BGB Projects LPR Manual

Registered Office: 18 Craig Avenue, Flixton, Manchester, M41 5PT – Tel: +44 (0) 161 748 3645 – Fax: +44 (0) 161 748 3645

Company Registration No: 333 7082 – VAT No: 693 2194 16

Dr J P Broomfield

Mr K G Davies

57 Brook Rd

Flixton, Manchester

M41 5RY, UK

Tel: +44 (0) 161 748 3645

Fax: + 44 (0) 161 748 3645

Email: corrosioneer@btconnect.com

BGB Projects

LPR Corrosion Rate Meter

Technical Information

INSTRUCTION MANUAL – LPR METER

1. INTRODUCTION

The LPR Corrosion Rate Meter measures rates of corrosion of metals in corrosive

environments. There are many similar devices available, these are usually intended to

be used with corrosion probes of a relatively small surface area. The LPR Corrosion

Rate Meter is specifically designed for measurement of corrosion of steel reinforcement

in concrete where the surface area of the test electrode (rebar) can be large.

The meter uses the linear polarisation resistance (LPR) measurement technique and

controls the test electrode potentiostatically. The meter reads both the corrosion

potential (Ecorr) and the corrosion rate (in µm/year) of the test electrode.

Additionally, the meter can read Dallas Semiconductor DS2401 (or similar) electronic ID

number chips (i-buttons). These may be used to uniquely identify measurement

locations.

The meter stores up to 512 measurement results in non-volatile memory, time and date

stamping each one.

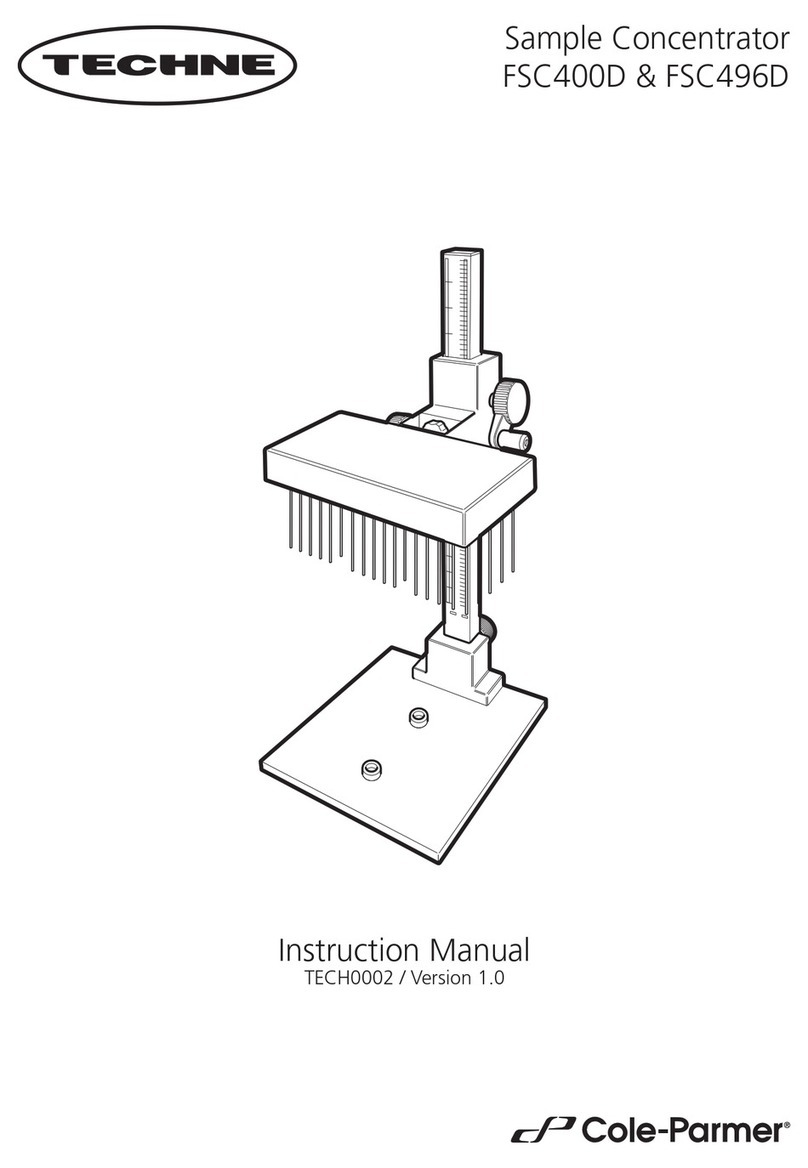

The LPR Corrosion Rate Meter is housed in a rugged polycarbonate enclosure and is

designed for a rough site use.

©2006 KH Design and Development Page 1 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

2. QUICK-START GUIDE

•Connect electrodes to the LPR Meter

oConnect reference electrode (half-cell) to the RE terminal (BLACK)

oConnect test electrode (rebar) to the WE terminal (GREEN)

oConnect auxiliary electrode to the AE terminal (YELLOW)

oEnsure that the SE (BLUE) and WE (GREEN) terminals are

shorted

•Power on the LPR Meter by turning the key switch

oAs the meter powers up check that the battery voltage is at least

10.5V - recharge the meter otherwise.

•Note the reading number, shown as for example 321.

•Press the GREEN button

oCheck that the measured Ecorr is plausible (+100 to -600 mV for

steel in concrete) and steady.

•Press the GREEN Button again

oCheck that a corrosion rate in the expected range is displayed (0.5

to 5 μm/year for sound concrete, 5 to 50 μm/year for mediocre

concrete and over 50 μm/year for actively corroding steel. Zero or

very low corrosion rate usually indicates a problem with the

auxiliary electrode connection.

oWait 60 seconds until the measurement completes

•Press the GREEN button again.

oReview the stored data if required or proceed to the next

measurement

•Press the GREEN button again for next measurement.

oetc.

•Power off the meter and disconnect the leads.

©2006 KH Design and Development Page 2 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

3. CONTROLS AND CONNECTORS

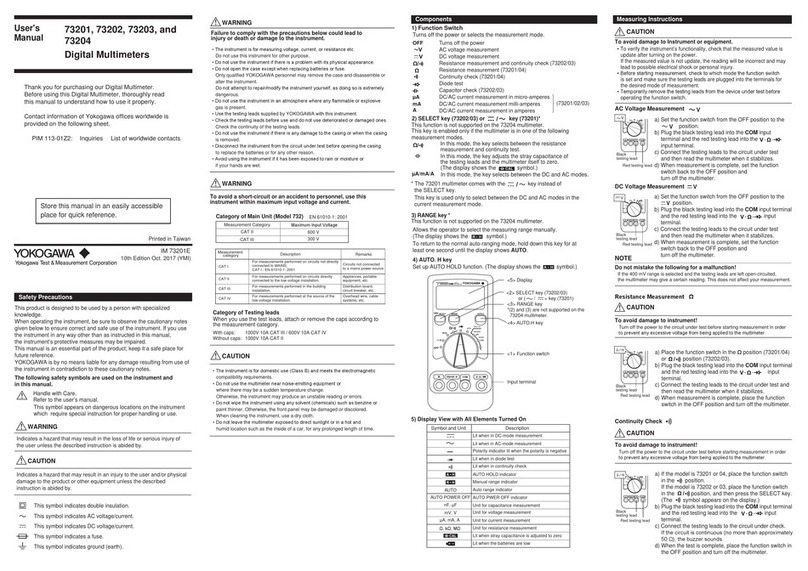

3.1. Controls

The LPR Corrosion Rate Meter is operated by two push buttons, green and red. A menu

system is used - the user selects an appropriate action by pressing one of the push

buttons. For most simple measurements only several presses of the green button are

required.

The meter is switched on and off using the key switch. The key may be removed only in

the ‘off’ position.

3.2. Connectors and leads

There are four 4mm screw terminals for connections to the test cell and a single round

connector for battery charger, communications and probe ID reading.

The test cell connectors are as follows :

RE – Black Connection to reference electrode.

SE – Blue Voltage sensing connection to test electrode.

WE – Green Current carrying connection to test electrode.

AE – Yellow Connection to auxiliary electrode.

In normal use the SE (Blue) and WE (Green) terminals should be shorted using the

link provided.

If long (more than ~ 5 meters) connections to the test electrode are necessary it is

recommended that the voltage sensing connection to the test electrode is used. This

compensates for any ohmic drop in the test electrode connection and improves

measurement accuracy in this situation. Simply connect a fourth wire in parallel with the

WE (GREEN) connection to the SE (BLUE) terminal. In all other cases short the SE

terminal to the WE terminal at the LPR Meter.

The five pin circular connector connects to the battery charger, probe ID chip or to a RS-

232 serial link.

©2006 KH Design and Development Page 3 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

4. MENU SYSTEM AND OPERATION

On power up the meter runs internal diagnostics and

displays the CCSL logo.

Corrosion

Control Services

The meter then displays its identification number and

displays the main battery voltage.

Meter # 101

Battery: 12.5V

Next, the meter shows its current clock settings

(day/month/year hour:minute). Meter # 101

15/10/2004 23:59

Finally, the present reading number is shown. The

reading number auto-increments whenever a set of

results had been stored. The meter can store up to 512

sets of results.

At this point the user can choose either to read the

measurement point ID or LPR measurement. Pressing

the left (RED) button selects ID read, pressing the right

(GREEN) button selects LPR measurement.

Reading # 001

<ID LPR>

Pressing the left (RED) button reads the measurement

point electronic identification. Use the supplied test lead

(5 pin to two 4mm plugs) to connect the meter to the

measurement point identifier connector.

The read ID is stored with the measurement results. If

no valid ID chip is found to be connected the meter

displays and stores 0000-0000 as the identifier.

ID: 53FE-1234

LPR>

Pressing the left (RED) button at this point returns the

meter to the previous display and the ID read may be

repeated if necessary.

Reading # 001

<ID LPR>

Selecting LPR by pressing the right (GREEN) button

initialises a measurement of the corrosion potential.

The measured value of the potential between the test

electrode and the reference electrode is displayed.

The flashing right pointing arrow prompts the user to

start the actual corrosion rate measurement by pressing

the GREEN button. This stage may be aborted by

pressing the RED button.

Ecorr: -234.5 mV

Go >>

Pressing the GREEN button starts the corrosion rate

measurement. The meter first initialises the

measurement and autoranges. A *WAIT* prompt is

shown for a few seconds during this time.

Ecorr: -234.5 mV

Rate: *WAIT* 03

©2006 KH Design and Development Page 4 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

The meter then shows the measured corrosion rate in

μm/year and a count timer showing the number of

seconds into the measurement. The corrosion rate

reading is updated approximately once per second.

Ecorr: -234.5 mV

Rate: 70.1 19

The corrosion rate measurement may be terminated by

pressing the RED button at any time during the

measurement process. Otherwise the corrosion rate

measurement proceeds for 60 seconds. On completion

the meter displays the measured corrosion potential

and the corrosion rate.

Pressing either button exits this display and leads to the

next menu.

Ecorr: -234.5 mV

Rate: 70.1 um/y

This display confirms that the measurement results had

been stored and shows the stored location number.

At this point the user can either review the results of the

last measurement (RED button) or proceed to a next

measurement (GREEN button).

Stored 101-001

<Review Next>

The review display simply cycles through all the

recorded parameters. Date and time are shown first.

Stored 101-001

15/10/2004 23:59

The measurement location ID number is shown next (if

absent the display shows 0000-0000-0000).

Stored 101-001

0123-4567-89AB

This is followed by a display of the recorded corrosion

potential (Ecorr).

Stored 101-001

Ecorr: -123.5 mV

Next, the polarised potential is shown. Normally this will

be about 20mV more positive than Ecorr.

Stored 101-001

Epol: -103.4 mV

The recorded corrosion rate is shown next.

Stored 101-001

Rate: 70.1 um/y

The measurement range, measurement time and error

flags are displayed next.

Stored 101-001

R:3 t:60 e:00

The meter battery voltage at the end of the

measurement is shown last. The display then cycles

back to the date/time screen.

Stored 101-001

Battery: 12.0 V

Pressing the RED button exits the preview and returns

to the previous screen.

Stored 101-001

<Review Next>

The meter may be safely turned off whenever this last screen is shown – the

measurement results are stored in the non-volatile memory just prior to the display of

this screen at the completion of the measurement.

©2006 KH Design and Development Page 5 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

5. OPERATING PRINCIPLE

5.1. Summary

The LPR Corrosion Rate Meter uses the LPR measurement method to determine the

corrosion rate of the connected test electrode.

The measurement is carried out potentiostatically, using 3 electrodes and a 20 mV

anodic polarisation.

5.2. Measurement Sequence

When the user selects a measurement start the internal analog to digital converter

measures the potential between the reference electrode (RE) and the test, or ‘working’,

electrode (WE). This is shown to the user as the corrosion potential, Ecorr.

When satisfied that a valid Ecorr is being measured, the user starts the polarisation

sequence. The meter connects the auxiliary electrode (AE) to the potentiostat circuitry

and polarises the test electrode to the measured Ecorr voltage. This is done by setting a

voltage equal to Ecorr on an internal digital to analog converter.

Next, the meter applies a 20mV anodic overpotential and measures the resulting

polarisation current. The polarised potential of the test electrode is also measured (Epol).

The ‘sense’ terminal is used to carry out this measurement, as to avoid any ohmic drops

in the test electrode lead. During the 60 seconds of measurement the meter monitors

the polarisation current and autoranges the current sensing circuitry as required.

The corrosion rate is computed from the value of the polarisation current (ΔIapplied) and

from the polarisation overpotential (ΔE = Ecorr – Epol)

The linear polarisation resistance measurement technique (LPR) relies on a

measurement of the slope of the current vs. voltage response of the corroding interface

at or near its natural free corroding potential. It can be shown that this slope,

(ΔIapplied/ΔE), is related to the corrosion current by the Stern-Geary equation:

II

E

corr applied ca

ca

=×

+

⎛

⎝

⎜⎞

⎠

⎟

Δ

Δ

1

23.

ββ

ββ

where βcand βaare the cathodic and anodic Tafel slopes. For practical purposes the

equation can be simplified to:

II

EBB

R

corr applied

p

=×=

Δ

Δ

where B is an empirically determined constant and Rpis the ‘polarisation resistance’ of

the corroding interface.

In order to calculate the actual penetration rate Icorr is substituted to the Faraday

equation, giving:

©2006 KH Design and Development Page 6 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

penetration I

area time atomic weight

F valency density

corr

=××

××1

Thus, for example, to convert to cm/year for iron:

penetration rate B

Rp

=× ×××× ××

×365 24 60 60 5585

9 645 10 2 1

787

4

.

..

The LPR Meter calculation assumes a Stern-Geary constant B of 60 mV, a test

electrode surface area of 100 cm2and shows the corrosion rate in μm/year. To convert

to other values it will be necessary to adjust the corrosion rate measurement result

accordingly.

On completion of the measurement the circuitry de-polarises the test electrode back to

Ecorr and disconnects the auxiliary electrode from the potentiostat.

5.3. Limitations

There are two major uncertainties in the measurement of corrosion rate of steel

reinforcement in concrete.

The first is that of the precision of the Stern-Geary parameter which depends on the

exact electrochemical conditions at the corroding interface. The value of 60 mV is a

reasonable compromise for passive steel embedded in concrete.

A second uncertainty is that of the test electrode area being polarised. The 100 cm2test

electrode surface area used in the calculation is only a nominal value, in practice the

measurement results should be adjusted for the actual test electrode area present.

Further errors can be caused by the resistivity of the concrete surrounding the test

electrode (rebar) and by the placement of the reference electrode relative to the auxiliary

electrode and to the rebar.

In practice, however, the reinforcement surface should be passive and ‘corroding’ at a

very low rate of 1μm/year or less. To put the sensitivity of the measurement into

perspective, consider that the wavelength of visible red light is about 0.68 μm. Active

corrosion processes on the rebar surface will result in an increase of the corrosion rate

by several orders of magnitude to 50-100 μm/year, which is easily detectable and

measurable.

©2006 KH Design and Development Page 7 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

6. RS-232 COMMUNICATIONS

6.1. Summary

The meter communicates via a RS-232 interface. An adaptor for connection of the LPR

Meter to a standard 9 pin RS-232 serial lead (male to female) is supplied.

All communications are at 9600 baud 8N1.

Communications may be carried out using a terminal emulator program (e.g. Windows

HyperTerminal), other suitable software or the supplied application (LPR232.EXE)

6.2. Protocol

All serial communications are at 9600 baud 8N1 (eight bits, no parity, one stop bit). No

handshaking is used as normally the host machine will be fast enough to handle the

relatively slow data throughput.

Three commands are available :

*D Dump stored data

*C Clear memory

*T Set LPR Meter clock

Note that <CR> or <LF> input terminator characters are not required.

When powered up, the LPR Meter automatically checks

whether an electrical connection to a RS-232 device is

present. If a RS-232 connection is found, the meter

display will confirm this and the meter will wait for

incoming RS-232 characters. Power off the meter and

disconnect the RS-232 lead to terminate the

communications and to return to normal operation.

RS-232 Ready

The hex value of any received character is displayed to

assist in serial link troubleshooting.

RS-232 Ready

0F

6.3. *C – Clear Memory

Send *C to clear all stored data. The stored data will be irreversibly erased.

All stored data is deleted and the next available data

slot pointer is set to 1

Clearing...

©2006 KH Design and Development Page 8 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

6.4. *T – Set Time and Date

Send *TYYMMDDHHMM.

For example, to set the date and time to 23:59 on 15th October 2004, send

*T0410152359.

Note that no checks are carried out for plausibility of the time and date value. Please

check that the value displayed immediately after this operation is correct. The ‘seconds’

value is set to zero on receipt of the final *T command character.

The meter will set its internal real time clock to the

required time, read back the clock time and show it on

the display.

Time set to :

15/10/2004 23:59

6.5. *D – Dump

Send *D to retrieve all stored data.

The output may be captured into a text file and further analysed in a spreadsheet or

similar.

After a 10 second delay the meter sends back all stored

data as 512 comma delimited lines. The reading

number currently being sent is shown on the display.

Sending...

123

The data output format is :

01, Meter number as set by switches on the LPR circuit board

123, Reading number from 1 to 512

DD/MM/YYYY, Reading date DD-day, MM-month, YYYY-year,

(e.g. 15/10/2004 for 15th October 2004)

HH:MM:SS, Reading time HH – hour, MM – minute SS – second

(e.g. 23:59:06)

XXXX-XXXX-XXXX, ID number (0000-0000-0000 if there was none connected)

+DDD.D, Ecorr in mV

(Corrosion potential of the test electrode prior to polarisation)

+DDD.D, Epol in mV

(Potential to which the test electrode was polarised – normally

+20 ±2 mV more positive than Ecorr)

DD.DDD, Measured corrosion rate in um/year

DD.D, Battery voltage in volt, recorded at the end of the measurement

DD, Polarisation time in seconds

D, Polarisation current measurement range

(5=1MΩ, 4=100kΩ, 3=10kΩ, 2=1kΩ, 1=100Ω)

D, DAC error (if Ecorr over +/-1024 mV)

D Rate error (corrosion rate negative etc.)

<CR><LF> Carriage return and line feed characters

©2006 KH Design and Development Page 9 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

7. CARE AND MAINTENANCE

7.1. Battery Charging

The LPR Meter is powered by a sealed lead acid gel 12V battery.

The battery must be charged only using the supplied charger. The use of any

other charger or power supply may result in a permanent damage to the

instrument or in its destruction.

Lead acid batteries are very reliable provided simple charging procedures are observed.

•Always fully charge the meter after use

•Store the meter fully charged

•Never ‘deep discharge’ the battery

To charge the LPR Meter connect the supplied charger lead to the five pin circular

connector. Ensure that the LPR Meter is turned off. Power up the charger. The charge

LED indicators will light as follows :

Red + Green Charger powered up but disconnected from the battery

Red Battery charging

Green Battery fully charged

Flashing Red or Green Fault condition – check connections

Charging from a discharged state (battery voltage of 9V) to a fully charged state (battery

voltage >12V) will take approximately three hours. The meter may be safely left on

charge after this period as the charger will automatically switch to a trickle charge mode.

The LPR Meter battery voltage is displayed after power-up of the meter. On a fully

charged battery the LPR Meter will take in excess of 250 readings before it needs to be

recharged.

The LPR Meter will continue to operate down to a battery voltage of approximately 7V,

however it is recommended that the battery is recharged when the battery voltage drops

to 9 to 10 V.

Recharge the LPR Meter battery after use and prior to long term storage.

7.2. Battery Replacement

The sealed lead acid battery may be replaced as follows :

1. Obtain a replacement battery (Yuasa NP0.8-12).

2. Open the LPR Meter case by unscrewing the four retaining screws located in the

case lid corners.

3. Release the battery retaining strap and loosen the two pillars securing the

battery bracket.

4. Remove the old battery from the case.

5. Carefully disconnect the battery lead from the terminal block.

6. DO NOT SHORT THE BATTERY LEADS.

©2006 KH Design and Development Page 10 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

7. Reconnect the new battery leads to the terminal block.

8. Replace the new battery in the LPR Meter case. Do not overtighten the battery

bracket pillars.

9. Re-assemble the case lid, ensuring that no wires are trapped between the lid

and the case body.

7.3. Real Time Clock Battery Replacement

The real time clock battery may need replacing after three or more years.

To replace the real time clock lithium coin cell proceed as follows :

1. Obtain a replacement battery (CR1220 3V LiMnO2coin cell).

2. Open the LPR Meter case by unscrewing the four retaining screws located in

the case lid corners.

3. The real time clock battery is located near the bottom edge of the display

circuit board. It may be necessary to remove the two circuit boards from the

case lid by undoing the four retaining screws from the top of the case lid.

Ensure that all the screws and washers are replaced correctly when re-

assembling.

4. Remove the old coin cell from the battery holder and replace.

5. Re-assemble the case lid, ensuring that no wires are trapped between the lid

and the case body.

6. Reset the real clock time using the RS-232 interface as described above.

7.4. Calibration Check

To check the LPR Meter calibration proceed as follows :

1. Ensure that the WE and SE terminals are shorted.

2. Short the AE and RE terminals.

3. Power up the meter and proceed through the menu system as far as the Ecorr

measurement.

4. Apply a known voltage of approximately -500.0 mV between the WE and RE

terminals.

5. Check that the measured Ecorr value is equal to this applied voltage ±2 mV

6. Disconnect the applied voltage.

7. Connect a 100Ωresistor between the RE and WE terminals, retaining the above

shorting links (100Ωfrom WE to RE, short from RE to AE, short from WE to SE).

8. Check that the measured Ecorr is 0.0 ±2 mV.

9. Proceed to the corrosion rate measurement.

10. Check that the measured corrosion rate is 70.0 ±3.5 μm/year

11. Proceed to the measurement review screen.

12. Check that the measured Epol was 20.0 ±2 mV.

Other calibration voltages and dummy cell resistances may also be checked, for

example a resistance of 1kΩshould give a corrosion rate reading of 7.00 ±0.35 μm/year

etc.

©2006 KH Design and Development Page 11 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

8. TROUBLESHOOTING AND FAQ

8.1. LPR Meter does not power up

Check that the main battery is charged. Recharge if required. The main battery is only

charged when the LPR Meter is turned off with the key switch.

If the main battery does not hold charge satisfactorily, replace it.

8.2. LPR Meter powers up but appears to lock up during the power up sequence

Replace the real time clock battery.

8.3. LPR Meter does not show the correct time

Reset the real time clock to the correct local time. If the real time clock unacceptably

loses or gains time replace the clock battery.

8.4. LPR Meter display backlight turns off

The display backlight is turned off automatically after a few minutes of inactivity to

conserve battery power. Pressing either of the push buttons will turn it back on.

8.5. The push buttons do not work

Press the buttons firmly. The meter actually waits for a button release before carrying

out the required operation.

8.6. Measured corrosion potential drifts

Check connections to the test and reference electrodes. Check the reference electrode

potential with a separate voltmeter. Interference from mains cables running close to the

measurement connections may also cause unsteady corrosion potential readings. A

changing corrosion potential will result in an inaccurate corrosion rate measurement.

8.7. Measured corrosion rate is negative

Check connections to the electrodes. This is usually the result of a changing corrosion

potential during the measurement.

8.8. Measured corrosion rate is very low or zero

Check connections to the electrodes. This is usually the result of a broken auxiliary (AE)

electrode lead.

8.9. Measured corrosion rate changes during the measurement

This is a normal response of the electrochemical processes at the test electrode surface

to the applied polarisation. The displayed corrosion rate value should start high and

decrease over the measurement period before levelling off to a final value. The

measurement may me terminated manually if a steady value is being measured before

the preset 60 second measured time.

©2006 KH Design and Development Page 12 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

8.10. What happens after taking 512 readings ?

The oldest data is overwritten.

8.11. How do I read the stored data ?

Connect the LPR Meter to a PC using the supplied adaptor. Run the supplied

application (LPR232.EXE). Select the appropriate serial port (COM1 to COM4). Power

up the LPR Meter. The circuitry will automatically detect that a PC is connected and will

display ‘RS-232 Ready’ message. Check operation by clicking the ‘Test’ button. The

LPR display will show ‘20’ indicating that the serial connection is operational. Click either

of the three function buttons (Get Data, Clear Data, Set Time) as required. Power off the

LPR Meter when done and disconnect from the PC.

8.12. What is the format of the retrieved data file ?

It is a comma delimited file which can be directly opened with spreadsheets such as

Microsoft Excel. The file format is as shown below.

The columns are as described above in the RS-232 section of this document.

Meter Number

Reading Number

Date

(DD/MM/YYYY)

Time (HH:MM:SS)

ID Number

Ecorr (mV)

Epol (mV)

Rate (um/y)

Battery (V)

Measurement

length

Range

DAC Error

Rate Error

111 1 19/04/2006 12:49:00 0000-0000-0000 -0.5 19.5 69.4 12.1 60 3 0 0

111 2 19/04/2006 12:50:23 0000-0000-0000 -0.4 19.7 69.4 12.1 60 3 0 0

111 3 19/04/2006 12:55:50 0000-0000-0000 -0.6 19.4 0.7 12.1 60 5 0 0

111 4 19/04/2006 12:57:35 0000-0000-0000 -0.5 19.5 7 12.1 60 4 0 0

111 5 19/04/2006 12:59:12 0000-0000-0000 -0.5 19.5 0.07 12.1 60 5 0 0

111 6 19/04/2006 13:00:39 0000-0000-0000 -0.4 19.6 69.8 12.1 60 3 0 0

111 7 19/04/2006 13:02:09 0000-0000-0000 -0.4 19.6 141 12.2 60 2 0 0

8.13. My PC does not have a serial RS-232 port

Inexpensive USB to RS-232 adaptors are widely available. Beware that some

motherboards will assign the USB/serial port thus created as COM9 or higher. Consult

manufacturer’s data to rectify this or contact us for a modified version of LPR232.EXE.

©2006 KH Design and Development Page 13 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

LPR Meter Specification :

Measurement Technique: Three electrode potentiostatic linear polarisation resistance

measurement using anodic polarisation of 20 mV applied for 60

seconds.

Corrosion Potential Measurement Range: +/-1024 mV w.r.t. Reference Electrode

Corrosion Potential Measurement Resolution: 0.1 mV

Corrosion Potential Measurement Accuracy : 0.1% FSD (1mV over full range)

Reference Electrode Input Impedance: 100MΩ

Corrosion Rate Measurement Range: Better than 0.1 to 100 µm/year relative to a mild steel electrode of

100 cm² surface area. Fully autoranging.

Corrosion Rate Measurement Resolution: 0.1%

Corrosion Rate Measurement Accuracy: Better than 5% (1% typical)

Auxiliary Electrode Potentiostat Output Capability: +/-100mA at +/-12V

Probe Identification: Dallas Semiconductor two wire ‘I-Button’ ID readout

Battery: Internal Sealed Lead Acid 12V (standard battery gives in excess of

8 hours continuous operation before recharge)

Connectors: 4x 4mm terminals - WE (test electrode), AE (auxiliary electrode),

SE (sense for test electrode), RE (reference electrode)

5 way connector for battery charger, communications and ID

readout

Display: 16 x 2 character backlight LCD

Operator Controls 2x push buttons – initiate measurement and access all functions

using a simple menu system

Power key switch

Data Storage: 512 measurement results stored in non-volatile EEPROM

Stored data for each measurement: Meter number

Reading number

Reading date

Reading time

Probe ID Number

Corrosion Potential

Achieved Polarisation Potential

Corrosion Rate

Battery

Polarisation time

Measurement range

Error flags

Communications: RS-232

Real Time Clock: Li cell powered (CR1220 3V LiMnO2 coin cell), user settable real time

clock

Supplied Accessories: Carry case

Battery Charger with lead

Measurement leads (4 off)

ID read lead

RS-232 lead adaptor

Operating Manual

Physical Size: 200mm x 120mm x 75mm

Weight: 1.25 kg approx

Enclosure : IP65 rated heavy duty polycarbonate

©2006 KH Design and Development Page 14 of 15 April 2006

INSTRUCTION MANUAL – LPR METER

LPR Meter Menu Flow Diagram.

Ecorr: -234.5 mV

Rate: *WAIT* 03

Stored 101-001

<Review Next>

Ecorr: -234.5 mV

Rate: 70.1 19

Ecorr: -234.5 mV

Rate: 70.1 um/y

Stored 101-001

2003/12/31 23:59

Stored 101-001

0123-4567-89AB

Stored 101-001

Ecorr: -123.5 mV

Stored 101-001

Epol: -103.4 mV

Stored 101-001

Rate: 70.1 um/y

Stored 101-001

R:3 t:60 e:00

Stored 101-001

Battery: 12.5 V

ID: 53FE-1234

LPR>

Ecorr: -234.5 mV

Go >>

Reading # 001

<ID LPR>

Corrosion

Meter # 101

15/10/2004 23:59

Control Services

Meter # 101

Battery: 12.5V

©2006 KH Design and Development Page 15 of 15 April 2006

These are the headers (not shown on downloads)………………

Meter Record Date Time Chip ID No Ecorr Epol Corrosion Rate Battery Timer Multiplier DAC RATE

No No (µm/yr/100cm²) Voltage (V) error error

These are the type of records downloaded. Note all 512 records are downloaded each time

201 1 07/08/2008 11:43:50 0000-0000-0000 -417.8 -398.0 13.4 12.1 60 1 0 1

201 2 07/08/2008 12:36:37 0000-0000-0000 -375.9 -356.7 5.2 12.1 60 1 0 1

201 3 07/08/2008 12:37:34 0000-0000-0000 -375.9 -356.8 5.6 12.1 60 3 0 0

201 4 07/08/2008 12:38:06 0000-0000-0000 -376.4 -357.0 11.6 12.1 60 1 0 1

Description of columns…………….

This column displays the Corrosion Rate

in terms of µm/yr/100cm² loss of steel

This column displays the Battery Voltage

This column displays the Test Time

which cannot be changed by the operator

This column displays the Multiplier

which cannot be changed by the operator

This column displays the DAC Error

(if Ecorr is over +/- 1024 mV)

This column displays the Rate Error

(corrosion rate negative etc)

(mV wrt Ag/AgCl/KCl)

This column displays the METER ID No

which cannot be changed by the operator

This column displays the RECORD No

which cannot be changed by the operator

This column displays the DATE

which cannot be changed by the operator

This column displays the TIME

which cannot be changed by the operator

This column displays the CHIP ID No

if connected during testing

This column displays the Steel Potential

which is - ECorr

This column displays the Polarised Steel

potential - Epol

Table of contents

Other BGB Projects Measuring Instrument manuals