Bevco IECAX480V125A Setup guide

Technical Publications

Installation, Operation, and Service Manual

SIEMENS HEALTHCARE

INTEGRATED ELECTRICAL CABINET

for

ARTIS Q / Q.ZEN / ONE

ARTIS ZEEGO / ZEEGO.ZEN

ARTIS ZEE MULTIPURPOSE

SINGLE PLANE

IECAX480V125A

Main Disconnect Panel

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 2 of 14

Bevco Engineering Company, Inc.

CONFIDENTIAL AND PROPRIETARY

This Bevco Engineering Company document contains confidential and

proprietary information of Bevco Engineering Company.

The intellectual properties contained herein may not be used or copied to the

detriment of Bevco Engineering Company. The information contained in this

document may not be copied without the express written approval of Bevco

Engineering Company.

Troubleshooting and servicing should be performed by a qualified

electrician.

De-energize and lockout the main disconnect before servicing this panel.

Table of Contents

1.0 DESCRIPTION OF OPERATION....................................................................................................................3

2.0 SYSTEM CONFIGURATION...........................................................................................................................4

3.0 SPECIFICATIONS...........................................................................................................................................5

•ELECTRICAL SPECIFICATIONS:...................................................................................................................5

•SEISMIC SPECIFICATIONS:..........................................................................................................................5

•ENVIORNMENTAL SPECIFICATIONS:..........................................................................................................5

•ELECTRICAL WIRING DIAGRAM: .................................................................................................................5

4.0 PANEL DIMENSIONS.....................................................................................................................................6

•CENTER OF GRAVITY ...................................................................................................................................7

•MOUNTING HOLE DIMENSIONS...................................................................................................................8

5.0 INSTALLATION...............................................................................................................................................9

6.0 TESTING and TROUBLESHOOTING..........................................................................................................12

7.0 MAINTENANCE.............................................................................................................................................14

8.0 REPLACEMENT PARTS...............................................................................................................................14

9.0 DOCUMENT REVISION HISTORY...............................................................................................................14

COMPONENTS SUPPLIED WITH EACH PANEL:

•The IEC Main Disconnect Panel

•This Installation, Operations & Service Manual

•(3) sets of Emergency Power Off pushbuttons with 2NC contacts on each EPO

•Drawings and Electrical Schematics

WARNING!

CAUTION!

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 3 of 14

1.0 DESCRIPTION OF OPERATION

This panel incorporates several features desirable for system installations to minimize down time,

protect the X-Ray Generator electronics, and to reduce operational delays after a power outage. This

product replaces the power panel, the lighting control relay box, and the Emergency Power Off

controls. The panel has a main circuit breaker, Q1, provides fully integrated “X-Ray ON” warning light

control and a relay to reduce the room lighting during the procedure. When the main circuit breaker is

turned off, all power circuits within the panel will be de-energized.

Q1 provides the disconnect means and lock-out and tag-out (LOTO) the X-Ray Generator power circuit

for maintenance purposes. The K2 contactor will open with any loss of power or by pressing any

Emergency Power Off (EPO) pushbutton. The contactor control circuit is factory configured to

automatically re-energize the X-Ray Generator upon restoration of facilities power. The control circuit

may be re-configured to require the operator to manually restart the equipment once the incoming

power has been restored. This protects the sensitive electronic circuits of the X-Ray Generator from

sags and surges that immediately follow power loss from blackouts, storms, utility reclosure operations,

and out of phase automatic transfer switch operations.

The SC1 cabinet is protected by an electronic circuit breaker, Q3, and controlled by contactor K6. The

contactor will open with any loss of power or by pressing any Emergency Power Off (EPO) pushbutton.

The control circuits for the EPOs are low voltage 24 VDC and are fully powered from within the panel.

The restart functionality and EPO circuitry is controlled with a safety relay, K10. See page 11 for detail.

The white SAFETIES OK indicator light on the front of the panel is illuminated when none of the EPOs

are pressed. When the white light is active, pressing the green START pushbutton will cause the X-

Ray Generator to be energized. The green START button will illuminate, and the white SAFETIES OK

light will go off. Pressing the STOP button will de-energize the system. Any EPO pressed while the

system is energized will result in the immediate de-energizing of the X-Ray Generator system.

If an EPO is pressed at any time, the EPO must be reset which will cause the SAFETIES OK light to

activate. Then the START button will activate the system.

The EPOs provided with the IEC include additional Normally Closed contacts for connections to a UPS

system.

IMPORTANT:

If building power is removed from the panel while the X-Ray system is energized, the power to the X-

Ray system will be restored when building power returns without any human interaction. The X-Ray

system can then be restarted normally.

Additional provisions are made to integrate the “X-Ray ON” warning lights and room lighting with the X-

Ray Equipment. The facility lighting panel provides 120- or 277-volt power that is controlled by

contacts relays of K4 and K5 mounted in the IEC. The signal controlling the relays comes directly from

the Siemens Generator/Power Cabinet. The IEC will accept signals from the generator as either Dry

Contacts or 24 Volts AC or DC. Note the maximum connected load to the X-Ray On lights is 20 Amps.

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 4 of 14

2.0 SYSTEM CONFIGURATION

UTILITY

SUPPLY

480V 3-PHASE

100A MAX

Q1

125A

WIRESIZE:

6-3/0AWG

K2

185A MAX

WIRE SIZE:

10-2/0AWG

F2

4A

G01

DC POWER

SUPPLY

DC CONTROL CIRCUITS

K1 –SAFETY CONTACTOR

K4 –ROOM LIGHT RELAY

K5 –WARNING LIGHT RELAY

EMERGENCY POWER OFF

CIRCUITS

EPO1

EPO2

LIGHTING

POWER PANEL

120/277V

KEY TO COMPONENTS:

Q1 –MAIN CIRCUIT BREAKER

Q2 –GENERATOR 2 CIRCUIT BREAKER

Q3 –GENERATOR 1 CIRCUIT BREAKER

F2 –POWER SUPPLY FUSES

F4 –DC CIRCUIT BREAKER

G01 –DC POWER SUPPLY

K1 –SAFETY CONTACTOR

K2 –X-RAY GENERATOR CONTACTOR

K4 –ROOM LIGHT RELAY

K5 –“X-RAY ON” WARNING LIGHT RELAY

K6 –SYSTEM CABINET CONTACTOR

GENERATOR 1

100A MAX

F4

5A

ROOM LIGHTS

20A MAX

“X-RAY ON”

WARNING LIGHT

20A MAX

EPO3

Q3

ADJUSTABLE

30A

K6

30A

WIRE SIZE:

14-8AWG

Q2

100A

SC1

DOOR SWITCH

CONTROL

ROOM LIGHT CONTROL

X-RAY ON CONTROL

30A MAX

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 5 of 14

3.0 SPECIFICATIONS

•ELECTRICAL SPECIFICATIONS:

UL design and ratings of this panel require the application of wire at the 75°C ampacity ratings

of NEC table 310.16. Wire rated at higher temperature ratings, such as 90°C, may be used

but ONLY applied at the 75°C ampacity ratings of NEC Table 310.16.

Catalog Number

Incoming Voltage &

Frequency

Incoming Power

Configuration

Main Circuit

Breaker Rating

Regulatory

Markings

IECAX480V125A

480VAC, 50/60Hz

3Ø + Ground + Neutral +

125 Amps

cULus

Short Circuit Current Rating is 35,000 Amperes RMS Symmetrical @ 480V

•SEISMIC SPECIFICATIONS:

This Integrated Electrical Cabinet has been certified by

an independent California structural engineer in

conformance with the shake testing requirements of

ICC-AC 156. The California OSHPD number is OSP-

0457-10.

The seismic performance characteristics are as follows:

SDS(g)≤ 2.56; z/h ≤ 1.0 ; Ip ≤ 1.5

•ENVIORNMENTAL SPECIFICATIONS:

FOR INDOOR USE ONLY

Temperature 59-90°F (15-32°C)

Humidity 30-75%, NON-CONDENSING

•ELECTRICAL WIRING DIAGRAM:

The Electrical Wiring Diagram is shipped along with the disconnect panel inside the enclosure

door for convenient reference to the circuitry.

PARTS, TECHNICAL SUPPORT AND SERVICE

FOR INQUIRIES DURING INSTALLATION

CONTACT BEVCO ENGINEERING,

SUSSEX WI (262) 820-2400

FOR ISSUES FOLLOWING INSTALLATION,

CONTACT SIEMENS UPTIME CENTER,

(800) 888-7436

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 6 of 14

4.0 PANEL DIMENSIONS

Refer to the Table and Illustrations below for the physical dimensions of the panel. The panel

may be recessed into the wall up to 5 inches for semi-flush installations. See Illustrations

below for typical front and side views with the mounting hole pattern. Refer to the drawing set

provided with the panel for total weight and center of gravity dimensions.

PANEL EXTERNAL PHYSICAL DIMENSIONS

Parameter

Dimensions

Height

30.0 inches

762 mm

Width

20.0 inches

508 mm

Total Depth

9.44 inches

244 mm

Enclosure Depth

8.0 inches

203 mm

Mounting Hole Width

18.37 inches

467 mm

Mounting Hole Height

28.5 inches

740 mm

Weight

67 pounds

30.4 kg

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 7 of 14

•CENTER OF GRAVITY

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 8 of 14

•MOUNTING HOLE DIMENSIONS

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 9 of 14

5.0 INSTALLATION

•The enclosure must be mounted at a height so the top of the main circuit breaker

handle, when in the ON position, does not exceed 6ft-7in. (2m) above the floor. (Per

National Electric Code (NEC # 404.8).

•Incoming power is connected to the main circuit breaker located at the upper right of

the Main Disconnect Panel. Refer to the schematic drawing for the incoming conductor

size range and tightening torques.

•There are no conduit knockouts provided in the panel. The installer must punch the

conduit holes in the enclosure walls in the desired locations. The conduits may enter

on the top, bottom, either side, or in designated areas from the back of the enclosure.

NOTE: When drilling or punching the conduit entry holes, protect the internal

components from the falling metal chips.

•All conductors must be sized per the wiring shown on the installation drawings or in the

system configuration diagram.

1. Determine the system configuration.

2. Note the model of X-Ray Generator. It will have a rating of 65kW or 80kW.

3. Connect the incoming power to the Line side of the Main CB, Q1, terminals L1, L2, and

L3.

4. Connect the X-Ray Generator directly to the load side of contactor K2, terminals 2T1,

4T2 and 6T3.

5. Connect the System Cabinet SC1 directly to the load side of contactor K6, terminals

2T1, 4T2 and 6T3.

6. Connect the IEC Emergency Power Off (EPO) circuits to terminals 1 and 2 of X02. All

EPOs should have normally closed contacts wired in series. See EPO wiring diagram.

7. Room light controls are on terminals X05 1 through 4. Verify first if the Siemens System

Cabinet is providing a dry contact or 24V AC or DC. If 24V AC or DC is provided,

connect the two wires coming from the Siemens System Cabinet to terminals 1 and 2 of

X05. If a dry contact is provided, connect the two wires coming from the Siemens

System Cabinet to terminals 3 and 4 of X05. See Lighting Wiring Diagram.

8. Connect Room light and lighting panel to terminals 5 and 6 of X05. See Lighting Wiring

Diagram.

9. “X-Ray On” controls are on terminals X06 1 through 4. Verify first if the Siemens

System Cabinet is providing a dry contact or 24V AC or DC. If 24V AC or DC is

provided, connect the two wires coming from the Siemens System Cabinet to terminals

1 and 2 of X06. If a dry contact is provided, connect the two wires coming from the

Siemens System Cabinet to terminals 3 and 4 of X06. See Lighting Wiring Diagram.

10.Connect Warning light and lighting panel to terminals 5 and 6 of X06. See Lighting

Wiring Diagram.

11.Connect the Door Switch DSW1 to terminals 1 and 2 of X07. See Door Switch Wiring

Diagram.

12.Connect the Door Switch Connections of the Siemens System Cabinet SC1 to the

terminals 3 and 4 of X07. See Door Switch Wiring Diagram.

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 10 of 14

INSTALLATION(continued)

TERMINAL LAYOUT (Located in the bottom left of the Disconnect Panel)

EPO WIRING

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 11 of 14

LIGHTING WIRING

DOOR SWITCH WIRING

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 12 of 14

6.0 TESTING and TROUBLESHOOTING

PRIOR TO TESTING THIS PANEL, ENSURE NO ONE IS WORKING

ON OR NEAR THE EQUIPMENT THAT THIS PANEL FEEDS.

Symptom

Possible Solutions

No Power to the X-Ray

Generator

•If attempting to energize the X-Ray immediately after applying power, the system

will not turn on; ten seconds must pass before starting the system in order to allow

the safety relay to start up.

•Verify the 3Ø incoming power is present at the top of Q1.

•Verify the Main Circuit Breaker is ON.

•Verify the DC power supply circuit breaker (F2) is on and the DC power supply is

producing 24VDC.

•Verify the control power circuit breaker (F4) is on.

•Verify S11 (Stop) is not depressed.

•Verify no Emergency Stop Pushbuttons are depressed and they are correctly wired

to terminals X02.

•Check the four lights on the front of the safety relay, when ready, the DEVICE light

should be solid green. When all e-stops are released, the IN light should be solid

green and the Safeties OK light on the front of the panel should be lit.

•Press the Start button, contactor K2 should pull in. If not, check the OUT light on

the safety relay, if not solid green, press and hold the RESET button for five

seconds then release. The lights should flash and the DEVICE and IN light should

be green. Press the Start button, contactor K2 should pull in.

•If the DEVICE light is red, the safety relay is defective and must be replaced.

For other Safety Relay Conditions, refer to the diagram and chart next page.

PDA Off circuit inoperable

•Verify the PDA field wiring is not crossed between terminals X03 and X04.

•Verify 24Vdc is present at X03

•Verify Safeties OK is lit on the front door. If not, see above.

X-Ray ON Warning Light

does not turn on as

expected

•Verify the circuit breaker from the lighting panel is turned on.

•Verify the signal, either 24 Volts AC or 24 Volts DC, is present on terminals 1 and 2

of terminal block X06.

•Verify Continuity between terminals 3 and 4 of terminal bloc X06 if dry contact

provided by Siemens System Cabinet.

•Verify K5 is off

Room lights does not turn

off as expected

•Verify the circuit breaker from the lighting panel is turned on.

•Verify the signal, either 24 Volts AC or 24 Volts DC, is present on terminals 1 and 2

of terminal block X05.

•Verify Continuity between terminals 3 and 4 of terminal bloc X05 if dry contact

provided by Siemens System Cabinet.

•Verify K4 is on.

WARNING!

PARTS, TECHNICAL SUPPORT AND SERVICE

FOR INQUIRIES DURING INSTALLATION

CONTACT BEVCO ENGINEERING,

SUSSEX WI (262) 820-2400

FOR ISSUES FOLLOWING INSTALLATION,

CONTACT SIEMENS UPTIME CENTER,

(800) 888-7436

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 13 of 14

K10 Safety Relay configurations

The Safety Relay DIP switches are set as follows from the factory.

1

2

3

4

5

6

7

8

On

On

Off

On

On

On

On

Off

INTEGRATED ELECTRICAL CABINET

Installation, Operation, and Service Manual

Copyright2016: Bevco Engineering Company, Inc., W222N5739 Miller Way, Sussex, WI 53089 USA

IECAX480V125A OM1_R51 Siemens IEC Manual for AX Systems Page 14 of 14

7.0 MAINTENANCE

•No components within this panel require adjustment or periodic servicing.

8.0 REPLACEMENT PARTS

9.0 DOCUMENT REVISION HISTORY

REV

DATE

AUTHOR

DESCRIPTION OF CHANGE

1

10/03/2013

RJB

Initial Release

2

02/27/2015

RJB

Added Artis Tradenames on first page

3

03/09/2015

XYUE

Update the manual based on schematic

50

03/30/16

DRO

IEC Redesign

51

07/10/18

JT

Update of system config data

PARTS, TECHNICAL SUPPORT AND SERVICE

FOR INQUIRIES DURING INSTALLATION

CONTACT BEVCO ENGINEERING,

SUSSEX WI (262) 820-2400

FOR ISSUES FOLLOWING INSTALLATION,

CONTACT SIEMENS UPTIME CENTER,

(800) 888-7436

Table of contents

Popular Control Panel manuals by other brands

Energenie

Energenie EG-PWC-PSWRC-01 user manual

Sony

Sony DME-3000 Operation manual

IFM

IFM PDM360NG Series System manual

Teknim

Teknim VAP404 Installation & operation manuals

Kathrein

Kathrein HDS 50 Instructions for use

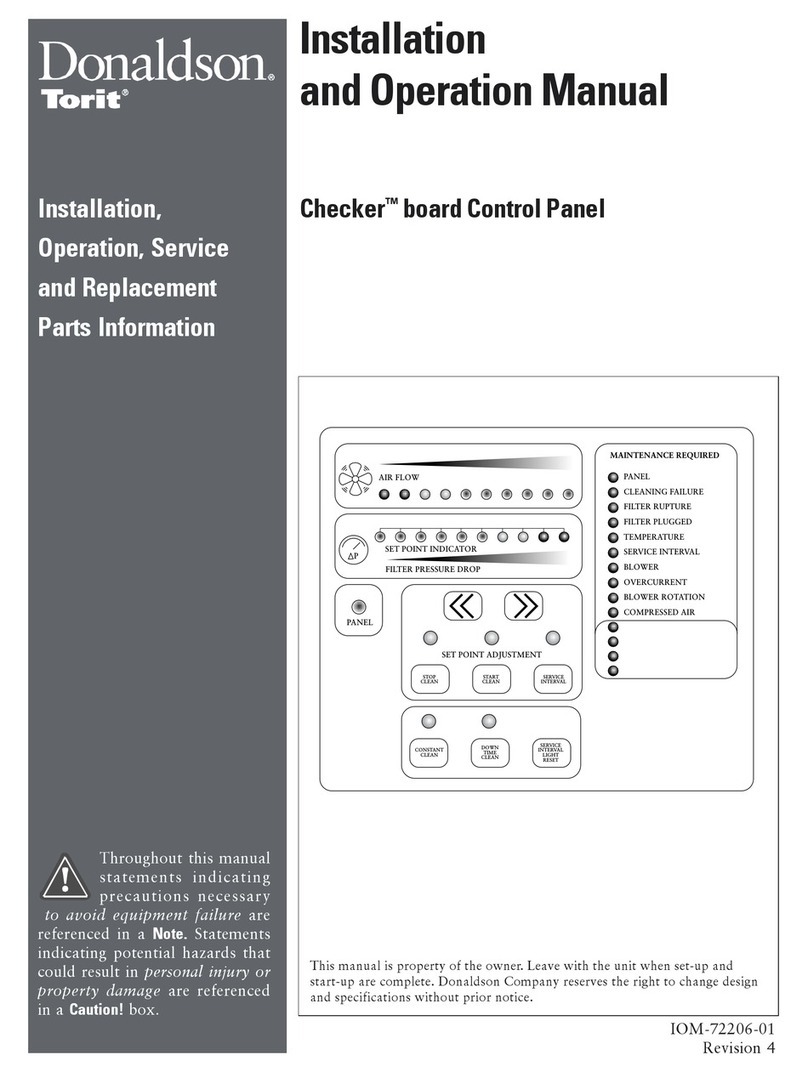

Donaldson Torit

Donaldson Torit Checker board Installation, Operation, Service and Replacement Part Information