPER 143672 1 143672 1

25 SLOTTED SPRING PIN 122432 1 122432 1

26 NAME PLATE 143129 1 163446 1

27 POP RIVET 1/8" 122744 2 122744 2

28 SWITCH ROD KNOB 163014 1 163014 1

29 SCREW (PART OF MOTOR) 122730 1 122730 2

30 POWER CORD 163018 1 163580 1

31 BELLCAP ASSEMBLY 163044 1 163895 1

32 LOCK WASHER 120232 3 120232 4

33 SCREW 120775 2 120775 2

34 PIPE NIPPLE 143212 1 143212 1

OPERATING BETTCHER MODEL UN-84 MOTOR

INSTRUCTIONS INDUSTRIES, INC. Rev. October 17, 2011

Page 16

21

22

10111121314

3

89

2

181920

456

17

16

15

7

8.3 Top View Of 115V Motor With Schematic

1021

115V/1PH/60HZ

1314

2324

N.O.

N.O.

1

4

SCHEMATIC DIAGRAM

WHITE

GREEN

RED/BLACK

BLACK

ORG

WHT

MOTOR

SWITCH

PLUNGER

SWITCH

Table of contents