BEX MultiBEX mx4 User manual

MULTIBEX CRIMP TOOL WITH ROTATIONAL DIES

Country of origin: Croatia (EU)

Manufacturer: BEX d.o.o., Mučići 37b, 51213 Jurdani

Instruction Sheet

MultiBEX mx4

06 SEP 22 REV 00

-1-

INSTRUCTION MANUAL

1. INTRODUCTION AND TOOL FEATURES

2. CONFIGURATION OF THE TOOL

3. STRIPPING OF WIRE OUTER INSULATION

4. TERMINAL CHART

5. WORKING WITH DIE SET

6. CRIMPING PROCEDURE

7. UNBLOCKING THE TOOL

8. TOOL REGULATION PROCEDURE

9. MAINTENANCE AND INSPECTION

10. WARRANTY

1. INTRODUCTION AND TOOL FEATURES

1.1. Instruction sheet provides application and maintenance procedures for Multibex hand tool with inserts. The hand tool consists

of the insert assembly and hand tool frame assembly.

❑With this tool only plugs of appropriate type have to be used. Crimping plugs of unsuitable type may result with unsatisfactory

characteristics of crimped connections and eventually with damaging of the tools and is to be strictly avoided.

1.2. FEATURES

❑Each insert can crimp 16 terminals crossections

❑Crimp nests are fully machined in high carbon steel, heat treated and nickel coated

❑Quality crimp due to parallel crimping performance

❑Precise eccentric adjustment

❑Safety ratchet relief

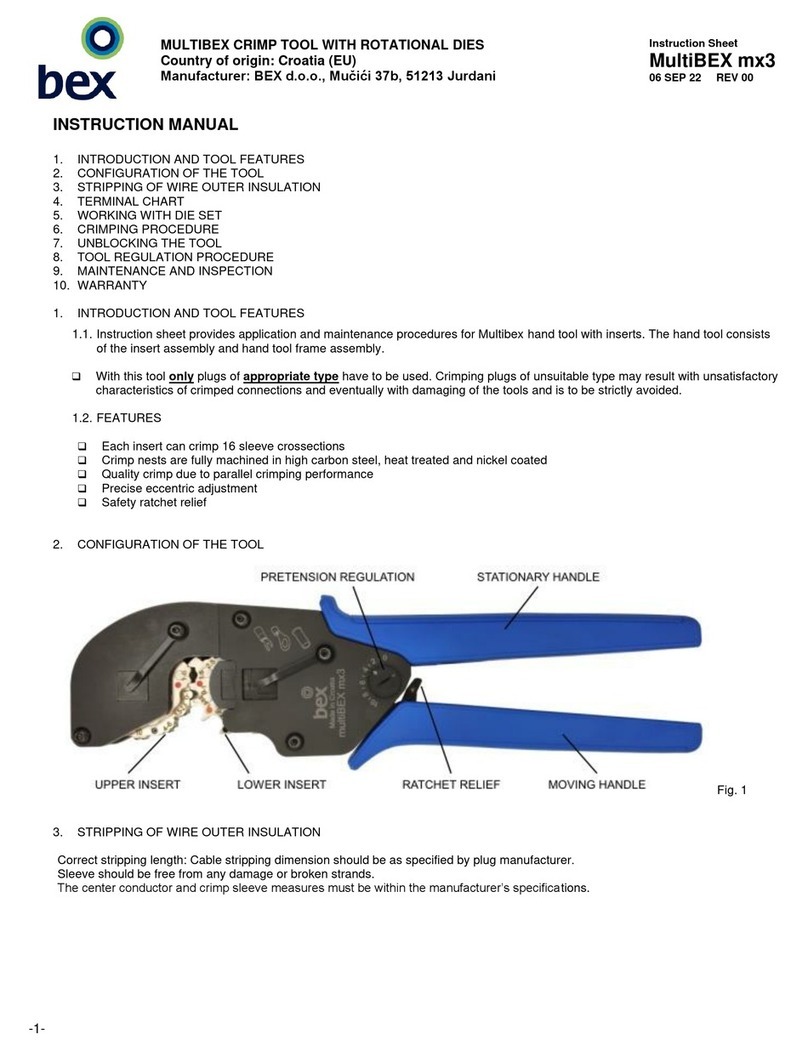

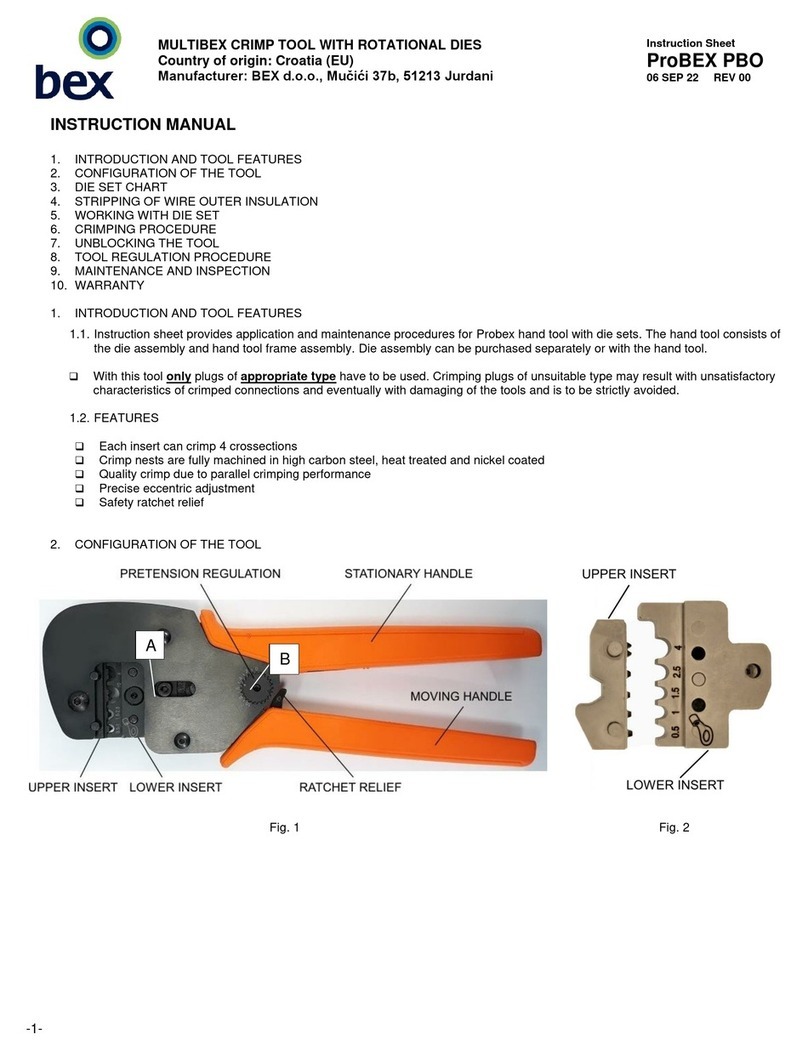

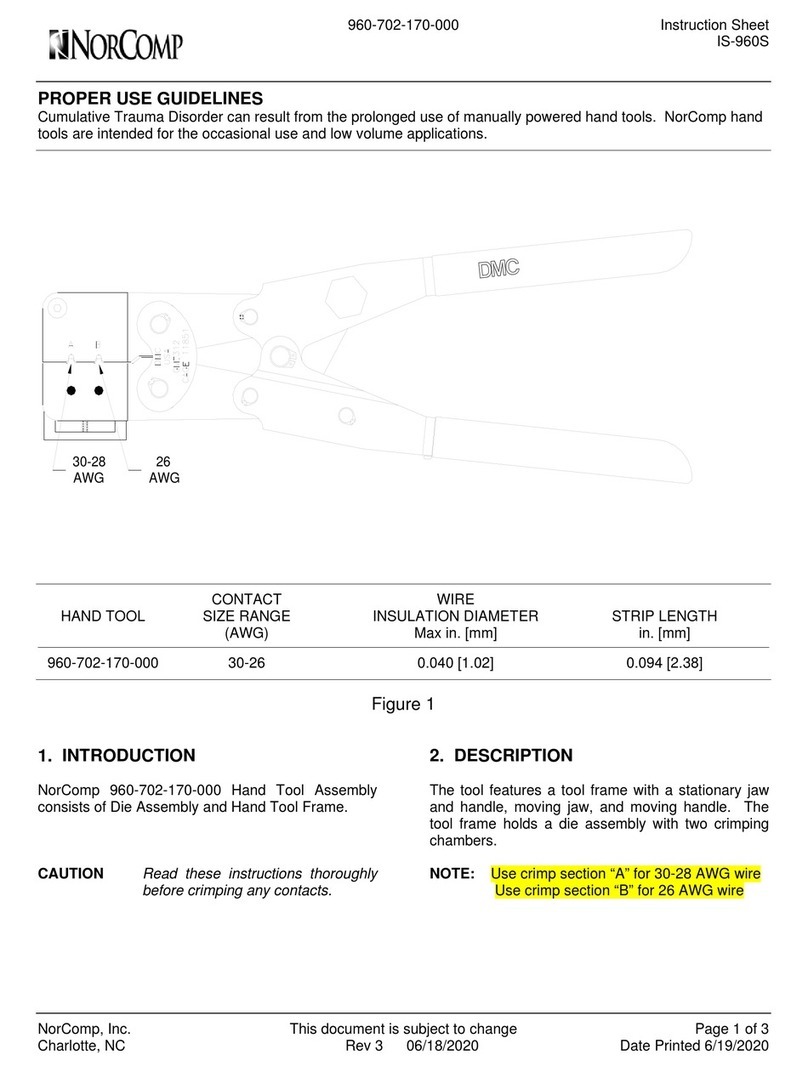

2. CONFIGURATION OF THE TOOL

Fig. 1

3. STRIPPING OF WIRE OUTER INSULATION

Correct stripping length: Cable stripping dimension should be as specified by plug manufacturer.

Sleeve should be free from any damage or broken strands.

The center conductor and crimp sleeve measures must be within the manufacturer’s specifications.

MULTIBEX CRIMP TOOL WITH ROTATIONAL DIES

Country of origin: Croatia (EU)

Manufacturer: BEX d.o.o., Mučići 37b, 51213 Jurdani

Instruction Sheet

MultiBEX mx4

06 SEP 22 REV 00

-2-

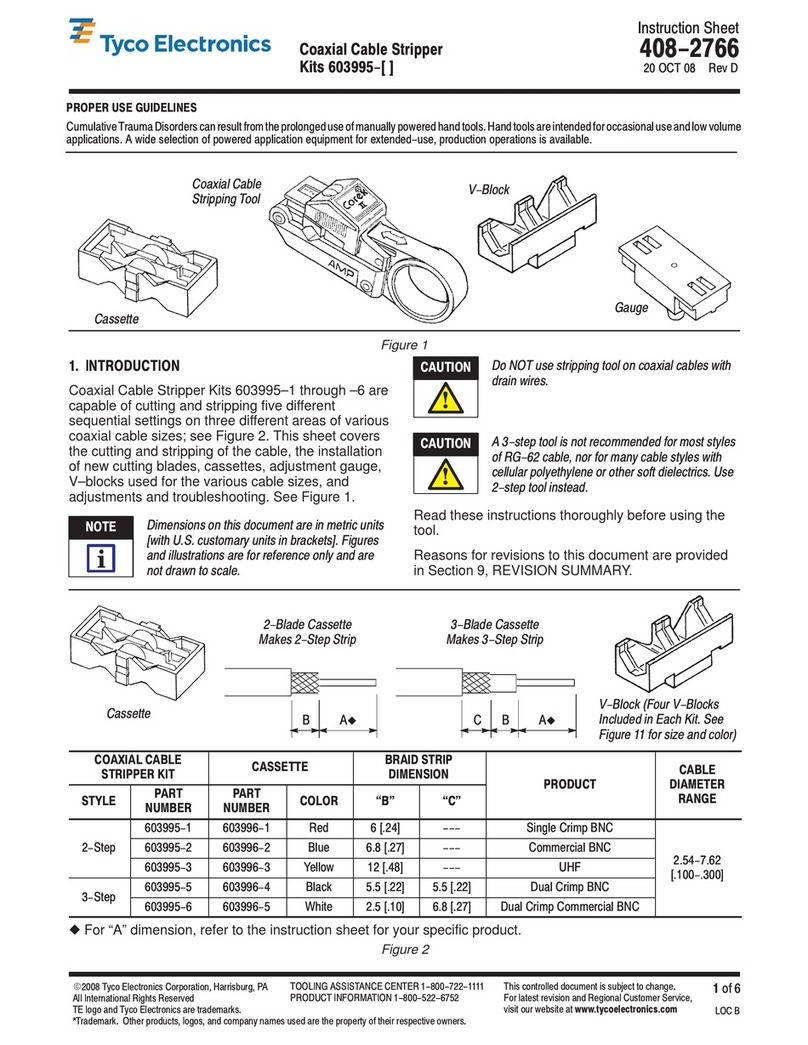

4. TERMINAL CHART

UPPER INSERT

Fig. 2

LOWER INSERT

5. WORKING WITH DIE SET

MultiBEX mx4 crimp tool consist of two rotational inserts. Inserts should be adjusted by pressing the release pin as shown in Fig. 3 and

rotating until reaching the right value. Rotation is possible in both ways. Handle should be open before die set rotating. Upper and lower

part of die set should be set to the same value to achieve the proper crimping. If upper and lower part of the die are not set to the same

value, the tool will block and crimping will be dimmed. Openings are marked with text and color code.

Fig.3 Fig.4 Fig.5

TOOL

TERMINAL TYPE

SIZE

MARKING DOT COLOR

mx4

COAXIAL

0,70

BLACK

COAXIAL

1,04

COAXIAL

1,07

COAXIAL

1,69

COAXIAL

1,73

COAXIAL

2,54

YELLOW

COAXIAL

3,25

PURPLE

COAXIAL

4,52

RED

COAXIAL

5,41

GREEN

COAXIAL

6,48

COAXIAL

6,65

RED

COAXIAL

7,06

PURPLE

COAXIAL

8,23

YELLOW

COAXIAL

9,14

BROWN

COAXIAL

9,70

WHITE

COAXIAL

10,9

BLUE

1. PRESS AND HOLD THE PIN

2. ROTATE INSERTS TO

DESIRED POSITION

3. MATCH TEXT MARKING

AND COLOR DOTS

MULTIBEX CRIMP TOOL WITH ROTATIONAL DIES

Country of origin: Croatia (EU)

Manufacturer: BEX d.o.o., Mučići 37b, 51213 Jurdani

Instruction Sheet

MultiBEX mx4

06 SEP 22 REV 00

-3-

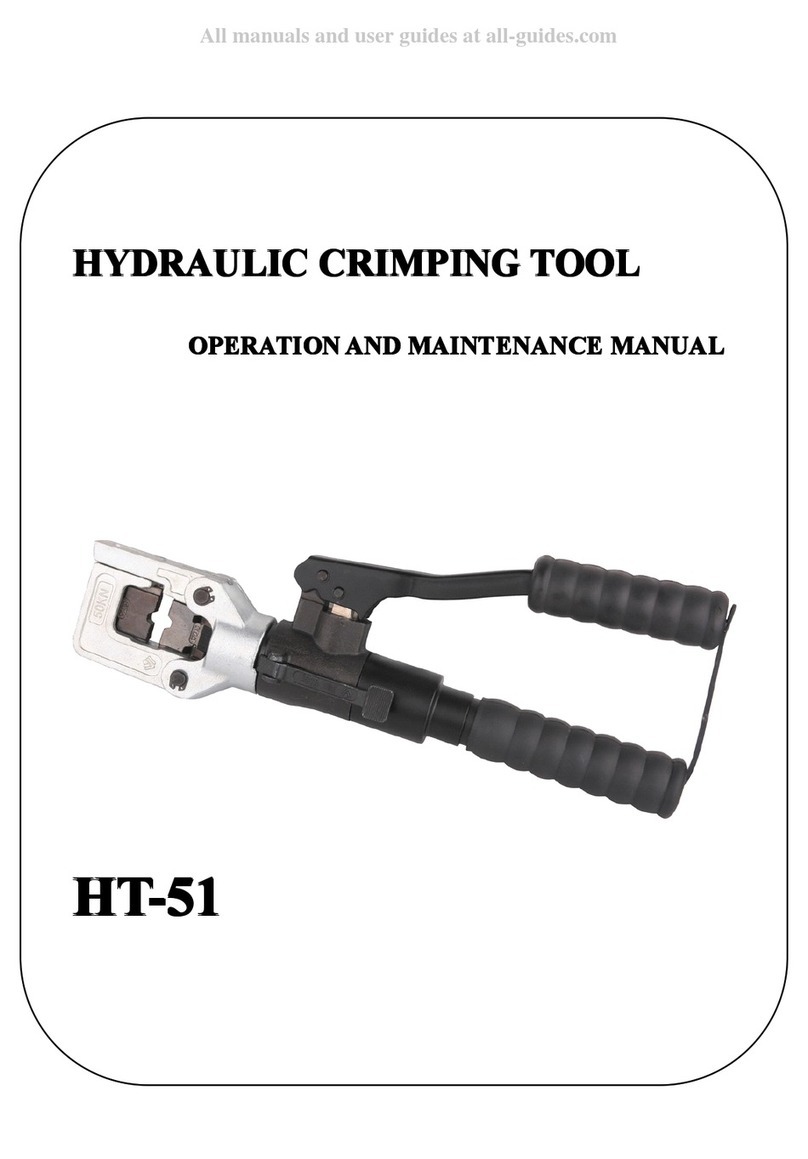

6. CRIMPING PROCEDURE

Prepare plug and cable according to the instructions packaged with the plug.

Ensure that appropriate contact is inserted into right crimping section. Follow instructions shown in Fig. 6 –Fig. 8

In case the tool becomes block for any reason, please follow unblocking procedure described in section 7.

After the full crimping cycle is done, let the tool open fully by itself in order to remove crimped plug.

Pull out the plug assembly. The tool is ready for next crimping cycle.

Fig.6 Fig.7 Fig.8

7. UNBLOCKING THE TOOL

❑IMPORTANT: Apply working force on the tool handles while unblocking. It will prevent hurting yourself and possible

damages on the tool.

❑In case of improper crimp, push the ratchet relief (Fig.9) in direction shown to unblock the tool and remove obstruction before

continuing with the work.

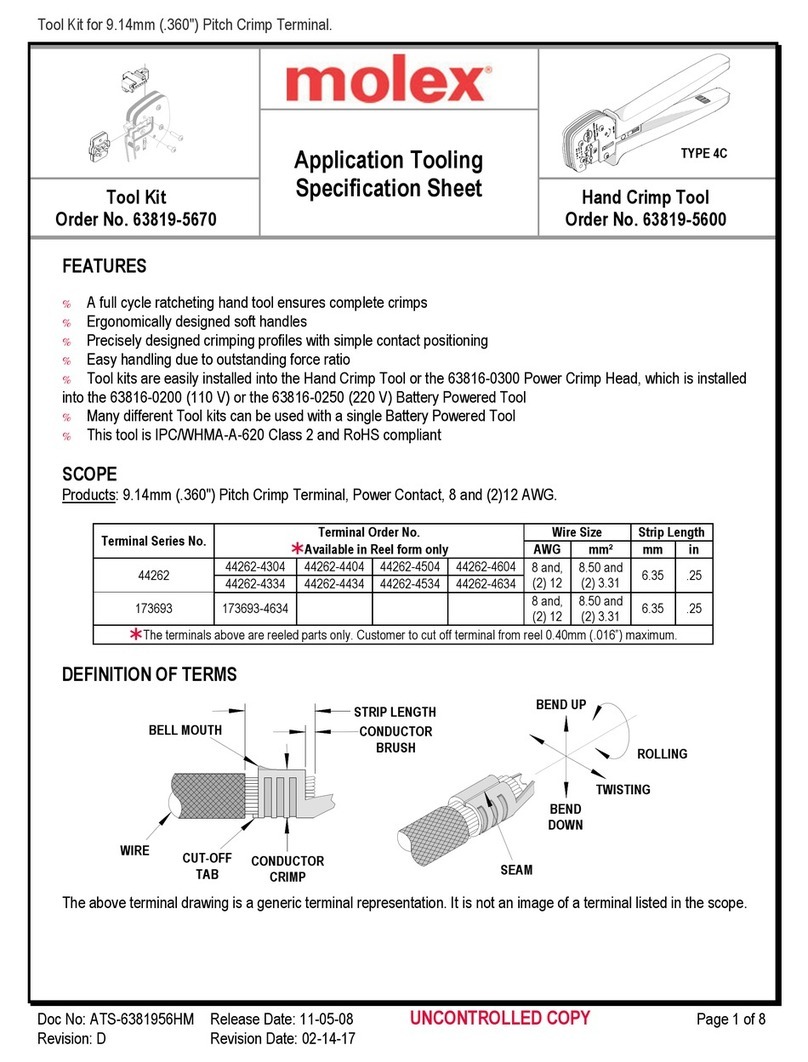

8. TOOL REGULATION PROCEDURE

❑After prolonged work period, tool crimping performance can change slightly due to final self-adjustment of the tools’ components.

This handtool is equipped with eccentric axle which allows periodical adjustment of crimping force and tool recalibration to

maintain correct crimp performance.

1. Loosen knurled nut (C) by turning it counter clockwise (Fig.10)

2. Press the nut until toothed adjustment wheel (B) is lifted so it can be rotated freely (Fig.9)

3. Insert screwdriver into adjustment wheel groove and rotate it to achieve desired pretension.

4. Marking dot at “0“ sets lowest pretension, while dot at “10“ sets highest pretension

5. Once pretension is set push adjustment wheel back into its position and tighten knurled nut

1. PRESS THE HANDLE UNTIL

TERMINAL IS HELD BY INSERTS

2. INSERT CABLE

3. PRESS THE HANDLE

UNTILL THE END OF STROKE

MULTIBEX CRIMP TOOL WITH ROTATIONAL DIES

Country of origin: Croatia (EU)

Manufacturer: BEX d.o.o., Mučići 37b, 51213 Jurdani

Instruction Sheet

MultiBEX mx4

06 SEP 22 REV 00

-4-

Fig.9 Fig.10

9. MAINTENANCE AND INSPECTION

❑Crimping handtool MultiBEX mx4 is intended to be used for crimping coaxial plugs. Using this handtool for any other purpose, or for

crimping of any other objects, can result in damaging the tool and the objects being crimped and prevention of its normal further

functioning, for what manufacturer cannot be held responsible.

❑Handtool is equipped with full cycle ratchet mechanism which with optimized leverage system within the tools makes working with these

tools easy and simple. In case of improper crimp, ratchet release mechanism allows you to easily open the handtool and remove

obstruction before work is continued. Check unblocking procedure (section 9.).

❑Tool itself also incorporates possibility of periodical adjustment of the crimping force and tool recalibration via eccentric axle to maintain

correct crimp performance. Check regulation procedure (section 10.)

❑For removal of dust, moisture and other contaminants usage of clean brush or soft, lint-free cloth is recommended. Do not use

agressive agents (thinner, alcohol,...) or hard objects that could damage the tool.

❑Make sure that during the work bearing surfaces, shafts and pivot points are protected with thin coat of quality machine or motor oil. Do

not oil excessively.

❑When the tool is not in use, store it in a closed position –with handles closed. That will keep other objects from becoming stuck

between crimping dies and damaging them. Keep the tool in a dry and clean area.

❑Use only original spare parts.

10. WARRANTY

This tool is made of the best quality materials. All vital components are long life tested. All tools are warranted to be free of manufacturing

defects for a period of 30 days. Should such a defect occur, we would exchange the tool free of charge. This will not be applicable to

altered, misused, or damaged tools. This tool is designed for hand use only. Any clamping, fixturing, or use of handle extensions voids this

warranty.

A

B

C

Table of contents

Other BEX Crimping Tools manuals

Popular Crimping Tools manuals by other brands

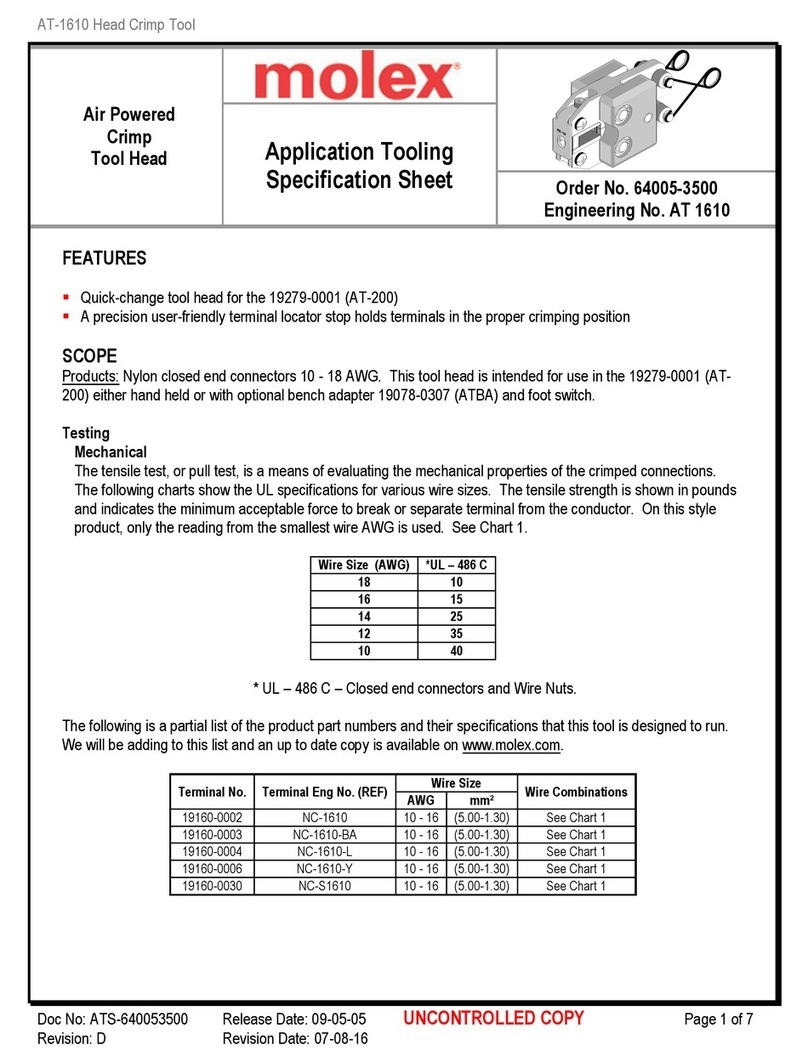

molex

molex AT 1610 Specification sheet

ALLSWAGE

ALLSWAGE AC CRIMP TOOL MAINTENANCE INSTRUCTIONS MANUAL

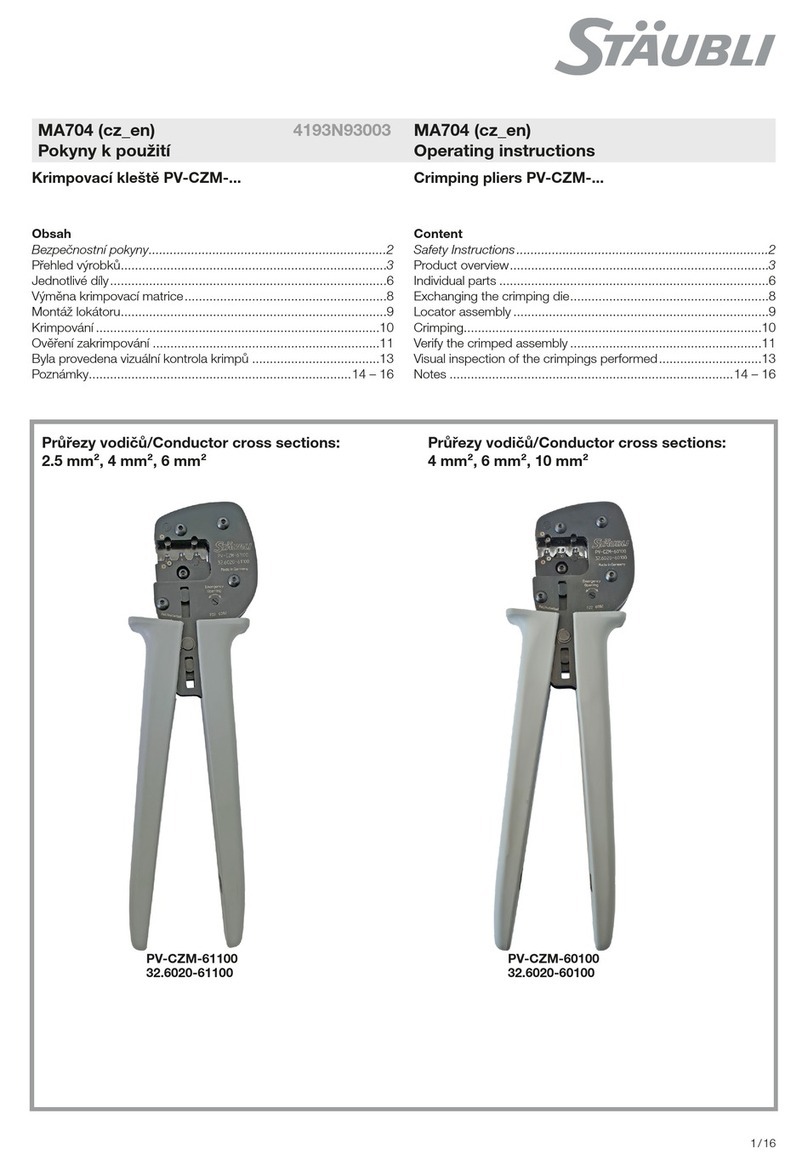

Staubli

Staubli PV-CZM Series operating instructions

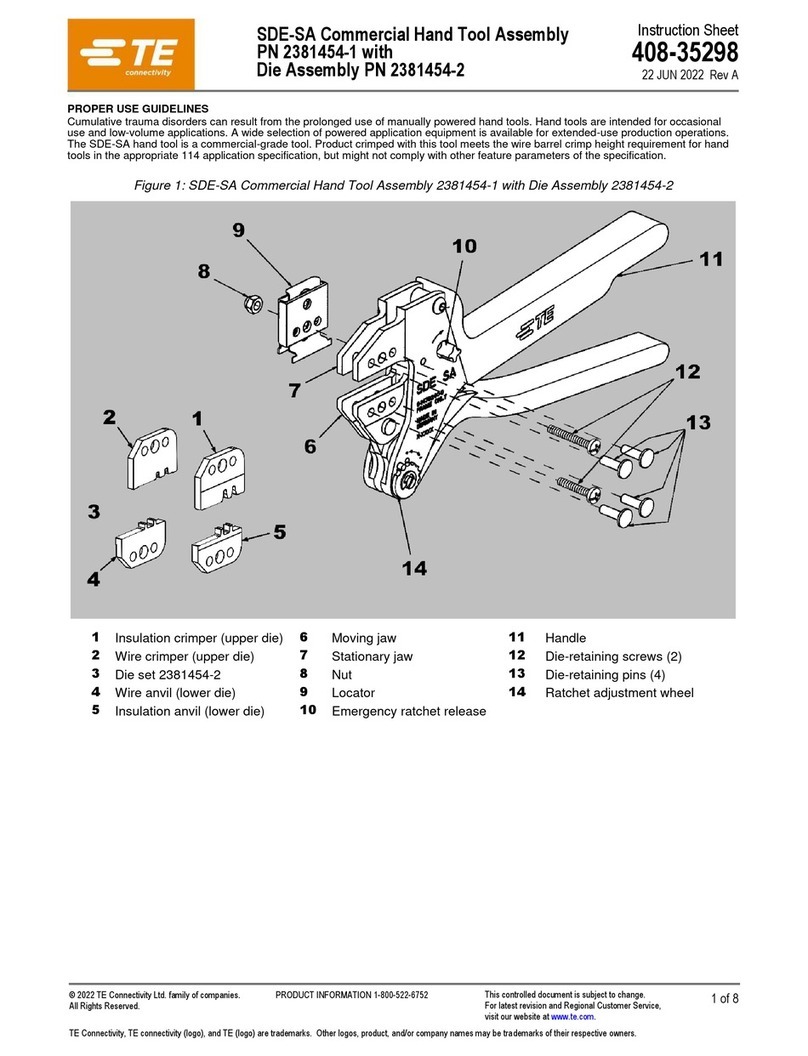

TE Connectivity

TE Connectivity 2381454-1 Guidelines

Milwaukee

Milwaukee M18 FORCE LOGIC 2878-20 Operator's manual

molex

molex 207128 Series Specification sheet

Burndy

Burndy PATRIOT 444S Series SAFETY OPERATING & MAINTENANCE INSTRUCTIONS

Staubli

Staubli CT-CP Assembly instructions

Ilsco

Ilsco TASKMASTER TB-6DF1000-P instruction manual

Tyco Electronics

Tyco Electronics SDE-SA 2063526 Series instruction sheet

Milwaukee

Milwaukee M18 FORCE LOGIC 2678-20 Operator's manual

Burndy

Burndy MRC840 quick start guide