Better Water EQASSY0.75KB2.03 User manual

REA 2339

Cartridge Based Pyrogen

Filtration System (2-4 Filters)

Operator Manual

Better Water LLC

rev. Apr 2017

REA 2339

Better Water LLC. All rights reserved.

The content of this manual is the intellectual property of Better Water LLC. It is furnished for the

express use by Better Water LLC, their customers and dealers, for informational use only for operation,

service, and internal training. No part of this manual may be reproduced for distribution, sale, or any

intent other than previously described without the written permission of Better Water LLC. This manual

is subject to change without notice. Better Water LLC assumes no responsibility or liability for any error

or inaccuracies that may appear in this documentation.

Adobe and Acrobat are registered trademarks of Adobe Systems, Inc.

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

rev. Apr 2017

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

TABLE OF CONTENTS

Our Company ……………………………………………………………………………………... 01

- Contact Us ……………………………………………………………………………………….. 01

- Technical Phone Support ………………………………………………………………………. 01

- Technical Support Info Online …………………………………………………………………. 01

- Specific Contacts ……………………………………………………….……………………….. 02

- Introduction ………………………………………………………………………………………. 02

Warnings & Cautions ……………………………………………………………………………... 03

General Requirements and Specifications ….…………………………………………………..04

Models ………………………………………………………………………………………………04

Product Description ……………………………………………………………………………… 05

Detailed View ……………………………………………………………………………………… 05

General System Operation ……………...……………………………………………………….. 06

- Initial Start-Up ……………………………………………………………………………………. 06

- Daily Operation ….………………………………………………………………………………. 06

- Monitoring Procedures …………………………………………………………………………. 07

- Adjusting Procedures …………………………………………………………………………… 07

- Daily Shutdown ………………………………………………………………………………….. 07

- Valves Legend and Operation ..……………………………………………………………….. 07

Disinfecting

- Disinfecting Overview …………………………………………………………………………… 08

- Disinfecting Procedure ………………………………………………………………………….. 08

- Sanitizing the Sanitary Sample Ports …………………………………………………………. 09

- Sample Collecting from a Sanitary Sample Port …………………………………………….. 10

System Maintenance

General …………………………………………………………………………………………….. 11

Changing the Filters ….…………………………………………………………………………… 12

Service Help ………………………………………………………………………………………. 13

Trouble-Shooting Guide ………………………………………………………………………….. 14

Limited Warranty Terms and Conditions ……………………………………………………….. 15

Appendix A, Sample Quality Assurance Check List …………..……………………………….17

Appendix B, Calculations & Conversions ………………………………………………………. 18

- Bleach Disinfecting Dilutions ……………………………………………………………………18

- Conversion of Ounces to Milliliters ……………………………………………………………..18

- Calculation for Area of Pipe Volume …………………………………………………………...19

- 3 Feet per Second Flow Velocity Rates ……………………………………………………….19

rev. Apr 2017

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

Visit our website to see our complete product line of

water purification products!

www.betterwater.com

Better Water LLC; rev. Apr 2017

Page 1 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

0

Our

Company

Contact

Us

Technical

Phone

Support

Technical

Support

Info

Online

Better Water LLC is a leading integrated manufacturer of water treatment

equipment and components for the industrial, commercial and institutional

markets.

Located in Smyrna, Tennessee,

Better Water LLC continues its history

of manufacturing and distribution of

equipment specifically designed for the

renal dialysis market.

Founded in 1971, Better Water LLC has

built a reputation for solving our

customers' toughest problems with high

quality products and unmatched service.

Better Water LLC Technical Support:

698 Swan Dr Phone (615) 355-6063, press "1"

Smyrna, TN 37167 Email support@betterwater.com

Phone (615) 355-6063 Customer Service:

Fax (615) 355-6065 Phone (615) 355-6063, press "3"

Email customerservice@betterwater.com

Support is available regarding all Better Water LLC systems,

24 hours a day,7 days a week.

Normal business hours are Monday through Friday from

8:00 am until 3:30 pm, Central Standard Time (excluding holidays)

Call (615) 355-6063, press "1" for Technical Support

Emergency assistance is available after normal business hours (including

holidays) by calling (615) 708-8627.

Our website, www.betterwater.com, which is updated

frequently, contains a wealth of technical support information on the

SUPPORT tab and includes:

Operator and Service Manuals

Consumables and Accessories Lists

Technical Service Bulletins

For your convenience there are also online forms for placing Orders

and requesting Returned Goods Authorization. These are Adobe

forms that can be downloaded and either faxed or emailed to us.

Better Water LLC; rev. Apr 2017

Page 2 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

Specific

Contacts

Technical Support Phone (615) 355-6063, option “1”

Email support@betterwater.com

To Place an Order Fax (615) 355-6065

(purchase orders) Email orders@betterwater.com

Phone (615) 355-6063

Customer Service Phone (615) 355-6063, option “2”

(returns) Fax (615) 355-6065

Email customerservice@betterwater.com

Website www.betterwater.com

Helpful information and forms that can be found on our website:

- Operator & Service Manuals

- Technical Service Bulletins

- Consumables and Replacement Parts List

- Brochures

- Order Form

- Return Goods Authorization Request Form

The Better Water LLC Cartridge Based Pyrogen Filtration System is

manufactured to the utmost quality. With proper care, preventative

maintenance, and proper use, it should provide you with a very effective

means of filtration for dialysis treatments.

Before starting you should first read and have a thorough understanding

of this entire Operator Manual. It describes in detail the steps and

procedures for safe usage of the system.

Once the this device has been delivered, it is the responsibility of the

Medical Director to ensure that it is used, monitored, and maintained in

such a manner so as to satisfy all applicable standards. Guidelines and

other related information are available from:

- Food and Drug Administration (FDA)

- National Association of Nephrology Technicians/Technologists (NANT)

- Association for the Advancement of Medical Instrumentation (AAMI)

NOTE concerning pictures in this manual:

Pictures of devices and components may vary slightly due to product

changes, and therefore should be for general reference only.

Information concerning their use, functionality, or replacement will not

differ unless noted.

Introduction

Better Water LLC; rev. Apr 2017

Page 3 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

WARNINGS

1. It is unsafe to operate or service this device without first reading and understanding the entire

Operator's Manual. Keep this manual and other associated documentation for future reference.

2. Misuse, improper operation, and/or improper monitoring of this system could result in serious

injury, death, or other serious reactions to patients undergoing hemodialysis treatment.

3. Misuse, improper use or handling of disinfectants and chemical cleaning solutions could result

in serious injury or even death. You must comply with the information contained in the Material

Safety Data Sheet (MSDS) for the chemical being used.

CAUTIONS

1. When used as a medical device, federal law restricts this device to sale by or on the authority

of a physician. Per CFR 801.109 (b)(1).

2. Improper operation of this device could result in a low or no-flow alarm on the dialysis

machines.

3. Misuse or improper operation of this device will void any warranty.

4. Where water is mentioned, unless otherwise noted, it must be AAMI standard quality water.

5. Plumbing connections must adhere to local statutes and any facility codes.

6. Do not remove any Caution, Warning or any other descriptive labels from the device.

7. Do not operate this device in an explosive environment or in the presence of flammable

materials. Do not use this device to store, mix, or transfer flammable liquids.

8. Movement or vibrations during shipment may cause connections to loosen.

9. Do not operate this unit in an environment where temperatures may be below 50oF or above

90oF.

10. This device should not be used for purposes outside the device’s stated applications,

specifications, or limitations.

Better Water LLC; rev. Apr 2017

Page 4 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

GENERAL REQUIREMENTS & SPECIFICATIONS

1. Water requirements:

a. A properly pretreated water supply consisting of RO/DI product water.

- Better Water recommends 1.2 megohms as the minimum for DI water (AAMI standard is 1

megohm), but these minimums are set by the Medical Director.

b. Pressure: 30-100 psi

2. Electrical requirements: None

3. Drain requirements: This equipment does not require a drain.

4. Floor space: This unit is normally assembled at Better Water LLC and mounted to the wall

surface. Requirements: Approx. 24” (depth-from wall) x 36” (width-along the wall) x 36” (height-up

the wall); maximum for a 4 filter device.

MODELS

There are six models of the 2-4 Cartridge Based Pyrogen Filtration System with the difference

being the number of filters, and the filter used. The operation and service for these models are

basically the same with only a slight physical difference between them.

Model

Number of Filters

Type of Filter

EQASSY0.75KB2.03

2

.03 micron filter

EQASSY0.75KB3.03

3

.03 micron filter

EQASSY0.75KB4.03

4

.03 micron filter

EQASSY0.75KB2.05

2

.05 micron filter

EQASSY0.75KB3.05

3

.05 micron filter

EQASSY0.75KB4.05

4

.05 micron filter

Better Water LLC; rev. Apr 2017

Page 5 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

PRODUCT DESCRIPTION

The Cartridge Based Pyrogen Filtration System uses replaceable filters that are enclosed in

special vessels to process RO/DI product water.

This device works from system water pressure. The output (product) water from this device is

affected by other components in the water treatment system; namely, pressure, temperature and

flow-rate.

Pyrogen filters are a consumable product. The life of the filter is directly related to the monitoring

and routine care programs that you maintain in your facility. A Pyrogen Filtration system, in

conjunction with good disinfecting programs, is a very effective means of controlling bacteria and

endotoxins in the post treatment and distribution segments of a water purification system.

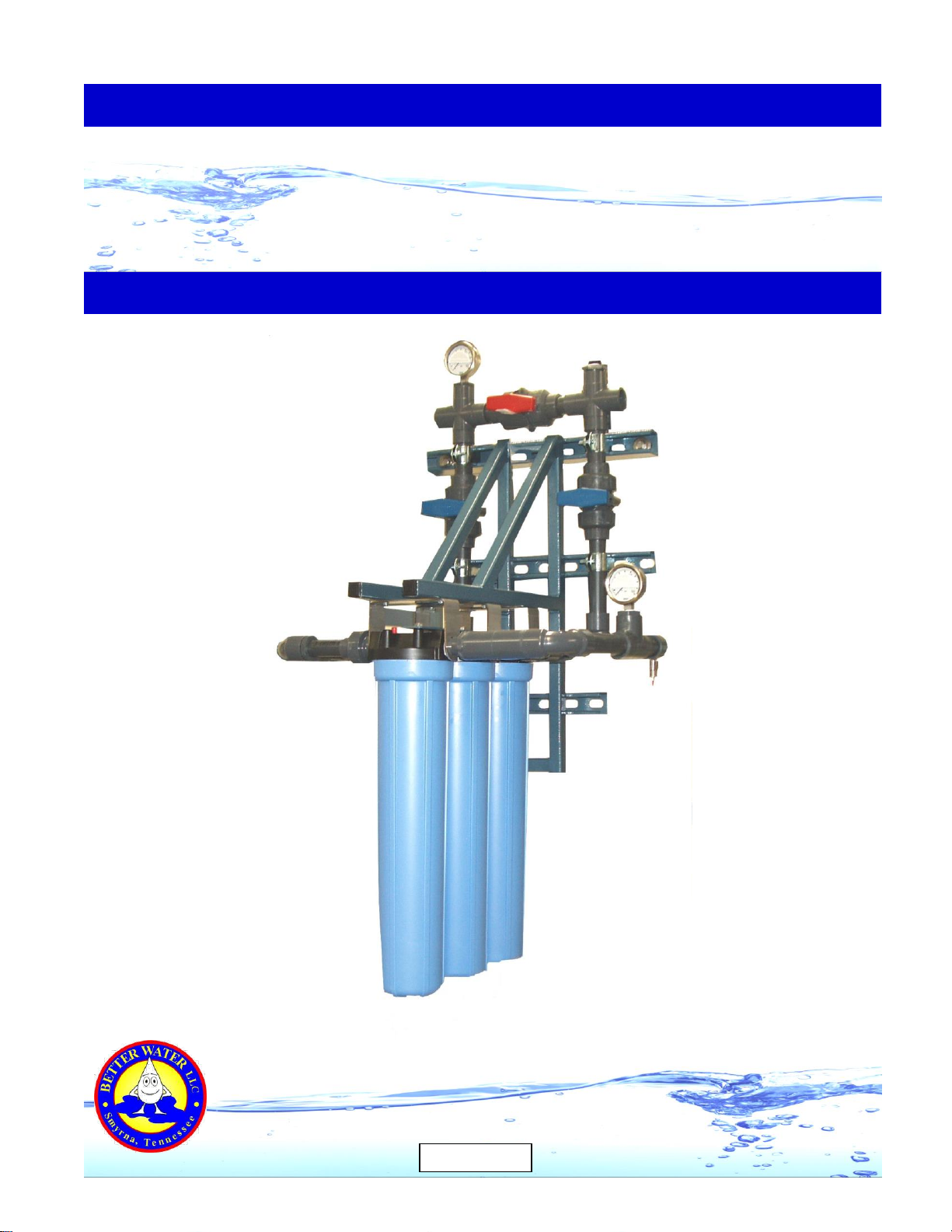

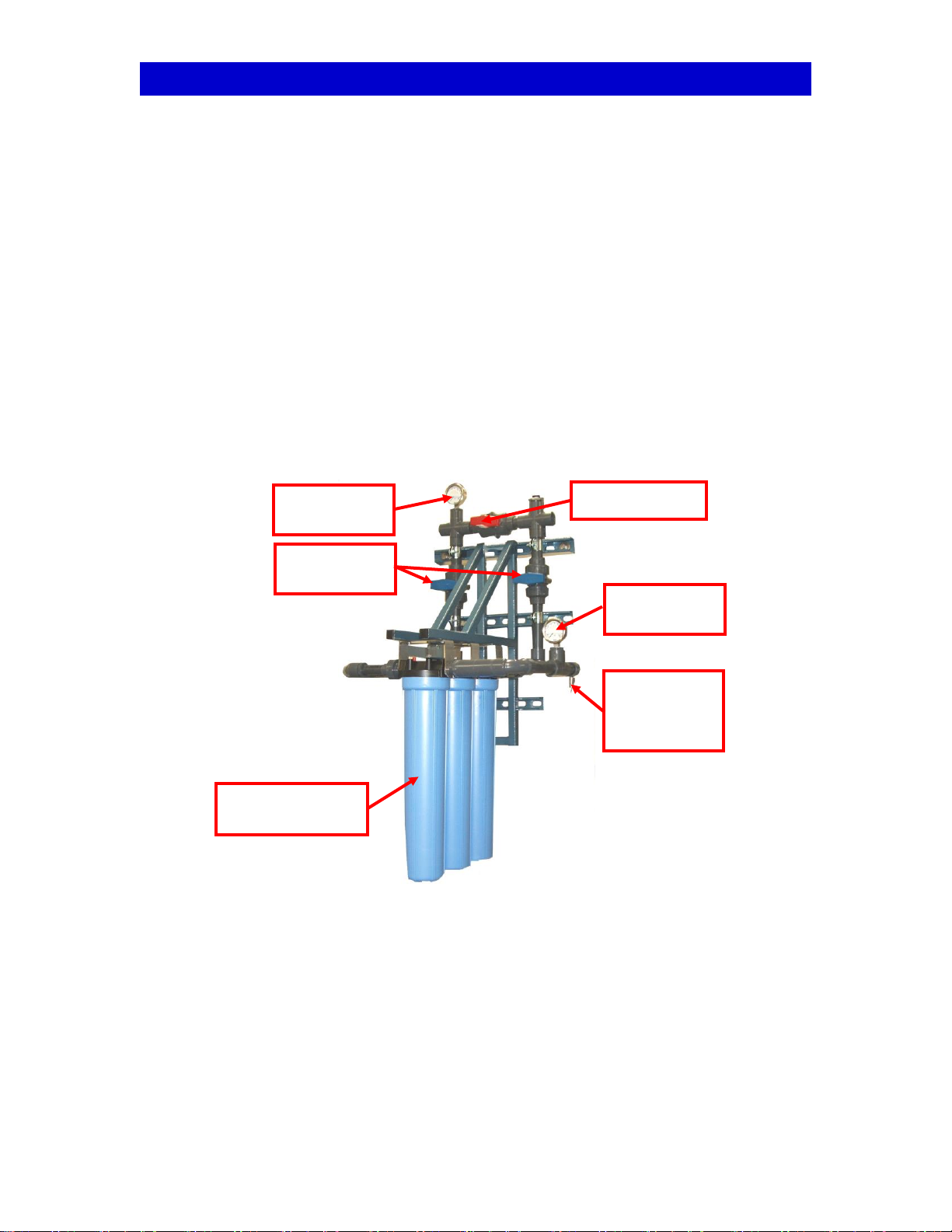

DETAILED VIEW

* NOTE: Details between the different models are basically the same with the exception of the

number of filters.

Sanitary

Sample Port

(second port on

opposite side)

Pressure

Gauge

Bypass Valve

20” Slim-Line

Housings

Inlet/Outlet

Valves

Pressure

Gauge

Better Water LLC; rev. Apr 2017

Page 6 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

GENERAL SYSTEM OPERATION

Before you start using this device, operators must read and understand this manual in its

entirety. This manual of Operator's Instructions describes in considerable detail all of the steps

and procedures required to safely operate this device. With proper operation, maintenance, and

care, this device should give you years of reliable service.

It is unsafe to operate this device without a basic understanding of water treatment and a

thorough understanding of the contents of this manual. Inadequately treated water for

hemodialysis poses a severe threat to the health and safety of hemodialysis patients. Education

and training of the staff in these facilities is critical given the technically complex subject of water

treatment. Guidelines and other related information are available from:

- Food and Drug Administration (FDA)

- National Association of Nephrology Technicians/Technologists (NANT)

- Association for the Advancement of Medical Instrumentation (AAMI)

Incoming tap water contaminants, temperature, pH, pressure, and flow-rates have a direct impact

on the quality and quantity of the RO output. The operator must be aware of changing tap water

conditions. This can be easily accomplished with good, two-way communications with the local

municipal water supplier and with routine testing of the tap water.

This device was designed and built to filter RO/DI product water, and is not intended for any other

application.

INITIAL START-UP

1. Verify filters are installed (if not see section Changing Filters).

2. Start with all valves, sample ports, and drains closed.

3. Slowly open the inlet valve to allow water to begin filling the housings.

4. Partially open the outlet sanitary sample port to allow air to be purged from the device.

5. When steady stream of water flows from the sanitary sample port, signaling that the air has

been purged from the device, close the sanitary sample port.

6. Let filters soak for 10 minutes at 45 psi (minimum).

7. Slowly open the outlet valve fully to allow water to flow through the device.

8. Filters are now on-line and ready for use.

DAILY OPERATION

1. This device does not require any specific daily operation procedures, other than that the valves

are in the proper position for normal operation.

Better Water LLC; rev. Apr 2017

Page 7 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

MONITORING PROCEDURES

The Cartridge Based Pyrogen Filtration System must be monitored on a daily basis by a

qualified technician recording the items listed below on a Quality Assurance Check List. An

example checklist is provided in the Appendix A of this manual and may be reproduced for use.

1. The filter gauges should be checked with water flowing, when there is NO demand for purified

water.

2. Monitoring Requirements: (record on the Quality Assurance Check List)

a. Filter system inlet pressure

b. Filter system outlet pressure

c. Bacteria/endotoxins (check at least monthly; more often if necessary) must meet established

standards

ADJUSTING PROCEDURES

1. There are no adjustments that can be made to this device.

DAILY SHUTDOWN

1. This device does not require any daily shutdown.

VALVES LEGEND and OPERATION

* NOTE: Valve legend and operation the same for all models, no matter the number of filter

housings.

* NOTE: Inlet and Outlet valves may be reversed if the device

requires Right-to-Left flow configuration. Reference labeling for

proper valve identification.

1. Bypass Valve

Open to prevent water from entering the device, and closed to

allow water into the device to be filtered.

* CLOSED during normal operation

2. Inlet Valve

Open to allow water into the device, and closed to prevent water

from entering the device.

* OPEN during normal operation

3. Outlet Valve

Open to allow water to exit the device, and closed to prevent water

from exiting the device.

* OPEN during normal operation

#1

#2

#3

Better Water LLC; rev. Apr 2017

Page 8 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

DISINFECTING OVERVIEW

The Cartridge Based Pyrogen Filtration system is disinfected as a component of the Post-

Treatment and/or Distribution Segment of the water treatment system. The disinfecting schedule

is determined by the Medical Director and the results of bacteria and endotoxins test, but Better

Water LLC recommends disinfecting monthly.

The use of typical household bleach (5.25%) is common for use in disinfecting water treatment

systems for hemodialysis. Bleach is a cost effective disinfectant and generally produces

satisfactory results. Varying concentrations of Sodium Hypochlorite (bleach) are used among

dialysis facilities for disinfection.

a. 5.25% household bleach is 50,000 ppm Sodium Hypochlorite

b. 6% household bleach is 60,000 ppm Sodium Hypochlorite

Better Water LLC recommends using IRON FREE bleach. Care should be taken to select iron

free bleach because many discount or generic brands will have high iron content. Iron will be

harmful to the equipment and shorten its lifespan.

* WARNING: DO NOT USE "SPLASH-LESS" BLEACH. The content of "splash-less" bleach

may damage the equipment, and will create foam.

* WARNING: Ozone should not be used as a disinfectant on the Cartridge Based Pyrogen

Filter System, because the filters will be damaged.

BLEACH SOLUTION FOR TANK FEED SYSTEMS

- NOTE: Bleach will only be used on Tank Feed Systems

a. 500 ppm solution of sodium hypochlorite (bleach)

This is 1 gallon (128 ounces) of bleach per 100 gallons of water or a 1:100 dilution

5.25% = 500 ppm dilution Water Gallons x 1.28 = ounces of bleach 5.25%

6% = 600 ppm dilution Water Gallons x 0.96 = ounces of bleach 6%

* Total water gallons should include gallons in the tank as well as the loop.

b. Recommended dwell time is 30-60 minutes

* See Appendix A for other bleach dilution ratios and pipe volume calculations, and 3 feet

per second flow velocity rates if needed.

RENALIN / MINNCARE SOLUTION FOR DIRECT FEED or TANK FEED

SYSTEMS

- NOTE: Renalin / Minncare can be used on Direct Feed or Tank Feed Systems

a. 1% Renalin / Minncare solution at a 1:25 dilution

This is 750 ml (25.36 ounces) of Renalin / Minncare per 25 gallons of water or 1:25 dilution

* Total water gallons should include gallons in the tank as well as the loop.

b. Recommended dwell time is 2-4 hours

DISINFECTING PROCEDURE

1. The Cartridge Based Pyrogen Filter System is disinfected as a component of the Post-

Treatment and/or Distribution Segment of the water treatment system. Better Water LLC

recommends that this filter assembly be disinfected monthly or more often if necessary.

2. Slowly open and close the bypass valve a few times during the disinfect process to allow the

bypass ball valve and associated piping to be disinfected.

3. Slowly open and close the sanitary sample ports a few times during the disinfect process to

allow these ports to be disinfected.

Better Water LLC; rev. Apr 2017

Page 9 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

4. Slowly open and close the bypass valve a few times during the disinfect rinse process to allow

the bypass ball valve and associated piping to be rinsed.

5. Slowly open and close the sanitary sample ports a few times during the disinfect rinse process

to allow these ports to be rinsed.

SANITIZING THE SANITARY SAMPLE PORTS

Sanitize the sanitary sample ports immediately BEFORE each sampling operation.

1. Turn the port stem to the left to open and allow a full flow of liquid to pass out of

the port for 1-2 minutes. Then close the port by turning the stem to the right.

2. Fill a 20 ml plastic polypropylene syringe with at least 10 ml of 70% ethanol, 90% isopropyl

alcohol, or 3% hydrogen peroxide solution. Attach the port-needle to the syringe.

3. Insert the needle all the way into the port through the stem opening, and express most of the

sanitizer into the port. Allow a few milliliters to flow out of the port outlet.

4. As the needle is removed from the opening, squirt the remaining few milliliters of sanitizer over

the outer surface of the stem.

5. When ready to sample, open the port for 1 to 2 minutes to allow product water to rinse the

residuals and any endotoxins from the sample port before sampling.

Better Water LLC; rev. Apr 2017

Page 10 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

SAMPLE COLLECTING from a SANITARY SAMPLE PORT

PROCEDURE

1. Put on surgical gloves (or similar) and a face shield.

- NOTE: Failure to do so may result in inaccurate and/or false readings from the

sampling.

2. Flush the Sanitary Sample Port with water by removing the Luer Lock Cap and

twist the valve until a steady Stream of water exits the sample port. Let the water

flow for a minimum of 2 minutes, then close the valve.

- NOTE: Do not misplace the Luer Lock Cap.

3. Prepare a 10cc syringe with the supplied injection needle, and draw into the syringe 10 cc of

70-90% isopropyl alcohol.

4. Inject the alcohol into the sample port. When the Injection is complete, replace the Cap and

let dwell for 10 minutes.

5. After the 10 minute dwell is complete, remove the cap and wipe the outside of the port with an

alcohol wipe.

6. Allow the alcohol to air dry, usually within 30 seconds after application.

7. Twist the valve until a steady stream is present.

- Flush at least 1000 ml from the port, then close the valve.

- Discard this water.

- This ensures that the port (internally) has been rinsed of alcohol residue and possible

endotoxins left from the disinfection.

8. Prepare a sample cup for sampling, and place it cup under the valve

- Open the Sanitary Sample Port slowly to collect the sample.

- Avoid splatter which could cross contaminate the sample.

- Do not allow the cup to touch or come in contact with the Sanitary Sample Port.

9. Close the valve when enough sample has been taken.

- Immediately replace the lid on the sample cup.

- Avoid sample cup cap contamination by coming in contact with any external surfaces.

- Replace the Luer Lock Cap on the Sanitary Sample Port.

10. Follow appropriate procedures for collection of samples with Accu Vials for colony count and

LAL.

Better Water LLC; rev. Apr 2017

Page 11 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

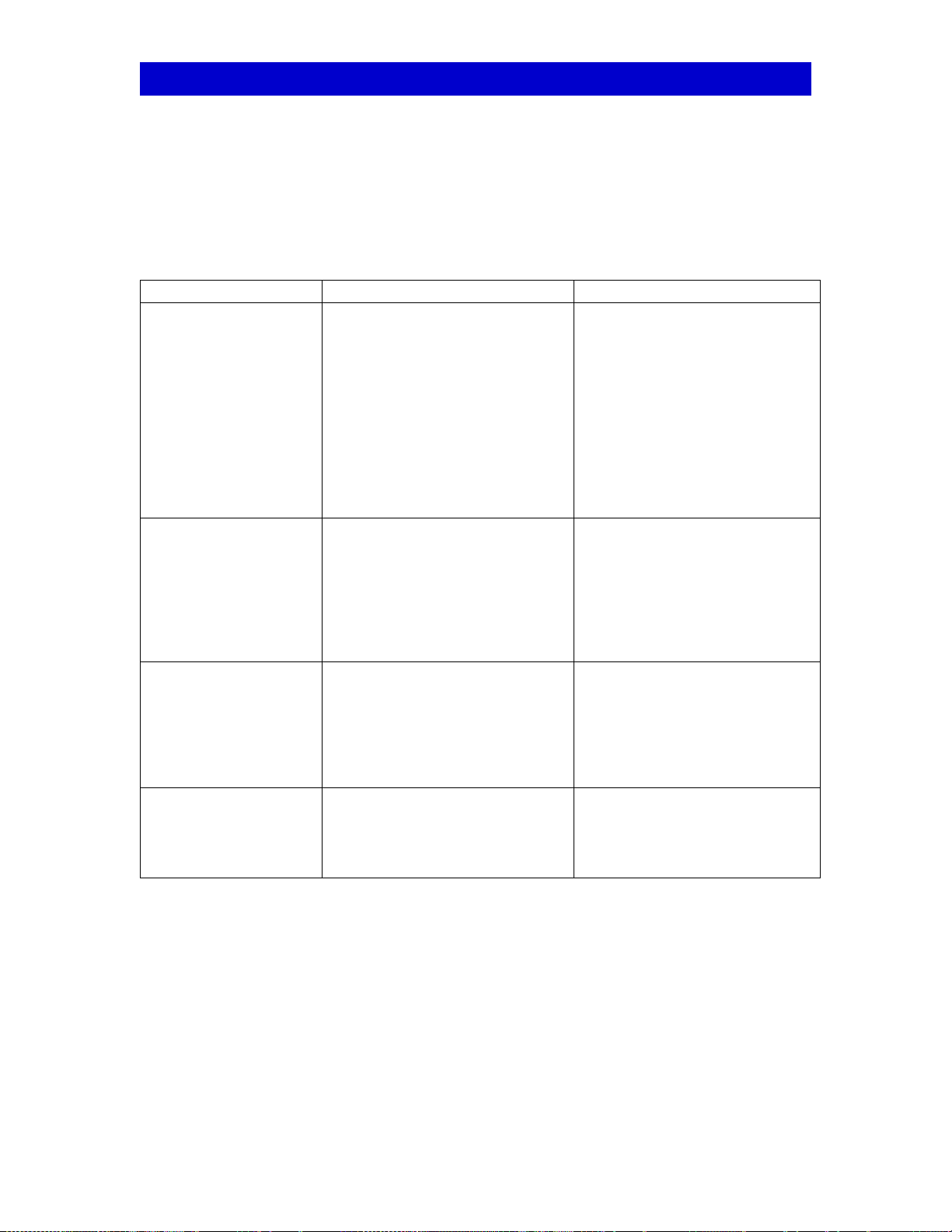

SYSTEM MAINTENANCE, General

Maintenance Task

Frequency

(more often if needed)

Notes

Check the system for leaks

Daily

Visual Inspection

Clean external surfaces

Weekly

Use a soft, damp towel or

sponge.

(DO NOT USE BLEACH)

Record operational pressures

Daily or more often as

required by the facility

Record on a Daily Check List

Disinfect

Monthly or as determined by

the Medical Director

See Disinfection Procedure

section

Change Filters

Every 6 months or if there is a

pressure drop across the

device greater than 15 psi

while the RO is running

See Changing the Filters

section

Perform Chemical, Microbial,

and Endotoxin Testing on

feed and product water as

per AAMI requirements

Schedule established by the

Medical Director

Submit samples to a qualified

testing laboratory

Better Water LLC; rev. Apr 2017

Page 12 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

SYSTEM MAINTENANCE, Changing the Filters

Better Water LLC, recommends that the Pyrogen filters be changed every 6 months, unless

otherwise dictated by, bacteria/endotoxin testing, and/or higher Delta-P (ΔP) pressure across the

system.

1. Start with all valves, sample ports, and drain ports closed.

2. Open the drain ports on the bottom of each of the housings to allow the water to drain

completely from the system. Close drain ports when water flow stops.

3. Using the housing wrench, unscrew the filter housings to remove them from the device.

4. Remove the old filters, and replace with the new filters.

5. Verify the o-ring in the top of each of the housings are properly seated.

6. Screw the filter housings back into place, and hand-tighten.

7. Slowly open the inlet valve to allow water to begin filling the housings.

8. Partially open the outlet sanitary sample port to allow air to be purged from the device.

9. When water flows from the sanitary sample port, signaling that the air has been purged from

the device, close the sanitary sample port.

10.Let the filters soak for 10 minutes at a minimum of 45 psi and check for leaks.

11.Slowly open the outlet valve fully to allow water to flow through the device.

12. Perform a disinfect.

13.The filters are now on-line and ready for use.

part#

SUCAPE00575

20” .03 micron Filter

- or -

SUCAPE00569

20” .05 micron Filter

part#

SUMIOO00588

20” Housing O-ring

Better Water LLC; rev. Apr 2017

Page 13 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

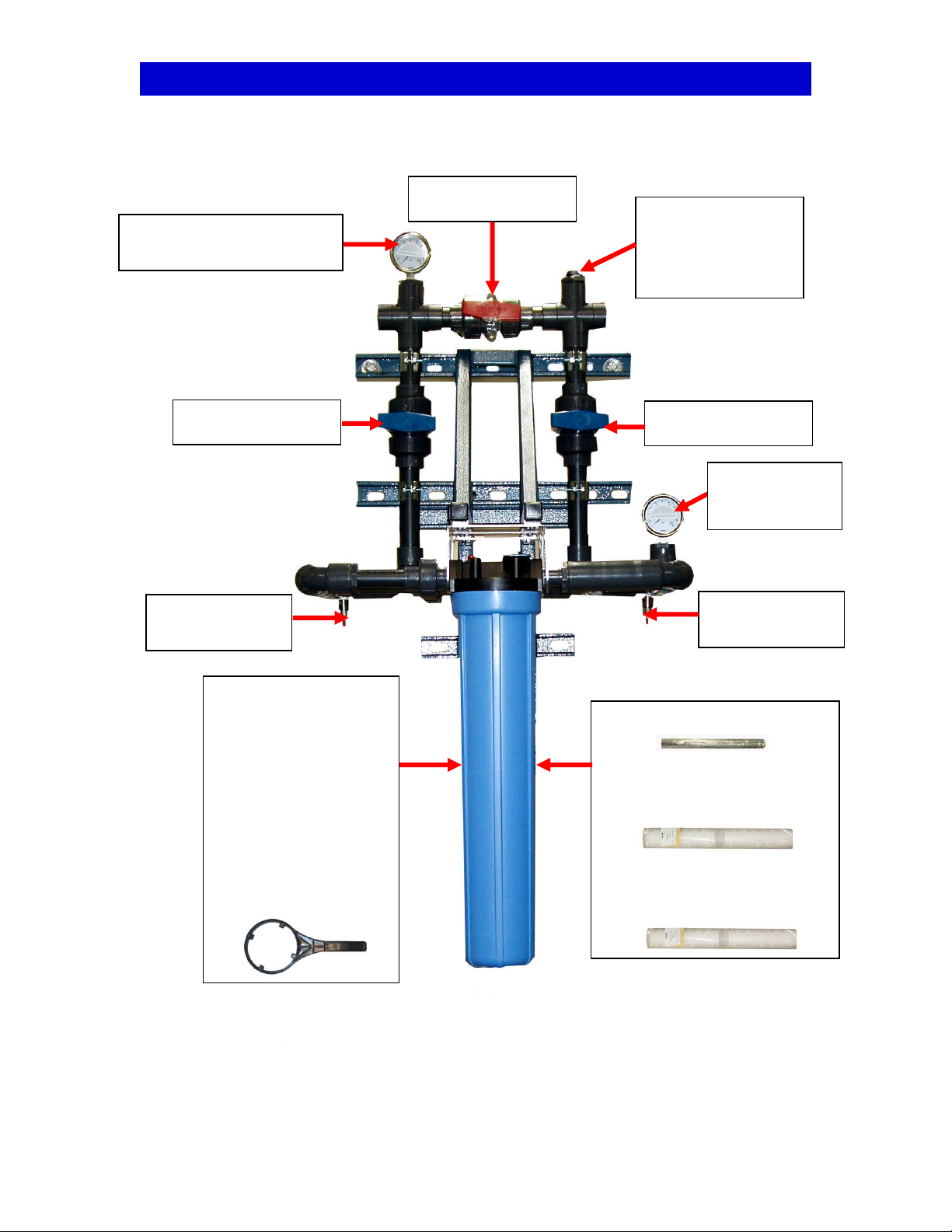

SERVICE HELP

Stainless Steel Inlet Pressure

Gauge

PLGAOO00431

½” Poly Plug

PLFIPO02072

S8 1” x ½” Reducer

Bushing

PLFIS800116

Outlet Sanitary

Sample Port

PLFISSOO02042

Inlet Sanitary

Sample Port

PLFISSOO02042

3/4" x 20" False Tube (inside housing)

SUFFOO00579

- or -

.03 micron Filter, 20" (inside housing)

SUCAPE00575

- or -

.05 micron Filter, 20" (inside housing)

SUCAPE00569

Bypass Valve 1” Red

PLVAS800174-A

Inlet Valve 1” Blue

PLVAS800172-A

Outlet Valve 1” Blue

PLVAS800172-A

Stainless Steel

Outlet

Pressure Gauge

PLGAOO00431

3/4" x 20" Filter Housing

EQFHOO00592

Note: If replacing specify

whether .03 or .05 micron

filters are used. The filter

housing must be drilled out for

.05 micron filters, so note when

ordering.

20” Housing O-Ring

SUMIOO00589

Housing Wrench

SUWROO00583

Better Water LLC; rev. Apr 2017

Page 14 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

TROUBLE-SHOOTING GUIDE

The information in this document is intended to serve as a guide only for qualified operators. It is

not all inclusive of the problems that may be encountered. This guide should aid operators with

reminders and routine trouble-shooting tasks.

For any problem outside the confines of this guide, call for technical assistance.

Problem

Possible Causes

Possible Solutions

The product

(permeate) pressure

has decreased

1. Filters are fouled

2. Filters exceed recommended

change out time

1. Check the inlet pressure to the

filter system.

- If the inlet pressure has

decreased below design

specification (30-100 psi); adjust

the pressure regulator at the loop

return at the reservoir to increase

the inlet pressure.

2. Perform a disinfect

3. If disinfection does not correct

the problem, the Pyrogen filters

must be replaced.

The product

(permeate) water is

contaminated with

microbiological

contaminants

(bacteria and/or

endotoxins)

1. Filter ruptured

2. Missing or damaged o-ring

1. Check the filter system inlet

pressure.

- If the Delta P is lower than

normal there is a possibility that

a Pyrogen filter has ruptured, or

an o-ring is missing or damaged.

Replace the filter and/or o-ring.

The product

(permeate) water is

contaminated with

microbiological

contaminants

(bacteria and/or

endotoxins)

1. Filters are fouled

2. Filters exceed recommended

change out time

3. Improper disinfection

1. Perform a disinfect

2. If disinfection does not correct

the problem, the Pyrogen filters

must be replaced.

The pressure drop is

greater than 15 psi

1. Filters are fouled

2. Filters exceed recommended

change out time

1. Perform a disinfect

2. If disinfection does not correct

the problem, the Pyrogen filters

must be replaced.

Better Water LLC; rev. Apr 2017

Page 15 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

LIMITED WARRANTY TERMS and CONDITIONS

a. This limited warranty is given only to the original buyer and covers the equipment delivered

with this limited warranty.

b. The buyer shall be barred from any recovery on this limited warranty or otherwise for damages

due in whole or in part to…

… unreasonable use

… improper operation

… use beyond normal fashion

… failure to follow instructions

… failure to maintain the product in good condition and repair

… or the like.

c. If the buyer discovers or should have discovered a defect in which it is reasonable to conclude

that damage, either personal, property, or economic, may result, the buyer's continued use of the

product shall constitute any assumption of risk by the buyer and a bar to any recovery for breach

of this limited warranty or otherwise.

d. No oral or written representation, information, or advice given by Better Water LLC or any of its

representatives shall create a warranty or in any way increase the scope of this express limited

warranty and shall not form a part of the basis for bargain.

WHAT IS WARRANTED AND FOR HOW LONG?

a. All equipment, excluding ion exchange and filtration media and cartridges, are warranted to be

free from factory defects in materials, and workmanship under normal use for a period of one (1)

year from the date of shipment.

b. It is a condition precedent to recovery on this limited warranty that the buyer strictly comply

with all operating and maintenance guidelines established by Better Water LLC and that the serial

number (if applicable) is intact and legible on the equipment.

c. It is a condition precedent to recovery on this limited warranty for damage to the external finish

of the equipment that the buyer notifies Better Water LLC at the time of the installation that the

finish is damaged.

WHAT IS REMEDY FOR BREACH OF THIS LIMITED WARRANTY or

NEGLIGENCE BY BETTER WATER LLC

a. Buyer's sole and exclusive remedy for any breach of this limited warranty or negligence by

Better Water LLC shall be repair or replacement of the defective part, at the option of Better

Water LLC, provided such defective part is returned to Better Water LLC for inspection.

b. Better Water LLC shall not be obligated to supply an exact replacement of the defective part

and reserves the right to substitute new and improved parts.

c. Better Water LLC shall provide at no cost to buyer, labor to remove and/or replace defective

parts covered by this limited warranty for a period of ninety (90) days from the date of installation

by Better Water LLC of the equipment.

d. After such ninety (90) day period, buyer shall be responsible for any labor or service charge for

the removal and/or replacement of any defective parts.

e. Buyer shall be responsible for all travel expenses and freight charges at all times.

f. Better Water LLC shall have no obligation to repair or replace any defective part if buyer fails to

follow the procedure set forth in “HOW TO OBTAIN A REPLACEMENT PART UNDER LIMITED

WARRANTY”.

IN NO EVENT SHALL THIS LIMITED WARRANTY BE CONSTRUED TO COVER, NOR SHALL

BETTER WATER LLC BE LIABLE TO BUYER AS ANY OTHER PERSON FOR, ANY

CONSEQUENTIAL, INCEDENTAL, ECONOMIC, DIRECT, INDIRECT, GENERAL OR SPECIAL

DAMAGES, WHICH ARE HEREBY EXPRESSLY DISCLAIMED.

HOW TO OBTAIN A REPLACEMENT PART UNDER LIMITED WARRANTY

a. Buyer should contact the Customer Service or Technical Support Departments and request a

Return Goods Authorization.

Better Water LLC; rev. Apr 2017

Page 16 of 20

Cartridge Based Pyrogen Filtration System (2-4 Filters) Operator Manual

b. Described part(s) will be sent with a purchase order.

c. The returned part(s) will be returned to the factory for limited warranty consideration. If part(s)

are not covered under the limited warranty, part(s) will be considered billable against the

purchase order supplied.

WHAT IS NOT COVERED BY THIS LIMITED WARRANTY:

By way of example and not limitation, this limited warranty does not cover:

Damage to or replacement of any ion exchange resin of filter media

Labor or service charges for the removal and/or replacement of any defective parts after

the ninety (90) day period from the date of installation or sale by Better Water LLC

Freight charges and travel expenses

Damage from inadequate or defective wiring, improper voltage, improper connections or

electrical service, inadequate or defective plumbing, water supply, or water pressure, or

in violation of applicable building, plumbing or electrical codes, laws, ordinances or

regulations.

Damage from improper installation or operation, including but not limited to, abuse,

accident, neglect, improper maintenance, freezing and fires, or abnormal use.

Damage caused by contaminants in Buyer’s water supply, including hardness, chlorine,

chloramines, sulfur, bacterial iron, tannin, algae, oil, organic matter or other unusual

substances, if special equipment has not been installed by Better Water LLC to remove

such contaminants

Damage to or caused by filters/membranes or other replacement parts not purchased

from Better Water LLC or damage caused by modification, alteration, repair or service of

the equipment or any of its parts by anyone other than Better Water LLC or its expressly

authorized representatives.

This manual suits for next models

5

Table of contents

Other Better Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

KENT

KENT Grand+ Mineral RO Instruction handbook for installation, operation and maintenance

Hydac

Hydac OLSW 20 Series Installation and maintenance instructions

Kenmore

Kenmore 625.349224 manual

EcoWater

EcoWater ETF2100PF10 owner's manual

BWT

BWT 1000 Installation and operating manual

Plymovent

Plymovent MultiDust BANK 2X user manual