BIFFI WGR Series Parts list manual

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 1

MAN 684

WGR - Worm Gear Reducer

Instruction and Operating Manual

5

19/01/2017

Added sight glass with optional

relief version

Toscani

Orefici

Vigliano

4

18/04/2016

Updated applicable regulation

(chapter 1.7)

Ermanni

Orefici

Vigliano

3

11/06/2012

Revised chapter 11 (parts list)

Ermanni

Ghiadoni

Vigliano

2

08/03/2012

Revised Pictures

Guarnieri

Ghiadoni

Vigliano

1

23/05/2010

Revised Chapter 7

Schiavi

Ghiadoni

Vigliano

0

04/12/2007

Issue

Orefici

Alfieri

Alfieri

Rev.

Date

Description

Prepared

Verified

Approved

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 2

BIFFI ITALIA has taken every care in collecting and verifying the documentation contained in this Instruction and

Operating Manual. The information herein contained are reserved property of BIFFI ITALIA.

Contents may change without notice.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 3

INDEX

1GENERAL SAFETY INSTRUCTIONS.................................................................................5

1.1 Manufacturer 5

1.2 Machine Intended Use 5

1.3 Terms and conditions 6

1.4 Manufacturer’s Liability 6

1.5 Applicable Standards and Regulations 6

1.6 Installation in hazardous area 6

1.7 Marking for application in hazardous area 7

1.7.1 Label for ICON2000/ICON2000EC ............................................................................................................................. 7

1.7.2 Extract from the Standard........................................................................................................................................... 7

2MACHINE DESCRIPTION .................................................................................................7

2.1 General 7

2.2 Main Parts Description 8

3TECHNICAL DATA..............................................................................................................9

3.1 Application range 9

4TRANSPORT AND STORAGE ..........................................................................................10

4.1 Transport 10

4.2 Checks to be carried out on receipt of the WGR reducer 11

4.3 Storage Procedure 11

5INSTALLATION ................................................................................................................12

5.1 Working condition 12

5.2 Safety Instructions for installation in Hazardous Area 12

5.2.1 Instructions for the explosion-proof enclosures ................................................................................................ 12

5.2.2 Installation in ambient with explosive dusts ...................................................................................................... 12

6ASSEMBLING THE WORM GEARBOX ONTO THE VALVE ...........................................13

7ADJUSTING THE MECHANICAL STOPPERS.................................................................15

7.1 Grease-lubrication-type gearbox (WGR standard type) 15

7.2 Oil-lubrication-type gearbox (WGR-DW series models) 15

8MAINTENANCE ................................................................................................................17

8.1 Standard Maintenance 17

8.2 Special Maintenance 17

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 4

9DISASSEMBLY INSTRUCTIONS ....................................................................................18

9.1 Access to the main reduction and to the epicyclical reduction 18

9.2 Epicyclical reduction removal 20

9.3 Main reduction removal 21

9.4 Greasing the main reduction and the epicyclical reduction 22

10 LUBRICATION ..............................................................................................................25

10.1 Grease lubrication type gearbox (WGR standard type) 25

10.2 Oil lubrication type gearbox (WGR-DW series models) 25

10.3 Refilling procedure (only for WGR-DW series models) 26

11 PARTS LIST...................................................................................................................27

11.1 How to Order Parts List 27

11.2 WGR100 Parts List 28

11.3 WGR200 Parts List 30

11.4 WGR400 Parts List 32

11.5 WGR800 Parts List 34

11.6 WGR1600 Parts List 36

11.7 WGR3200 Parts List 38

11.8 WGR6300 Parts List 40

11.9 Optional Relief on sight glass Parts List ( applicable to all WGR Models) 42

12 DISASSEMBLING AND DEMOLITION .......................................................................44

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 5

1GENERAL SAFETY INSTRUCTIONS

1.1 Manufacturer

Manufacturer with respect to the Machinery Directive 2006/42/EC is BIFFI ITALIA, as specified on the machinery

label.

1.2 Machine Intended Use

The machines to whose this Instruction and Operating Manual applies are the WGR series (on-off type, up to

60 starts/hour) and WGR-DW series (intermittent type up to 1200 starts/hour), designed to operate

any kind of quarter-turn industrial valve for applications in heavy industrial, chemical, petrochemical, food, water

and power generating plants. They are designed for motor operation in conjunction with electric actuators.

BIFFI ITALIA will not be liable for any possible damage or physical injury resulting from use in other than the

designated application or by lack of care during installation, operation, adjustment and maintenance of the

machinery. Such risks lie entirely with the User.

Depending on the specific working conditions, additional precautions may be required.

WGR reducers are produced by BIFFI ITALIA and identified on the proper label by product designation WGR-

XXXX.

Important

This Manual provides basic information for the setting of WGR series reducers;

more detailed information on the setting and control of Electric Actuators

ICON2000 can be found in MAN 618, which forms part of the mandatory

instructions documentation.

Warning

It is assumed that the installation, setting, commissioning and maintenance and

repair works are carried out by qualified personnel and checked by responsible

Specialists.

Warning

Read this installation and maintenance manual carefully and completely before

storage or installation of the device. If an electric actuator is attached to the WGR

reducer, please be aware of the electrical hazards and consult the relevant

electric actuator installation and maintenance manual for guidance.

The WGR series is designed in accordance with the applicable International Rules and Specifications, but in all

cases the following Regulation must be observed:

the general installation and safety regulations

the plant specific regulations and requirements

the proper use of personal protective equipment (goggles, clothing, gloves)

the proper use of tools, lifting and transport equipment.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 6

1.3 Terms and conditions

BIFFI ITALIA guarantees each single product to be free from defects and in accordance to current goods

specifications and applicable regulations. The warranty period is 12 months from the date of installation by the first

User or 18 months from the date of shipment to the first User, whichever occurs first. No warranty is given for

products which have been subject to damage or corrosion due to improper storage, improper installation, misuse,

or which have been modified or repaired by unauthorised personnel.

Repair work due to improper use will be charged at standard rates.

1.4 Manufacturer’s Liability

Biffi Italia declines all liability in the event of:

use of the machinery in contravention of local Safety-at-work legislation.

incorrect installation, disregard or incorrect application of the instructions provided on the product nameplate

and in this Instruction and Operating Manual.

modification of the product without Biffi’s authorisation.

work done on the product by unqualified or unsuitable personnel.

1.5 Applicable Standards and Regulations

EN ISO 12100-1 Safety of machinery - Basic concepts, general principles for design.

Part 1-Basic terminology, methodology.

EN ISO 12100-2 Safety of machinery - Basic concepts, general principles for design.

Part 2-Technical principles and specification.

2006/42/EC Machinery Directive.

2014/34/EU ATEX Directive.

1.6 Installation in hazardous area

Warning

In case the WGRs are to be installed in a HAZARDOUS AREA, as defined by

the applicable Rules, it is mandatory to check whether the nameplates of the

associated ICON2000/ICON2000EC specify that the assembly is suitable to

be installed in HAZARDOUS AREA with the indication of appropriate degree

of protection.

Maintenance and repair works must be carried out by qualified personnel and

checked by responsible Specialists.

Standard WGRs have IP66/67/68 degree of protection according to EN 60529.

IP 68 achieved with a submersion under 15 meter for 100 hours.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 7

1.7 Marking for application in hazardous area

1.7.1 Label for ICON2000/ICON2000EC

The ICON 2000/ICON 2000 EC associated to the WGR, for the application in hazardous areas, must bear a label

with the following marking description:

0080 = Notified Body for ATEX

II = Group II (Surface)

2 = Category 2 apparatus

G = explosive atmosphere by gas

D = explosive atmosphere by dust

IP 66/68= degree of protection

1.7.2 Extract from the Standard

Type of Hazard

Classification of Zones

Categories acc. to 2014/34/EU Directive

Gas, mists or vapours

Zone 0

1G

Gas, mists or vapours

Zone 1

2G

Gas, mists or vapours

Zone 2

3G

Dust

Zone 20

1D

Dust

Zone 21

2D

Dust

Zone 22

3D

2MACHINE DESCRIPTION

2.1 General

The WGR is a worm gear reducer designed to operate, in conjunction with ICON2000 electric actuator, any kind of

quarter-turn industrial valve.

The gear box is suitable to guarantee the output bush rotation of 90° with the possibility to obtain an extra stroke

of 5° for each direction of rotation. The rotation bush is stopped, in both the rotation direction, against mechanical

stoppers integrated in the gear box frame with the possibility to regulate the travel of 5° for each rotation

direction. The housing is provided with an optional vent valve in order to avoid any eventual overpressure.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 8

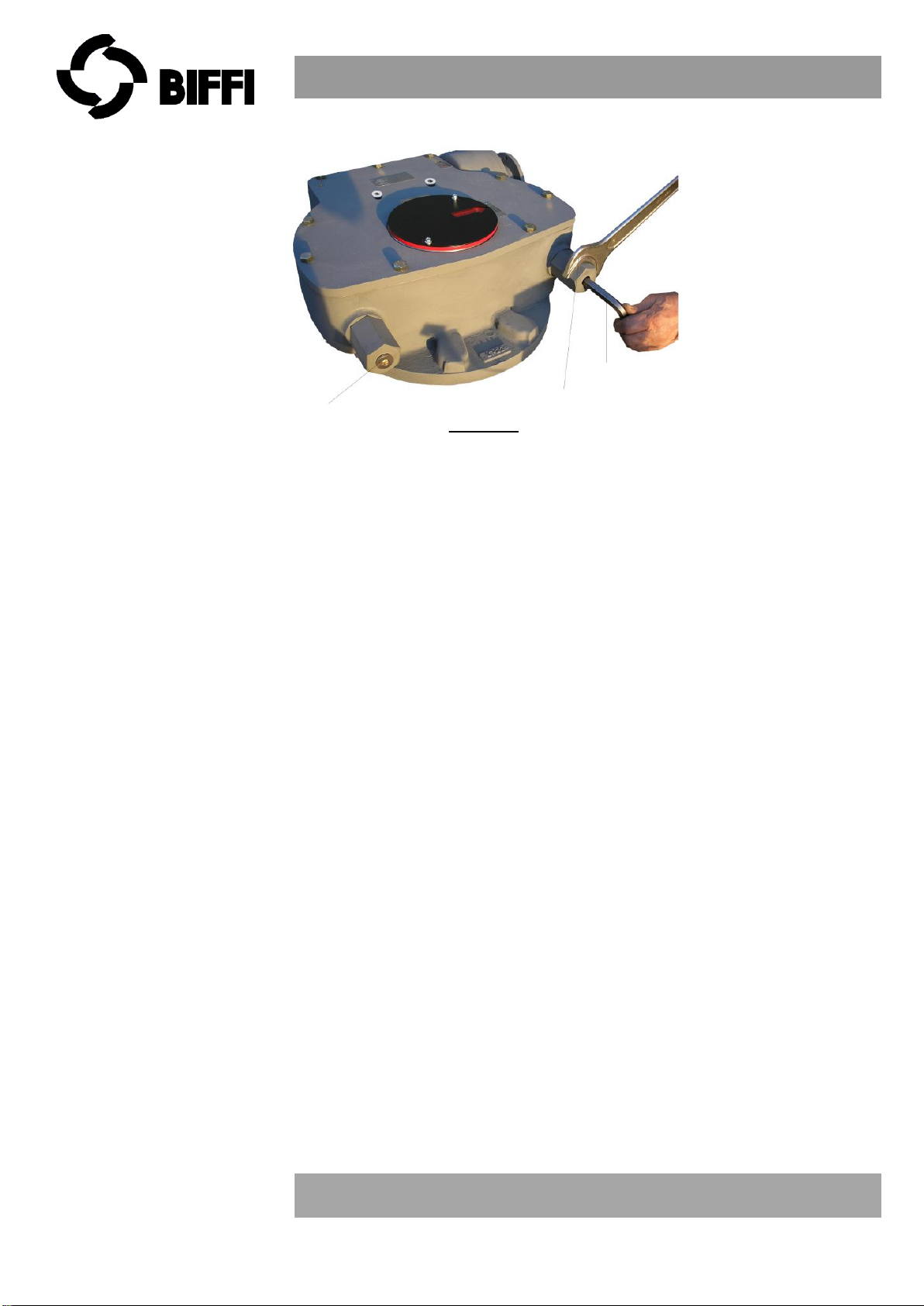

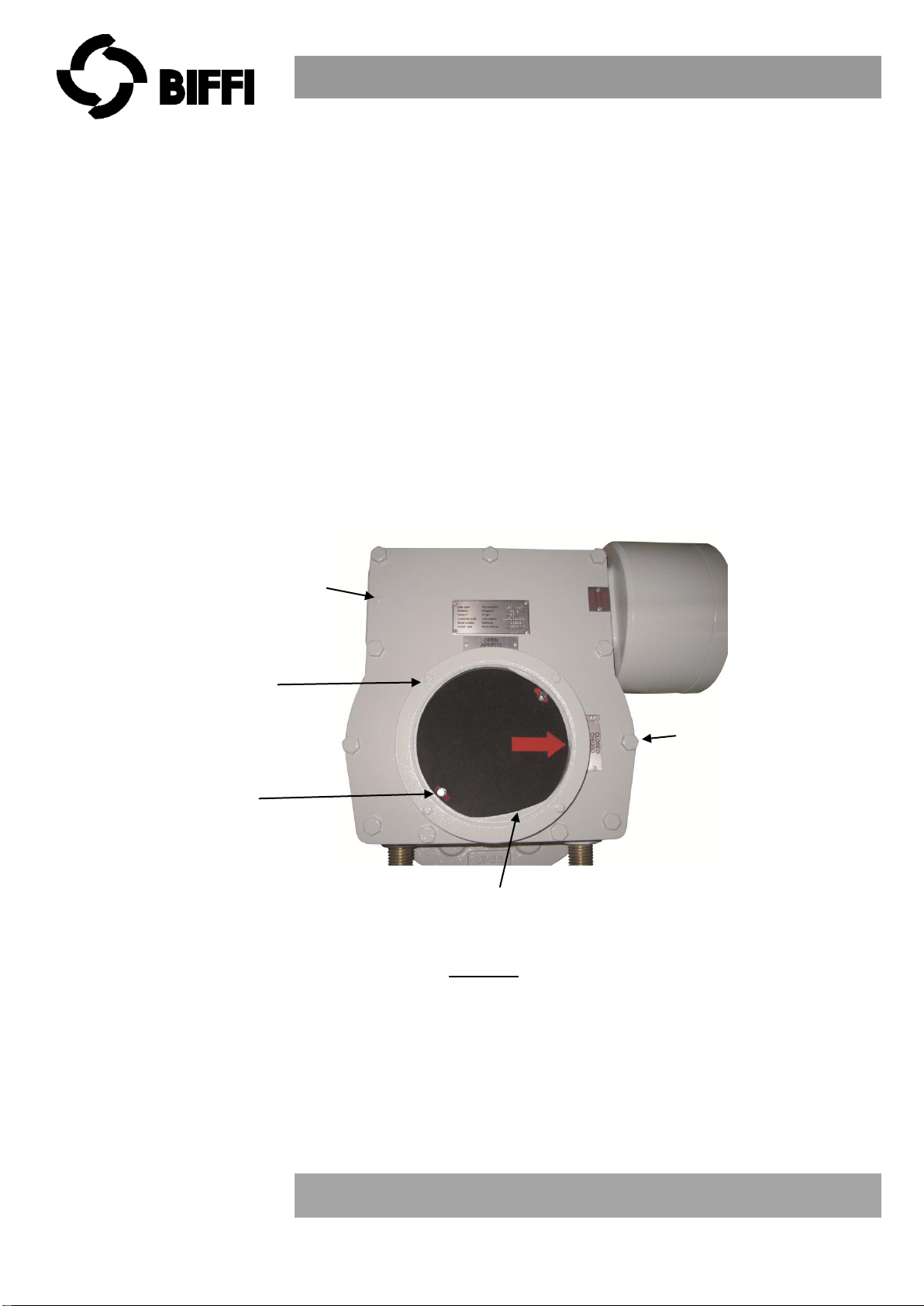

2.2 Main Parts Description

Picture 1

Picture 2

Main Reduction Case

Epicyclical Reduction Case

Mechanical Stoppers

Close Position Label

Open Position Label

Position Indicator

WGR Identification and

Characteristics Label

Closing Direction Label

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 9

3TECHNICAL DATA

WGR Model

ICON2000

Model

Nominal Torque (100%)

[Nm]

Maximum Torque

[Nm]

WGR Ratio

(10%)

Valve Attachment

ISO 5211

WGR 100

010

1.000

1.500

50:1

F14

WGR 200

010

2.000

3.000

98:1

F16

WGR400

010

4.000

6.000

124:1

F16

WGR 800

020

8.000

12.000

183:1

F25/F30

WGR 1600

020

16.000

24.000

373:1

F25/F30

WGR 3200

020

32.000

48.000

747:1

F30/F35

030

32.000

48.000

400:1

F30/F35

WGR6300

020

63.000

94.500

1680:1

F40

030

63.000

94.500

920:1

F40

040

63.000

94.500

377:1

F40

3.1 Application range

WGR gear boxes are suitable to operate in on-off or intermittent service up to 60 starts/hour max.

WGR-DW gear boxes are suitable to operate in modulating service (up to 1200 starts/hour max).

Quarter-turn worm screw gear boxes are suitable to be motorized for applications in standard temperature range

from –30°C to +85°C (low temperature version are suitable to operate in temperature range from -40°C up to

+85°C).

WGR gear boxes are suitable to guarantee the output bush rotation of 90° with the possibility to obtain a 5° extra

stroke for each direction of rotation.

WGR gear boxes have protection degree IP66M and IP67M according to EN 60529, complete with third-party

certificate (the enclosure protection IP66/IP67/IP68 refers to the interior of the gearboxes, but not to the coupling

compartment).

IP 68 achieved with a submersion under 15 meter for 100 hours.

WGR gear boxes are also available with protection degree IP68 according to EN60529 (the enclosure protection

IP68 refers to the interior of the gearboxes, but not to the coupling compartment).

Please check with Biffi the acceptance of the submersion request (depth, medium, etc.) in order to verify the

compatibility requirements.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 10

4TRANSPORT and STORAGE

Important

Not performing the following procedures will invalidate the product guarantee.

Important

Gear box (and actuator) lifting and transportation must be done by qualified

personnel only and in accordance with the local regulation and area classification.

Warning

The lifting studs are suitable for the transportation of the actuator and gear box

only, NOT for the valve-actuator assembly.

The actuator and gear box weights are indicated on delivery documents.

4.1 Transport

Make sure the worm gearbox has a strong protecting packing during transport to destination.

If the worm gearbox is assembled onto the electric actuator, hoist it with ropes or hooks making sure they are

attached to the gearbox and not to the actuator.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 11

4.2 Checks to be carried out on receipt of the WGR reducer

Carefully remove the reducer from its shipping carton or skid. Check that the worm gearbox has not been

damaged during transport. If damaged, immediately report the damage to the transport company.

First of all check whether the information on the nameplate (Model, Nominal torque, Degree of protection,…)

correspond to the order acknowledgement data.

If the actuator and WGR are already assembled onto the valve, the setting of the mechanical stops and of the

electric end of travel has already been done in-house.

If the actuator and WGR are shipped separately from the valve, the setting of the mechanical stops and of the

electric end of travel must be checked and, if necessary, carried out while assembling the actuator and the

gearbox onto the valve.

Check that the fitted accessories comply with those listed in the order acknowledgement and the delivery note.

4.3 Storage Procedure

Important

Please make sure you stick to the following storage procedure to maintain top

WGR integrity during storage; failure to comply with the recommended procedure

will invalidate the warranty.

The worm gearboxes leave the factory in excellent working conditions and with an excellent finish (these

conditions are guaranteed by an individual inspection); in order to maintain these characteristics until installation

on the plant, it is necessary to observe a few rules and take appropriate measures during the storage period.

Store in a well-ventilated, protected, dry room.

Store the gearboxes on wooden skids or shelves to protect the machined mounting flange.

If the WGRs are supplied separately from the valves, they must be placed onto a wooden pallet. In case of

long-term storage (over six months), the worm gearboxes must be covered and protected from dust and dirt,

and it is necessary to apply a suitable corrosion protection agent to bare surfaces, particularly the output drive

parts and mounting surfaces.

In case of long-term storage, it is advisable to keep the worm gearboxes in a clean, dry place in order to

provide at least some means of weather protection.

If the gearboxes must be stored outside, they must be adequately protected (for example covered in

polyethylene protection with silica gel crystals to absorb moisture).

For the storage of the Electric Actuator supplied together with the worm gearbox, please refer to the storage

instructions included in the actuator’s IOM (MAN 618).

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 12

5INSTALLATION

5.1 Working condition

Standard WGR gearboxes are suitable for the following ambient temperatures:

from -30°C to +85°C (from -22°F to +185°F)

The low temperature version is suitable for temperature ranges from -40°C up to +85°C

Important

Check the "temperature ambient range" on the nameplate for correct use.

Installation in ambient with temperature range outside the specified values

will invalidate the warranty.

5.2 Safety Instructions for installation in Hazardous Area

5.2.1 Instructions for the explosion-proof enclosures

Important

For the installation of the assembly WGR - Electric Actuator in hazardous

areas, please refer to the Electric Actuator IOM (MAN 618).

5.2.2 Installation in ambient with explosive dusts

Important

For the installation of the assembly WGR - Electric Actuator in ambient with

explosive dusts, please refer to the Electric Actuator IOM (MAN 618).

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 13

6ASSEMBLING the WORM GEARBOX ONTO the VALVE

The worm gearbox is provided with an output flange and an insert (machined or not machined, based on Customer

requirements) for the coupling to the valve. The assembly position (orientation) of the valve/actuator (gearbox)

package must comply with the plant requirements.

To assemble the actuator onto the valve proceed as follows:

Check that the valve coupling dimensions of the flange and stem, or of the relevant extension, meet the worm

gearbox coupling dimensions.

Arrange the valve in the position related to the worm gearbox operation (for both butterfly valves and ball

valves the recommended position is OPEN).

Lubricate the valve stem with oil or grease in order to make the assembly easier: be careful not to contaminate

with lubricant the flange surfaces which have to be connected to transmit the actuator torque.

Clean the valve flange and remove anything that might prevent a perfect adherence to the worm gearbox

flange and especially all traces of grease.

If the insert supplied is not machined, remove it from the WGR output drive, machine it and reassemble it in

the WGR output drive.

Bring the worm gearbox to the recommended position (for both butterfly valves and ball valves the

recommended position is OPEN).

Clean the worm gearbox flange and remove anything that might prevent a perfect adherence to the valve

flange and especially all traces of grease.

Lower the actuator/WGR package onto the valve so that the WGR output drive couples with the valve stem

(for example, if the connection is made by key, the valve stem key groove must match with the WGR output

drive key groove). This coupling must take place without forcing and only with the weight of the actuator and

worm gearbox. When the worm gearbox output drive and the valve stem are connected, check the holes of the

valve flange. If they do not meet with the holes of the spool piece flange or the stud bolts screwed into them,

the worm gearbox output drive must be rotated until coupling is possible.

Tighten the nuts of the connecting stud bolts evenly with the torque prescribed in the table. If no different

materials are specified, the stud bolts must be made of ASTM A 320 Grade L 7 steel, the nuts must be made of

ASTM A 194 Grade 2 or better.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 14

Thread size

Recommended tightening

torque (Nm)

M16

160

M20

320

M22

420

M24

550

M27

800

M30

1100

M36

1700

If possible, operate the actuator to check that it moves the valve smoothly.

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 15

7ADJUSTING THE MECHANICAL STOPPERS

7.1 Grease-lubrication-type gearbox (WGR standard type)

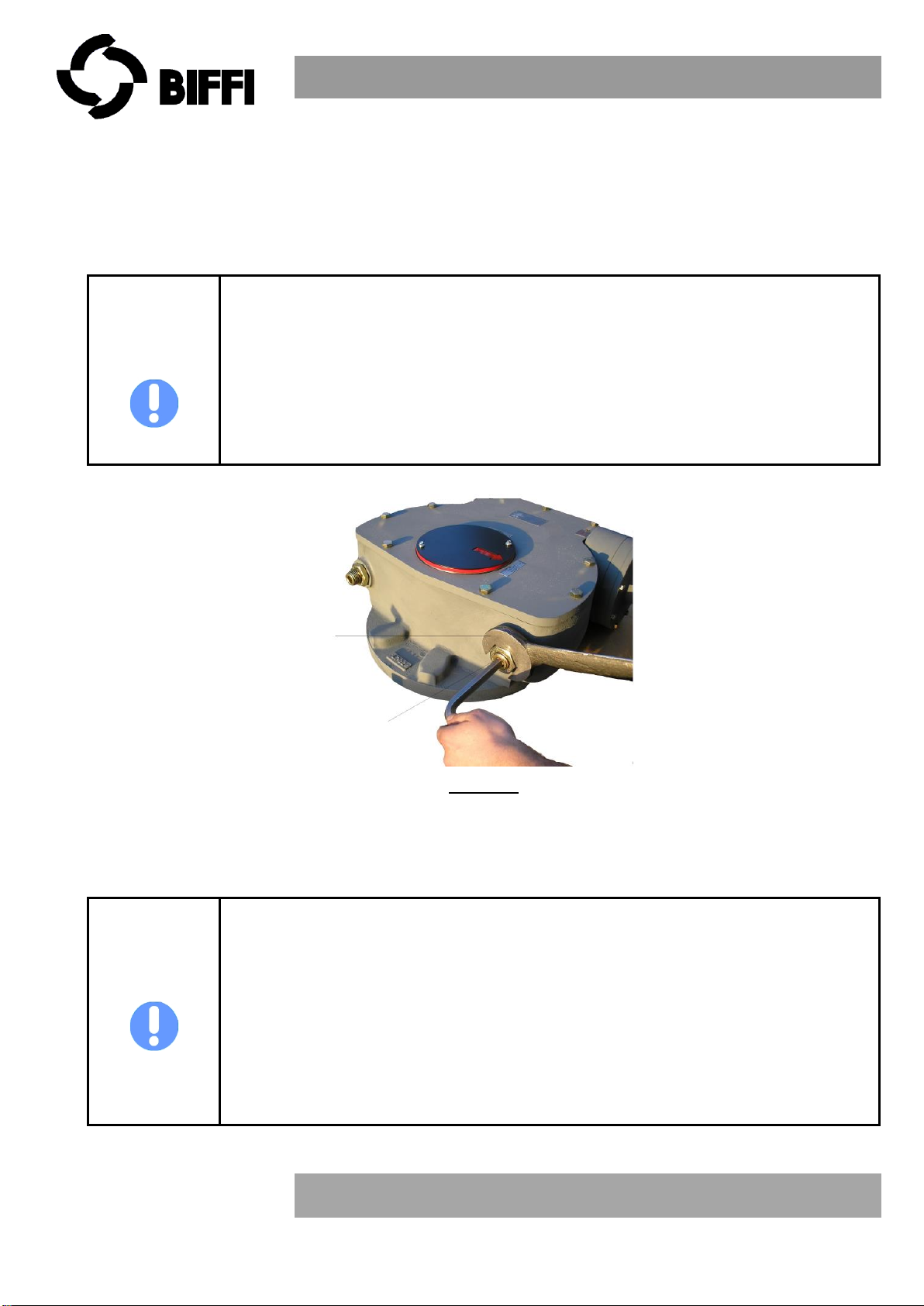

Please refer to the following Picture 3

Important

Closed position:

1. Loose the nut (1).

2. Loose the stopper (2) with a hex-head wrench. Stopper shall be taken out

as much as possible from the body of the gear.

3. Set-up actuator stroke limits according to the procedure described in

MAN618, chapter 1, paragraphs 1.1 and 1.2.

4. Tighten the stopper (2) until it stops, then step back a quarter of turn.

5. Tighten the nut (1).

Open position:

the same procedure of closed position, on the opposite stopper.

Picture 3

7.2 Oil-lubrication-type gearbox (WGR-DW series models)

Please refer to the following Picture 4

Important

Closed position:

1. Remove the plug (1) with a hex-head wrench.

2. Release the cap (2).

3. Loose the nut (1).

4. Loose the stopper (2) with a hex-head wrench. Stopper shall be taken out

as much as possible from the body of the gear.

5. Set-up actuator stroke limits according to the procedure described in

MAN618, chapter 1, paragraphs 1.1 and 1.2.

6. Tighten the stopper (2) until it stops, then step back a quarter of turn.

7. Tighten the nut (1).

Open position:

the same procedure of closed position, on the opposite stopper.

(1)

(2)

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 16

Picture 4

(1)

(2)

(3)

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 17

8MAINTENANCE

8.1 Standard Maintenance

BIFFI worm gearboxes require no maintenance.

After commissioning and once a year, check the paint-coat of the worm gearbox. If some areas

are damaged, repair the paint-coat according to the applicable specification.

In chemically aggressive or saline environments, remove rust from surfaces and protect with a

rust preventative.

Approx. six months after commissioning and once a year, check that the nuts and bolts securing

the worm gearbox to the electric actuator and to the valve are tight, and, if necessary, re-tighten.

Approx. every 2 years visually inspect the gearbox for grease leakage. For oil lubrication type

gearboxes (WGR-DW series models) visually inspect for oil leakage approximately every year.

For severe applications or if worm gearbox operation is infrequent, perform maintenance checks

at shorter intervals.

8.2 Special Maintenance

In case of malfunction, in case of grease leaks, or in case of scheduled preventive maintenance, the

worm gearbox must be disassembled: any damaged part can be requested from BIFFI with reference

to the attached exploded view drawing and parts list.

Every spare parts request must clearly indicate the relevant gearbox Serial Number and the spare part

item number.

Special maintenance is also recommended when, during operations, the actuator generates an

excessive noise.

Important

After maintenance works, a few operations of the assembly actuator/WGR

must be done to check that movement is regular.

Important

For maintenance instructions of the Electric Actuator ICON2000 supplied

together with the worm gearbox WGR, please refer to the ICON2000 IOM

(MAN 618).

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 18

9DISASSEMBLY INSTRUCTIONS

9.1 Access to the main reduction and to the epicyclical reduction

Please refer to the following Pictures 5, 6 and 7.

Unscrew the screws (1) and remove the position indicator cover

Unscrew the screws (2) and remove the position indicator (3)

Release the cylindrical pin (4)

Unscrew the screws (5) and remove the upper cover (6)

Unscrew the screws (7) and remove the trunk (8)

After completing these operations, the main reduction and the epicyclical reduction will appear as

shown in Picture 7.

The flexoid gasket (9) and the o-ring (10) (please refer to Picture 7) must be replaced every time the

upper cover is opened.

Picture 5

(4) cylindrical pin: release it

to remove the upper cover

(5) screws: unscrew to remove

the upper cover

(1) screws: unscrew to remove

position indicator cover

(3) position indicator

(2) screws: unscrew to remove

position indicator

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 19

Picture 6

Picture 7

(3) position indicator

(6) upper cover

(8) trunk

(7) screws: unscrew to

remove the trunk

Main Reduction

Epicyclical Reduction

(9) Flexoid gasket

(10) o-ring

(5) screws: unscrew to remove

the upper cover

(4) cylindrical pin: release it

to remove the upper cover

(2) screws: unscrew to remove

position indicator

WGR –Worm Gear Reducer

Instruction and operating manual

© Copyright by BIFFI Italia. All right reserved MAN 684/Rev 5 Page 20

9.2 Epicyclical reduction removal

Please refer to the following Picture 8

Remove the trunk (8 in Picture 6) following the instructions of Par. 9.1

Remove the pin (1)

Remove the operating gear (planet wheel) (2)

Remove the seeger (3)

Remove the satellite holder (4)

Picture 8

(1) Pin

(2) Planet Wheel

(3) Seeger

(4) Satellite Holder

This manual suits for next models

7

Table of contents

Other BIFFI Industrial Equipment manuals