Better Water 1232 RO User manual

REA 2390

1232 RO

Operator Manual

Better Water LLC

rev. May 2020

REA 2390

Better Water LLC. All rights reserved.

The content of this manual is the intellectual property of Better Water LLC. It is furnished for the

express use by Better Water LLC, their customers and dealers, for informational use only for operation,

service, and internal training. No part of this manual may be reproduced for distribution, sale, or any

intent other than previously described without the written permission of Better Water LLC. This manual

is subject to change without notice. Better Water LLC assumes no responsibility or liability for any error

or inaccuracies that may appear in this documentation.

Adobe and Acrobat are registered trademarks of Adobe Systems, Inc.

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

rev. May 2020

1232 RO Operator Manual

TABLE OF CONTENTS

Our Company ……………………………………………………………………………………... 01

- Contact Us ……………………………………………………………………………………….. 01

- Technical Phone Support ………………………………………………………………………. 01

- Technical Support Info Online …………………………………………………………………. 01

- Specific Contacts ……………………………………………………….……………………….. 02

Introduction ………………………………………………………………………………………… 02

Warnings & Warnings ……………………………………………………………………………. 03

QUICK REFERENCE ….………………………………………………………………………….05

- Specifications, Features, and Requirements ………………………………………………… 06

- Membrane Array Flow Rate Specifications ….………………………………………………. 07

- Maintenance Schedule ……………………………………………………………………….… 08

- Related Consumable and Replacement Parts ………………………………………………. 09

DEVICE INFORMATION ………………………………………………………………………… 11

- Reverse Osmosis Process …………………………………………………………………….. 12

- Models …………………………………………………………………………………………… 13

- Important Information for Support ……………………………………………………………... 13

- Product Description ……..………………………………………………………………………. 14

- Detailed View of 1232 RO, Front Side …………………………………………….... 15

- Detailed View of 1232 RO, Right Side …………………………………….………… 15

- Detailed View of 1232 RO, Back Side ………………………….…………………… 16

- Detailed View of Control Box …………………………………………………………. 16

- System Components ……………………………………………………………………………. 17

- Control Box…………….……………………………………………………………….. 17

- Water Quality Monitor ……..……………………………………………….... 17

- Digital Flush Timer …………………………………………………………… 18

- Temperature Controller ……………………………………………………… 18

- Tank-Stby-Direct Switch …………………………………………………….. 18

- Components That Work In Conjunction With the Control Box ………….. 19

- Membranes …………………………………………………………………………….. 20

- Pre-Filter; Particulate Filtration Cartridge (10”, 5 micron filter) …………………... 20

- Final Filter; Particulate Filtration Cartridge (.03 micron capsule filter) …………… 21

- Pump …………...……………………………………………………………………….. 21

- Remote Alarm Box …………………………………………………………………….. 22

- Clean/Disinfect Tank …………………………………………………………..……….22

OPERATION ………………………………………………………………………………........... 23

- Familiarization with the Control Box and RO Front Panel ……..…………………………… 24

- Initial Start-Up ………………………………………………………………………………….... 27

- Daily Operation ………………………………………………………………………………….. 29

- Monitoring Procedures …………………………………………………………………………. 30

- End of Day Procedure …………………………………………………………………………...30

- Shut Down Procedure ………………………………………………………………………….. 30

- General Cleaning and Disinfecting Information ……………………………………………… 31

- Sanitizing the Sanitary Sample Ports ………………………………………………...33

- Sample Collecting from a Sanitary Sample Port ……………………………..……. 33

- Cleaning and Disinfecting Required Materials ……………………………………… 34

- Cleaning and Disinfecting Procedure (Tank Feed) ……………………………….. 35

- Cleaning and Disinfecting Procedure (Direct Feed) ………………………………. 39

rev. May 2020

1232 RO Operator Manual

SYSTEM MAINTENANCE ………………………………………………………………………. 43

- User Adjustments: ……………………………………………………………………………… 44

- Product and Reject Flow …………………………………………………………….. 44

- Recirculation Flow ……………………………………………………………..………. 44

- Membrane Pressure …………………………………………………………..………. 45

- Reject Pressure ………………………………………………………………..………. 45

- Product Pressure ………………………………………………………………………. 45

- Maintenance Schedule …………………………………………………………………………. 46

- Digital Flush Timer, Standard Operation …..…………………………………………………. 47

- Replace Digital Flush Timer Battery …………………………………………………………... 47

- Set Digital Flush Timer Current Day/Time ……………………..……………...………………48

- Set Digital Flush Timer, Flush Mode Frequency …….………………………………………. 48

- Perform a Manual Flush Using the Digital Flush Timer …………………………………...… 49

- Change 5 Micron, 10” Pre-Filter ……………………………………………………………….. 51

- Change .03 Micron, Capsule Final-Filter ………………………………………………………52

- Change Membranes and O-Rings ……………………………….……………………………. 53

- Factory Reset the Water Quality Monitor Board …………….………………………………. 56

- Calibration of the Water Quality Monitor Board …………………………………..………….. 57

- Long Term Storage: Preserve and Pack ………………………………………………………59

- Trouble-Shooting Guide for 1232 RO ………………………………………………………….63

APPENDIX

- Appendix A: Limited Warranty Terms and Conditions ………………………………………. 65

- Appendix B, Sample Check Lists ……………………..….……………………………………. 67

- RO Daily Start-Up Check List ……………………………………………………….. 68

- RO Quality Assurance Check List …………………………………………………… 69

Appendix C, Technical Service Bulletins ………………………………………………………..71

- TSB2014001: Replacing Chromalox Temperature Controller with Omron

Temperature Controller ……………………………………………………………….. 72

Appendix D, Pre-Ship Test Data …………………………………………………………….….. 75

Better Water LLC; 698 Swan Dr; Smyrna, TN 37167; www.betterwater.com

Visit our website to see our complete product line of

water purification products!

www.betterwater.com

Better Water LLC; rev. May 2020

Page 1 of 78

1232 RO Operator Manual

0

Our

Company

Contact

Us

Technical

Phone

Support

Technical

Support

Info

Online

Better Water LLC is a leading integrated manufacturer of water treatment

equipment and components for the industrial, commercial and institutional

markets.

Located in Smyrna, Tennessee,

Better Water LLC continues its history

of manufacturing and distribution of

equipment specifically designed for the

renal dialysis market.

Founded in 1971, Better Water LLC has

built a reputation for solving our

customers' toughest problems with high

quality products and unmatched service.

Better Water LLC Technical Support:

698 Swan Dr Phone (615) 355-6063, press "1"

Smyrna, TN 37167 Email support@betterwater.com

Phone (615) 355-6063 Customer Service:

Fax (615) 355-6065 Phone (615) 355-6063, press "3"

Email customerservice@betterwater.com

Support is available regarding all Better Water LLC systems,

24 hours a day,7 days a week.

Normal business hours are Monday through Friday from

8:00 am until 3:30 pm, Central Standard Time (excluding holidays)

Call (615) 355-6063, press "1" for Technical Support

Emergency assistance is available after normal business hours (including

holidays) by calling (615) 708-8627.

Our website, www.betterwater.com, which is updated

frequently, contains a wealth of technical support information on the

SUPPORT tab and includes:

Operator and Service Manuals

Consumables and Accessories Lists

Technical Service Bulletins

For your convenience there are also online forms for placing Orders

and requesting Returned Goods Authorization. These are Adobe

forms that can be downloaded and either faxed or emailed to us.

Better Water LLC; rev. May 2020

Page 2 of 78

1232 RO Operator Manual

Specific

Contacts

Technical Support Phone (615) 355-6063, option “1”

Email support@betterwater.com

To Place an Order Fax (615) 355-6065

(purchase orders) Email orders@betterwater.com

Phone (615) 355-6063

Customer Service Phone (615) 355-6063, option “2”

(returns) Fax (615) 355-6065

Website www.betterwater.com

Helpful information and forms that can be found on our website:

- Operator & Service Manuals

- Technical Service Bulletins

- Consumables and Replacement Parts List

- Brochures

- Order Form

- Return Goods Authorization Request Form

The Better Water LLC 1232 RO is manufactured to the utmost quality.

With proper care, preventative maintenance, and proper use, it should

provide you with a very effective means of treating water for dialysis

treatments.

Before starting you should first read and have a thorough understanding

of this entire Operator Manual. It describes in detail the steps and

procedures for safe usage of the 1232 RO.

Once the this device has been delivered, it is the responsibility of the

Medical Director to ensure that it is used, monitored, and maintained in

such a manner so as to satisfy all applicable standards. Guidelines and

other related information are available from:

- Food and Drug Administration (FDA)

- National Association of Nephrology Technicians/Technologists (NANT)

- Association for the Advancement of Medical Instrumentation (AAMI)

The RO cannot do the job alone. It is important to understand and

monitor the changing tap water conditions, which include contaminants,

temperature, pH, pressure and flow-rates, which have a direct impact on

the quality and quantity of the RO’s output. This RO was designed to

your specifications and requirements. Since municipal water conditions

are constantly changing, good two-way communications with your

municipal water supplier coupled with routine testing of the tap water is

vital to the safe and effective operation of this device.

NOTE concerning pictures in this manual:

Pictures of devices and components may vary slightly due to product

changes, and therefore should be for general reference only.

Information concerning their use, functionality, or replacement will not

differ unless noted.

Introduction

Better Water LLC; rev. May 2020

Page 3 of 78

1232 RO Operator Manual

WARNINGS

1. It is unsafe to operate or service this device without first reading and understanding the entire

Operator and Service Manuals. Keep this manual and other associated documentation for future

reference.

2. Misuse, improper operation, and/or improper monitoring of this system could result in serious

injury, death, or other serious reactions to patients undergoing hemodialysis treatment.

3. Misuse, improper use or handling of disinfectants and chemical cleaning solutions could result

in serious injury or even death. You must comply with the information contained in the Material

Safety Data Sheet (MSDS) for the chemical being used.

4. To avoid electrical shock hazard, do not operate this device when the covers or panels are

removed.

5. ELECTROMAGNETIC INTERFERENCE: This device can create and radiate

radio frequency energy and may cause harmful interference if not installed

according to the manufacturer's instructions.

CAUTIONS

1. When used as a medical device, federal law restricts this device to sale by or on the authority

of a physician. Per CFR 801.109 (b)(1).

2. Improper operation of this device could result in a low or no-flow alarm on the dialysis

machines.

3. Misuse or improper operation of this device will void any warranty.

4. Where water is mentioned, unless otherwise noted, it must be AAMI standard quality water.

5. Electrical and plumbing connections must adhere to local statutes and any facility codes.

Connect this device to a proper ground connection in accordance with the National Electrical

Code. Do not remove the ground wire or ground plug. Do not use an extension cord with this

device.

6. Do not remove any Caution, Warning or any other descriptive labels from the device.

7. Do not operate this device in an explosive environment or in the presence of flammable

materials. Do not use this device to store, mix or transfer flammable liquids.

8. Movement or vibrations during shipment may cause connections to loosen.

9. Do not operate this unit in an environment where temperatures may be below 50oF or above

90oF.

10.This device should not be used for purposes outside the device’s stated applications,

specifications or limitations.

Better Water LLC; rev. May 2020

Page 4 of 78

1232 RO Operator Manual

Better Water LLC; rev. May 2020

Page 5 of 78

1232 RO Operator Manual

QUICK REFERENCES

- Specifications, Features, and Requirements

- Maintenance Schedule

- Related Consumable and Replacement Parts

Better Water LLC; rev. May 2020

Page 6 of 78

1232 RO Operator Manual

SPECIFICATIONS

Operating Weight

250-300 lbs

Dimensions

Height 66” x Length 32” x Width 12”

Electrical

24 vac Control Voltage

120V Models: 1 phase, 20 amp, 60 Hz (1 hots, 1 neutral, 1 ground)

FEATURES

Sample Port

Product sample port, sanitary, stainless-steel, post .03 filter

Standard Alarms

Poor Water Quality Alarm

High Feed Temperature Alarm

Low Pressure Alarm

High Pump Pressure Alarm

High Membrane Pressure Alarm

High Product Pressure Alarm

Optional External

Accessories

Remote Alarm Box, Disinfect Tank

REQUIREMENTS

Floor Space

Level floor with sufficient space around the device for

installation, operation, and service.

Electrical

Power outlet near the center of the device per specifications

above.

Inlet Water Connection

Pre-treated water.

Connection: 1”, 90°, Hose-barb

Product Water Connection

Connection: 3/4", male, threaded

Drain

Sanitary drain capable of discharging 20 gallons per minute.

Must be an open drain (air-gapped)

Primary Drain Connection: 3/4", female, threaded

Loop

The distribution loop should be constructed of

materials that comply with current AAMI standards. It is

critical for direct-feed systems, that the distribution loop be

properly sized, so assistance should be sought from Better

Water or an authorized dealer when determining its size and

length. Installation should also comply with current AAMI

standards.

Pressure

Feed water pressure should be a minimum of 20 psi, a

maximum of 90 psi, with the optimum pressure at 40 psi. The

minimum pressure must be maintained with the water flowing

at the maximum required flow-rate.

Flow Rate

The minimum flow-rate in gallons per minute is based on the

incoming pre-treatment equipment.

Chlorine / Chloramines

Chlorine is commonly used as a disinfecting agent in

municipal water systems. Disinfection by-products can form

when disinfectants, such as chlorine, react with naturally

present compounds in the water. Chlorine/Chloramines in the

feed water must be less than 0.1 ppm.

Silt Density Index (SDI)

Silt Density Index (SDI) is a measure of the amount of

suspended solids and colloidal materials in the feed water.

High SDI values can lead to membrane fouling. A SDI of less

than 3 SDI units is considered acceptable.

Turbidity

Turbidity in water is caused by suspended and colloidal matter

such as clay, silt, finely divided organic matter, inorganic

matter, plankton, and other microscopic organisms. Feed

Better Water LLC; rev. May 2020

Page 7 of 78

1232 RO Operator Manual

water turbidity must be less than 1 nephelometric turbidity

units.

Hardness

Hardness is characteristic of feed water due to the presence

of dissolved calcium and magnesium. Water hardness is

responsible for most scale formation and can form insoluble

residue in pipes and other water contact surfaces. Hardness

is usually expressed in grains per gallon, or parts per million,

all as calcium carbonate equivalent. Hardness level in the

feed water must be less than 3 grains per gallon, or 51.3 parts

per million.

Temperature

Feed water temperature must be between 50oF and 92oF.

The optimum temperature is 77oF. The maximum

temperature is factory set at 92°F, so the RO will shut-down at

93°F. This setting can be adjusted if necessary.

MEMBRANE ARRAY FLOW RATE SPECIFICATIONS

The flow rates for the arrays listed below are rated at 77˚F feed water, ± 20% and at 50%

recovery.

1232 RO Series

Product Flow

Reject Flow

Re-Circulate Flow

3 Membrane Array

(older models)

1.5 GPM

1.5 GPM

1.5 GPM

4 Membrane Array

2.0 GPM

2.0 GPM

2.0 GPM

The importance of monitoring and controlling the feed water cannot be underestimated.

Better Water LLC; rev. May 2020

Page 8 of 78

1232 RO Operator Manual

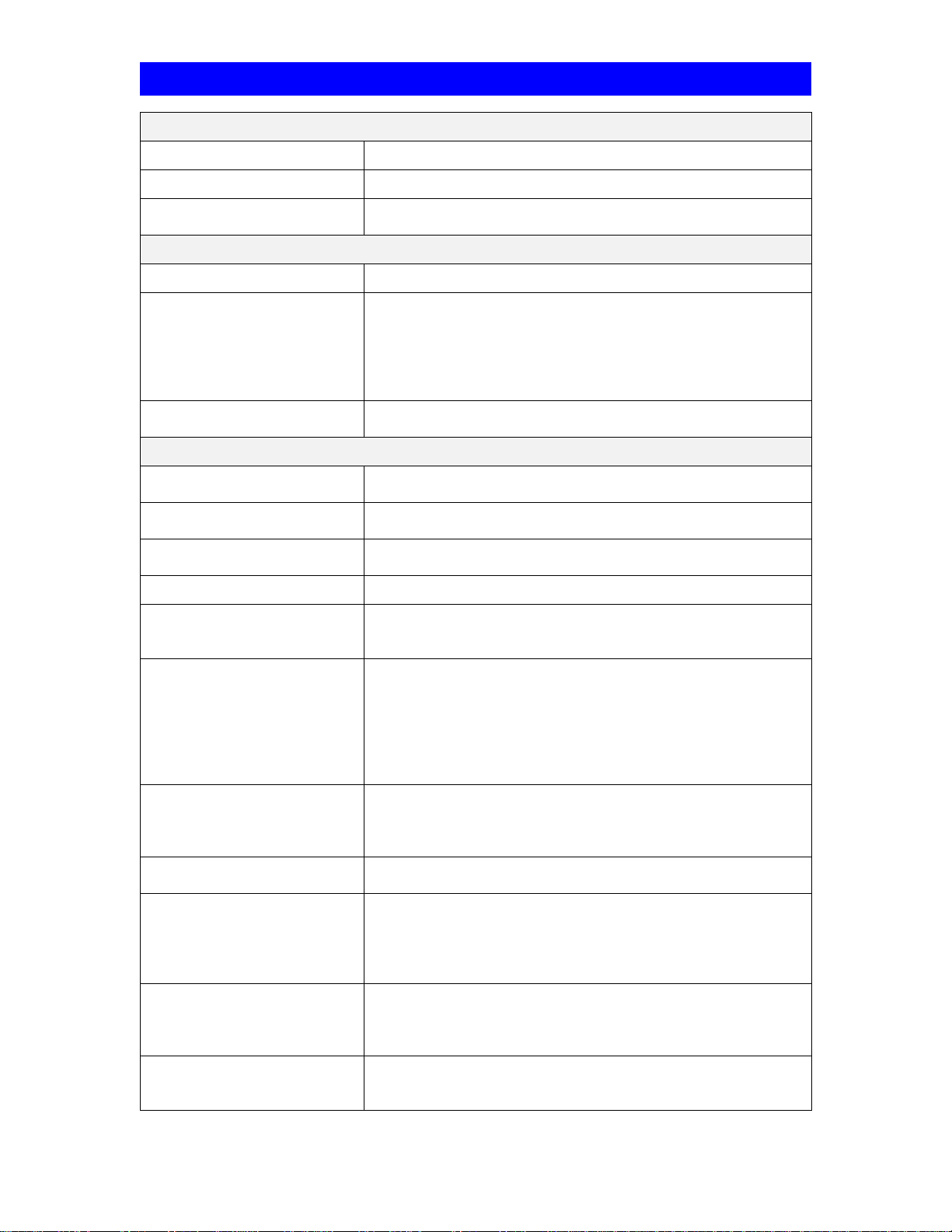

MAINTENANCE SCHEDULE

MAINTENANCE TASKS

Each

Shift

Daily

Weekly

Monthly

3

Months

6

Months

Other

Check the system for leaks

X

X

Visual

inspection

Monitor the system for unusual

sounds

X

X

Auditory

inspection

Clean external surfaces;

- Use a soft damp cloth. Do not

use bleach.

X

Use a soft,

damp towel or

sponge. DO

NOT USE

BLEACH.

Perform low pH cleaning and

disinfection.

- See “General Cleaning and

Disinfecting Information” section

X

Perform low pH cleaning , high

pH Cleaning, and disinfection.

- See “General Cleaning and

Disinfecting Information” section

X

Verify Water Quality Monitor

Board, calibrating if necessary

- See “System Maintenance”

section

X

Verify Flush Timer day and time

setting

- See “System Maintenance”

section

X

X

Change 5 micron Pre-Filter

- See “System Maintenance”

section

X

Change every

30 days or

when the oP

reaches or

exceeds 15

psi.

Change .03 micron Final Filter

- See “System Maintenance”

section

X

Change every

6 months or

when the oP

reaches or

exceeds 15

psi.

Change Membranes

- See “System Maintenance”

section

Every 3-5

years, or

when low flow

rates are

experienced,

or percent

rejection

drops below

operational

parameters.

Perform chemical, microbial,

and endotoxin testing on feed

and product water as per AAMI

requirements. Submit to a

qualified testing laboratory.

Annually, or

more often as

needed.

NOTE

The maintenance schedule is merely a recommendation by Better Water, but it is up to

the discretion of the Medical Director of the facility as to when they are performed,

which may be more often or less often at their discretion as circumstances and

company policy dictate.

Better Water LLC; rev. May 2020

Page 9 of 78

1232 RO Operator Manual

RELATED CONSUMABLE and REPLACEMENT PARTS

DESCRIPTION

PART#

PICTURE

REPLACEMENT PARTS

2.5” x 40” Membrane

- Large O-Ring EQFHOO01996

- Small O-Ring EQFHOO01588

SUMEM01356

10”, 5 micron, Pre-Filter

- Housing O-Ring SUMIOO00587

SUCAOO00551

.03 micron, Capsule Final-Filter

SUCAPE00547

BWI-1000, Acid Cleaner, low pH cleaner

SUMCOO00572

BWI-2000, Alkaline Cleaner, high pH

cleaner

SUMCOO00571

MinnCare Cold Sterilant, Disinfectant

SUMCOO00575

MinnCare 1% Test Strips

SUMCOO00577

MinnCare Residual Test Strips

SUMCOO00576

Pictures do not reflect the size of the item in relation to the other pictures

Better Water LLC; rev. May 2020

Page 10 of 78

1232 RO Operator Manual

RELATED CONSUMABLE and REPLACEMENT PARTS

DESCRIPTION

PART#

PICTURE

BWI-3000, MemStore, Preservative

SUMCOO00574

Clean/Disinfect Tank

- Includes hoses and connections

EQASSYDISTANK

RO Pump

EQPUTE01883

Remote Alarm Box

EQASSYNSMB01601

24V Digital Flush Timer

ELPWSW00991

RO Monitor PCB

EQMOBO01351

RO Display Board

EQMOBO01352

Conductivity Probe

EQSUBCP01545

Pictures do not reflect the size of the item in relation to the other pictures

Better Water LLC; rev. May 2020

Page 11 of 78

1232 RO Operator Manual

DEVICE INFORMATION

Better Water LLC; rev. May 2020

Page 12 of 78

1232 RO Operator Manual

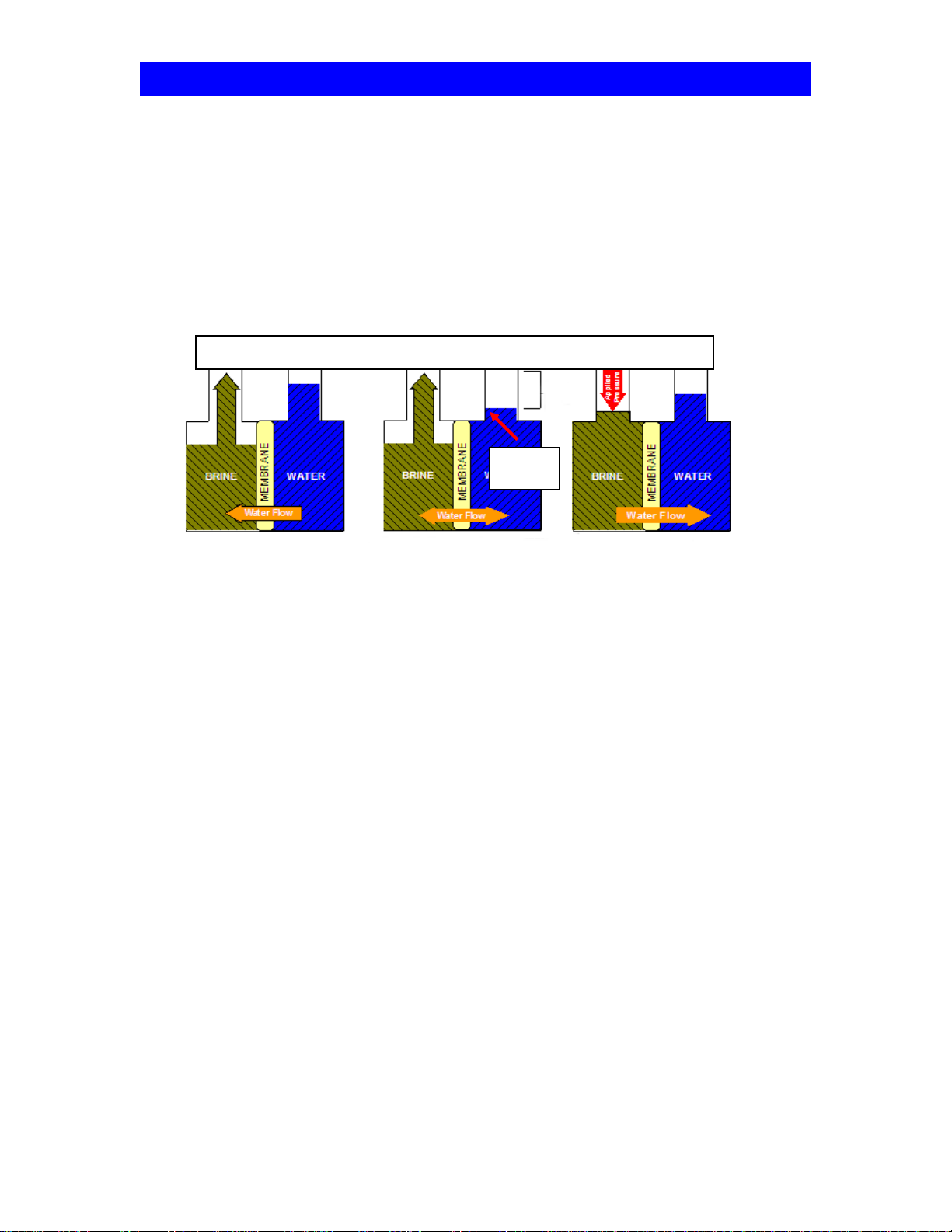

REVERSE OSMOSIS PROCESS

The Reverse Osmosis (RO) Machine is a multiple-membrane, device that is pressurized by a

stainless steel pump and motor. The Reverse Osmosis process uses a semi-permeable

membrane to separate and remove dissolved solids, organics, Pyrogen, submicron colloidal

matter from the water. The process is called "reverse" osmosis since it requires pressure to force

pure water across a membrane, leaving the impurities behind. Reverse Osmosis is capable of

removing 95%-99% of the total dissolved solids (TDS) thus providing safe, pure water. Based

upon your facility’s specifications and information about tap water data, the RO was designed and

built to exacting standards and Good Manufacturing Practices as outlined by the FDA. The RO is

a device that uses a membrane separation process for removing solvent (contaminants) from

solution (tap water).

The RO is the most important and costly component in the water treatment system. With

appropriate pretreatment of the tap water, proper cleaning and disinfection, the RO membrane life

can be prolonged for several years.

.

OSMOSIS EQUILIBRIUM REVERSE OSMOSIS

Osmonic

Pressure

Water flows from the

lower concentration of

salts across a permeable

membrane to the higher

concentration.

Osmotic Pressure is

the pressure

required to stop

water flow and reach

equilibrium.

By applying pressure

greater than the osmotic

pressure, the flow of water

is reversed. The water flows

from a higher concentration

of salts to a lower

concentration.

Better Water LLC; rev. May 2020

Page 13 of 78

1232 RO Operator Manual

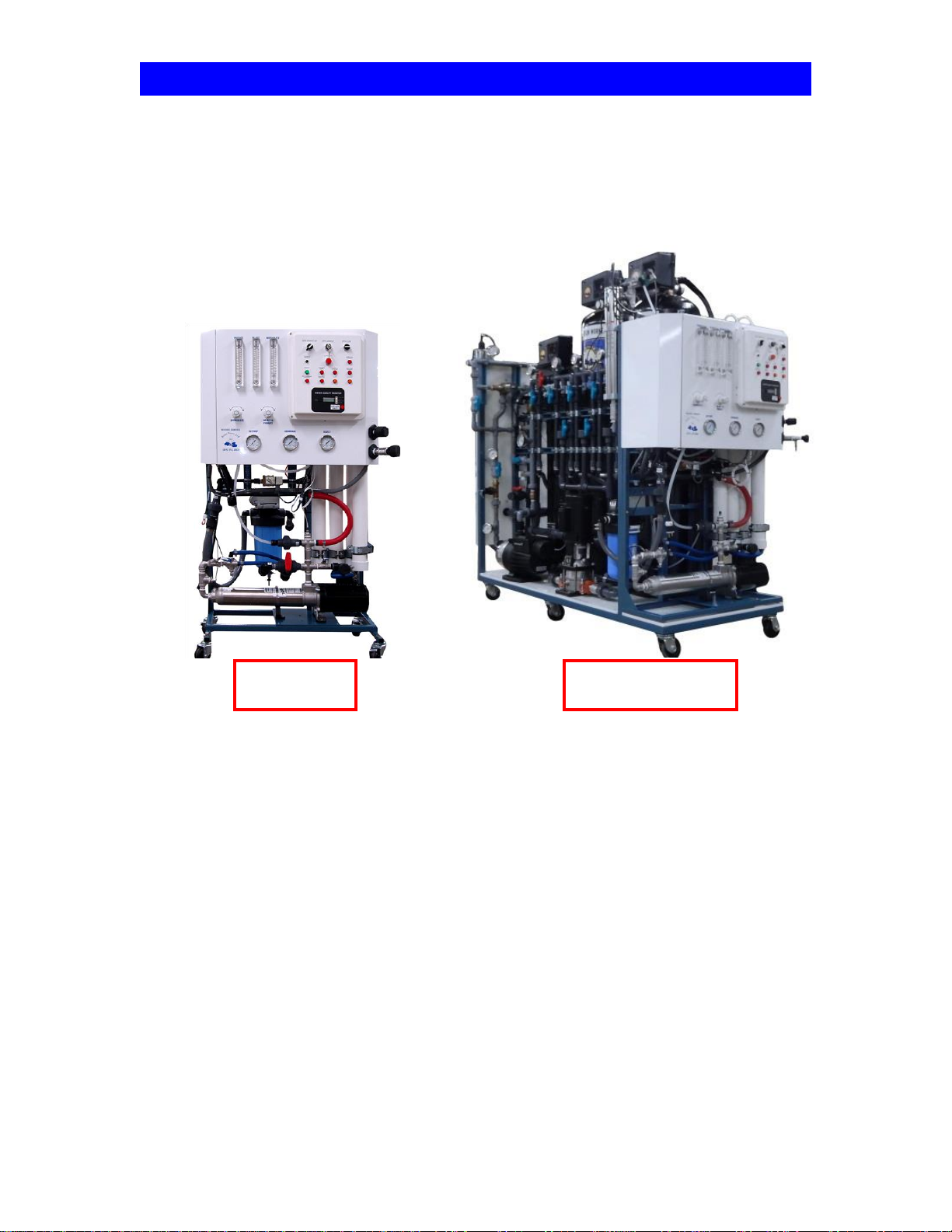

MODELS

There are two models of the 1232 RO. One which is used as a stand-alone RO, and the other as

part of a MediPac unit.

Part#

Membranes

Gallons

per Day

Gallons per

Minute

Electrical

Requirements

EQRO-1232-2800-01001

4

2880 gpd

2.0 gpm

120V, Single Phase

EQRO-1232-2800-M1001

* Part of Medipac *

4

2880 gpd

2.0 gpm

120V, Single Phase

IMPORTANT INFORMATION FOR SUPPORT

Adhered to the front of each 1232 RO is a label containing important information relating to the

specific unit, and details both the Model and Serial Number. Both of these pieces of

information are very important in obtaining support, determining warranty, and properly servicing

the unit. Please have this information available if you contact Technical Support.

For STAND-ALONE 1232 RO:

The first four numbers in the serial number denote the year and month the device was

manufactured. In the example above the RO was produced in 2016, in the month of November.

For 1232 RO THAT IS PART OF A MEDIPAC:

The RO is not serialized itself, and is considered a part of

the Medipac system. The Medipac as a whole is serialized,

and that label is found on the opposite end on the Medipac’s

control box. If obtaining technical support, refer to which type

of RO (stand-alone or Medipac) is in question.

“16” –Year

“11” - Month

1232 RO mounted as part

of a Medipac system

Better Water LLC; rev. May 2020

Page 14 of 78

1232 RO Operator Manual

PRODUCT DESCRIPTION

The 1232 RO has been designed and built to meet the specific needs for your water system in a

minimal amount of floor space, adding a neat and clean look to your water room. Based on the

number of membranes it is designed to produce RO water at 1.50 to 2.00 gallons per minute for

hemodialysis. It can be used for both Tank-Feed and Direct-Feed applications. It also can be a

stand-alone central delivery unit or mounted on a rack as part of the Medipac system, but

operation is the same for both.

The Frame is constructed of welded stainless-steel with a durable powder-coat paint finish to

reduce rust and corrosion.

The RO has a Pump that is used to raise the osmotic pressure across the thin film composite

2.5” x 40” Membranes to produce safe, pure water. For additional filtration, this unit has a Pre-

Filter (5 micron, 10”) as well as a Final Filter (.03 micron capsule filter).

The Control Box contains the electronic components for operational control, monitoring, and

alarms. The following are additional features incorporated into the RO’s Control Box:

- A Digital Flush Timer to control the frequency and duration of a flush cycle.

- A Water Quality Monitor to display % rejection, feed TDS, and product TDS, and alarm in a

poor water quality condition.

- Timed Operate feature to allow the RO to run for thirty minutes prior to the operator performing

daily checks.

- Interfaces with the Interlock Wiring System to shut the RO off when any of the pre-treatment

components go into regenerate or backwash mode, and provide a visual indicator.

- Interfaces with the Level Control System to turn the RO off and on based on water levels in the

Storage Tank.

Mounted on the Front Panel of the RO, are Flow-Meters and Pressure Gauges for monitoring,

as well as Adjustment Handles to achieve optimum performance.

Stand-Alone

1232 RO

1232 RO mounted as part

of a Medipac System

Better Water LLC; rev. May 2020

Page 15 of 78

1232 RO Operator Manual

DETAILED VIEW OF 1232 RO, Front Side

DETAILED VIEW OF 1232 RO, Right Side

Control

Box

Pump

Product Flow-Meter

Disinfect

Valve on

Pump

Reject & Product Adjust

Handle

Recirculate Adjust Handle

Reject Flow-Meter

Recirculate Flow-Meter

Pressure

Gauges

2.5” x 40”

Membranes

Final Filter,

.03 Capsule

Control

Box

Pre-Filter,

10”, 5 mic

Drain Port

Product Port

Direct Feed 3-

Way Valve

(direct feed

model only)

Better Water LLC; rev. May 2020

Page 16 of 78

1232 RO Operator Manual

DETAILED VIEW OF 1232 RO, Back Side

DETAILED VIEW OF CONTROL BOX

2.5” x 40”

Membranes

Junction

Box

Final Filter,

.03 mic.

Capsule

Pre-Filter,

10”, 5 mic.

Table of contents

Other Better Water Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Franklin Water Treatment

Franklin Water Treatment PNR1-0948 Installation instructions and owner's manual

Sterling

Sterling IM Series Installation instructions & owner's manual

MATALA

MATALA Aqua2use GWDD Installation and operating instructions

AquaTru LLC

AquaTru LLC AquaTru owner's manual

Millipore Sigma

Millipore Sigma Pellicon 3 Cassettes Installation and user guide

AQV

AQV AQV5 user manual