BevLes PHC70-32-A User manual

Innovative Foodservice Equipment Custom

Designed for Performance, Service and Value.

INSTALLATION AND OPERATING

INSTRUCTIONS

Proofer/Holding

Cabinet

Models:

PHC70-32-A

PHC70-32INS-A

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

This equipment has been engineered to provide you with year round dependable service when used

according to the instructions in this manual and standard commercial kitchen practices.

Toll Free: (844) 265-0250

Fax: (800) 548-9392

Website: www.BevLes.com

E-mail:

05/19

BevLes

1525 East Lake Rd

Erie, Pa 16511

!

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

!

!

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the Installation, Operating and

Maintenance Instructions thoroughly before installing or servicing this equipment.

!

The BevLes Company takes pride in the design and quality of our products. When used as intended and

with proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructions in this manual carefully.

Installation and start-up should be performed by a qualified installer who thoroughly read, understands and

follows these instruction. If you have questions concerning the installation, operation, maintenance or

service of this product, write Technical Service Department BevLes Company, Inc., 1525 east Lake Rd. Erie,

PA 16511

TABLE OF CONTENTS

ITEM PAGE

Safety Precautions 1

General Information 2

Unpacking Instructions 3

Setting-Up

3

Operation Solid State Thermostat

4

Operation Digital Thermostat

5

Operating Tips 6

Safety and Health

6

Maintenance

6

Assistance/Service

7

Trouble Shooting

7

Additional Information 8

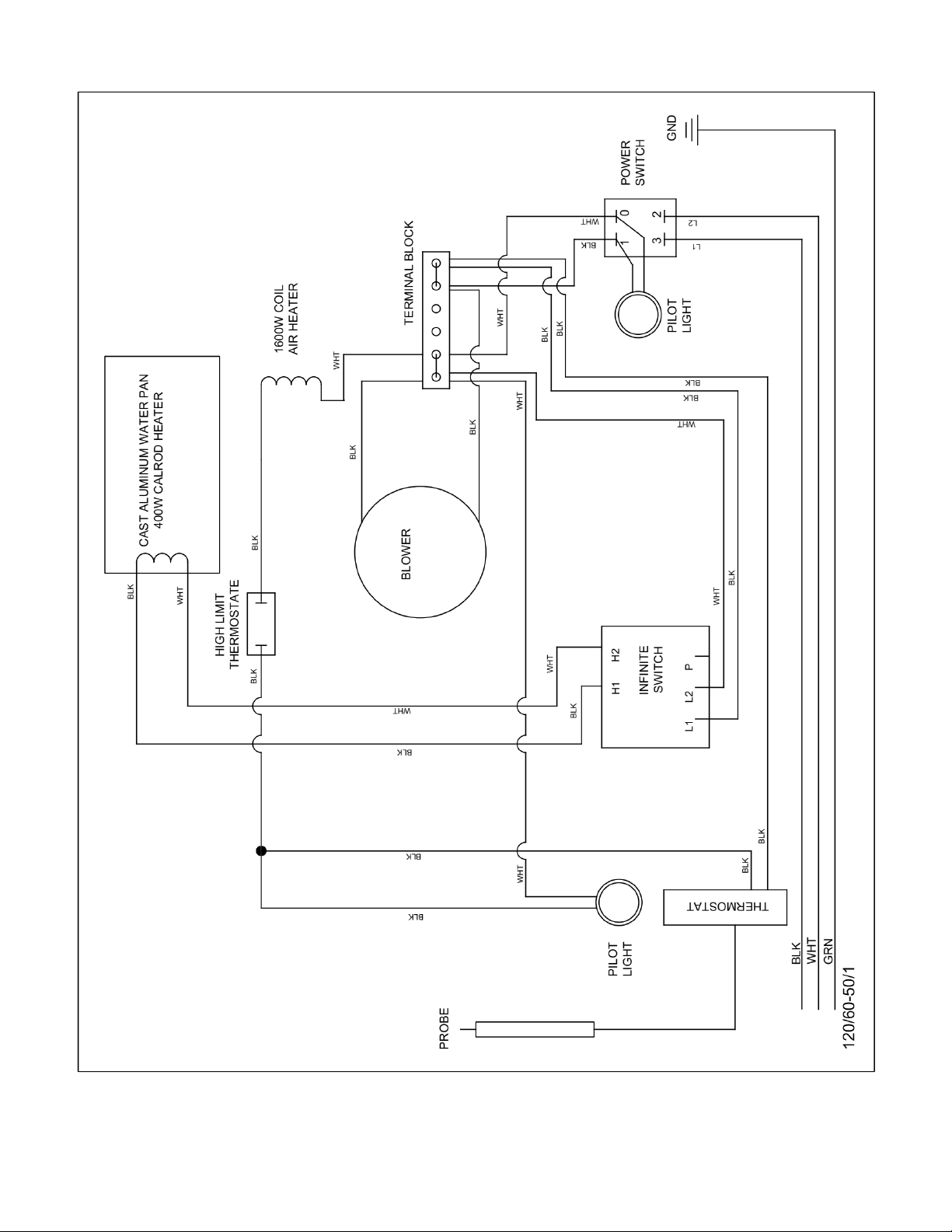

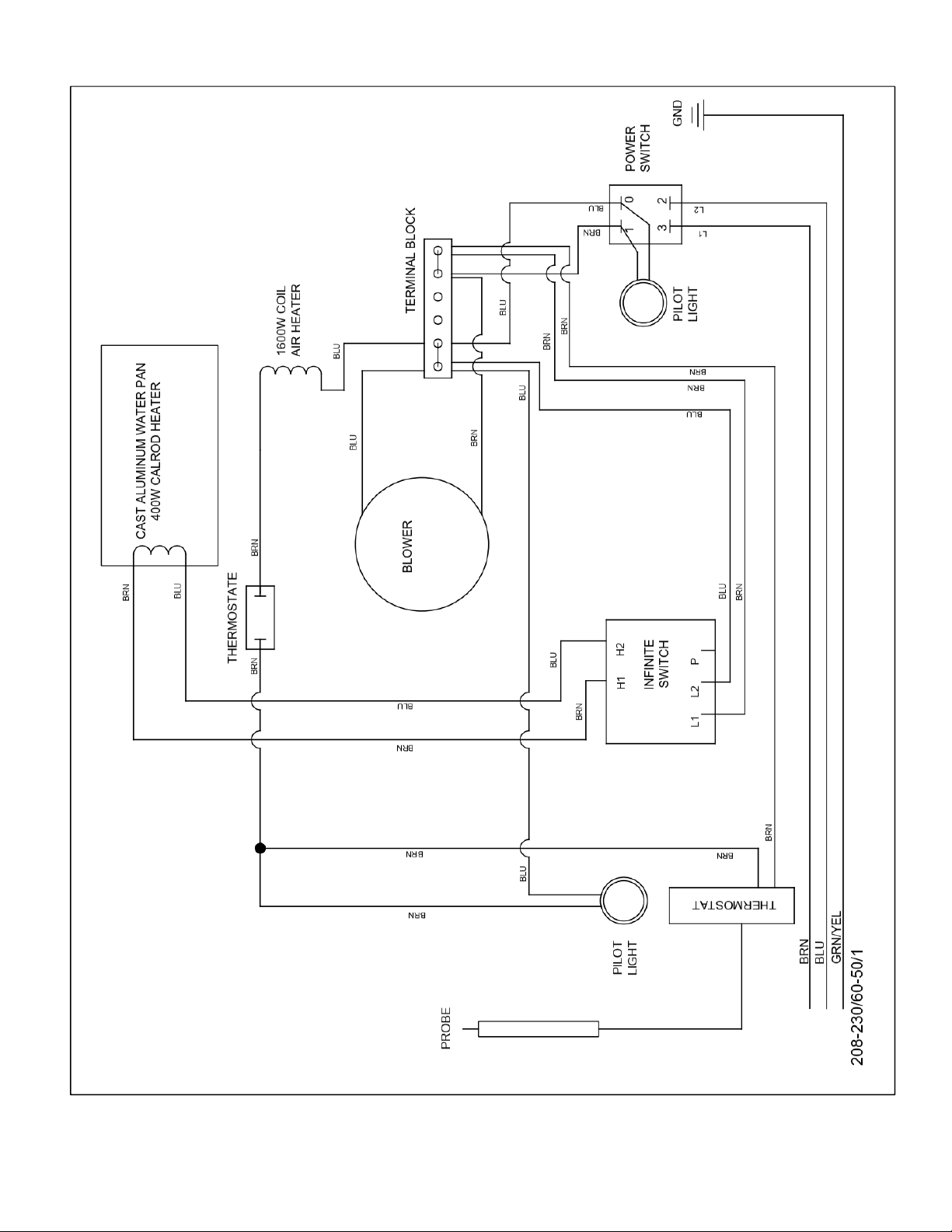

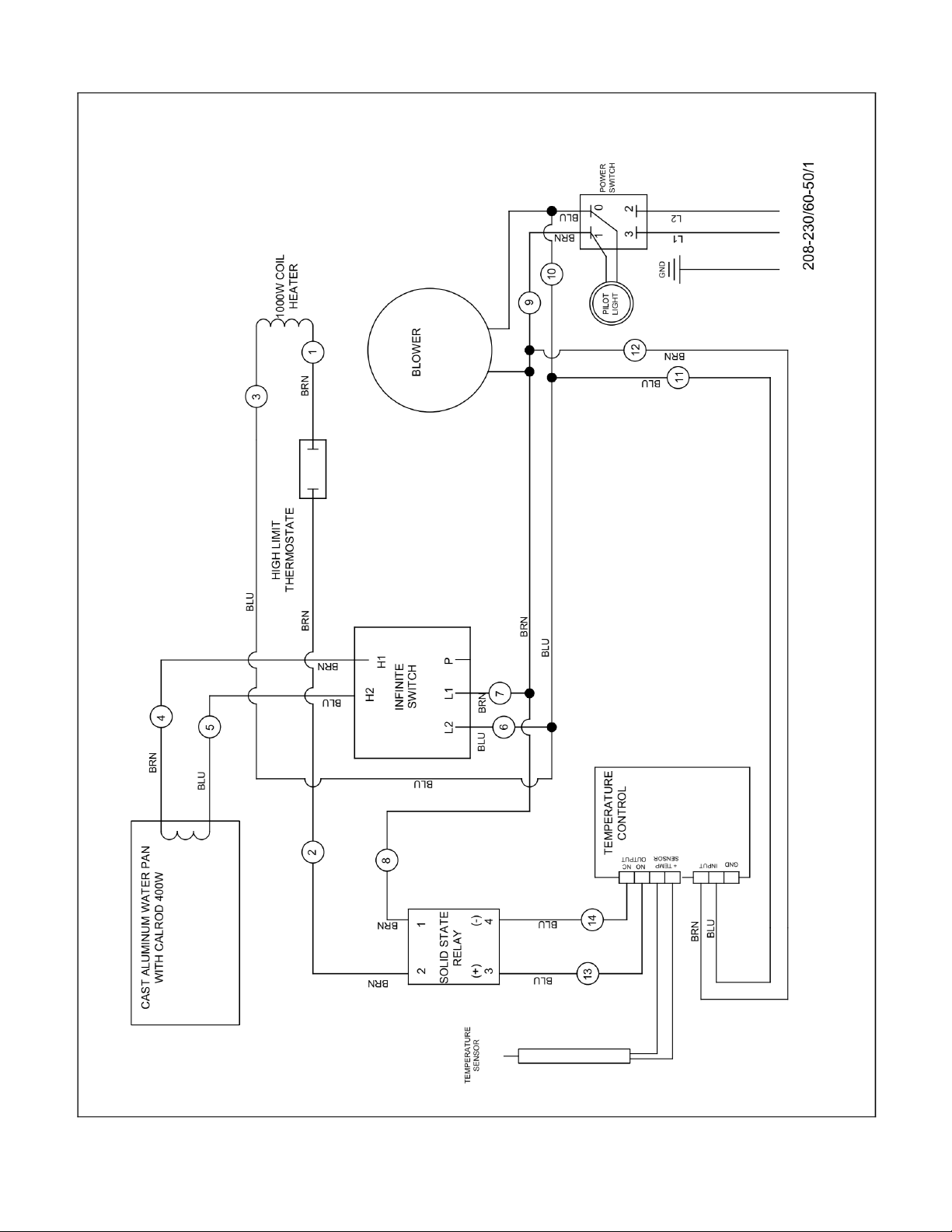

Wiring Diagrams 9,10,11,12

Parts List 13

Warranty 15

SAFETY PRECAUTIONS

Before installing and operating this equipment be sure everyone involved in its operation is fully trained and

aware of all precautions. Accidents and problems can result by a failure to follow fundamental rules and

precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnel or the equipment. The words are defined as follows:

DANGER: This symbol warns of imminent hazard which may result in serious injury or death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result in

serious injury or death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result in minor or!

moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be fully understood

! even though not dangerous.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

GENERAL INFORMATION

NOTICE: This product is intended for commercial use only. Not for household use.

CAUTION: These models are designed, built, and sold for commercial use. If these models are

positioned so the general public can use the equipment make sure that cautions, warnings, and

operating instructions are clearly posted near each unit so that anyone using the equipment will

use it correctly and not injure themselves or harm the equipment.

WARNING: Check the data plate on this unit before installation. Connect the unit only to the voltage

and frequency listed on the data plate. Connect only to 1 phase as listed on the data plate.

WARNING: Install per the spacing requirements listed in the installation section of this manual. We

strongly recommend having a competent professional install the equipment. A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always be

used when connecting these units to electrical power. In the absence of local codes, use the latest

version of the National Electrical Code.

WARNING: This device should be safely and adequately grounded in accordance with local

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, latest

edition to protect the user from electrical shock. It requires a grounded system and a dedicated

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

comply with the Canadian Electrical Code, CSAC22.2, as applicable.

NOTICE: Local codes regarding installation vary greatly from one area to another. The National

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are “Authority

Having Jurisdiction” when it comes to requirement for installation of equipment. Therefore,

installation should comply with all local codes.

WARNING: SHOCK HAZARD De-energize and lock-out all power to equipment before

performing any maintenance, servicing or, cleaning of the equipment.

WARNING: SHOCK HAZARD Never clean any electrical unit by immersing it in water.

WARNING: SHOCK HAZARD - Operators should not open any panels that require the use of tools.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

or concealed, a claim must be made with the delivering carrier.

A)

Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be signed

by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The carrier can

supply the necessary forms.

B)

If concealed damage or loss is not apparent until after equipment is uncrated, a request for inspection

must be made to the carrier within 15 days. The carrier should arrange an inspection. Be certain to hold all

contents and packaging material.

Installation and start-up should be performed by a qualified installer who has thoroughly read, understands

and follows these instructions.

UNPACKING INSTRUCTIONS:

Note: All Bevies cabinets are tested, inspected and expertly packed to insure arrival in a ready-to-use

condition. If any damage or loss is discovered when unpacking, ask the carrier's agent (in writing) to inspect

the product. This must be done within 15 days of delivery. You can then file a formal claim with the carrier.

This product has been shipped securely packed on a wooden pallet, covered with a protective bag and

corrugated shipping container and sealed with durable banding material. Carefully read the following

unpacking instructions and properly dispose of all packaging materials.

To open:

1.

Carefully cut and remove banding material.

2.

Carefully lift the corrugated container off the product.

3.

Remove the protective bag, tear, or tie several knots and appropriately place in a trash

container.

4.

Open door(s) and remove the carton containing the universal pan supports, and all packing

materials (tape, cardboard, etc.)

5.

Carefully lift cabinet off pallet.

6.

Check model number on the serial number label, located on the back of the unit.

7.

Release all wheel brakes

SETTING-UP

1.

Remove all protective film from interior and, exterior surfaces on cabinet, and doors

2.

Open the carton containing the universal pan supports and install all supports in cabinet. Install

the pan supports from the bottom up leaving one extra (unused) slot at the top of each of the four

uprights.

3.

Make certain that the polycarbonate water pan cover is properly installed over the cast water

pan and over the louvers in front of the pan.

4.

Insert a standard 18” x 26" sheet pan (not provided with proofer) in the slides under the base of

the cabinet. This will serve as a drip pan when cabinet is in use.

5.

Place the cabinet in the location where it will be operated. When in position secure the brakes on

the front two wheels. These brakes should always be locked when the cabinet is in use.

6.

Make certain that your unit is properly connected to the correct power source as specified on

the serial number label, located on the side of the unit.

OPERATION THERMOSTAT CONTROL

1.

Verify that wheel brakes are in locked position (front two casters).

2.

Inspect humidity pan for proper water level (1/2 to 3/4 full) for proofing.

3.

Make sure the polycarbonate water pan cover is properly in place with the holes over the pan.

Refer to picture of Solid State control panel below for the following steps.

4.

Set the temperature control to the desired cabinet temperature. 90°F to 110°F is recommended as

a starting position for proofing. Increase or decrease the cabinet temperature as needed to best

suit your application.

5.

Set the humidity control to the #3 or #4 position. This can be increased if necessary to suit your

specific application.

6.

Make certain that a standard 18" x 26" sheet pan (not provided) has been inserted as a drip pan in

the slides on the bottom "outside" of the cabinet.

7.

Verify that the door(s) is closed and latched.

8.

Push the power switch to the "ON" Position. Always use this switch to turn the unit "ON” or "OFF".

9.

Allow approximately 45-60 minutes for the cabinet to achieve the necessary temperature and

humidity that you desire.

10.

The cabinet is now ready for product placement, for proofing or holding.

SOLID STATE CONTROL PANEL

Humidity

Control

Heater Indicator

Light

Power

Indicator Light

Temperature

Control

Power

Temperature

Guage

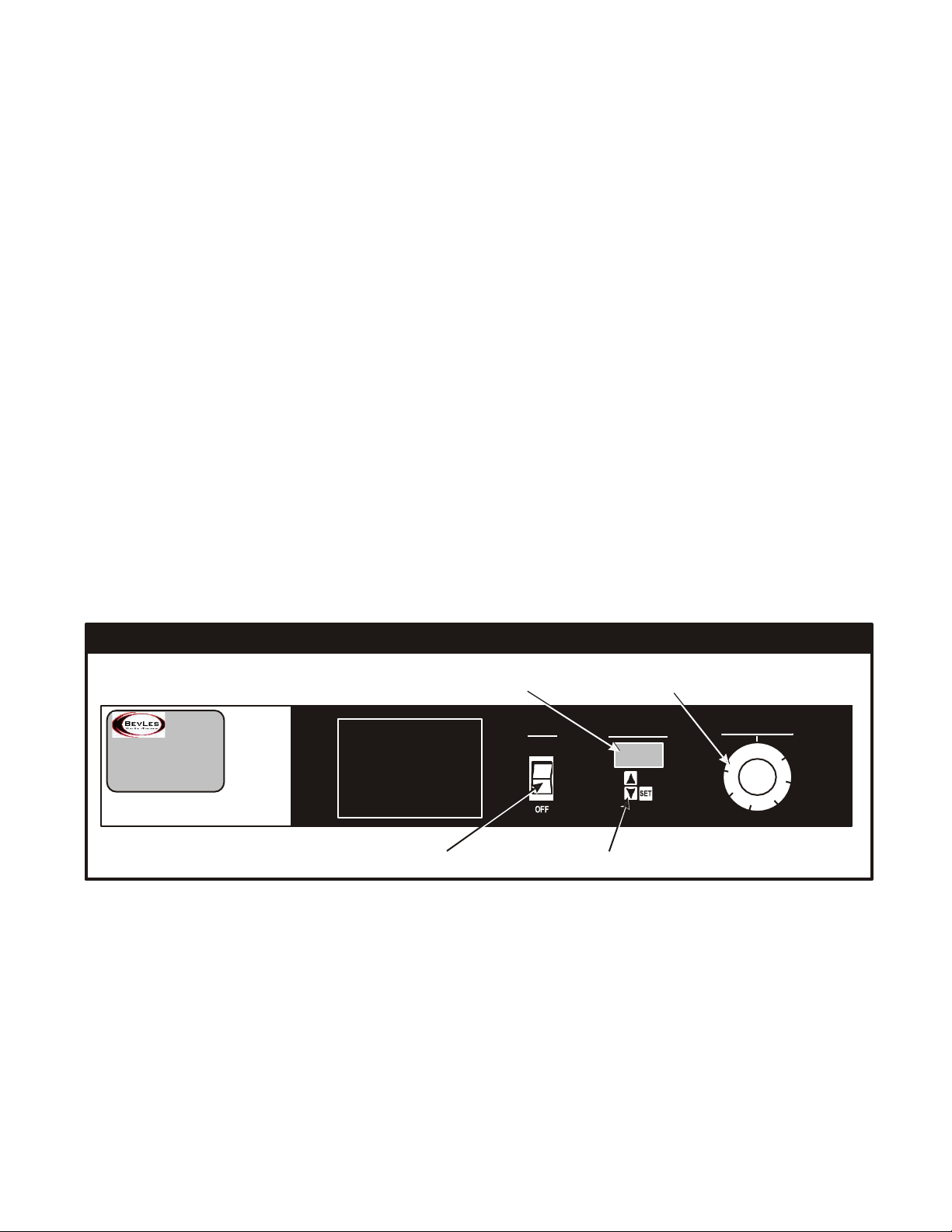

OPERATION DIGITAL THERMOSTAT

1. Verify that wheel brakes are in locked position (front two casters).

2. Inspect humidity pan for proper water level (1/2 to 3/4 full).

3. Make sure the polycarbonate water pan cover is properly in place with the holes over the pan.

Refer to picture of Digital control panel below for the following steps.

4. Push the power switch to the "ON" Position. Always use this switch to turn the unit "ON" or "OFF".

5. Set the temperature control to the desired cabinet temperature. 90°F to 110°F is recommended as a

starting position for proofing. Increase or decrease the cabinet temperature as needed to best suit

your application.

a. To select desired cabinet temperature:

b. Press SET key under cabinet temperature display. .

c. Press INCREASE key or DECREASE key to adjust cabinet temperature.

d. Press SET key to lock-in desired cabinet temperature. (If you don't press the SET key the

temperature setting will revert back to previous setting).

6. Set the humidity control to the #3 or #4 position. This can be increased if necessary to suit your

specific application.

7. Make certain that the 18" x 26" sheet pan (not provided) that has been inserted in the slides on the

bottom of the base is under the square hole to catch any condensation.

8. Verify that the door(s) is closed and latched.

9. Allow approximately 45-60 minutes for the cabinet to achieve the necessary temperature and

humidity that you desire.

10. The cabinet is now ready for product placement and the start of the proofing process.

DIGITAL CONTROL PANEL

Cabinet Temperature Display

Humidity Control

OPERATING INSTRUCTIONS

xxxxxxxx xxx xxx xxxxx xxxxx xxxxxxxx

xx xxxx xx xx x xxxxxxxx xx x xxxxxxxx xxxxx

xxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxx xx

x x xxx xxxxx xx x xx xxx x xxxxx xx xxxxxxxx

xxxxxxxxxxxxxxxxx xxxxxxxxxxxxx xx xx xx x

xxxx xxxxxxxxxx xxxxxxxxx xxxxxxxxxxx xx

xxx xxxx xx xx xx xxxxxx xxxxxxxxxxxx xxxx x

POWER

ON

CABINET TEMP.

CABINET HUMIDITY

Power Switch

Temperature Control

OPERATING TIPS

Always inspect wheel brakes before attempting to move the cabinet. Make certain that brakes are in the

locked position before placing cabinet into operation.

During "cold" start-up you may want to set the Humidity Control to the HI setting for 10 to 15 minutes to

accelerate the humidity process. Remember to re-set the Humidity Control back to the desired setting

before beginning the proofing process. Once the cabinet has been loaded with product and the proofing

process has started, the door(s) should not be opened until proofing has been completed.

The 18" x 26" sheet pan (not provided) that serves as a drip pan under the cabinet base should be

checked, and if necessary, emptied at the end of each day.

The cabinet should be cleaned whenever necessary. It should be thoroughly cleaned at least once a week.

Note: It is recommended that humidity be kept at the minimum level that is practical for your operation.

Excessive humidity with condensation on the walls and/or base of the cabinet is not considered desirable.

SAFETY AND HEALTH

BevLes Proofing/Holding Cabinets meet all cUL and NSF requirements. Always operate this unit in

accordance with the operating instructions found in this manual. Never remove the humidity-heating

module without first disconnecting (unplugging) the unit from its power source. The cabinet is designed

and built for easy cleaning. It should be cleaned frequently as described in the maintenance section.

MAINTENANCE

Cleaning: This cabinet was designed and built for maximum sanitation. It is not self cleaning, so it should be

cleaned frequently with soap and water.

1.

NEVER USE STEEL WOOL OR CAUSTIC CLEANING COMPOUNDS.

2.

Make sure that the unit is turned OFF and disconnected from the electrical service.

3.

Remove the polycarbonate water pan cover and side covers from the humidity-heating

module.

4.

Remove the pan supports and vertical uprights.

5.

Remove the vent from the rear wall.

6.

Clean inside of cabinet with soap and water. Clean clear polycarbonate water pan cover and

door(s) with soft sponge, soap and water.

NEVER USE HARSH CLEANING SUBSTANCES OR ABRASIVES TO CLEAN LEXAN®

SURFACES, OR THE CAST ALUMINUM WATER PAN.

7.

Remove and clean the 18" x 26" drip pan (not provided) from under the cabinet base

If necessary, the humidity-heating module can be removed by loosening the two (2) black knobs (one

located at each side on the module on the exterior of the cabinet). The module can be pulled out of the

cabinet for additional cleaning. We suggest that you clean the water pan at least once a month with a

solution of white vinegar and hot water. Allow white vinegar to remain in water pan overnight. Then use a

soft cloth to wipe away any mineral buildup.

Important: When placing the humidity heating module back into the cabinet make certain that the module

is pushed tightly against the cabinet and secured with the two (2) black knobs. Check to see that the one

inch air flow opening at the rear of the humidity-heating module is behind the back vent that hangs on the

rear wall of the cabinet. This is necessary to maintain uniform temperature and humidity distribution

throughout the cabinet.

IF REPLACEMENT PARTS ARE EVER REQUIRED, ONLY USE PARTS THAT HAVE BEEN

APPROVED BY BEVLES COMPANY, INC.

ASSISTANCE I SERVICE

Should you ever require assistance or service contact the BevLes service line, at (844)265-0250 When

you phone please have the model number and serial number of the unit.. This will assist our service

technicians in providing you immediate assistance. You may want to briefly review the Troubleshooting

Tips before you contact our factory.

TROUBLESHOOTING TIPS

No Power

If your cabinet fails to start when the power is applied via power switch:

1.

Check to see if the unit is properly connected to correct power source as specified on the serial

number label.

2.

Check to see that your power source (wall receptacle) has power - inspect circuit breaker.

3.

Disconnect power cord and visually inspect for any damage.

4.

Contact the Bevies Technical Service Department tor assistance.

Excessive Humidity

If your cabinet is producing excessive humidity:

1.

Check the setting on the humidity control knob to see if it is set where you normally operate

at.

2.

Check the base of the cabinet to see if the excess humidity is draining through the drain hole in

the center of the base.

3.

Contact the BevLes Technical Service Department for assistance.

No Humidity

If your cabinet is producing no humidity, or considerably less than normally achieved:

1.

Inspect water level in the water pan.

2.

Check the humidity control knob to see if it is set where you normally operate at.

3.

Check to see if the cabinet door(s) is closed.

4.

Make certain that the humidity-heating module's one inch air flow opening (at rear of module) is

behind the cabinet back vent that hangs on the rear wall of the cabinet.

5.

Make certain that the polycarbonate water pan cover is correctly positioned over the entire

water pan and the louvers located in front of the water pan.

6.

Verify that the fan blower is operating.

7.

Contact the BevLes Technical Service Department for assistance.

Excessive Heat

If your cabinet temperature is higher than normal:

1.

Check the setting on the temperature control to see if it is set where you normally operate at.

2.

Check the ambient room temperature to see if it is greater than your desired proofing

temperature.

3.

Contact the BevLes Technical Service Department for assistance.

No Heat

If your cabinet is producing no heat, or considerably less than you normally achieve:

1.

Check the setting on the temperature control to see if it is set where you normally operate at.

2.

Check to see if the cabinet door(s) is completely closed.

3.

Make certain that the humidity-heating module's one inch air-flow opening (at rear of module) is

behind the cabinet back vent that hangs on the rear wall on the cabinet.

4.

Verify that the fan blower is operating.

5.

Contact the BevLes Technical Service Department for assistance.

ADDITIONAL INFORMATION

Part Replacement Instructions

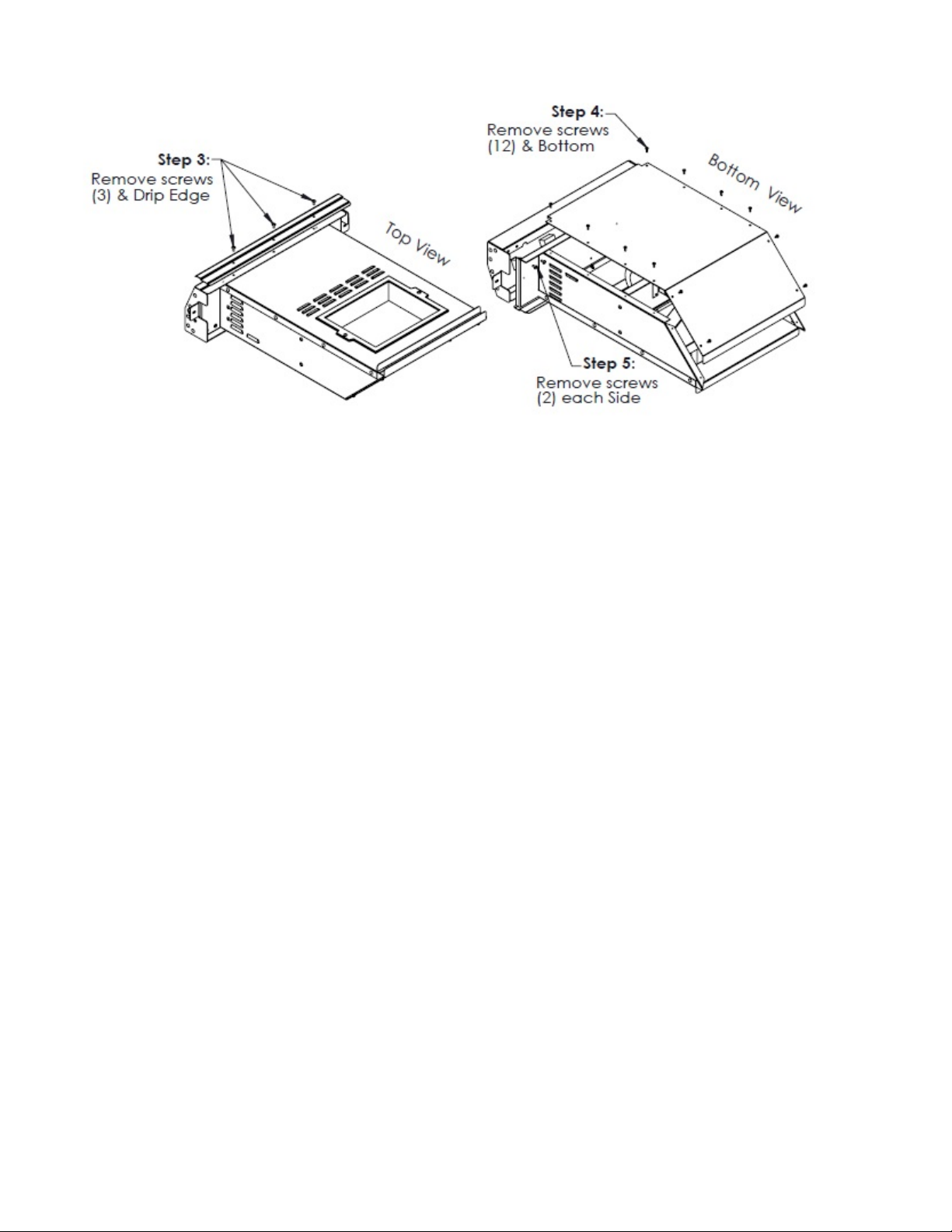

TO ACCESS ELECTRICAL COMPONENTS:

1.

Make sure the unit is turned off and disconnected from electrical service.

2.

Remove the two black handled knobs (one located on each side of the control panel).

3.

Pull the module out from the cabinet.

Refer to drawings above for steps 4, 5 and 6.

4.

Remove screws(3) and stainless steel drip edge.

5.

Turn module over, and remove screws from the bottom of the module. (6 screws each side).

There will be (4) nylon caps and spacers, save and reuse.

6.

Remove screws from the back side of control panel. (2 screws each side).

7.

Carefully pull control panel forward.

After installing any new components, reverse the above steps. Make certain that the one inch air-flow

opening at the back of the module is up behind the cabinet's back vent hanging on the rear wall.

Refer to wiring diagrams for additional information.

120v Solid State Control Amp rating: 16.7 amps

120v Digital Control Amp rating: 16.7 amps

208/230v Solid State Control Amp rating: 9.7/8.7 amps

208/230v Digital Control Amp rating: 9.7/8.7 amps

Part Number Description

720671 Pin Hinge

740333 Hinge Right

740334 Hinge Left

750720 Pin, Latch

750419 Latch

781285 Latch Spring

750132 Latch, Butt

780036 Caster 5" Swivel w/Brake

780040 Caster 5" Swivel

783116 Knob Threaded 1/4-20 Bottom Module

781291 Knob Thermostat 80-180 degree

782092 Knob, Infinite Switch, Black

740352 Back Vent Panel

740368 Retainer, W iper Strip

702520 Wiper Blade Santoprene

741182 Vally Cover, Heating Unit Aluminum

760040 Water Pan Cover, Polycarbonate

784124 Handle, W ater Pan Cover

760028 Replacment Door Glass Polycarbonate, Single Door

760004 Replacment Door Glass Polycarbonate, Double Door

740223 Bracket, Mounting, Sensor

750420 Slide Glide (Pan Support)

740348 Vertical Upright, 1.50" Spacing

1488400 Thermostat 80-180 Degr ee 120/240v

784662 Temperatur e Controller Digital 120/240v

1302400 Switch, Rocker, DPST, 277V, 20A 120/240v

1107200 Block Terminal, 6 Station 600V

782162 Relay , Solid State, 50A-240VAC

784448 Transformer, 120/240V

780016 High Temperature Cut Out, Bi-Metal, 350°F, 40AMP 120/240V

782004 Heating Element Blower 1600W , 120V

784288 Heating Element Blower 1600W 240V

782036 Heating Element W ater Pan 400W , 120V

784304 Heating Element W ater Pan 400W , 240V

782088 Switch, Infinite, 120V /15A

782224 Switch, Infinite, 240V/15A

1509600 Pilot Light, Green (Power) 120/240V

45653000 Pilot Light, Amber (Heater) 120/240V

720850 Motor, Blower, & Housing 120V

720851 Motor, Blower & Housing, 240V

Replacement Parts Mechanical

Replacement Parts Electrical

Notes:

BEVLES COMPANY LIMITED WARRANTY

1525 East Lake Road • Erie, PA 16511

Phone: (844) 265-0250 Fax: (800) 548-9392

1.

Bevles warrants to the original purchaser that on the date the equipment is shipped (sold), it will be

free of defects in materials or workmanship. Bevles will, at it’s discretion, repair or replace, during

the warranty period printed below, any part that has a defect in material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the warranty

period under normal use and service.

Parts: Two* years from date of original shipment from the Bevles factory.

Labor: One** year from date of original shipment from the Bevles factory.

* Air Circulation Blower Assemblies (motors) and Power Switches shall be one year from date of

original shipment.

Calrod “Air” Heating Elements shall be three years from date of original shipment.

** All electrical components 120 days from date of original shipment.

2.

Bevles must be contacted, and pre-approval must be issued by the Bevles factory prior to any type

of service being performed. Bevles assumes no responsibility for any charges that were not expressly

authorized by the Bevles factory, or for any charges that exceed, in Bevles’sole judgement, normal and

customary amounts.

3.

Bevles will pay UPS Ground charges for any part that has a defect in material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the first year of the

warranty period under normal use and service. All warranty replacement parts will ship F.O.B. Bevles

factory, Erie, PA 16511.

4.

This warranty shall be void in its entirety if any abuse of, misuse of, alteration/modification of or

improper maintenance of original product occurs. If, at any time a claim is reported to Bevles, and the

purchaser is delinquent in payment for the product, warranty will not apply.

5.

Buyer’s Remedies-If a Bevles product fails due to a defect in material or workmanship in conformity

with the warranties in paragraph one, buyer shall notify Bevles of such failure within a reasonable time,

but in no event beyond fifteen (15) days of such discovery of defect in material or workmanship.

Bevles shall provide, in its sole discretion, either the repair or replacement of any defective or any non-

conforming part. Bevles specifically disavows any other representation, warranty or liability relating

to the continued use of the product.

6 Exclusion of consequential and incidental damages-In no event shall Bevles be liable for any

incidental, special, indirect, or consequential damages, whether resulting from non-delivery or from

the use, misuse, or inability to use the product, or from defects in the product, or from

Bevles’ own negligence or other tort. This exclusion applies regardless of whether such damages are

sought for breach of warranty, breach of contract, negligence, or strict liability in tort or under any other

legal theory.

7. Disclaimer of warranties-The warranties contained in paragraph one above are the exclusive

warranties given by Bevles and supersede any prior, contrary, or additional representations,

whether oral or written. Bevles hereby disclaims and excludes all other warranties-whether

expressed, implied, or statutory-including any warranty of merchantability, any warranty of

fitness for a particular purpose, and any implied warranties otherwise arising from course of

dealing or usage of trade.

12/15

Innovative Foodservice Equipment Custom

Designed for Performance, Service and Value.

Toll Free: (844) 265-0250

Fax: (800) 548-9392

Website: www.BevLes.com

E-mail:

BevLes

1525 East Lake Rd

Erie, Pa 16511

This manual suits for next models

17

Table of contents

Other BevLes Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use