A: 9300 S.W. Gemini Drive Beaverton, OR 97008 USA W: biamp.com

PRODUCT DESCRIPTION

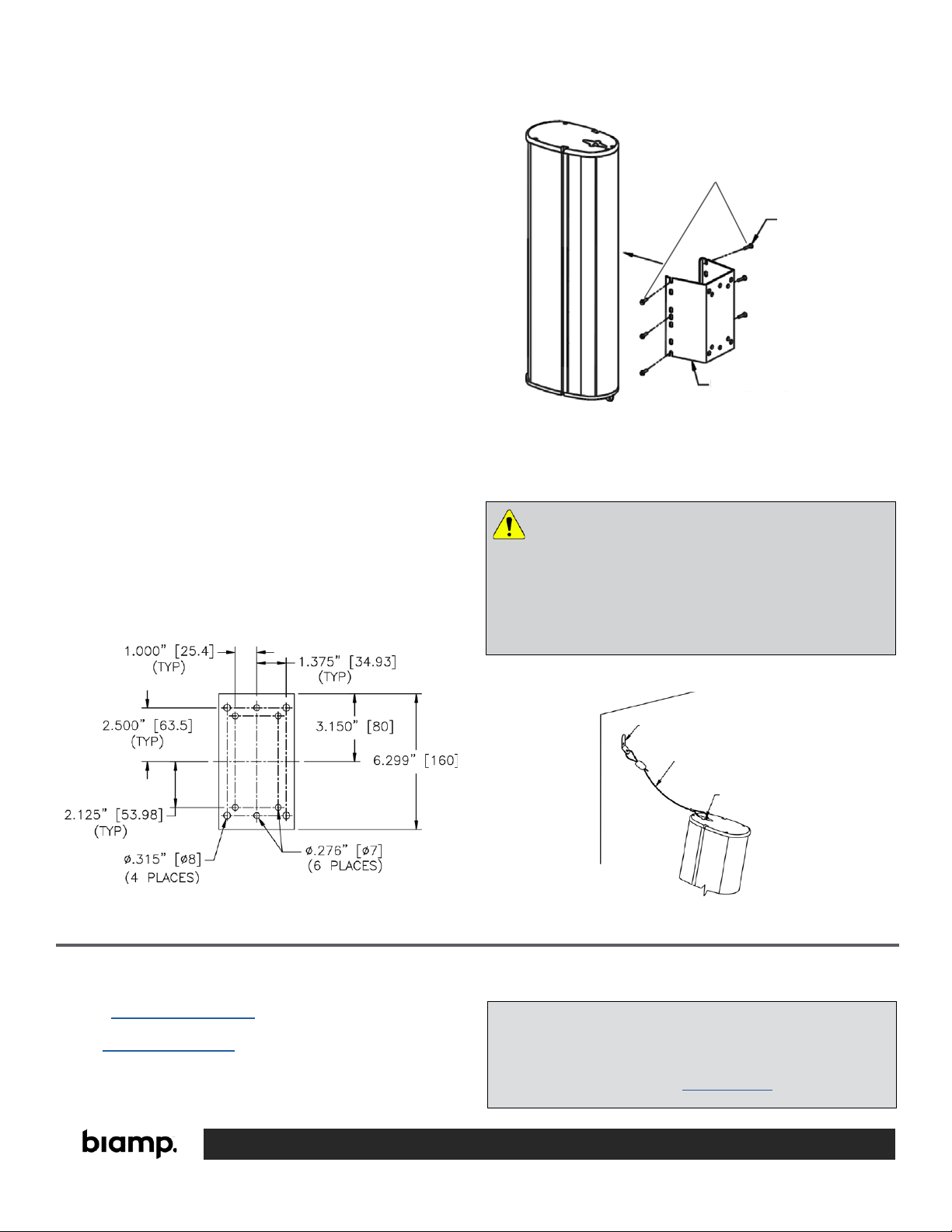

The E200-UMK is a rugged bracket designed to flush mount a single Desono™

ENT200 column loudspeaker enclosure tightly against a wall or ceiling, or to

accommodate third-party mounting brackets. Use with models ENT203, ENT206,

ENT212 and ENT220. Typically, one E200-UMK bracket is used per loudspeaker.

Kit includes:

• One (1) Universal Mount Bracket

• Six (6) M3.5x16 Philips truss-head sheet metal screws

FEATURES

• Mounting hole pattern has standard spacings to accommodate third-party 30

lb or 60 lb working load mounting brackets

• All parts are engineered to provide a high margin of safety for mounting and

suspending Desono ENT200 loudspeakers

• Steel construction finished with a durable dual-layer powder-coat finish

• Available in black (E200-UMKB) or white (E200-UMKW) to match the color

of the loudspeaker enclosure

CAUTION: It is strongly recommended that a licensed and

certied professional structural engineer approve the

mounting. Severe injury and/or loss of life may occur if this

product is improperly installed.

IMPORTANT: Installation of loudspeakers should only be

performed by trained and qualied personnel. All electrical

connections must conform to applicable city, county, state,

and national (NEC) electrical codes.

. DANGER: It is possible to experience severe electrical

shock from a power amplier. Always make sure that all

power ampliers are in the "OFF" position and unplugged

from an AC Mains supply before performing electrical work.

DANGER: It is essential that the secondary cable be

secured to a suitable load-bearing point separate from the

primary loudspeaker mounting point, with as little slack as

possible so as not to develop undue kinetic force if the

primary mount were to fail.

Desono™

E Series ENT200 Universal Mounting Kit (E200-UMK)

Installation & Operation Guide

RIGGING AND ELECTRICAL SAFETY

IMPORTANT: When attaching the E200-UMK to the

loudspeaker, tighten all fasteners rmly, but do not

over-tighten to avoid stripping the threads. Always use the

safety attachment point at the top of the loudspeaker

enclosure for a safety cable (not intended as a primary

suspension point). The E200-UMK is pre-drilled with

standard spacings to accommodate third-party 30 lb or 60

lb working load mounting brackets.

IMPORTANT: The E200-UMK is provided with the

hardware required to attach it to the loudspeaker

enclosure. No additional hardware is provided to attach

the bracket to the mounting surface, or to attach

suspension cables to the bracket. Such hardware must be

supplied by the installer and should be sized and rated for

the weight load of the loudspeaker. The installer is solely

responsible for determining if the mounting surface is

capable of safely supporting the weight load of the

loudspeaker, for selecting appropriate hardware to install

it, and for determining if all rigging components that are

used to suspend the enclosures are adequately sized and

rated and whether the structure they are suspended from

is capable of safely supporting the aggregate weight load.