BGB Projects S100 User manual

LPR Meter

Handbook

CONTENTS

Section

Number

Page

Number

One Introduction Page 1

Two Major Components Page 2

Three Operating Instructions Page 3

Four Corrosion Rate Measurement Operation Page 6

Five LPR Standard Page 9

LPR Meter Handbook Page 1

1. Introduction

This handbook provides the Users Guide to the corrosion

rate monitoring handheld meter supplied by BGB Projects

Limited.

The meter has been designed to remove the complex nature

of corrosion rates by carrying out all of the calculations

internally.

The meter is supplied in a IP65 enclosure and is suitable for

external use.

The handheld meter equipment consist of the following

items:

•LPR Meter Part No. LPR174u

•Bigfoot Part No. BF225

•Ag/AgKCl(0.5M) Reference Electrode Part No. S100

All equipment is calibrated annually and calibration

certificates are available upon request.

LPR Meter Handbook Page 2

2. Major Components

Handheld Meter

Bigfoot

Reference Electrode

Reinforcing Bar Connection

The following section outlines the major components of the

system with a detailed explanation to there use.

The handheld meter is the major component within the

system and carries out the Linear Polarisation test after

pressing a series of buttons.

The meter provides the following functions:

•Date & time

•Data logging up to 512 Readings

•PC Download Capability

•PT100 temperature Measurement

•LPR ID Reader (permanent probes only)

To carry out the corrosion rate measurement the big foot is

used to record the Corrosion potential (Ecorr) utilising the

reference electrode and pass a small current through the

integral Auxiliary electrode (AE).

The reference electrode is attached to the Big foot for

recording the corrosion potential from the reinforcing steel.

In carrying out the corrosion rate measurement the

handheld meter must be provided with a connection to the

reinforcing steel. This is carried out by either a single

connection (WE) if less than 10metres from the meter or by

two connections (WE & SENSE) for distances up to 30

metres.

NOTE: No testing should be carried out in excess of 30

metres and additional reinforcing steel connections are to be

made.

When using a single connection to the reinforcing steel the

supplied link must be installed between the WE and SENSE

terminals on the meter.

LPR Meter Handbook Page 3

3. Operating Instructions

Set Up

The following section provides a step by step guide to the

operating instructions for the corrosion rate meter.

The above diagram provides the connections required to

carry out the corrosion rate measurement. Note that either

two connections are provided to the reinforcement or a

single connection is acceptable if less than 10metres. In this

application a link is required to interconnect the WE and SE

terminals on the meter.

Reinforcement

Reference Electrode Auxiliary

Electrode

Big Foot

LPR Meter Handbook Page 4

Connections

PC Communication

How to Use Meter

Charger Lead (5 pin plug):

Red +ve charger

Black -ve charger and RS485 ground

Yellow RS485 A

Blue RS485 B

ID Reader Lead (5 pin plug):

White ID chip

Black ID chip ground

Pt100 Lead (4 pin plug):

Red Pt100 sensor top

Black Pt100 sensor ground

RS485 Comms Protocol :

All comms at 9600, 8N1

When using a personal computer to access the meter please

install the supplied software. The software is supplied with

a separate manual and is not provided as standard please

consult manufacture for data logging software download.

Black is reference electrode (RE)

Blue is sense (short to Green if not used)

Green is test electrode (WE)

Yellow is auxilary electrode (AE)

Connect probe ID lead if used.

Connect Pt100 sensor lead if used.

•Power on.

•Meter displays its number, battery voltage and clock

setting.

•Meter then displays current reading slot number (eg.

01-006 is reading six on meter number one).

•Select GREEN button (LPR)

(RED button selects communications with computer)

•Meter reads Ecorr and probe ID number (if

connected).

•Select GREEN button (->)

(RED button aborts)

LPR Meter Handbook Page 5

•Meter reads corrosion rate for 60 seconds (shown

on display)

(RED button pressed during the measurement skips

any remaining delay)

•Ecorr and corrosion rate are displayed

•Select EITHER button

•Meter confirms that data was stored

•Select GREEN button for next reading and repeat.

•RED button starts cycling through displays of stored

data as :

Date and Time

ID number

Ecorr

Epol

Corrosion rate

Temperature, Flags (Range, Measurement Time,

Errors)

Battery Voltage.

•Select RED button to exit data display.

•Power Off

LPR Meter Handbook Page 6

4. Corrosion Rate

Measurement Operation

Introduction

Overview

Current Measurement

Autoranging

The LPR Handheld meter provides a complete corrosion rate

measurement system on a single Eurocard PCB.

Corrosion rate measurement is carried out potentiostatically,

using the three electrode linear polarisation resistance

measurement method.

The circuit samples the free corrosion potential of the test

electrode, applies a 20mV anodic polarisation and measures

the resulting polarisation current. This is directly

proportional to the corrosion rate of the test electrode.

The current measurement circuitry is fully autoranging and

the board is simply configured to take the measurement on

an instruction from the Main Control Unit.

Two outputs proportional to the polarisation current are

provided. The first is simply the output of the current

measuring amplifier. This varies during the time the

polarisation is applied to the test electrode, usually

approaching a steady state value after some 100 seconds or

more. At times when polarisation is not being applied to the

test electrode this output will be zero. The magnitude of

this output is simply equal to the polarisation current times

the range resistance.

The second output is proportional to the absolute value of

the polarisation current at the end of the polarisation period.

It is generated by a digital to analog converter and retains

its level during the ‘off’ (no polarisation applied) periods.

The value of this output represents the last polarisation

current measurement before the polarisation was removed

from the test electrode. The voltage of this output is equal

to the absolute value of the polarisation current times the

range resistance divided by two.

The polarisation current is measured as the voltage drop

across a resistance in the auxiliary electrode path. Some

+/- 12V are available at the output of the inbuilt potentiostat

for the test electrode polarisation, any voltage drop across

the current sensing resistor will reduce this amount

proportionally, in the extreme leading to a loss of

potentiostatic control of the test cell and erroneous

readings.

The autoranging circuitry is programmed to switch to the

next less sensitive range (lower measuring resistance) as

this voltage drop approaches some 3V and to switch to a

more sensitive range (larger resistance) as it decreases

below some 0.26V. In the autoranging mode the output of

the current measuring amplifier will therefore normally be

somewhere between these two limits. In certain situations

LPR Meter Handbook Page 7

External Control Mode

Conversion of Reading to

Corrosion Rate

this output may move outside these limits to anywhere in

the +/- 15V range. Although the circuit is designed to

normally give a positive output, again, under certain

conditions, (test electrode potential drift etc) it may be

negative.

Since the second output is generated by a digital to analog

converter, it is somewhat more predictable, being always

the 0 to 2.048V range.

The Main Control Unit indicates the measurement by a logic

low input on the GO line. This causes the processor to

initiate the measurement and polarisation sequence.

Polarisation is then applied to the cell as long as the GO line

remains low. The RUN output is set high when the cell is

connected to the circuitry (RUN relay closed). The DONE

output is set high when the current measuring amplifier

output and the range indicator outputs are valid, it returns

low during any autoranging. The output of the current

measuring amplifier always reflects the current going to the

test electrode. The DAC2 output is set when the GO line is

released to high to reflect the cell current at that time.

The Outstation LPR board measures the current required to

polarise the test electrode anodically by 20mV. Conversion

to actual corrosion rate may be carried out as follows:

The voltage at the output of the current measuring amplifier

is the voltage drop across the current measuring resistor.

By Ohm’s law:

reading in mV/range = polarisation current in µA.

This is the applied current lapplied (or more accurately,

Δlapplied).

The linear polarisation resistance measurement technique

(LPR) relies on a measurement of the slope of the current

vs. voltage response of the corroding interface at or near its

natural free corroding potential. It can be shown that this

slope, Δlapplied /ΔE), is related to the corrosion current by the

Stern-Geary equation:

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

+

×

Δ

Δ

=ac

acapplied

corr E

I

I

ββ

ββ

3.21

where βcand βaare the cathodic and anodic Tafel slopes.

For practical purposes the equation can be simplified to:

p

applied

corr R

B

b

E

I

I=×

Δ

Δ

=

LPR Meter Handbook Page 8

where B is an empirically determined constant and Rpis the

‘polarisation resistance’ of the corroding interface.

In order to calculate the actual penetration rate Icorr is

substituted to the Faraday equation, giving:

densityvalencyF weightatomic

time

area

I

npenetratio corr 1

×

×

××=

Thus, for example, to convert to cm/year for iron:

87.71

210645.9 85.55

606024365 4×

××

×××××=

p

R

B

ratenpenetratio

The PICLPR-2 board uses a 20mV anodic polarisation

applied potentiostatically to the test electrode. Hence ΔE is

0.02V, substituting in the above and solving gives:

87.71

210645.9 85.55

606024365

02.0

4×

××

×××××

×

×

Δ

=area

BI

ratenpenetratio applied

yearm

area

I

ratenpenetratio applied /35

μ

×

Δ

≅

(lapplied in µA, area in cm², B=60mV)

Or, using this board:

[]

²][][ ][35

/ cmareasurfacerebarkrange mVoutputamplifiercurrent

yearmratenpenetratio ×Ω

×

=

μ

For example, a voltage of 1.00V at the DAC2 output on the

R1 range and using a 100cm² test electrode area is

equivalent to a penetration rate of:

35 x 1000 x 2 / 10 / 100 = 70µm/year

The nominal maximum measurable rate for this electrode

area, using the DAC2 output would be:

35 x 2047 x 2 / 1 / 100 = 1.4mm/year

and the minimum rate (assuming 20mV at DAC2 output):

35 x 20 x 2 / 100 / 100 = 0.14µm/year

LPR Meter Handbook Page 9

5. LPR Standard

This manual suits for next models

2

Other BGB Projects Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

LogikaControl

LogikaControl HTR Installation and use manual

FNM

FNM alpha SM 230 user manual

GLI International

GLI International P33 Operating instructions manual

ICM Controls

ICM Controls ICM450 Installation, operation & application guide

Hi-Target

Hi-Target ZTS-120 user manual

ISTEC

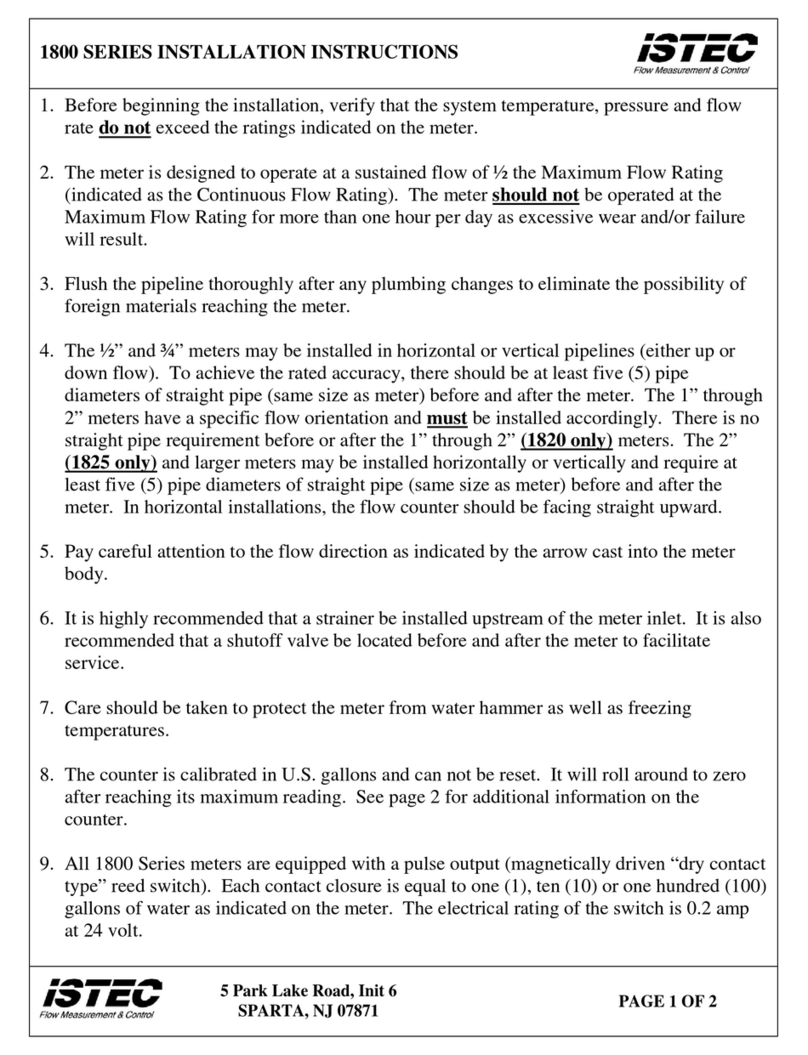

ISTEC 1820 installation instructions