Donaldson Company, Inc.

4

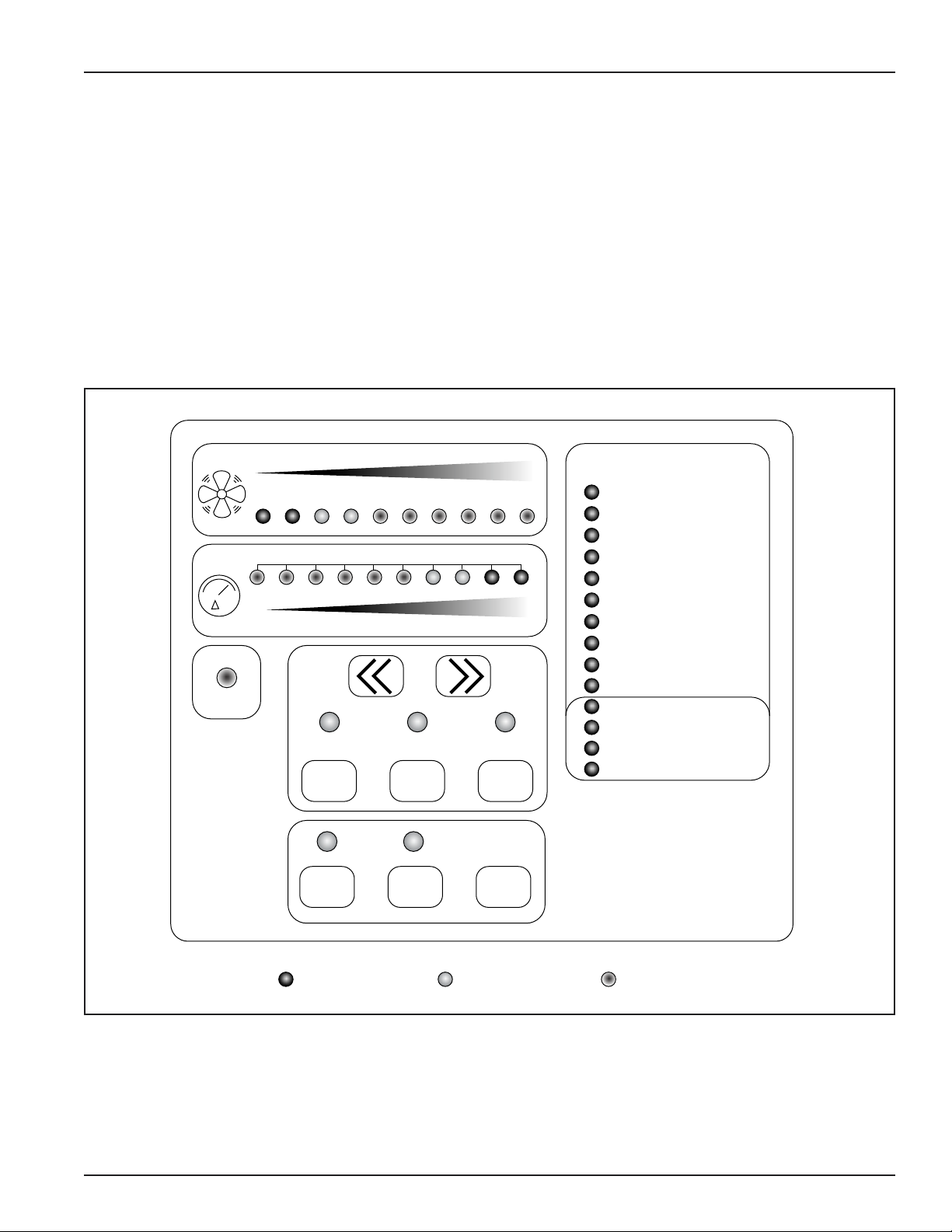

Checker board Control Panel

The Checker board provides cleaning control,

diagnostic review of the operational parameters,

diagnostic review of the system components, and a

record of operational data and fault conditions for

future review. The operator interface provides

control of unit functions and operational status

information.

The design allows for a host computer to remotely

control the unit, change operational parameters,

and check operational status.

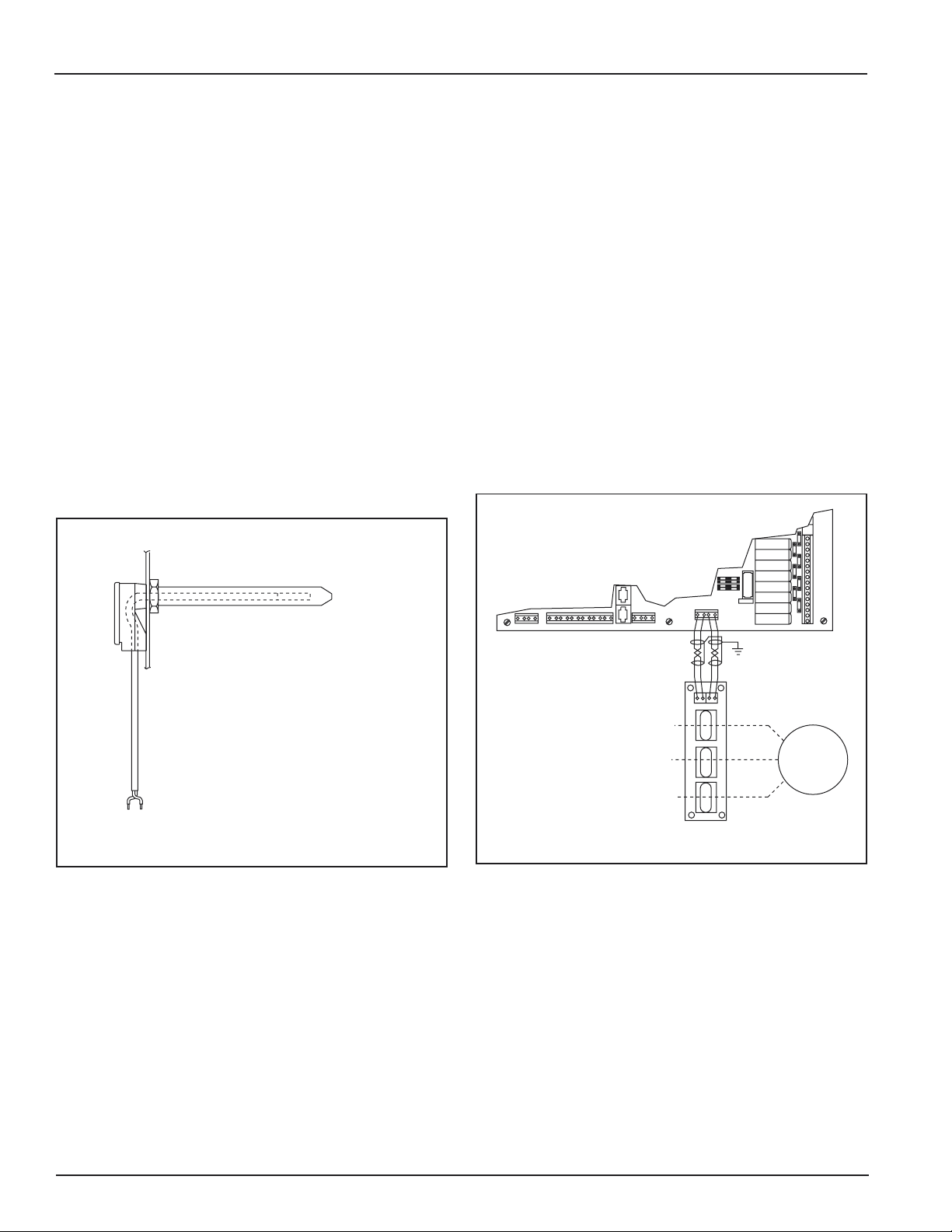

Inspection on Arrival

1. Unpack and open the Checker board enclosure

by loosening the clamp screws on the sides.

Remove packing materials. Compare

components received with the packing list.

2. Inspect unit on delivery.

3. Report any damage to the delivery carrier.

4. Request a written inspection report from the

Claims Inspector to substantiate claim.

5. File claims with the delivery carrier.

6. Report incomplete shipments to the delivery

carrier and your Donaldson representative.

Items shipped loose include:

Control box Safety filter

Current sensor board Connector, tube to tube

Twisted pair cables Print 3EA-37129

Clear tubing, two 35-ft Label stickers, 1/4 x 4-in

Black tubing, 35-ft long

Tools Required

Wire strippers Wire cutter

Knife Needle nose pliers

Crescent wrench Channel lock pliers

Screw driver, 5/16-in wide and 9/64-in narrow slot tip

Hole knockout: 1/2-in connector use .859 to .906

and for 3/4-in connection use 1.094 to 1.141.

Supplies Required

Conduit, 1/2 and 3/4-in Grounding lugs

Elbow connectors Wire ties

Straight connectors Wire nuts

Wire, green/white/black/red, #16, 14, or 12 awg

Operation

The Checker board is used to control, diagnose,

and troubleshoot Donaldson Torit dust collectors.

The microprocesser-based control can be

programmed to control solenoid valves used for

filter cleaning, control the blower motor starter,

control setpoints used to start and stop the filter

cleaning operation, monitor and diagnose the

mechanical and electronic system components, and

store diagnostic readings for up to one year.

Operating system parameters, abnormal operating

conditions, and mechanical failure messages appear

on the Checker board display. It also allows a host

computer to control the unit, change operational

parameters, and check operational status from a

remote location.

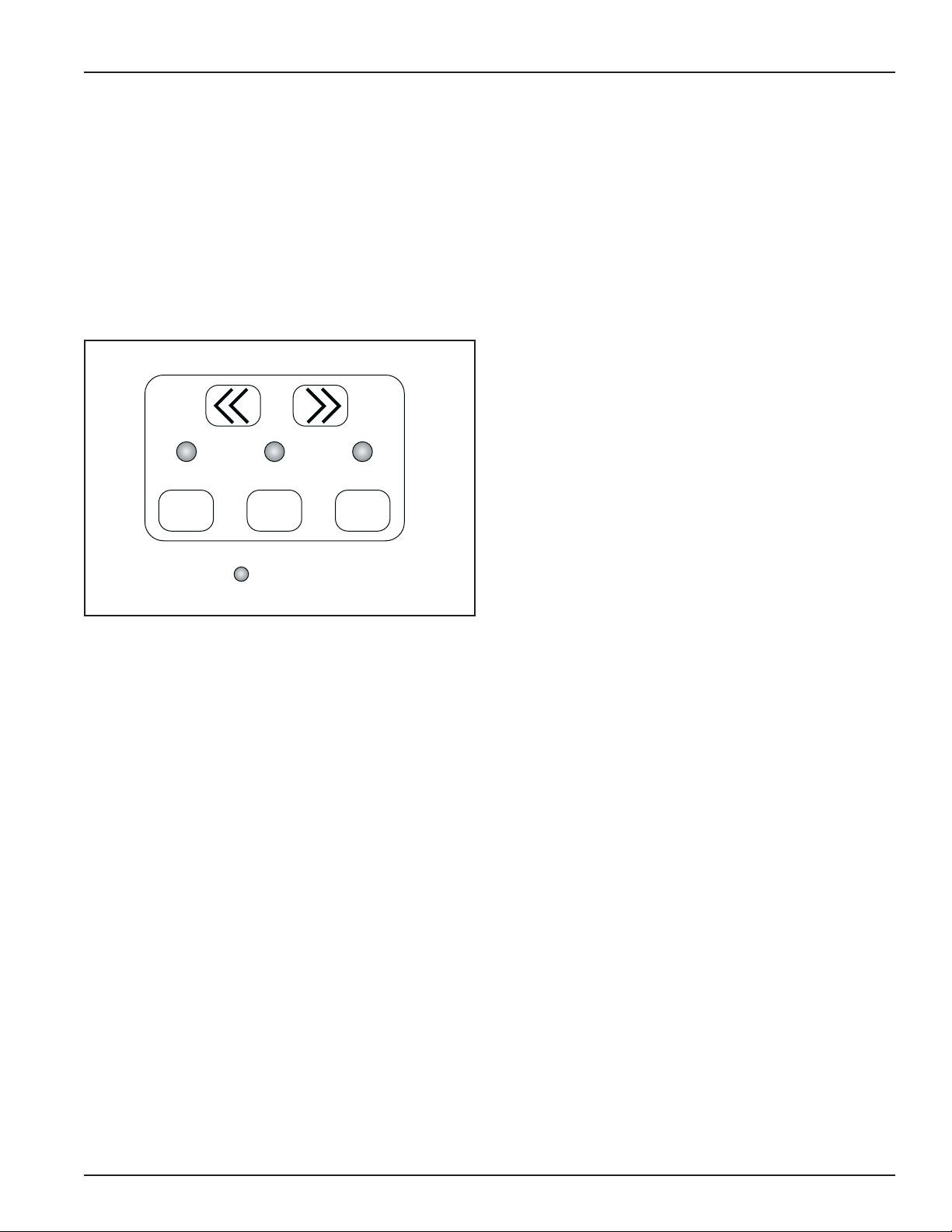

Pulse Cleaning Operation

The Checker board can be set to control the filter

cleaning operation of the unit, including starting

and stopping at adjustable setpoints, initiating the

pulse, pulse sequence, and pulse duration. The

Checker board also provides the logic to control

alternate cleaning modes.

The microprocessor compares the sensor readings

with the stored values to determine the operational

health of the system. This comparison can indicate

ruptured or plugged filters, cleaning system

component malfunction, excessive temperature,

and blower motor overload due to excess air flow

or motor failure. The microprocessor also has an

extensive self-diagnostic test program that provides

technical assistance to the service technician when

necessary.