Bewator FH07B Series User manual

FH07B Series

Phoenix™ 7” Flameproof

Camera Housing

INS00306 Page 1 of 24

Installation Instructions

Manual: INS00306 Issue: 3.0

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 2 of 24

IMPORTANT NOTE

Please thoroughly read these Instructions before installing the

FH07B Series Phoenix™ 7” Flameproof Camera Housing.

Table of Contents

About This Manual...................................................................................................................................3

Health & Safety Notice.............................................................................................................................3

INTRODUCTION......................................................................................................................................5

General Description .................................................................................................................................5

Contents of Package................................................................................................................................9

Before Starting Installation.......................................................................................................................9

After Installation .......................................................................................................................................9

Suggested Tools....................................................................................................................................10

ORDERING THE FH07B SERIES UNIT ...............................................................................................11

Certification Requirements For The Camera/Lens ................................................................................11

INSTALLING THE FH07B SERIES UNIT.............................................................................................12

Removing The Rear Cap Assembly.......................................................................................................12

Pre-installation Wiring............................................................................................................................13

Refitting The Rear Cap Assembly And Fitting The Sunshield...............................................................18

Locating The Unit...................................................................................................................................19

Mounting The Unit..................................................................................................................................19

MAINTENANCE.....................................................................................................................................20

1 Month After Installation .......................................................................................................................20

6 Monthly Checks...................................................................................................................................20

2 Yearly Checks.....................................................................................................................................20

5 Yearly Checks.....................................................................................................................................20

SPECIFICATIONS.................................................................................................................................21

Mechanical.............................................................................................................................................21

Electrical.................................................................................................................................................21

Mechanical Dimensions.........................................................................................................................22

Wiring Diagram ......................................................................................................................................23

NOTES...................................................................................................................................................24

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 3 of 24

About This Manual

This manual describes the following equipment, certified to the EC (ATEX) Directive

94/9/EC as II 2 GD (EEx d IIB T85°C):

FH07B-40 Phoenix™ 7” diameter, IP67, Camera Housing (420 x114 x 93mm

internal) c/w sunshield, demister ~ 230Vac.

FH07B-40/L Phoenix™ 7” diameter, IP67, Camera Housing (420 x 114 x 93mm

internal) c/w sunshield, demister ~ 24Vac.

FH07B-40/U Phoenix™ 7” diameter, IP67, Camera Housing (420 x 114 x 93mm

internal) c/w sunshield, demister ~ 110Vac.

FH07B-30 Phoenix™ 7” diameter, IP67, Camera Housing (290 x 114 x 93mm

internal) c/w sunshield, demister ~ 230Vac.

FH07B-30/L Phoenix™ 7” diameter, IP67, Camera Housing (290 x 114 x 93mm

internal) c/w sunshield, demister ~ 24Vac.

FH07B-30/U Phoenix™ 7” diameter, IP67, Camera Housing (290 x 114 x 93mm

internal) c/w sunshield, demister ~ 110Vac.

Health & Safety Notice

SELECT SUITABLE EQUIPMENT

• Please ensure that all equipment is suitable for the application and the environment for

which it is intended.

• Check operating temperatures and where applicable “protection against water ingress”

specifications.

• Please take particular care that the inter-connected equipment is fully compatible with

each other and suitable for such use.

• Check load ratings and dimensions.

SECURELY MOUNT THE ASSEMBLY

• This equipment may be subject to remote control and may move at any time. It should be

installed such that moving parts cannot be exposed to anyone. Persons working on the

equipment should take appropriate precautions to ensure that unexpected movement does

not occur as this could lead to injury.

• This unit must be mounted properly and securely.

• In situations where there could be a risk of injury, should any part of the assembly become

detached for any reason and fall, normal safety precautions should be employed.

• Care should be exercised to select suitable hardware to install the unit, taking into

account both the compositions of the mounting surface and the total weight of the

hardware.

• It is important that only the recommended or supplied fixings are used. In some cases

the fixings material and other details are critical.

• Ensure that each part of the assembly is attached securely.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 4 of 24

• The mounting surface must be sufficiently solid and strong to take the complete weight of

the assembly and take into account environmental aspects such as exposure to strong

wind.

• It is recommended that the bracket and column spacers detailed on Page 21 should be

used, where appropriate.

• As the mounting surface to which this housing could be attached is site dependent,

Bewator Ltd. does not supply fixings for securing the base of the unit to its mounting

surface. It is the responsibility of installers to ensure that fixings are selected that are fit for

the specific purpose required.

INSTALL OUT OF REACH

• This equipment is to be installed out of reach of the user, or anyone who will come into

casual contact with the installation.

• It is recommended that a prominent warning notice be affixed near to all moveable

Camera Housing assemblies indicating that sudden movement of the equipment may

occur.

• Be sure to provide suitable access equipment to ensure the safety of installation or

service personnel working on the equipment.

INSTALL CORRECTLY

• All persons installing and maintaining this equipment should be suitably qualified and work

to national and local standards and codes of practice.

• Use the appropriate tools. Specific tools may be required for installation purposes

dependant upon the site in which the assembly is to be installed.

• The installation should comply with local codes and standards e.g. EN 60079–14:1997

and its guide PD 60079-14:2000.

• Check that correct cable types and input cable glands are used - Refer to local and

national standards for wiring and follow recommendations.

• Always use the recommended or supplied screws. Failure to do so will invalidate the

certification to EC (ATEX) Directive 94/9/EC.

• Ensure that power is removed from the assembly before attempting installation.

• Ensure the power CANNOT be re-connected by external sources while the unit is being

worked upon.

• Installation must comply with data protection and privacy codes of practice.

WARNINGS

The unit must be connected to Earth.

Do not open the unit when an explosive atmosphere is present.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 5 of 24

Introduction

General Description

Hazardous Areas

The Phoenix™ 7” FH07B Series Flameproof Camera Housing is certified to the EC (ATEX)

Directive 94/9/EC for use in hazardous areas.

A hazardous area is defined as an area in which explosive atmospheres are, or may be

expected to be, present in quantities such as to require special precautions for the

construction and use of electrical equipment. An explosive atmosphere consists of a mixture

of flammable substances with air in the form of gas, vapour, mist or dust in such proportions

that it can be exploded by excessive temperatures, arcs, sparks or flames.

Equipment is housed in an enclosure into which gas may gain access. Should this gas be

ignited within the enclosure, the resulting explosion will not reduce the pressure integrity of

the enclosure or will not be transmitted to any flammable atmosphere external to the

enclosure.

Note: This equipment may contain an ignition source even after disconnection.

Customer Orders

The FH07B Series of Flameproof Camera Housings are fitted with a customer (free issue)

supplied Camera and Lens and supplied with ATEX Equipment Certification by Bewator Ltd.,

at an additional cost. (Bewator Ltd. Part Number FH07-CERT). The Camera/Lens and the

installation MUST be compatible with the certification to the EC (ATEX) Directive 94/9/EC,

see Page 11. Bewator Ltd. can supply and fit suitable cameras and lenses on request.

The FH07B Series of housings can be supplied fitted with the following optional accessories:

FH07W Wiper Unit Kit ~ 230Vac ~ 50/60Hz.

FH07W/L Wiper Unit Kit ~ 24Vac ~ 50/60Hz.

FH07W/U Wiper Unit Kit ~ 110Vac ~ 60Hz.

FH07-RX210 10 - function Receiver Kit ~ 110-230Vac.

FH07-RX217 17 - function Receiver Kit ~ 230Vac.

FH07-TKIT Tamper Switch Kit.

To ensure compliance with the certification to the EC ‘ATEX’ Directive 94/9/EC, ANY of

these optional accessories MUST be pre-ordered and supplied factory fitted by Bewator Ltd.

The maximum combined power dissipation for all of the equipment fitted into the Camera

Housing MUST not exceed:

FH07B-40 Series 63W

FH07B-30 Series 50W

To ensure compliance with the EC (ATEX) Directive 94/9/EC, all orders that are placed for

Phoenix™ 7” FH07B Series Camera Housings MUST follow Bewator Ltd. Procedure

20G040, which includes the completion of a Phoenix™ Pre-Compliance Form by the

customer.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 6 of 24

Certification

EC (ATEX) Directive 94/9/EC Certification is to :-

CE Marking. Bewator Ltd. Declaration Of Conformity. Bewator Ltd. Quality

System certified to ISO9001.

Specific explosion protection mark.

II Equipment group II. Group II comprises equipment intended for use in places

liable to be endangered by explosive atmospheres, other than mining

applications.

2 Equipment category 2. Equipment in this category is intended for use in

areas in which explosive atmospheres caused by gases, vapours, mists or

air/dust mixtures are likely to occur frequently under normal operating

conditions.

G Explosive atmospheres caused by gas.

D Explosive atmosphere caused by dust.

European Harmonised Standard EN 50014:1998 and EN 50018:2000 Certification is to:

E Complies with European Harmonised Standard.

Ex For use in explosive atmospheres.

dFlameproof enclosure to European Harmonised Standard EN 50018.

IIB Gas Grouping – For atmospheres containing ethylene or gases of an

equivalent hazard. Also includes Gas Group IIA for atmospheres containing

propane or gases of an equivalent hazard.

Zone 1 Hazardous area zone – Where an explosive atmosphere is likely to occur in

normal operation. Also includes Zone 2, where an explosive atmosphere is

not likely to occur in normal operation and if it does occur it will exist only for a

short time.

T85°C Temperature - Based on an ambient temperature of 40°C, the maximum

surface temperature generated by the unit, with approved internal fittings,

does not exceed 85°C.

EC-Type Examination Certificate

Baseefa (2001) Ltd., Buxton, UK, notified body number 1180, certifies compliance of the

equipment with the EC (ATEX) Directive 94/9/EC.

EC-Type Examination Certification Number: Baseefa03ATEX0464X.

European Harmonised Standard EN 60529:1992 Certification is to:

IP67Ingress Protection

IP6X Dust tight. No ingress of dust at normal temperature and pressure.

IPX7 Protected against the effects of temporary immersion in water. Immersed for

30 minutes at a depth of 1.00m.

Abtest Limited, Abercynon, UK certifies compliance of the equipment to the Standard EN

60529:1992, with an IP67code.

Environmental Test Report No : EQ8481, dated 16 July 2003.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 7 of 24

Equipment Marking

The equipment has a special yellow label attached to the outside of the Rear Cap Assembly.

The label includes the following:

1180 II 2 GD EEx d IIB T85°C

Equipment Description

• The housing is manufactured using a 7” external diameter extruded aluminium body

(polyester powder coated) with two clear anodised aluminium Front and Rear (end)

Caps.

• The housing body incorporates 6 off M6 x 1.0 screw thread holes, in two sets of 4 holes

equi-spaced on a 4” (101.6mm) p.c.d. (pitch circle diameter), to enable the housing to be

mounted on a suitable surface.

• The Front Cap Assembly incorporates a 15mm thick toughened glass window.

• Two M4 screw mounting holes are provided on the Front Cap Assembly, beneath the

glass window, for fitting additional user supplied accessories (See Figure 1).

Note: The penetration of the M4 mounting screws into the Front Plate Assembly

mounting holes MUST NOT exceed 8mm. It is recommended that dimensional checks

be performed to determine the correct length of the M4 mounting screws.

• The Rear Cap Assembly includes a ‘mono rail’ assembly to which is fitted a

Camera/Lens and any optional accessories. It also includes 4 off M20 x 1.5 screw

thread cable entries, which are normally fitted with stopping plugs on delivery.

• 4 off ATEX certified flame proof Cable Glands are supplied for use with suitable cable.

(See Page 13.)

• Housings are available in six variants - two lengths (nominally 290mm and 420mm

internal) and three ac mains input voltages (230Vac, 110Vac and 24Vac).

• A Terminal Block Assembly, fitted to the ‘mono rail’ assembly, is used where required for

the connection of external electrical equipment.

• Housings are provided with an external Earth Bonding Stud.

• A thermostatically controlled window demister (heater) and a Sunshield are fitted as

standard.

• Spare Wiper Arm and Blade Kits (Bewator Ltd. Part Number WI01AB) are also available.

• A detailed product specification is provided on Page 21.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 8 of 24

Figure 1 Typical Flameproof Camera Housing

Figure 2 Detail Showing Flame Path Zone Locations

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 9 of 24

Contents of Package

The product should reach you in perfect working order. If the unit is damaged in any way or

if the supplied kit is incomplete, please contact Bewator Ltd. immediately.

1 x FH07B Series Camera Housing, including Sunshield, fitted with optional accessories.

1 x General Packing Kit comprising:

4 x M5 x 16 Hex Socket Button Head Screw.

4 x M5 Nylon Washer.

3 x M5 x 60mm M5 Hex Head Special - Rear Cap Removal Screw.

2 x M6 x 70 Cap Head - Rear Cap Fitting Guide Screw.

4 x Cable Gland (Hawke Cable Gland Type 501/421).

1 x Installation Instructions INS00306.

Optional

1 x Optional Accessories Packing Kit comprising:

Either 1 x Installation Instructions INS00054 (complete with ‘D’ Type Telemetry Module)

– 10 function Receiver [RX210].

Or 1 x Installation Instructions INS00093 (complete with ‘D’ Type Telemetry Module)

– 17 function Receiver [RX217].

Before Starting Installation

1. Ensure that the contents of the package (see above) are correct.

2. Read all of these Installation Instructions.

3. Ensure that the correct tools are used when installing – see below.

4. Ensure that the complete assembly is tested in the workshop, prior to installation on

site.

After Installation

1. Save these Installation Instructions for future use.

2. Save the 3 off Rear Cap Removal Screws and the 2 off Rear Cap Fitting Guide

Screws for future use.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 10 of 24

Suggested Tools

The following tools are suggested for the installation of a FH07B Series Flameproof Camera

Housing:

• 3mm A/F (across flats) Allen key

• 5mm A/F (across flats) Allen key

• 10mm A/F (across flats) Allen key

• No 1 ‘Posidrive’ screwdriver

• Torque wrench set to 4.5Nm

• Rubber hammer

• 8mm A/F (across flats) ring spanner

• Small flat bladed (electrical) screwdriver.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 11 of 24

Ordering the FH07B Series Unit

Certification Requirements For The Camera/Lens

To ensure compliance with the certification to the EC ‘ATEX’ Directive 94/9/EC Equipment-

group II, Category 2, the Camera/Lens to be fitted into the FH07B Series Camera Housing

MUST adhere with the maximum requirements shown in Figures 3 and 4. Cameras and

Lenses with equal or lesser dimensions may be fitted into the Camera Housing.

Note: Fitting any of the optional accessories may restrict the size of the Camera and the

Lens that can be used.

²

Figure 3 Camera Dimensions

²

Figure 4 Lens Dimensions

INS00306 Page 12 of 24

Installing the FH07B Series Unit

Removing The Rear Cap Assembly

1. This procedure should ONLY be

performed in the workshop.

2. NOTE: It is recommended that the

Front Cap Assembly is NOT

removed at any time.

3. Remove the Rear Cap Assembly.

a) If the Wiper Unit Kit (FH07W) is

fitted, ensure that the wiper arm

is resting in the PARK position.

(See Figure 1.)

b) Remove the 6 off M6 x 25 Cap

Head A4-80 stainless steel

screws and star washers from

around the periphery of the

Rear Cap Assembly. Retain for

future use. (See Figure 5.)

c) Screw the 3 off M5 Special Rear

Cap Removal Screws into the

special screw holes and

gradually tighten in sequence to

withdraw the Rear Cap

Assembly, maintaining an equal

gap between the Cap and the

housing Body. Initial resistance

will be provided by the ‘O’ ring

seal. (See Figure 6.)

Figure 5 Rear Cap Assembly Removal (1)

d) Withdraw the Rear Cap

Assembly (including the

Monorail) from the Body.

Note: Care should be taken to

avoid damage to the flame path

zone. (See Figure 2.)

Figure 6 Rear Cap Assembly Removal (2)

e) Remove the 3 off M5 Rear Cap

Removal Screws from the Rear

Cap Assembly and retain for

future use.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 13 of 24

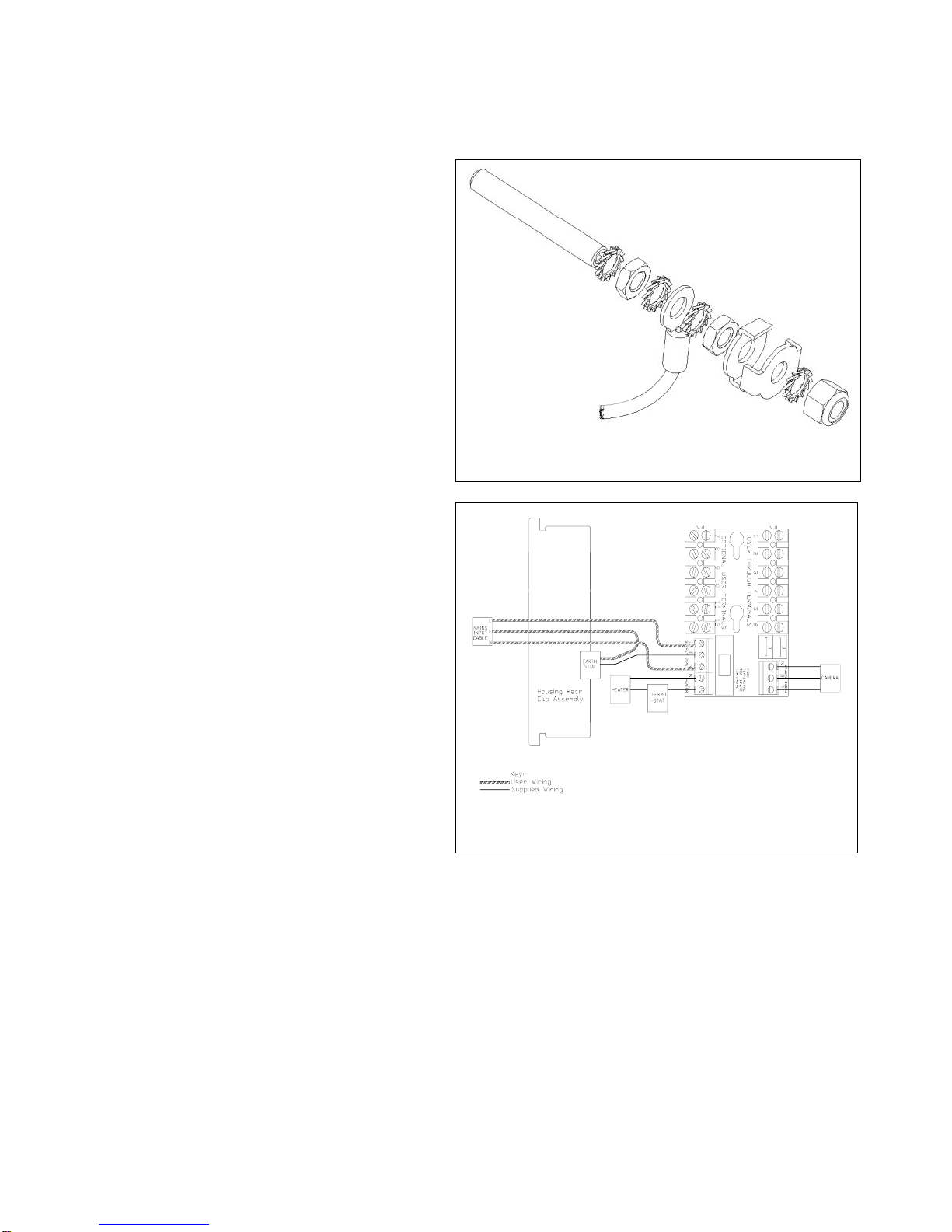

Pre-installation Wiring

General

1. This procedure should ONLY be performed in the workshop.

2. Note: Use only cable suitable for the application and that meets the standards required

by the installation.

3. Ensure that the maximum cable distances are not exceeded.

Cable Diameter Impedance Maximum Distance

0.50mm250.4 Ohm/km 67 metres

0.75mm232.3 Ohm/km 100 metres

1.00mm219.9 Ohm/km 167 metres

4. Phoenix™ FH07B Series housings are supplied with four cable entries (M20 x 1.5

threaded) in the Rear Cap Assembly. Each threaded entry hole MUST be fitted either

with a suitable flameproof entry device (cable gland) or a stopping plug certified to the

EC ‘ATEX’ Directive 94/9/EC or local standards, where relevant.

Inside the Packing Kit (see Page 9) are supplied four off ATEX certified flameproof

cable glands which can be used by installers ONLY WHEN THE CABLE

GOING THROUGH THE GLANDS IS BETWEEN 7.5 & 11.9mm IN DIAMETER

AND IS NON-ARMOURED ELASTOMER AND PLASTIC INSULATED.

The glands are manufactured by Hawke Cable Glands Ltd., part reference

A501/421/O/M20. EC-Type Examination Certificate Number: BAS01ATEX2070X.

These glands MUST be fitted using Hawke Assembly Instructions AI307.

Suitable ATEX certified alternative glands to suit different cable specifications may also

be used, if necessary.

Any of the supplied stopping plugs (4 off normally fitted) may also be used.

5. Note: Electrical installation methods should comply with current local and national

regulations and site regulations.

Only service personnel who are qualified to the appropriate level should carry out the

installation.

6. When connecting cables for the electrical supply ALWAYS ensure that High (mains)

voltage power conductors are separated from Low voltage (e.g. telemetry, lens, etc.) data

conductors. This will reduce potential problems that can arise through electrical noise

and interference.

7. The video cable enters the housing through one of the other cable entries, using a

suitable cable gland, and is connected directly to the Camera Video Out connector or the

(optionally fitted) Receiver.

8. An Earth Bonding Stud is provided on the outside of the Rear Cap Assembly.

9. A Terminal Block Assembly is provided to aid the electrical installation. It is securely

mounted on a Plate – Mounting, which is fixed on the Monorail.

Note: The Terminal Block Assembly is not provided with the optional 10 – function

Receiver Kit (FH07-RX210).

10. The Mains Input Cable Earth wire (E) MUST always be fitted as the primary Earth to the

internal Earth Stud. (See Figure 7.) Ensure that any factory fitted Earth wires are refitted

onto the internal Earth Stud in accordance with current local and national codes and

standards.

11. A wiring diagram for a typical configuration is provided on Page 23.

INS00306 Page 14 of 24

Wiring Requirements for FH07B Series Housings supplied WITHOUT any

optional accessories fitted

1. Confirm that the special Earth wire is

connected between the Earth Stud

on the inside of the Rear Cap

Assembly and the SUPPLY INPUT

earth (E) terminal on the Terminal

Block Assembly.

2. Confirm that the Heater cable is

connected to the HEATER (N L)

terminals on the Terminal Block

Assembly. The L wire is connected

via. the Thermostat, which is

mounted on the inside of the Rear

Cap Assembly.

3. The user supplied mains input cable

enters the housing through one of

the 4 cable entries, using a suitable

cable gland. The Earth wire (E)

MUST be connected as the primary

Earth to the Earth Stud on the inside

of the Rear Plate. (See Figure 7.)

The Live and Neutral wires are

connected to the SUPPLY INPUT (L

N) terminals (respectively) on the

Terminal Block Assembly. (See

Figure 8.)

Figure 8 Wiring Requirements (1)

Figure 7 Internal Earth Stud

Mains Input Cable

Earth Wire (E)

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 15 of 24

Wiring Requirements for FH07B Series Housings supplied fitted with a Wiper

Unit Kit (FH07W Series)

1. Confirm that the special Earth wire is

connected between the Earth Stud

on the inside of the Rear Cap

Assembly and the SUPPLY INPUT

earth (E) terminal on the Terminal

Block Assembly.

2. Confirm that the Heater cable is

connected to the HEATER (N L)

terminals on the Terminal Block

Assembly. The L wire is connected

via. the Thermostat, which is

mounted on the inside of the Rear

Cap Assembly.

3. The user supplied mains input cable

enters the housing through 1 of the 4

cable entries, using a suitable cable

gland. The Earth wire MUST be

connected as the primary Earth to

the Earth Stud on the inside of the

Rear Plate. (See Figure 7.) The

Live and Neutral wires are

connected to the SUPPLY INPUT (L

N) terminals (respectively) on the

Terminal Block Assembly.

4. The Wiper control cable enters the

housing through a different cable

entry, using a suitable cable gland,

and is connected to screw terminal

10 on the Terminal Block Assembly.

(See Figure 9.)

WARNING: The Wiper control

(WIPE) wires remain at supply

voltage (even AFTER the applied

WIPE voltage is removed) until the

Wiper AUTOPARK is complete and

the microswitch is activated.

(See Figure 10.)

Figure 9 Wiring Requirements (2)

WIPER

CONTROL

(WIPE)

M

L

(PARK)

N

NC

NO

C

W

W

BR

BU

MICROSWITCH

Figure 10 Wiper Unit Kit ~ Circuit Diagram

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 16 of 24

Wiring Requirements for FH07B Housings supplied fitted with a 10 - function

Telemetry Receiver Kit (FH07-RX210)

1. Note: All electrical connections to

any external equipment (e.g. a PTZ

unit) are via. the 10 - function Preset

Receiver Assembly (RX210). The

receiver is securely fitted to an

integral mounting plate fixed on the

Monorail.

2. Note: The 10 - function Preset

Receiver offers both coaxial (“C”

Type) and twisted pair (“D” Type)

telemetry options, using plug-in

modular circuit boards, as detailed in

the Bewator Ltd. Installation

Instructions (INS00054).

3. Note: The 10 - function Receiver

MUST be connected and tested in

accordance with the Installation

Instructions (INS00054).

4. Confirm that the special Earth wire is

connected between the Earth Stud

on the inside of the Rear Cap

Assembly and the AC INPUT earth

(E) terminal on the Receiver.

5. Confirm that the Heater cable is

connected to the AC INPUT (N L)

terminals on the Receiver. The L

wire is connected via. the

Thermostat, which is mounted on the

inside of the Rear Cap Assembly.

6. The user supplied mains input cable

enters the housing through one of

the 4 cable entries, using a suitable

cable gland. The Earth wire MUST

be connected as the primary Earth to

the Earth Stud on the inside of the

Rear Plate. (See Figure 7.) The

Live and Neutral wires are

connected to the AC INPUT (L N)

terminals (respectively) on the

Receiver. (See Figure 11.)

Figure 11 Wiring Requirements (3)

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 17 of 24

Wiring Requirements for FH07B Housings supplied fitted with a 17 - function

Receiver Kit (FH07-RX217)

1. Note: The fitting of a 17 – function

Receiver Kit (FH07-RX217) creates

space limitations for the fitting of

other items into the housing, which

must be addressed. It is

recommended that the 17 – function

Receiver Kit should ONLY be fitted

to a –40 (420mm) version of the

Housing.

2. Note: The 17 - function Receiver

Assembly (RX217) is fitted upside

down to 2 mounting brackets, which

are mounted on to 2 Plate - PCB

Mountings fixed on the Monorail.

3. Note: The 17 - function Receiver

offers both coaxial (“C” Type) and

twisted pair (“D” Type) telemetry

options, using plug-in modular circuit

boards, as detailed in the Bewator

Ltd. Installation Instructions

(INS00093).

4. Note: The 17 - function Receiver

MUST be connected and tested in

accordance with the Bewator Ltd.

Installation Instructions (INS00093).

Release the 4 plastic clip fasteners

from the 17 – function Receiver PCB

and turn the PCB over, placing it on

a clean workbench.

Figure 12 Wiring Requirements (4)

5. Confirm that the Heater cable is

connected to the HEATER (N L)

terminals on the Terminal Block

Assembly. The L wire is connected

via. the Thermostat, which is

mounted on the inside of the Rear

Cap Assembly.

6. The user supplied mains cable

enters the housing through one of

the 4 cable entries, using a suitable

cable gland. The Earth wire (E)

MUST be connected as the primary

Earth to the Earth Stud on the inside

of the Rear Plate. (See Figure 7.)

The L and N wires MUST be

connected to the SUPPLY INPUT (L

N) spade connectors (respectively)

on the Mains Filter unit. The Mains

Filter is securely mounted on a Plate

- Mounting which is fixed on the

Monorail. (See Figure 12.)

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 18 of 24

Refitting The Rear Cap Assembly And Fitting The Sunshield

1. Refitting the Rear Cap Assembly.

Note: Before refitting the Rear Cap

Assembly, test the Camera functions

and check that the lens dust cover is

removed!

a) Take care that the ‘O’ ring seal is

free from grit and dirt. Lightly

grease the ‘O’ ring and the flame

path zone (shoulder/neck) of the

Rear Cap Assembly with clean

general purpose grease.

b) Lightly grease the ‘O’ ring and the

locating spigot at the front of the

Monorail with clean general

purpose grease.

c) Present the Rear Cap Assembly to

the housing Body, taking care to

maintain the correct rotational

alignment.

d) If the optional Wiper Unit

Kit (FH07W) is fitted:

i) Ensure that the wiper arm is

resting in the PARK position.

ii) Confirm that the rear wiper shaft

coupling is correctly aligned with

the wiper drive unit mating-half

coupling.

e) Locate the Monorail locating

spigot into the circular groove in

the bottom of the Body.

f) Slide the Monorail into the Body.

Fit the 2 off Cap Fitting Guide

Screw into a diagonal pair of fixing

holes (say 3 and 4) to ensure that

all the fixing holes line up. (See

Figure 13.) Partially insert the

Rear Cap Assembly into the Body

until the 6 off M6 x 25 screws can

engage. Remove the 2 off Cap

Fitting Guide Screws and retain for

future use. Note: Care should be

taken to avoid damage to the

flame path zone. (See Figure 2.)

g) Refit the 6 off star washers and

the 6 off M6 x 25 Cap Head A4-80

stainless steel screws. Tighten

the screws evenly to a Torque

rating of 4.5Nm, in the order as

shown in Figure 14. It is essential

that only A4-80 screws be used.

Figure 13 Refitting the Rear Cap Assembly

Figure 14 Screw Tightening Sequence

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 19 of 24

Figure 15 Fitting the Sunshield

2. Fitting the Sunshield.

a) Carefully place the Sunshield in

position on the Body, ensuring that

the front of the Sunshield is at the

front of the Body.

b) Fit the 4 off M5 nylon washers and

the 4 off M5 x 16 hex socket

button head screws. (See Figure

15.)

Locating The Unit

1. Please ensure that all equipment is suitable for the application and the environment for

which it is intended.

2. Please take particular care that the inter-connected equipment is fully compatible with

each other and is suitable for such use.

3. This equipment is to be installed out of reach of the user, or anyone who will come into

casual contact with the installation.

4. It is recommended that a prominent warning notice be affixed near to all moveable

Camera housing assemblies indicating that sudden unexpected movement of the

equipment may occur.

5. Be sure to provide suitable access equipment to ensure the safety of the installation or

the service personnel working on the equipment.

Mounting The Unit

1. The Camera Housing must be mounted properly and securely.

2. The Camera Housing can be mounted to a bracket, a column spacer, and a pan and tilt

(PTZ) unit or directly to a suitable structure.

3. Two sets of 4 x M6 screw mounting holes, equi-spaced on a 4” (101.6mm) p.c.d. (pitch

circle diameter), are provided on the base of the housing. It is recommended that the

rear set of 4 holes be used when cabling weighing greater than 5.0kg is connected to the

housing.

4. Note: When attaching to a pan and tilt unit, the Camera Housing MUST be bolted directly

to the mounting surface. The use of additional spacers is NOT recommended.

5. Note: The penetration of the 4 x M6 mounting screws into the housing mounting holes

MUST NOT exceed 13mm. It is recommended that dimensional checks be performed to

determine the correct length of the M6 mounting screws to be used for the installation.

6. As the mounting surface to which this Camera Housing could be attached is site

dependent, Bewator Ltd. does not supply fixings for securing the base of the unit to its

mounting surface. It is the responsibility of installers to ensure that fixings are selected

that are fit for the specific purpose required.

7. An appropriate disconnection device MUST be included in the installation.

8. The Camera Housing may be subject to remote control and therefore may move at any

time. Persons working on the equipment should take appropriate precautions to ensure

that unexpected movement does not occur.

FH07B Series Installation Instructions Issue 3.0

INS00306 Page 20 of 24

Maintenance

The following guidelines for maintenance should be observed:

1 Month After Installation

All external fastenings and cables should be thoroughly checked for tightness, security and

wear.

6 Monthly Checks

All external fastenings and cables should be thoroughly checked for tightness, security and

wear.

Perform checks to ensure that cables are not fouling on any obstruction.

Check cables for signs of wear. Replace as necessary.

If fitted, the wiper arm and blade should be checked for wear or corrosion. Replace as

necessary.

2 Yearly Checks

If fitted, the wiper arm and blade should be replaced.

5 Yearly Checks

If the unit is exposed to very severe weather conditions or other harsh environments, the two

‘O’ ring rubber weather seals, on the Rear Cap Assembly and on the Front Cap Assembly,

should be replaced. The unit should be returned to Bewator Ltd. for ‘O’ ring replacement.

Table of contents