BevLes Cinnabon PICA70-32-AED User manual

Innovative Foodservice Equipment Custom

DesignedforPerformance,ServiceandValue.

INSTALLATION AND OPERATING

INSTRUCTIONS

CinnabonTM Proofing Cabinet

PICA70-32-AED

INTENDED FOR OTHER THAN HOUSEHOLD USE

RETAIN THIS MANUAL FOR FUTURE REFERENCE

UNIT MUST BE KEPT CLEAR OF COMBUSTIBLES AT ALL TIMES

This equipment has been engineered to provide you with year round dependable service when used

accordingtotheinstructionsinthismanualandstandardcommercialkitchenpractices.

Toll Free: (844) 265-0250

Fax: (800) 548-9392

Website: www.BevLes.com

E-mail:

sales@BevLes.com

P/N 780086 3/06

BevLes

1525 East Lake Rd

Erie, Pa 16511

®

!

WARNING

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the Installation, Operating and

MaintenanceInstructionsthoroughlybeforeinstallingorservicingthisequipment.

!

!

FOR YOUR SAFETY

Donotstoreorusegasolineorotherflammablevaporsandliquidsinthevicinityof

thisoranyotherappliance.

!

1

The BevLes Company takes pride in the design and quality of our products. When used as intended and

with proper care and maintenance, you will experience years of reliable operation from this equipment. To

ensurebestresults,itisimportantthatyoureadandfollowtheinstructionsinthismanualcarefully.

Installationandstart-upshould be performedbya qualified installer whothoroughly read, understandsand

followstheseinstruction.

If you have questions concerning the installation, operation, maintenance or service of this product, write

TechnicalServiceDepartment BevLesCompany,Inc.,1525 east Lake Rd. Erie, PA 16511

TABLE OF CONTENTS

ITEM PAGE

Safety Precautions 1

General Information 2

Unpacking Instructions 3

Setting-Up

3

Operation

4

Operating Tips 5

Safety And Health 5

Maintenance 5

Trouble Shooting 6

Parts Replacement 7

Wiring Diagram 120v 8

Wiring Diagram 208/230v 9

Parts List 10

Notes 11

Warranty 12

SAFETY PRECAUTIONS

Beforeinstallingandoperatingthisequipmentbesureeveryoneinvolvedinits operationisfullytrainedand

aware of all precautions. Accidents and problems can result by a failure to follow fundamental rules and

precautions.

The following words and symbols, found in this manual, alert you to hazards to the operator, service

personnelortheequipment.Thewordsaredefinedasfollows:

DANGER:Thissymbolwarnsofimminent hazardwhichmayresultinseriousinjuryor death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which could result in

seriousinjuryordeath.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which may result inminor or!

moderateinjuryorproductorpropertydamage.

NOTICE:Thissymbolreferstoinformationthatneedsspecialattentionormustbefullyunderstood

! eventhoughnotdangerous.

THIS MANUAL SHOULD BE RETAINED FOR FUTURE REFERENCE

2

GENERALINFORMATION

NOTICE:Thisproductisintendedforcommercialuseonly.Notforhouseholduse.

CAUTION: These models are designed, built, and sold for commercial use. If these models are

positioned so the general public can use the equipment make sure that cautions, warnings, and

operating instructions are clearly posted near each unit so that anyone using the equipment will

useitcorrectlyandnotinjurethemselvesorharmtheequipment.

WARNING:Checkthedataplateonthisunitbeforeinstallation.Connecttheunitonlytothevoltage

andfrequencylistedonthedataplate.Connectonlyto1phaseaslistedonthedataplate.

WARNING: Installperthespacingrequirementslistedintheinstallationsectionof thismanual.We

strongly recommend having a competent professional install the equipment. A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

be used when connecting these units to electrical power. In the absence of local codes, use the

latest versionoftheNationalElectricalCode.

WARNING: This device should be safely and adequately grounded in accordance with local

codes, or in the absence of local codes, with the National Electrical code, ANSI/NFPA 70, latest

edition to protect the user from electrical shock. It requires a grounded system and a dedicated

circuit, protected by a fuse or circuit breaker of proper size and rating. Canadian installation must

complywiththeCanadianElectricalCode,CSAC22.2,asapplicable.

NOTICE: Local codes regarding installation vary greatly from one area to another. The National

Fire Protection Association, Inc. states in its NFPA96 latest edition that local codes are “Authority

Having Jurisdiction” when it comes to requirement for installation of equipment. Therefore,

installationshouldcomplywithalllocalcodes.

DANGER: SHOCK HAZARD De-energize and lock-out all power to equipment before

performing any maintenance, servicing or, cleaning ofthe equipment.

DANGER: SHOCK HAZARD Never clean any electrical unit by immersing it in water.

DANGER:SHOCKHAZARD- Operators should notopenanypanelsthatrequiretheuseoftools.

IMMEDIATELYINSPECTFORSHIPPINGDAMAGE

All containers should be examined for damage before and during unloading. The freight carrier has

assumed responsibility for its safe transit and delivery. If equipment is received damaged, either apparent

orconcealed,aclaimmustbemadewiththedeliveringcarrier.

A)

Apparent damage or loss must be noted on the freight bill at the time of delivery. It must then be

signed by the carrier representative (Driver). If this is not done, the carrier may refuse the claim. The

carrier can supplythenecessaryforms.

B)

If concealed damage or loss is not apparent until after equipment is uncrated, a request for inspection

must bemadetothe carrier within 15days.Thecarriershouldarrangean inspection. Be certaintoholdall

contentsandpackagingmaterial.

Installationandstart-upshouldbeperformedbyaqualifiedinstallerwhohasthoroughlyread,understands

andfollowstheseinstructions.

3

UNPACKING INSTRUCTIONS:

Note: All Bevies cabinets are tested, inspected and expertly packed to insure arrival in a ready-to-use

condition.Ifanydamageorlossisdiscoveredwhenunpacking,askthecarrier'sagent(inwriting)toinspect

theproduct.Thismustbedonewithin15daysofdelivery.Youcanthenfileaformalclaimwiththecarrier.

This product has been shipped securely packed on a wooden pallet, covered with a protective bag and

corrugated shipping container and sealed with durable banding material. Carefully read the following

unpackinginstructionsandproperlydisposeofallpackagingmaterials.

To open:

1.

Carefullycutandremovebandingmaterial.

2.

Carefullyliftthecorrugatedcontainerofftheproduct.

3.

Opendoor(s)and removethecartonscontainingthewire racks,pansupports, andallpacking

materials(tape,cardboard,etc.)

4.

Carefullylift cabinetoffpallet.

5.

Check model number on the serial number label, located on the left side of the unit.

6.

Releaseallwheelbrakes

SETTING-UP

1.

Remove all protective film from interior and, exterior surfaces on cabinet, and doors.

2.

Placethecabinetinthelocationwhereitwillbeoperated.Wheninpositionsecurethebrakeson

thefronttwowheels.Thesebrakesshouldalwaysbelockedwhenthecabinetisinuse.

3.

Install 1" NPT drain coupling, if needed (fig. 1) and connect drain line (by others) This will be

used to drain the cast aluminum water pan.

4.

Make certain that your unit is properly connected to the correct power source as specified on

the serialnumberlabel, located on the side of the unit.

5.

Insert a half size sheet pan 18” x 13" (not provided with proofer) in the slides under the base of

thecabinet.Thiswillserveasacondensation drippanwhencabinetisinuse.

6.

Open the cartons containing the pan supports and install all supports in cabinet. Starting from

thebottom. Skip (2) slots between each support, to achieve a 4 1/2" spacing between racks.

7.

Open the cartons containing the wire racks, and install racks in cabinet.

Fig. 1

4

OPERATION

1.

Verifythatwheelbrakesareinlockedposition(fronttwocasters).

2.

Make sure stainless steel drain plug is in place in the cast aluminum water pan,

and fill it 1/2to3/4full

3.

Make sure the polycarbonate water pan cover is properly in place with the holes over the pan.

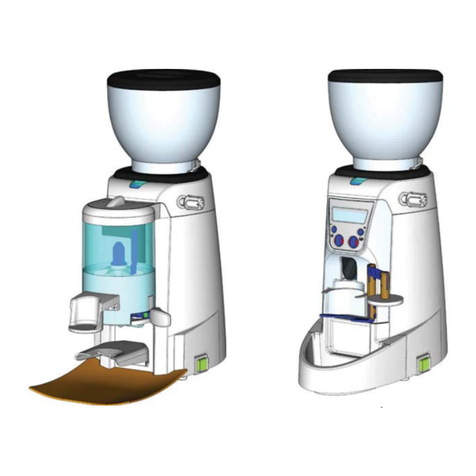

for steps 4,5 and 6 see fig.2

4.

Pushthepowerswitch tothe"ON"Position. Alwaysusethisswitchtoturntheunit"ON"or"OFF".

5.

Set the temperature control to the desired cabinet temperature. 90°F to 110°F is recommended as

a starting position. Increase or decrease the cabinet temperature as needed to best suit your

application.

Toselectdesiredcabinettemperature:

1.

PressSETkeyundercabinettemperaturedisplay. .

2.

PressINCREASEkeyorDECREASEkeytoadjustcabinettemperature.

3.

PressSETkeytolock-indesiredcabinettemperature.(Ifyoudon'tpresstheSETkey the

temperaturesettingwillrevertbacktoprevioussetting).

6.

Set the humidity control to the #3 or #4 position. This can be increased if necessary to suit your

specificapplication.

7.

Makecertainthatthe18"x13" sheetpan(notprovidedwithproofer)thathasbeeninsertedinthe

slidesonthebottom ofthebase is under the square hole to catch any condensation.

8.

Verifythatthedoor(s)isclosedandlatched.

9.

Allow approximately 30-45 minutes for the cabinet to achieve the necessary temperature and

humiditythatyoudesire.

10.

Thecabinetisnowreadyforproductplacementandthestartoftheproofingprocess.

Fig.2

Note: Different products, or even different batches of the same product may require different cabinet

temperaturesandhumiditysettings.Thismayresultinlonger,orpossiblyevenshorterproofingtimes.

OPERATINGTIPS

Always inspect wheel brakes before attempting to move the cabinet. Make certain that brakes are in the

lockedpositionbeforeplacingcabinetintooperation.

During "cold" start-up you may want to set the Humidity Control to the HI setting for 10 to 15 minutes to

accelerate the humidity process. Remember to re-set the Humidity Control back to the desired setting

before beginning the proofing process. Once the cabinet has been loaded with product and the proofing

Proofer Control Panel

Cabinet Temperature Display

Humidity Control

OPERATING INSTRUCTIONS

xxxxxxxx xxx xxx xxxxx xxxxx xxxxxxxx

xx xxxxxxxxx xxxxxxxx xx x xxxxxxxx xxxxx

xxxxxxxxxxxxxxxxxxxx xxxxxxxxxxx xxx xx

x x xxx xxxxxxxx xxxxx x xxxxx xx xxxxxxxx

xxxxxxxxxxxxxxxxx xxxxxxxxxxxxx xxxxxxx

xxxx xxxxxxxxxx xxxxxxxxx xxxxxxxxxxx xx

xxx xxxxxxxx xxxxxxxx xxxxxxxxxxxx xxxxx

POWER

ON

CABINET TEMP.

CABINET HUMIDITY

SET

OFF

Power Switch

Temperature Control

5

processhasstarted,theprooferdoor(s)shouldnotbeopeneduntilproofinghasbeencompleted.

The 18" x 13" sheet pan (not provided with proofer) that serves as a drip pan under the cabinet base

should bechecked,andifnecessary,emptiedattheendofeachday.

Thecabinetshouldbecleanedwhenevernecessary.Itshouldbethoroughlycleanedatleastonceaweek.

Note: It is recommended that humidity be kept at the minimum level that is practical for your operation.

Excessivehumiditywithcondensationonthewallsand/orbaseofthecabinetisnotconsidereddesirable.

SAFETY AND HEALTH

BevLes Proofing Cabinets meet all cUL and NSF requirements. Always operate this proofer in

accordance with the operating instructions found in this manual. Never remove the humidity-heating

module withoutfirst disconnecting (unplugging) the unit from its power source. The cabinet is designed

and built for easy cleaning.Itshouldbecleanedfrequentlyasdescribedinthemaintenancesection.

MAINTENANCE

Cleaning: This cabinet was designed and built for maximum sanitation. It is not self cleaning, so it should

be cleanedfrequentlywithsoapandwater.

1.

NEVERUSESTEELWOOLORCAUSTICCLEANINGCOMPOUNDS.

2.

MakesurethattheunitisturnedOFFanddisconnected fromtheelectricalservice.

3.

Remove the polycarbonate water pan cover and side covers from the humidity-heating

module.

4.

Removethepansupportsandverticaluprights.

5.

Removetheventfromtherearwall.

6.

Clean inside of cabinet with soap and water. Clean polycarbonate water pan cover and

door(s)withsoftsponge,soapandwater.

NEVER USE HARSH CLEANING SUBSTANCES OR ABRASIVES TO CLEAN

POLYCARBONATE SURFACES,ORTHECAST ALUMINUMWATERPAN.

7.

Remove and clean the 18" x 13" drip pan (not provided with proofer) from under the cabinet

base.

If necessary, the humidity-heating module can be removed by, first disconnecting the external drain and

removing the coupling,(fig.1). Then removing the two (2) black knobs (one located at each side on the

moduleonthe exteriorof the cabinet).The module can be pulledout of the cabinet for additional cleaning.

We suggest that you clean the water pan at least once a month with a solution of white vinegar and hot

water.Allowwhite vinegartoremainin waterpan overnight.Thenuseasoft clothtowipeawayanymineral

buildup.

Important:Whenplacingthehumidityheatingmodulebackintothecabinetmakecertainthatthemoduleis

pushed tightly against the cabinet and secured with the two (2) black knobs. Check to see that the one

inch air flow opening at the rear of the humidity-heating module is behind the back vent that hangs on the

rear wall of the cabinet. This is necessary to maintain uniform temperature and humidity distribution

throughoutthecabinet.

IF REPLACEMENT PARTS ARE EVER REQUIRED, ONLY USE PARTS THAT HAVE BEEN

APPROVED BYBEVLESCOMPANY,INC.

Should you require assistance, or service contact the BevLes service line at (844)265-0250 When you

phone please have the model number and serial number of the proofer. This will assist our service

technicians in providing you immediate assistance. You may want to briefly review the Troubleshooting

Tipsbeforeyoucontactourfactory.

6

TROUBLESHOOTING TIPS

NoPower

Ifyourprooferfailstostartwhenthepowerisappliedviapowerswitch:

1.

Check to see if the unit is properly connectedto correct power source as specified on the serial

numberlabel.

2.

Check to see that your power source (wall receptacle) has power - inspect circuit breaker.

3.

Disconnectpowercordandvisuallyinspectforanydamage.

4.

ContacttheBevlesTechnicalServiceDepartmenttorassistance.

ExcessiveHumidity

Ifyourprooferisproducingexcessivehumidity:

1.

Check the setting on the humidity control knob on the control panel, to see if it is set where

you normally operateat.

2.

Check the base of the cabinet to see if the excess humidity is draining through the drain hole

in thecenterofthebase.

3.

ContacttheBevLesTechnicalServiceDepartmentforassistance.

NoHumidity

Ifyourprooferisproducingnohumidity,orconsiderablylessthannormallyachieved:

1.

Inspectwaterlevelinthewaterpan.

2.

Check the setting on the humidity control knob on the control panel, to see if it is set where

you normally operateat.

3.

Checktoseeifthecabinetdoor(s)areclosed.

4.

Makecertainthatthe humidity-heatingmodule's one inch air flowopening (at rear of module)is

behindthecabinetbackventthathangsontherearwallofthecabinet.

5.

Make certain that the polycarbonate water pan cover is correctly positioned over the entire

water pan andthelouverslocatedinfrontofthewaterpan.

6.

Verifythatthefanblowerisoperating.

7.

ContacttheBevLesTechnicalServiceDepartmentforassistance.

ExcessiveHeat

Ifyourproofertemperatureishigherthannormal:

1.

Check the setting on the temperature control to see if it is set where you normallyoperateat.

2.

Check the ambient room temperature to see if it is greater than your desired proofing

temperature.

3.

ContacttheBevLesTechnicalServiceDepartmentforassistance.

NoHeat

Ifyourprooferisproducingnoheat,orconsiderablylessthanyounormallyachieve:

1.

Check the setting on the temperature control to see if it is set where you normally operateat.

2.

Checktoseeifthecabinetdoor(s)iscompletelyclosed.

3.

Makecertainthatthehumidity-heatingmodule'soneinchair-flowopening(atrearof module)is

behindthecabinetbackventthathangsontherearwallonthecabinet.

4.

Verifythatthefanblowerisoperating.

5.

ContacttheBevLesTechnicalServiceDepartmentforassistance.

7

Parts Replacement

TOACCESS ELECTRICAL COMPONENTS:

1.

Make sure the unit is turned off and disconnected from electrical service.

2.

Disconnect drain line and remove coupling (see fig. 1 page 4)

3.

Remove the two black handled knobs (one located on each side of the control panel).

4.

Pullthemoduleoutfromthecabinet.

Refertodrawingsaboveforsteps5,6and7.

5.

Remove screws(3) and stainless steel drip edge.

6.

Turn module over, and removescrewsfromthebottom of the module.(7screwseach side).

There will be (4) nylon caps and spacers, save and reuse.

7.

Removescrewsfromtheback side ofcontrolpanel.(4screwseach side).

8.

Carefully pull control panel forward.

After installing any new components, reverse theabove steps. Make certainthat the oneinchair-flow

opening at thebackofthemoduleisupbehindthecabinet'sbackvent hangingontherear wall.

Refertowiringdiagramsforadditionalinformation.

8

Amp rating: 120v Models 13 amps

9

Amp rating: 208/230v Models 7.5/6.8 amps

10

Part Number Description Qty.

720671 Pin Hinge 6

741874 Hinge, Cabinet Side 6

741875 Hinge, Door Side 6

750720 Pin, Latch 3

750419 Latch 3

781285 Latch Spring 3

750132 Latch, Butt 6

780036 Caster 5" Swivel w/Brake 2

780040 Caster 5" Swivel 2

783116 Knob Threaded 1/4-20 Bottom Module 2

784013 Wire Shelf 11

751121 Hanger, Slide Guide (Shelf/Pan Support ) 22

740352 Back Vent Panel 1

751061 Retainer, Wiper Strip Extrusion 3

702520 Wiper Strip, White Silicone 3

742764 Side Cover, Heating Unit Aluminum 2

760040 Water Pan Cover, Polycarbonate 1

784124 Handle, Water Pan Cover 1

760055 Replacment Door Glass Polycarbonate, Clear 3

740223 Bracket, Mounting, Sensor 1

782092 Knob, Infinite Switch, Black 1

740348 Upright, 50.75" Long 1 1/2" Spacing 4

781295 Drain Brass 1

742745 Drain Coupling Weldment 1

781503 Drain Plug Stainless Steel 1

1

784448 Transformer, 120/240V 1

782204 Motor, Blower, & Housing 120V Proofer 1

782205 Motor, Blower & Housing, 240V Proofer 1

782088 Switch, Infinite, 120V/15A 1

782224 Switch, Infinite, 240V/15A 1

782226 Switch, Rocker, DPST, Black/Whi, 277V, 20A 1

1107200 Block Terminal, 6 Station 600V 1

782020 Heating Element Blower 1000W, 120V 1

784308 Heating Element Blower 1000W, 240V 1

782162 Relay, Solid State, 50A-240VAC 1

784737 Controller, Temperature Set 60-125 Deg. F 1

Replacement Parts Mechanical

Replacement Parts Electrical

11

Notes:

12

BEVLES COMPANY LIMITED WARRANTY

1525 East Lake Road • Erie, PA 16511

Phone: (844) 265-0250 Fax: (800) 548-9392

1.

Bevles warrants to the original purchaser that on the date the equipment is shipped (sold), it will be

free of defects in materials or workmanship. Bevles will, at it’s discretion, repair or replace, during

the warranty period printed below, any part that has a defect in material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the warranty

periodundernormaluseandservice.

Parts:Two*yearsfromdateoforiginalshipmentfromtheBevlesfactory.

Labor:One**yearfromdateoforiginalshipmentfromtheBevlesfactory.

* Air Circulation BlowerAssemblies (motors) and Power Switchesshall beone year fromdate of

originalshipment.

Calrod“Air” HeatingElementsshallbethreeyearsfromdateoforiginalshipment.

** Allelectricalcomponents120daysfromdateoforiginalshipment.

2.

Bevles must be contacted, and pre-approval must be issued by the Bevles factory prior to any type of

service being performed. Bevles assumes no responsibility for any charges that were not expressly

authorizedbytheBevlesfactory,orforanychargesthatexceed, inBevles’sole judgement, normaland

customaryamounts.

3.

Bevles will pay UPS Ground charges for any part that has a defect in material or workmanship that was

present when the product shipped from Bevles, and which manifests itself during the first year of the

warranty period under normal use and service. All warranty replacement parts will ship F.O.B. Bevles

factory, Erie, PA16511.

4.

This warranty shall be void in its entirety if any abuse of, misuse of, alteration/modification of or

improper maintenance of original product occurs. If, at any time a claim is reported to Bevles, and the

purchaserisdelinquentinpaymentfortheproduct,warrantywillnotapply.

5.

Buyer’s Remedies-If a Bevles product fails due to a defect in material or workmanship in conformity

with the warranties in paragraph one, buyer shall notify Bevles of such failure within a reasonable time,

but in no event beyond fifteen (15) days of such discovery of defect in material or workmanship.

Bevles shall provide, in its sole discretion, either the repair or replacement of any defective or any non-

conforming part. Bevles specifically disavows any other representation, warranty or liability relating

tothecontinueduseoftheproduct.

6 Exclusion of consequential and incidental damages-In no event shall Bevles be liable for any

incidental, special, indirect, or consequential damages, whether resulting from non-delivery or from

the use, misuse, or inability to use the product, or from defects in the product, or from Bevles’

own negligence or other tort. This exclusion applies regardless of whether such damages are sought

for breach of warranty, breach of contract, negligence, or strict liability in tort or under any other legal

theory.

7. Disclaimer of warranties-The warranties contained in paragraph one above are the exclusive

warranties given by Bevles and supersede any prior, contrary, or additional representations, whether

oral or written. Bevles hereby disclaims and excludes all other warranties-whether expressed,

implied, or statutory-including any warranty of merchantability, any warranty of fitness for a

particular purpose, and any implied warranties otherwise arising from course of dealing or usage of

trade.

12/15

Table of contents

Other BevLes Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Welbilt

Welbilt Delfield ASM-P Series Installation, operation and maintenance manual

Glastender

Glastender GT-18 Operation manual

MICROMATIC

MICROMATIC CAS-36X Assembly instructions

Alto-Shaam

Alto-Shaam 10-18W Installation operation & maintenance

GGM gastro

GGM gastro ST16 Series user manual

Avantco

Avantco 177CS11V user manual