96-0012 rev G 1

June 2003

OM

PERATOR’S ANUAL

Automatic

Automatic

Pallet Changer

Pallet Changer

INTRODUCTION

1.0 AUTOMATIC PALLET CHANGER (APC)

1.1 OVERVIEW

IMPORTANT!

Read this entire section before attempting to install or run the APC. Serious in ury or dam-

age to the machine could result from not following these procedures.

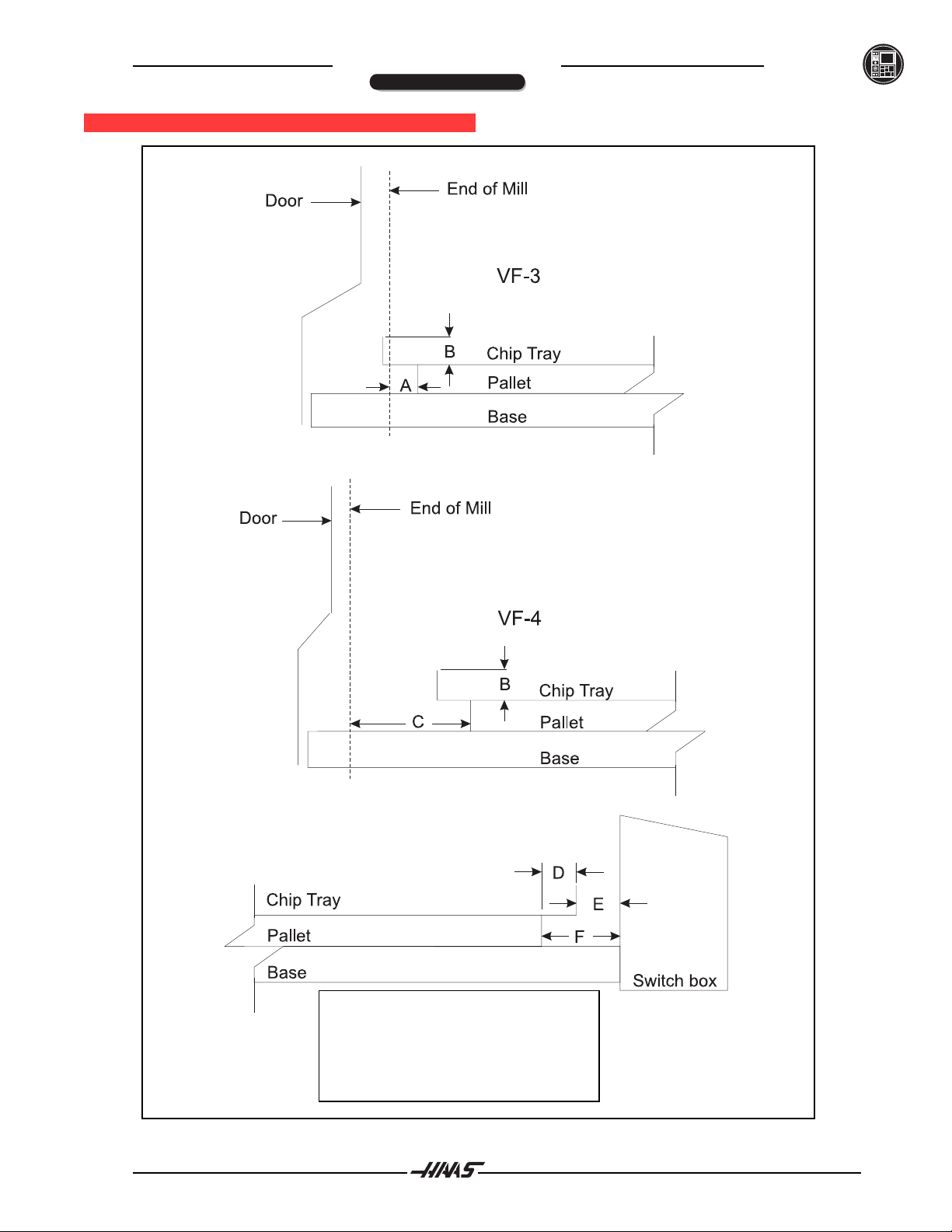

The HAAS Automatic Pallet Changer (APC) is used to automatically load and unload pallets into a HAAS VF-3

or VF-4 The APC is controlled by the VMC control, and uses the same air and power supplies A simple M

code (M50) is all that is required to change pallets

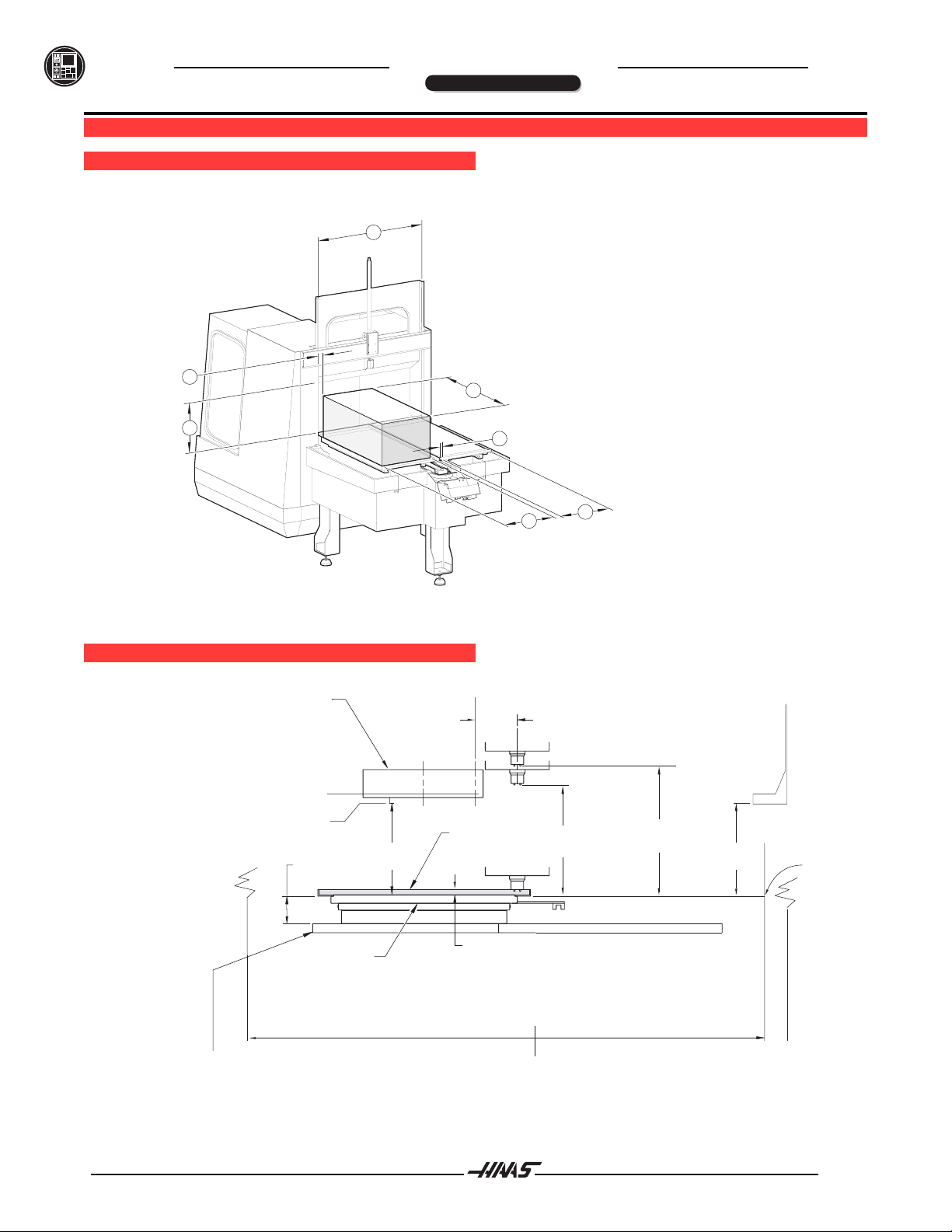

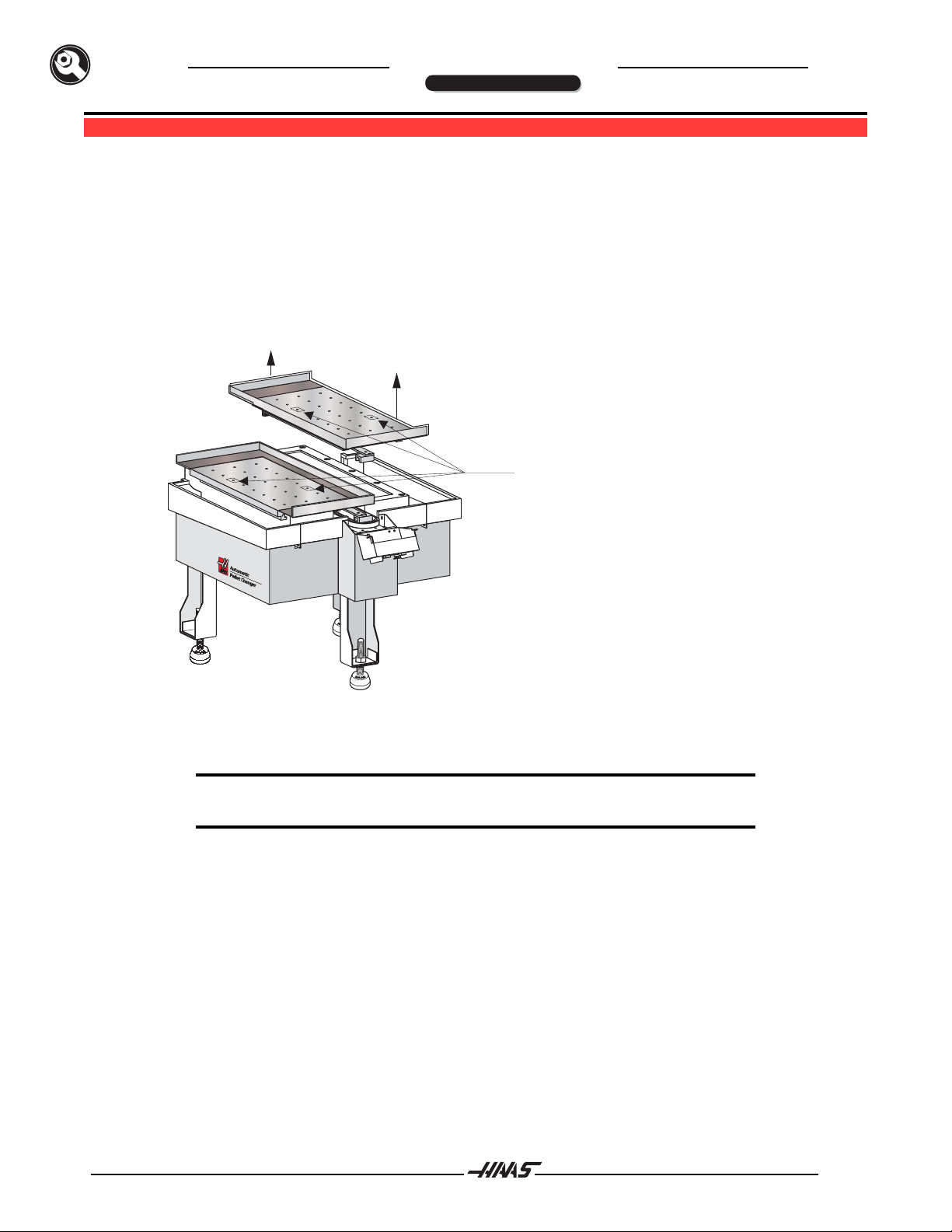

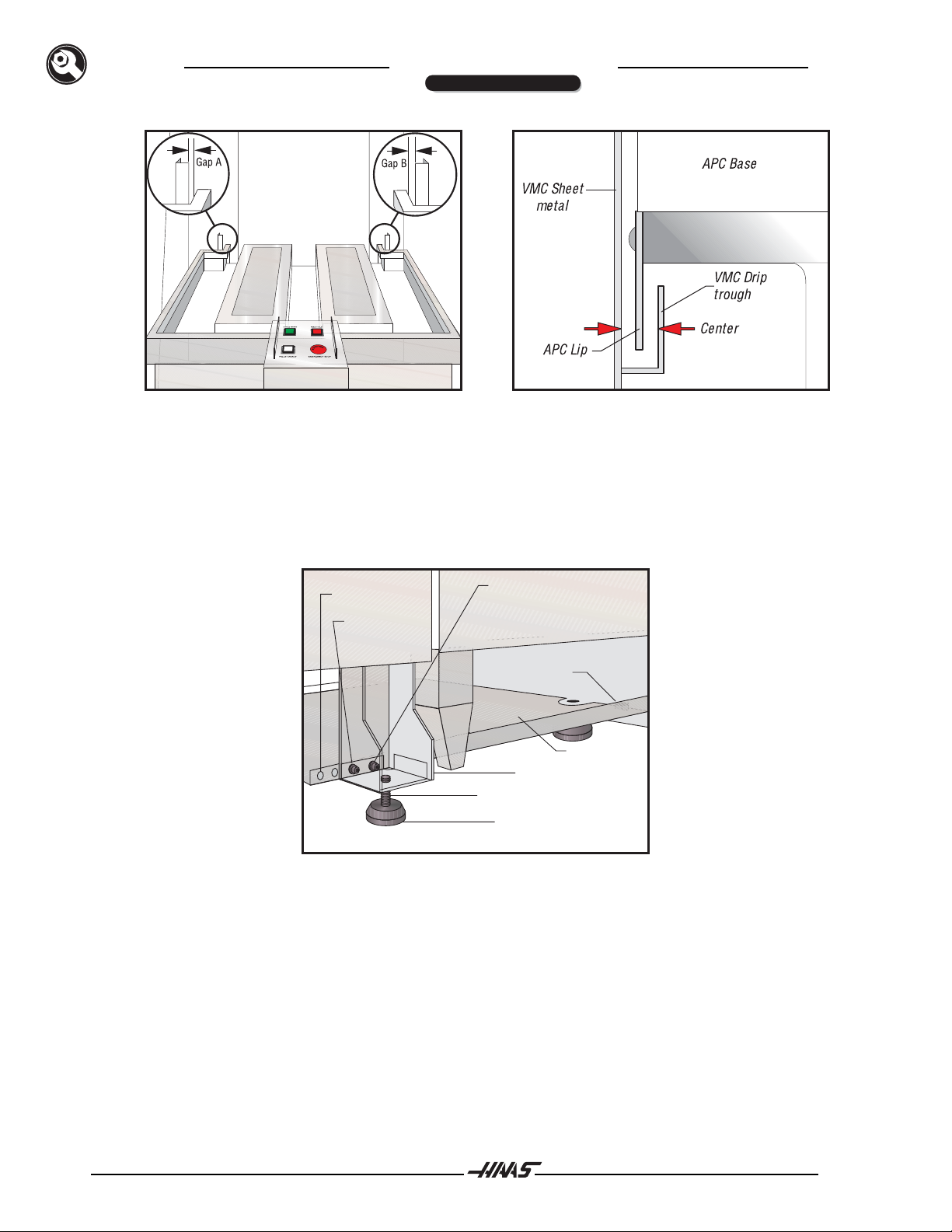

The APC assembly consists of the base, which serves as the home position for the two pallets, and a receiver

assembly, which is bolted to the VMC table and holds the pallets in place during machining operations The

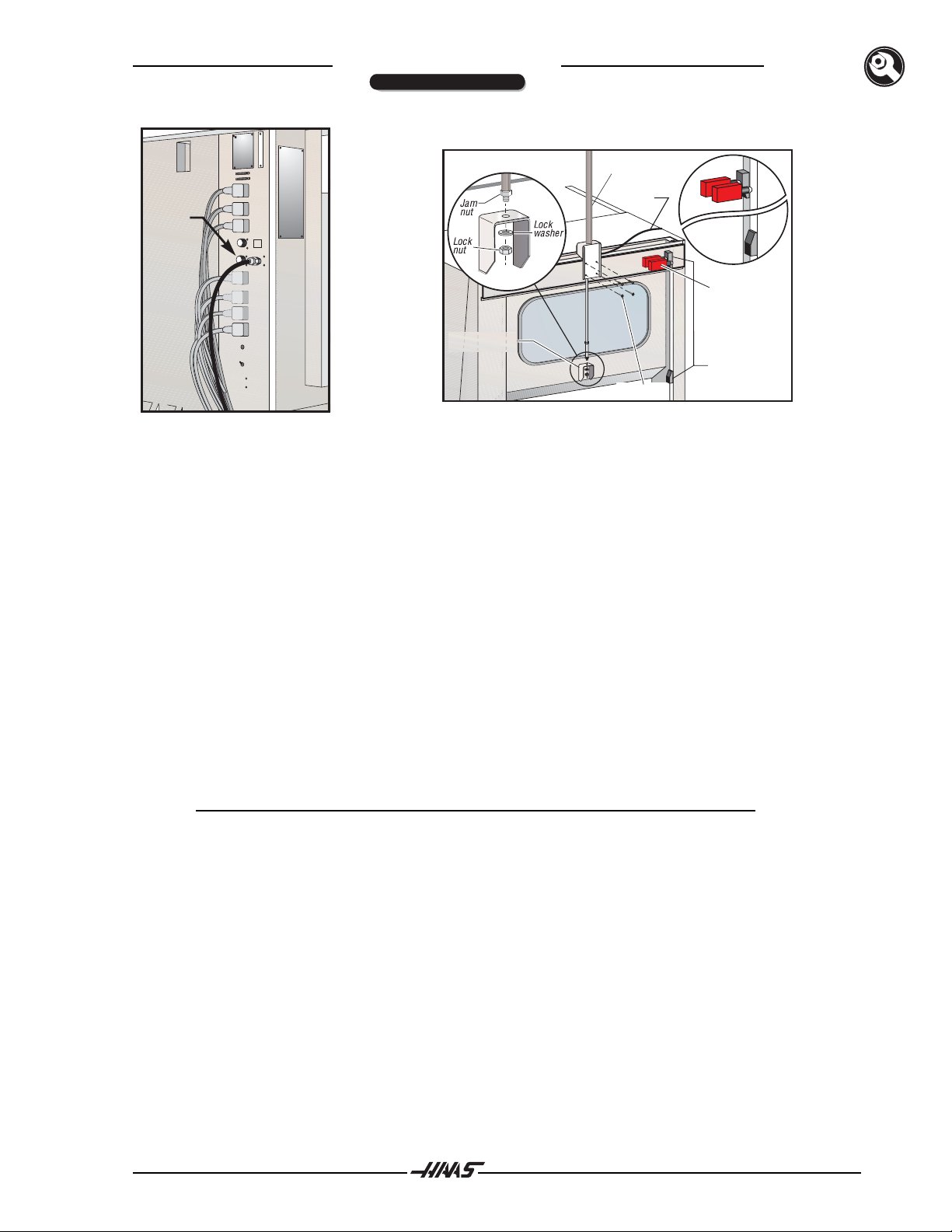

VMC unit contains air lines for clamping pallets, and a special automatic door in the side of the VMC enclosure

allows for loading and unloading of pallets The APC has its own operator's panel, which includes CYCLE

START, FEED HOLD, PALLET READY, and EMERGENCY STOP buttons

The APC can be programmed to load a pallet or change pallets by calling an M50 When a pallet change is

programmed, the VMC table moves to the right and adjacent to the empty pallet position on the APC base The

receiver assembly then unclamps the pallet The automatic door opens, the table moves to the unload position,

and the pallet is pulled into its home position The VMC table moves over to the other pallet position, the next

pallet is pushed onto the receiver, and the pallet is clamped into position The table then returns to its pro-

grammed position and the door closes

Pallet movement is accomplished through the use of a drive motor and chain The drive motor has a nonadjust-

able slip clutch that prevents damage to the motor if the pallet change is physically blocked

NOTE: The machine will beep during a pallet change. This is an audible warning

signal, and not an alarm.