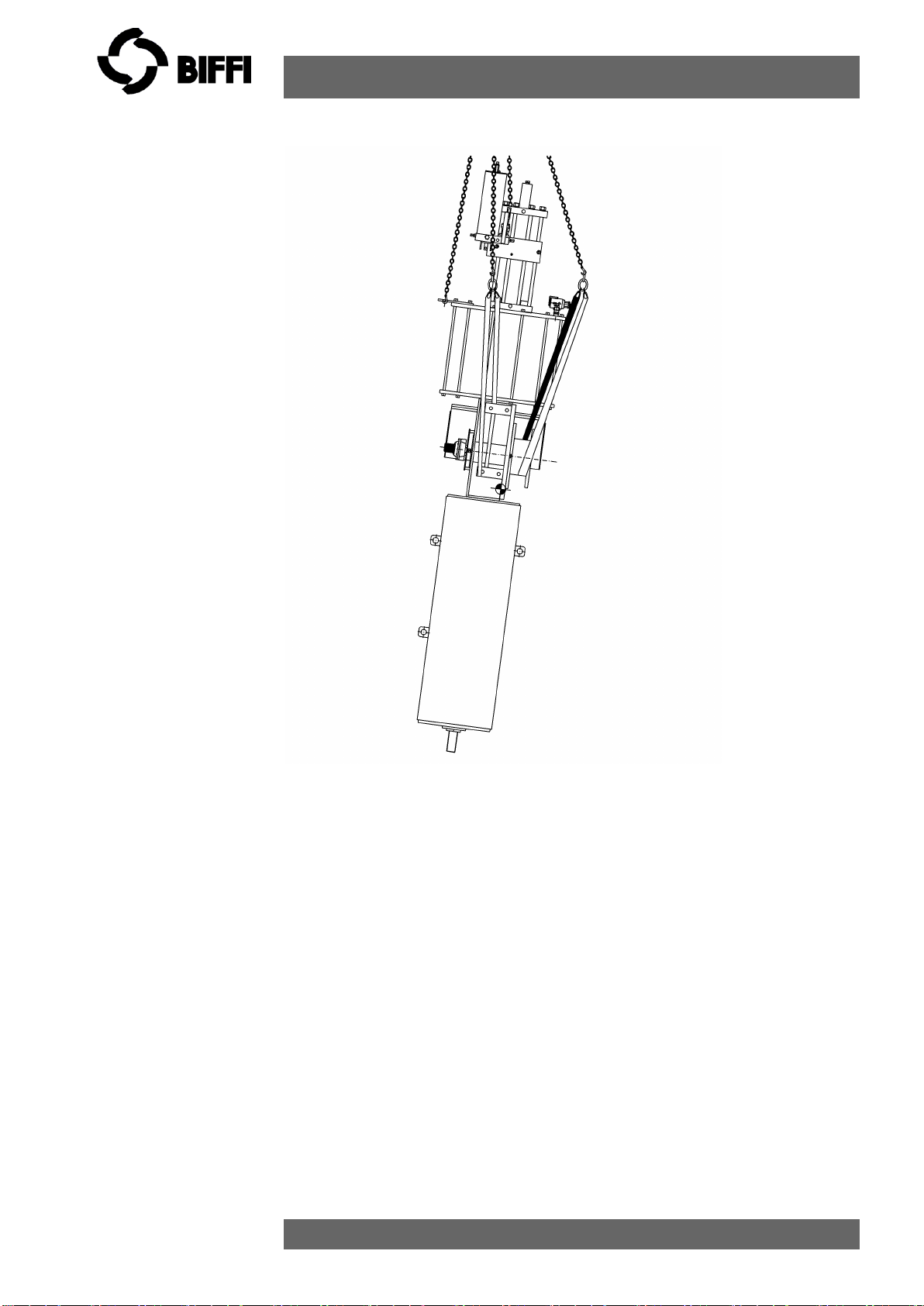

2 Installation

2.1 Checks to be carried out on receiving the actuator

1) If the actuator arrives already assembled onto the valve, the

settings of the mechanical stops and of the micro switches (if

existing) has already been made by the person who assembled

the actuator onto the valve. If the actuator arrives separately from

the valve, the settings of the mechanical stops and of the micro

switches (if existing) must be checked and, if necessary, carried

out while assembling the actuator onto the valve.

2) Check that the actuator has not been damaged during transport. If

necessary, repair all damages to the paint-coat, etc.

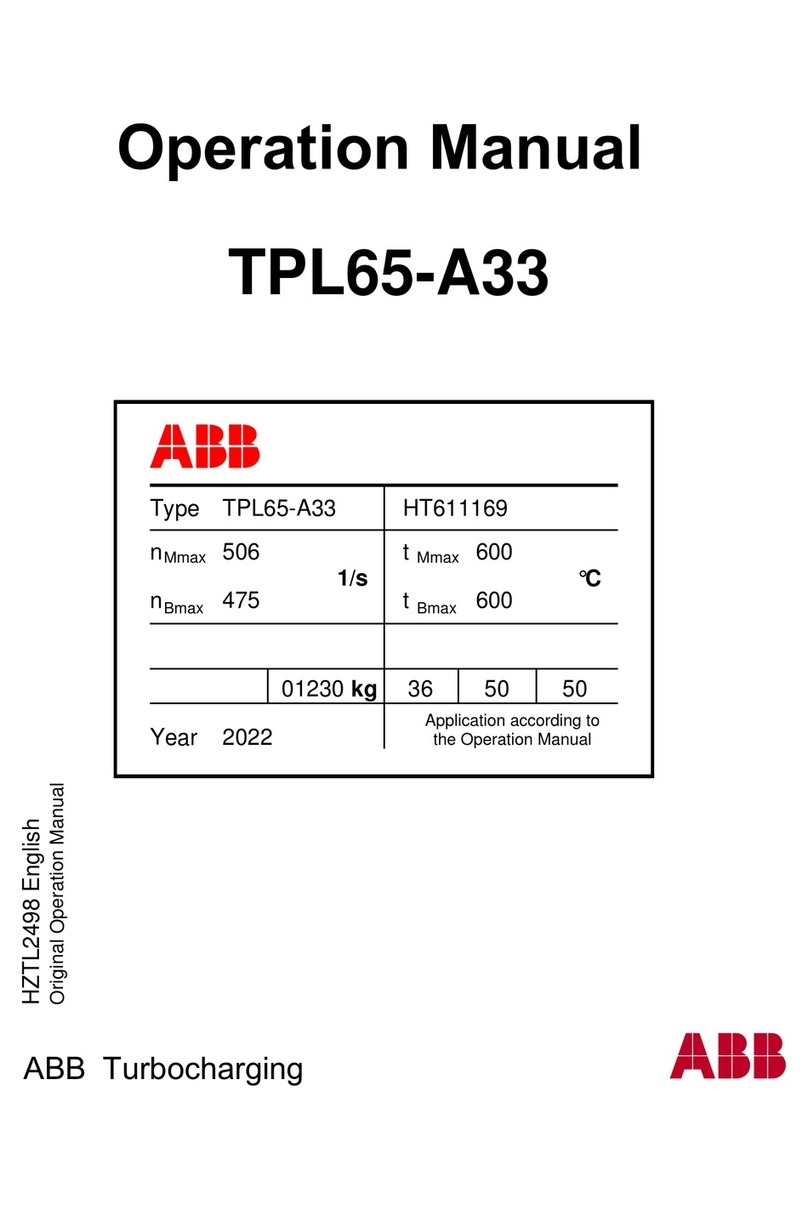

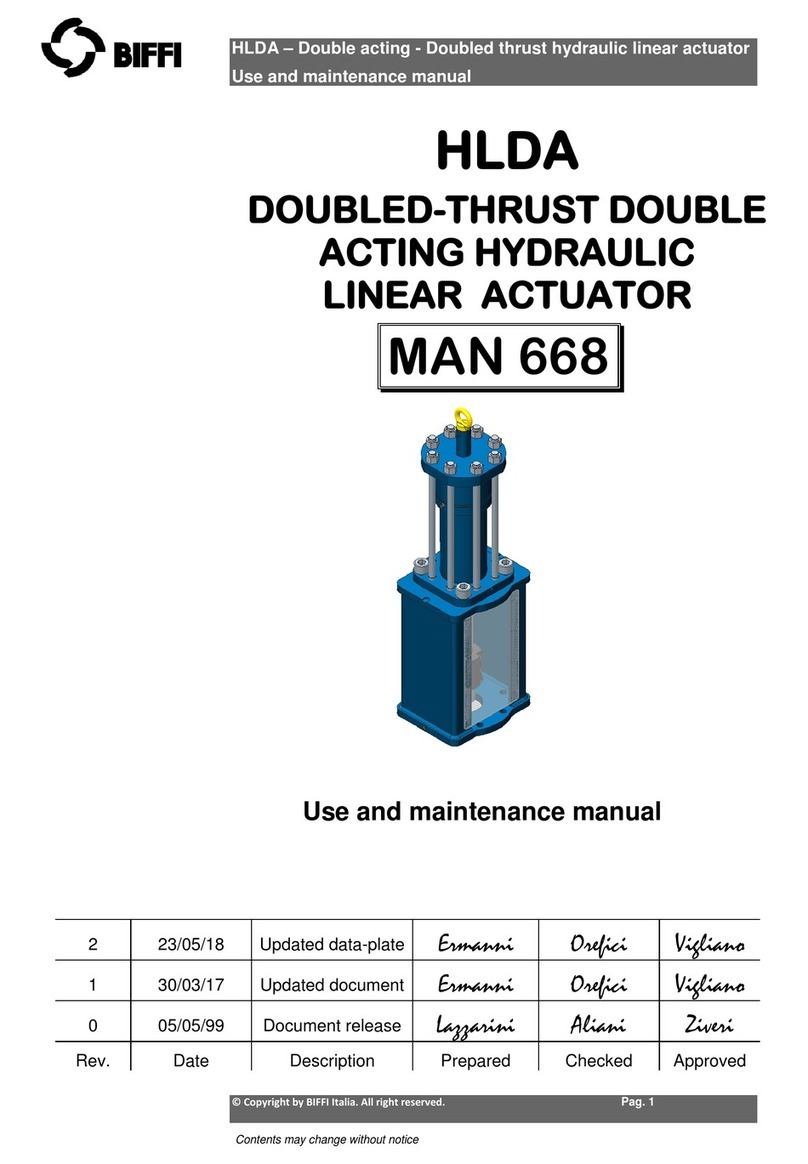

3) Check that the model, the serial number of the actuator and the

performance data written on the data-plate are in accordance with

those described on the order acknowledgement, test certificate

and delivery note.

4) Check that the fitted accessories comply with those listed in the

order acknowledgement and the delivery note.

2.2 Storage

The actuators leave the factory in excellent working conditions and

with an excellent finish (these conditions are guaranteed by an

individual inspection certificate); in order to maintain these

characteristics until the actuator is installed on the plant, it is

necessary to observe a few rules and take appropriate measures

during the storage period.

1) Make sure that plugs are fitted in the air connections and in the

cable entries. The plastic plugs, which close the inlets, do not have

a weatherproof function, but are only a means of protection

against the entry of foreign matter during transport. If long-term

storage is necessary and especially if the storage is outdoors,

metal plugs must replace the plastic protection plugs, which

guarantee a complete weatherproof protection.

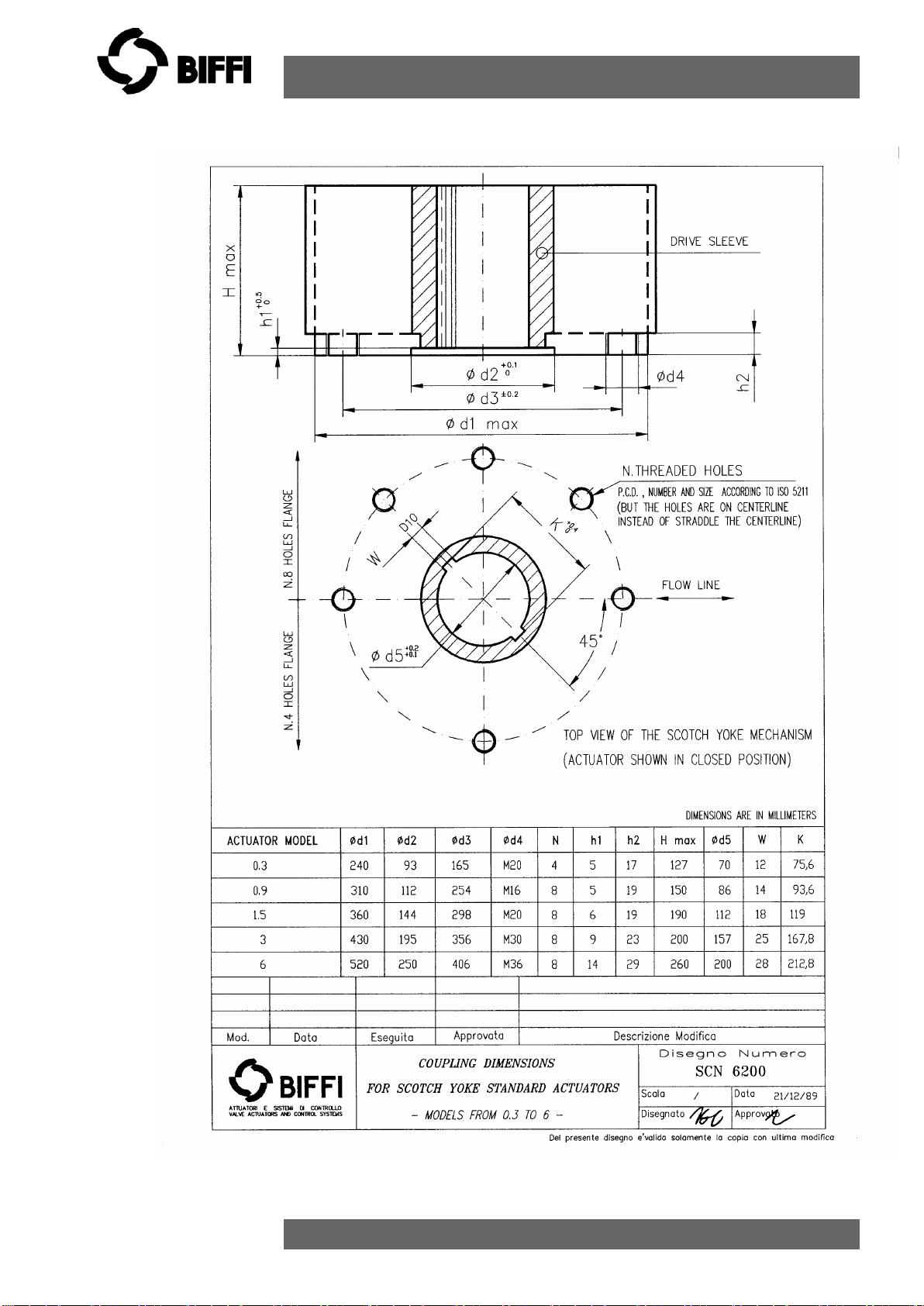

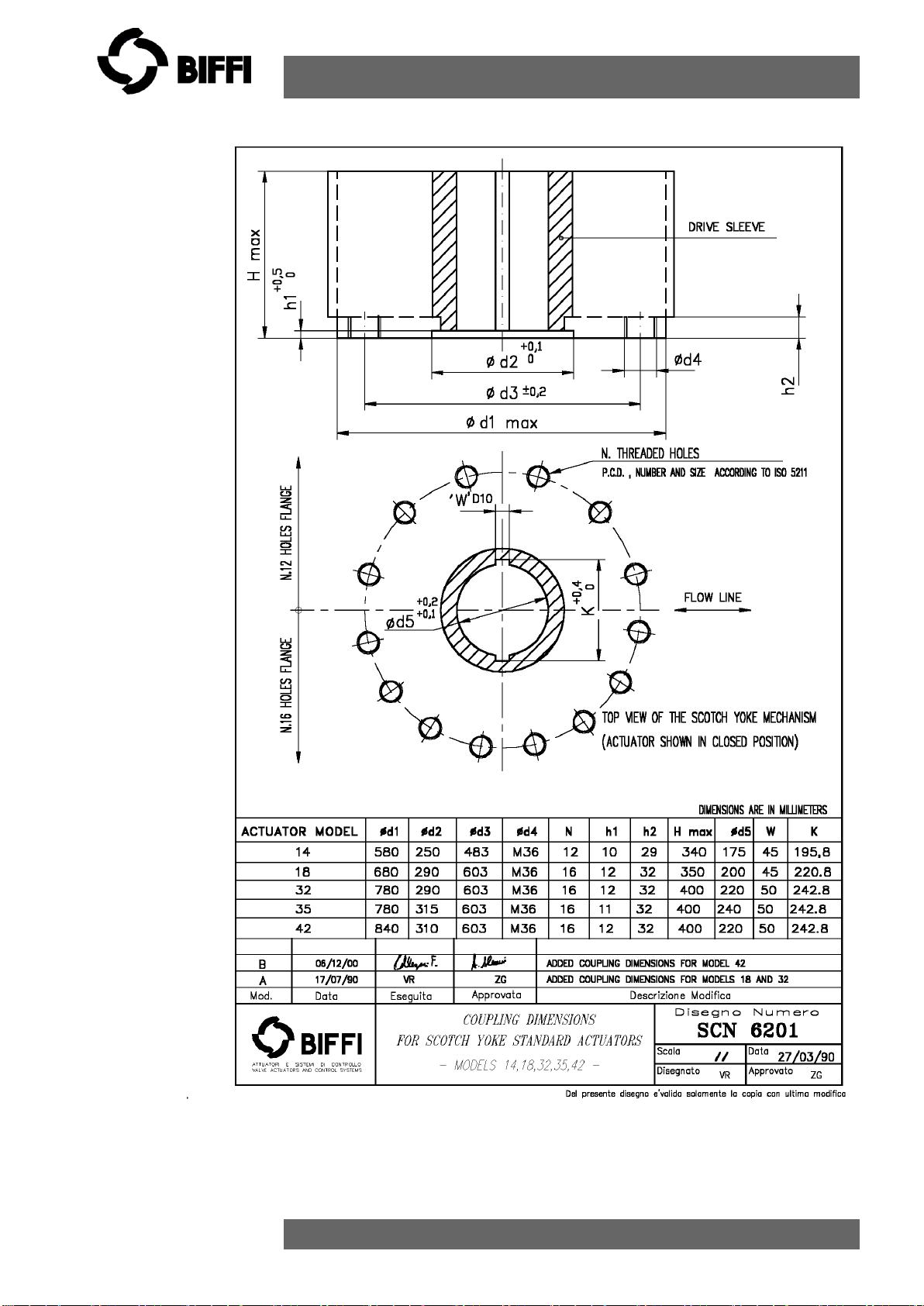

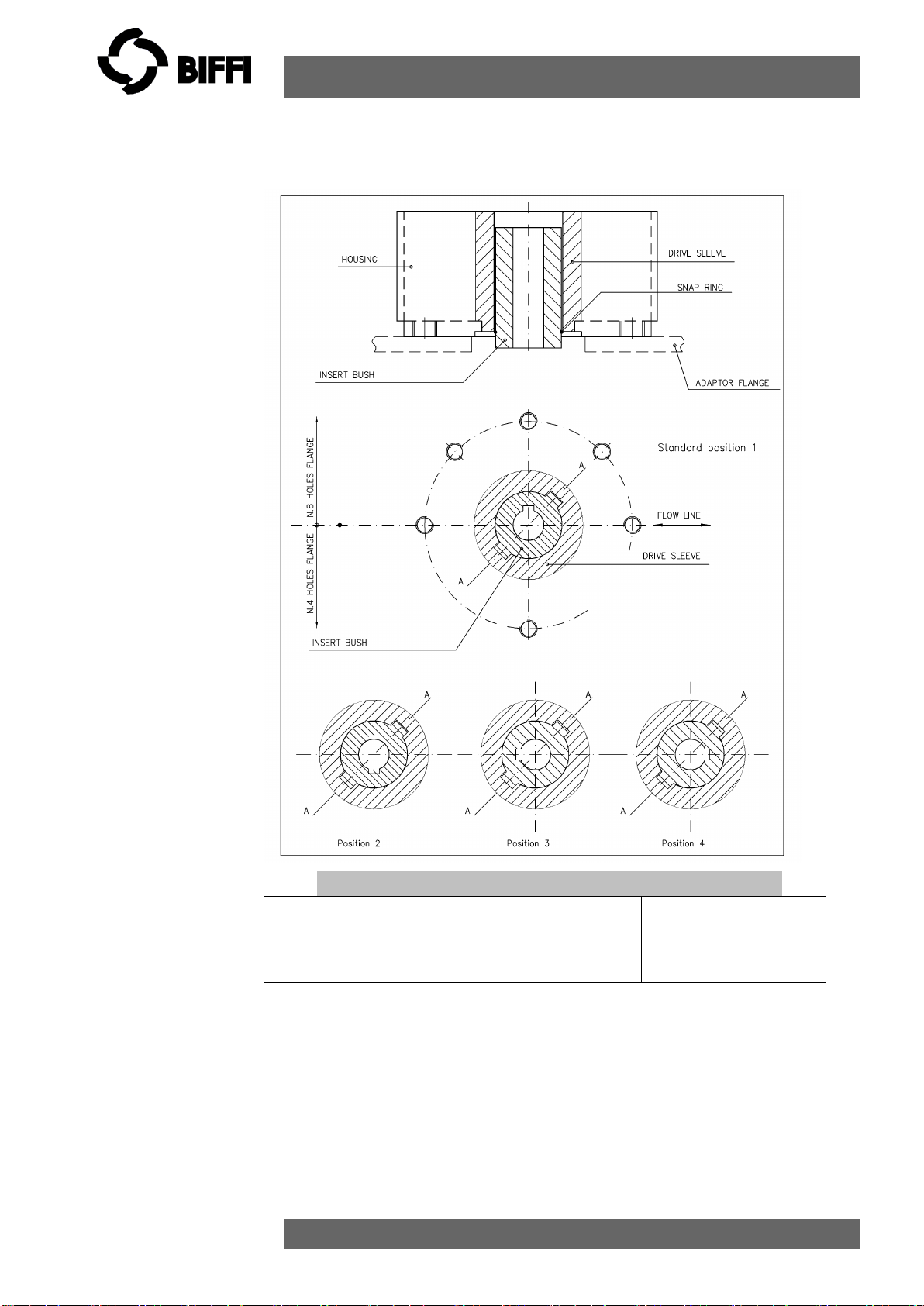

2) If the actuators are supplied separately from the valves, they must

be placed onto a wooden pallet so as not to damage the coupling

flange to the valve. In case of long-term storage, the coupling

parts (flange, drive sleeve, insert bush) must be coated with

protective oil or grease. If possible, blank off the flange by a

protection disk.

3) In case of long-term storage, it is advisable to keep the actuators

in a dry place or to provide at least some means of weather

protection. If possible, it is also advisable, to periodically operate

the actuator with filtered, dehydrated and lubricated air; after such