Simpro Multi-Tip User manual

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021

USER MANUAL

Copyright © 2021 Simpro Handling Equipment Ltd.

No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the written

permission of Simpro Handling Equipment Ltd.

For the purposes of standards compliance and international conformity, this document uses

Système International (SI) units. These may be converted to Imperial units as follows:

1 kilogram (kg) = 2.2 pounds (lb)

1 metre (m) = 1000 millimetres (mm) = 39.37 inches (in) = 3.28 feet (ft) = 1.09 yards (yd)

The following stylistic conventions are used throughout this document:

Point of interest.

Point of warning or safety hazard.

§Internal section reference or hyperlink

Simpro partcode or SKU

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 2

Contents

1. Product Overview........................................................................................................ 5

1.1 Key Features .......................................................................................................................... 6

1.2 Construction .......................................................................................................................... 6

1.3 Mechanism ............................................................................................................................ 6

1.4 Safe Lifting Capacity ............................................................................................................ 6

1.5 Duty cycle.............................................................................................................................. 7

1.6 Service life..............................................................................................................................7

1.7 Noise emissions ...................................................................................................................... 7

1.8 Environmental restrictions .................................................................................................... 8

1.9 Ingress protection ................................................................................................................. 8

1.10 Notes ...................................................................................................................................... 8

2. Safety Information ....................................................................................................... 9

2.1 Safety features ...................................................................................................................... 9

2.2 Reasonably foreseeable misuse ......................................................................................... 9

2.3 OSH Compliance Specification Guide .............................................................................. 9

2.4 Hazard and Risk Assessment Guide..................................................................................11

2.5 Safety Norms........................................................................................................................ 17

3. Operating Instructions ............................................................................................... 19

3.1 Before operation................................................................................................................. 19

3.2 Emplacing and removing bins .......................................................................................... 19

3.2.1 Cradle identification..................................................................................................................... 19

3.2.2 Type-E Cradle (standard)............................................................................................................. 21

3.2.3 Type-C Cradle ............................................................................................................................... 21

3.2.4 Type-A Cradle ............................................................................................................................... 21

3.2.5 Type-A Cradle with base............................................................................................................. 22

3.2.6 Type-D and Type-F Cradle .......................................................................................................... 22

3.2.7 Type-X Cradle (custom) ............................................................................................................... 22

3.3 Operation of controls .........................................................................................................23

4. Care and Maintenance............................................................................................ 25

4.1 Quick Troubleshooting Guide............................................................................................ 25

4.2Cleaning ..............................................................................................................................26

4.3 Cradle jams ......................................................................................................................... 26

4.4 Electrical System (battery) ................................................................................................. 28

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 4

4.4.1 International conformance ......................................................................................................... 28

4.4.2 Voltmeter ....................................................................................................................................... 28

4.4.3 Battery charging ........................................................................................................................... 28

4.4.4 Batteries ......................................................................................................................................... 29

4.4.5 Battery charger ............................................................................................................................. 29

4.4.6 IEC power lead ............................................................................................................................. 29

4.4.7 Emergency Stop............................................................................................................................ 29

4.4.8 Circuit breaker............................................................................................................................... 29

4.4.9 Solar panel..................................................................................................................................... 30

4.5 Electrical System (3-phase mains) .................................................................................... 31

4.5.1 International conformance ......................................................................................................... 31

4.5.2 Transformer .................................................................................................................................... 31

4.6 Electrical System (1-phase mains) .................................................................................... 32

4.6.1 International conformance ......................................................................................................... 32

4.6.2 Transformer .................................................................................................................................... 32

4.6.3 Variable Speed Drive ................................................................................................................... 32

4.7 Hydraulic System ................................................................................................................. 33

4.7.1 Powerpack .................................................................................................................................... 33

4.7.2 Control valves................................................................................................................................ 33

4.7.3 Lift ram............................................................................................................................................ 33

4.7.4 Hydraulic fluid................................................................................................................................ 33

4.7.5 Maintenance................................................................................................................................. 33

4.7.6 Hydraulic system schematic ........................................................................................................ 34

5. Assembly, Handling, Transport & Storage................................................................ 35

6. Preventative Maintenance Inspections................................................................... 37

6.1 Pre-inspection checklist ..................................................................................................... 37

6.2 Monthly inspection ............................................................................................................. 37

6.3 Annual inspection ............................................................................................................... 39

7. Spare Parts ................................................................................................................. 41

8. Warranty..................................................................................................................... 43

9. EC Declaration of Conformity .................................................................................. 45

10.Notes ....................................................................................................................... 46

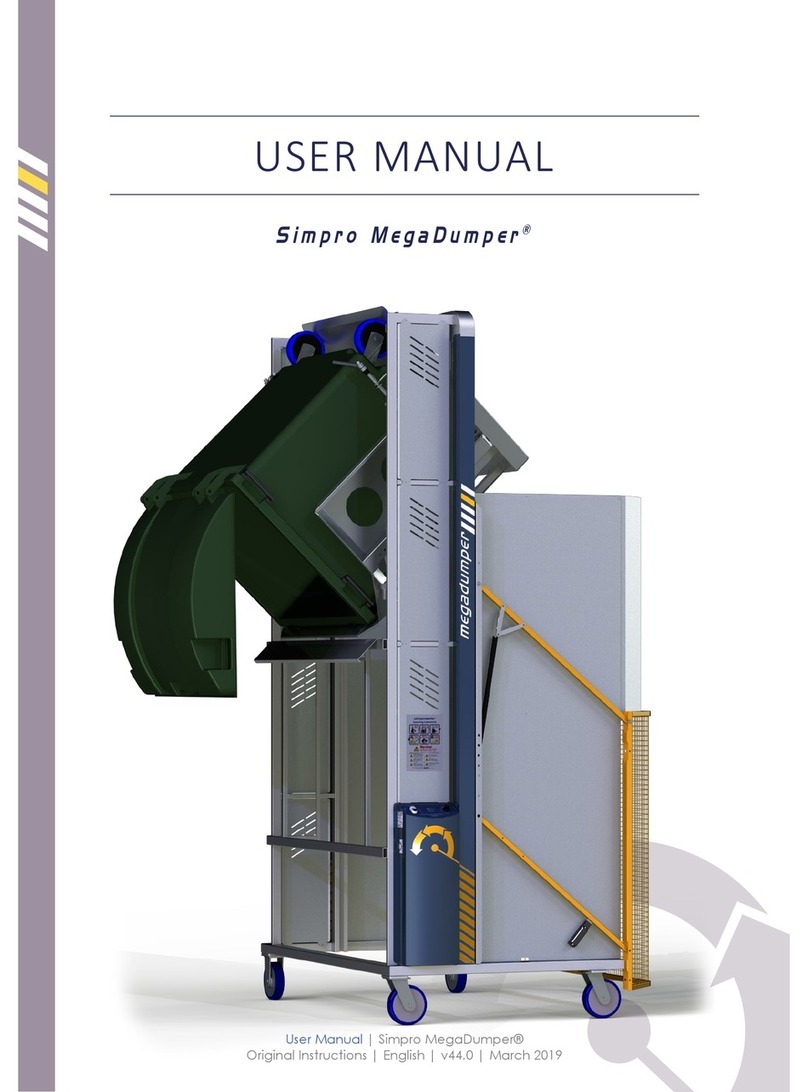

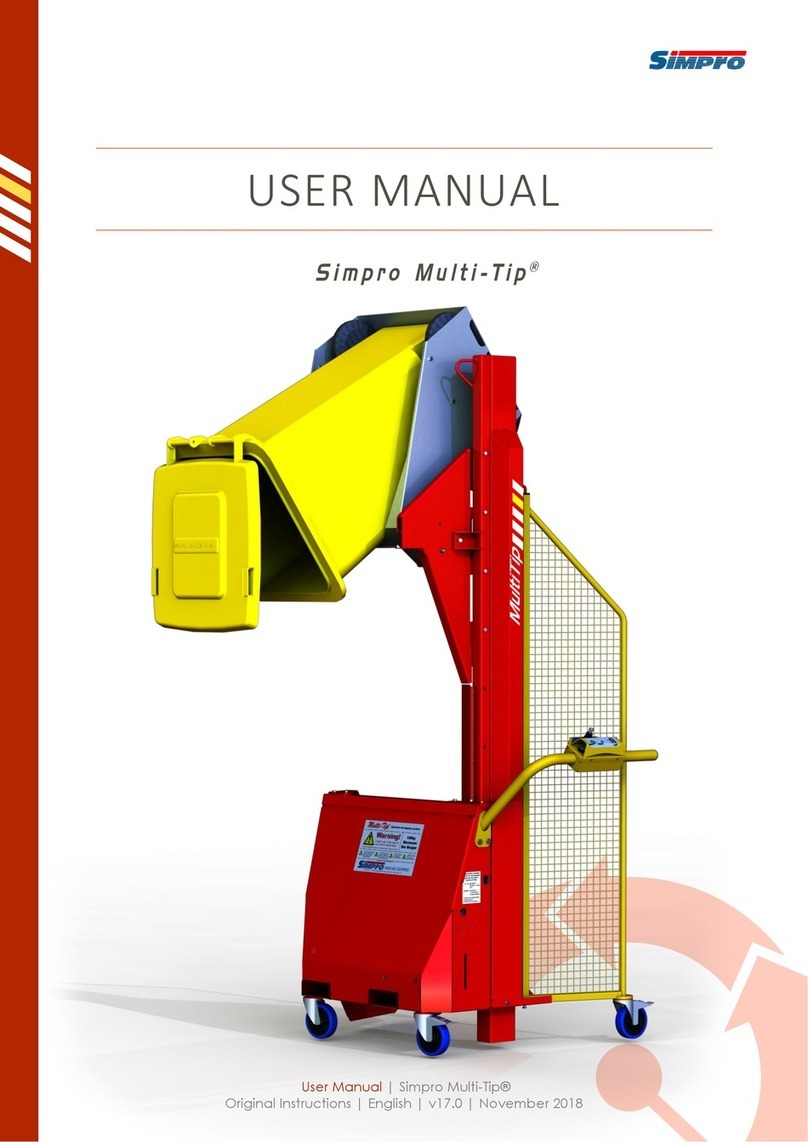

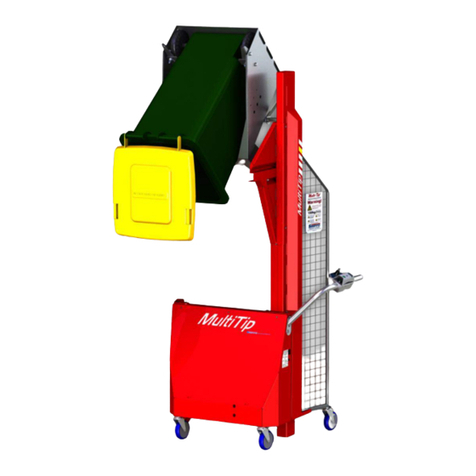

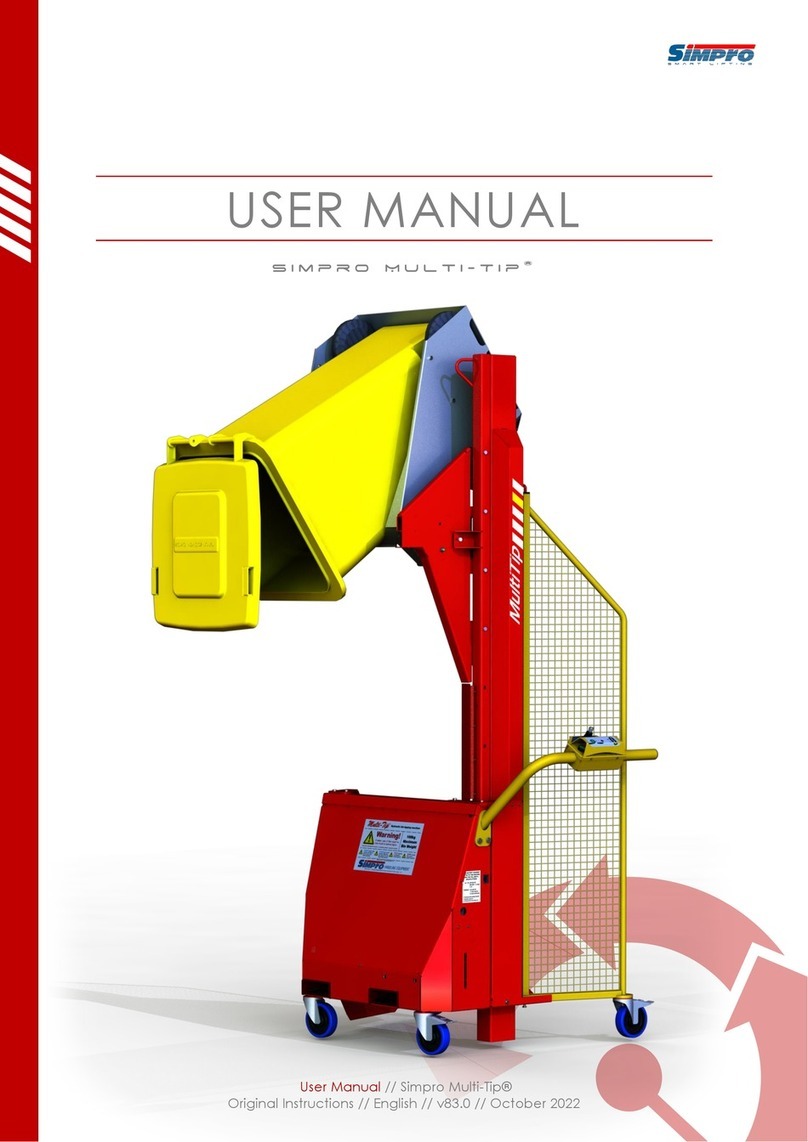

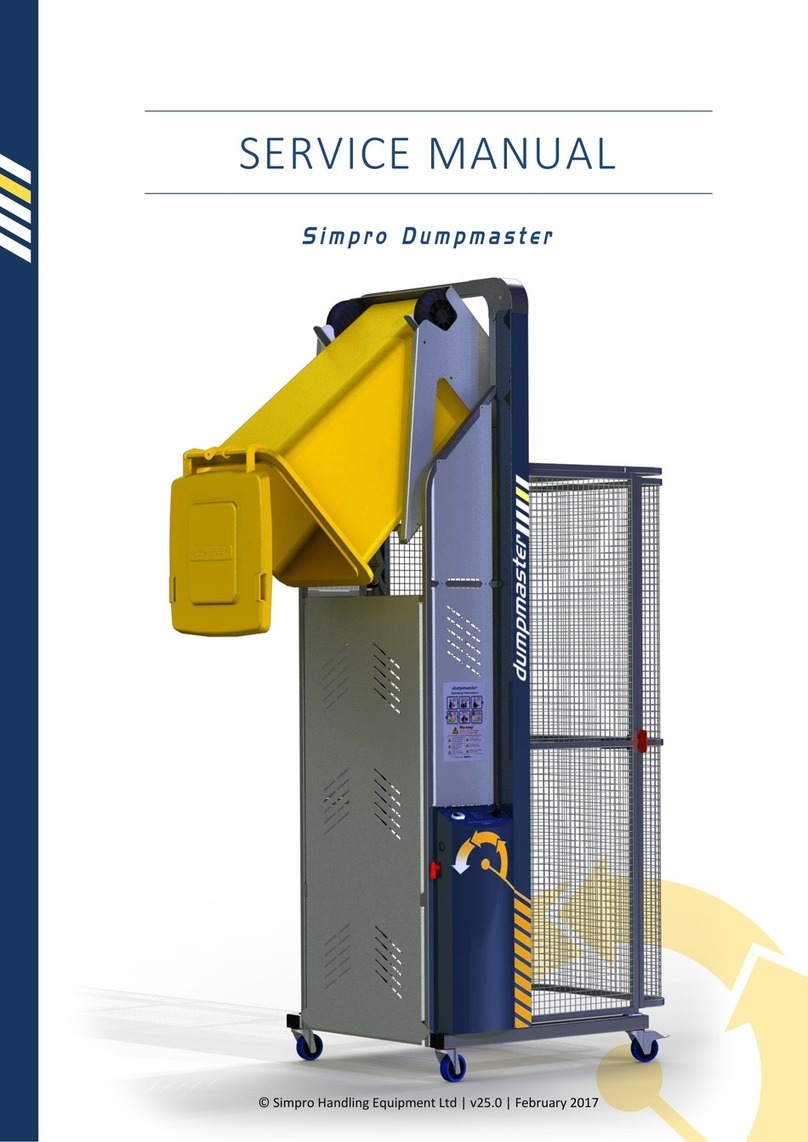

1. Product Overview

Congratulations on your purchase of a Simpro Multi-Tip. The Multi-Tip is everything a bin lifter

should be; safe, cost-effective, and easy to use. With a 150kg lifting capacity and 15-second

tipping cycle, it is an ideal solution for schools, recycling centres and small businesses.

The Multi-Tip has a mono-mast design which provides the operator with a clear view of

operations to ensure safety. No cage-guard is required, because the two-hand control

system prevents operators from accessing any moving

parts while using the machine. The mono-mast

design is very simple to clean and maintain.

The standard Multi-Tip dumps bins at

1600mm and is fitted with a cradle

which can empty most EN840

wheelie bins with no clamping or

modification. However, Simpro's

modular architecture allows the

Multi-Tip to be adapted to empty

a wide range of containers

including US-style ANSI trash carts,

BRUTE® bins, 205-litre drums, and

fish bins at 1200mm, 1600mm or 1800mm.

Like all Simpro products, the Multi-Tip is very robust and

needs little regular maintenance.

As far as compliance and relieving me of hard work, this is the best -

absolutely the best!

Graham Hawkes –Caretaker –One Tree Hill College

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 6

1.1 Key Features

Key features of the Multi-Tip include:

1. A unique tipping action whereby bins are lifted straight up, and then gently rolled

forward around the lip of the container being emptied into. Benefits of this design

and high stability in use.

2. A large lifting capacity of 150kg.

3. A reliable, maintenance-free design.

4. Castor wheels and grab-handles for ease of movement.

5. A powder-coated frame and zinc-plated cradle for corrosion protection.

6. A modular cradle architecture which can be easily adapted to suit different bins, and

does not require clamping or fastening simply place the bin into the cradle and

1.2 Construction

The Multi-Tip consists of a steel frame with one vertical mast, a bin cradle, one hydraulic ram,

guarding, castor wheels, powerpack cover, grab handle with control buttons, power lead or

battery, hydraulic powerpack and control systems.

1.3 Mechanism

When operated, the bin cradle moves vertically in the masts, and is inverted at the

appropriate height by track. A hydraulic ram provides

the force to lift the bin. The ram is operated by a hydraulic powerpack, which is normally

powered by a battery. Electronic control systems allow the operator to raise or lower the bin

in a controlled manner.

1.4 Safe Lifting Capacity

The Safe Lifting Capacity of the standard Multi-Tip is 150kg (330lb).

Some machines may be specified with different capacities. Refer to the rating plate to verify

the Safe Lifting Capacity on any given machine.

Safe Lifting Capacity is a gross figure, referring to the weight of the bin, its contents, and

any other external objects which have been placed on the cradle.

Never attempt to lift more than the factory-designated Safe Lifting Capacity.

1.5 Duty cycle

The duty cycle of the Multi-Tip depends on the installed powerpack, available power supply,

environmental factors, and the manner in which the machine is being used. The figures given

below are indicative only.

Power supply

Duty Cycle tipping at 1600mm

Throughput (net

tipped material)

No. of bins equivalent

(avg. ~100kg each)

Units

24V/20Ah Battery*

5,000kg

50 bins

Per charge

24V/20Ah Battery* on

continuous charge

2000kg

20 bins

Per hour

24V/20Ah Battery* with Solar Kit

2,000kg

20 bins

Per day**

Mains, 3-Phase ~415VAC

12,000kg

120 bins

Per hour

Mains, 1-Phase ~230VAC

6,000kg

60 bins

Per hour

12V/20Ah Battery***

2,500kg

25 bins

Per charge

12V/55Ah Battery***

6,000kg

60 bins

Per charge

*2x 12V/20Ah batteries in series; default from 2022 **Subject to weather, latitude, and panel orientation; see §4.4.9 ***Discontinued 2022

1.6 Service life

The Multi-Tip nominal service life is as follows.

Average Gross Bin Weight

Nominal service life

< 50kg

100,000 cycles

50kg –100kg

75,000 cycles

100kg –150kg

50,000 cycles

> 150kg

10,000 cycles

1.7 Noise emissions

The noise emissions of the Multi-Tip in standard operation have been assessed as not

exceeding ~60 dB(A) .

Operators are not required to wear hearing protection but are recommended to do so if

using the machine on a constant basis.

ISO standards for machinery safety specify that noise emissions are to be measured in A-

weighted decibels (dB(A)), a unit of volume which is adjusted to reflect the sensitivity of

human hearing. The measurements are taken at a point 1.6 metres above the ground at

ing position.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 8

1.8 Environmental restrictions

The Multi-Tip may be used indoors or outdoors. However, the following restrictions apply:

1. A minimum floor area of two square metres, with a clear passage to exits;

2. Height above sea level not more than 1000m;

3. Ambient temperature not higher than +40℃and not lower than -10℃;

4. At ambient temperatures above 35℃, the relative humidity should not exceed 50%; at

lower temperatures, higher relative humidity is permitted;

Never operate the machine in explosive, corrosive, acidic or alkaline environments.

1.9 Ingress protection

Item

IP Rating

Push buttons, switches, and lamps

IP66

Door interlock

IP66

Coded magnetic switch

IP66

Motor

IP54 (note additional protection provided by covers)

Overall

IP54 (optional upgrade to IP66 or IP69K)

1.10 Notes

1. This User Manual describes approved procedures for the operation, maintenance,

and routine inspection of the Multi-Tip hydraulic bin-tipping machine.

2. This manual is written in English, and is to be considered th

the purposes of Machinery Directive 2006/42/EC.

3. Operator(s) must read and understand this manual before using the machine.

4. If the machine is to be leased, then this manual shall accompany the machine.

5. This is a generic manual. Simpro reserves the right to change the design of our

products at any time without notification. In cases where the manual does not

correspond with the actual product, use the manual as a reference guide only, and

contact your authorized Simpro agent for assistance if required.

6. Contact your authorized Simpro agent if you encounter any problems or faults with

the machine.

7. Any errors in this manual should be reported by email to i[email protected].

2.Safety Informat ion

The Multi-Tip has been designed to be as safe as possible without restricting the ease-of-use

and versatility of the machine.

A Hazard and Risk Assessment should be undertaken before the machine is used for the

first time, as described in §2.4.

2.1 Safety features

The safety features of the Multi-Tip are as follows:

1. A shrouded dual-hand control system, which immediately stops the cradle whenever

2. A welded mesh panel which physically prevents the operator from accessing moving

parts while using the machine.

3. A tipping action which maintains the weight of the bin within the machine footprint.

4. A pressure-compensating lowering valve which automatically regulates the lowering

speed regardless of the weight of the bin.

2.2 Reasonably foreseeable misuse

The reasonably foreseeable misuse considered in the Multi-Tip design is as follows:

1. Attempts to use the machine by untrained operators;

2. Attempts to empty bins that the cradle is not specifically designed to hold;

3. Attempts to bypass dual-hand controls or other safety systems;

4. Attempts to access the operational area beneath the cradle without following

proper procedures;

5. Attempts to clean the machine without following proper procedures.

2.3 OSH Compliance Specification Guide

Companies in most jurisdictions (including Australia, NZ, UK, USA, Canada, and the EU) are

required by law to provide a safe workplace for their staff, including ensuring that all new

and existing machinery is safe to operate.

Although the particulars of safety legislation differ, most countries accept that machinery is

comply with ISO 13849-1:2015 (or a regional

equivalent thereof).

ISO 13849-1:2015 may call for additional guarding and safety features, depending on the

particular circumstances in which a machine is to be used. The purpose of this section is to

assist potential Multi-Tip owners to determine whether special safety features may be

required on their machine.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 10

ISO 13849-1:2015 is a machinery-safety standard issued by the International Standards

Organisation. It provides safety requirements and guidance on the principles for the

design and integration of safety-related parts of control systems (SRP/CS), including the

design of software.

ISO 13849-1 has been modified for local conditions and reissued under different

terminology by some national standards authorities. In Australia and New Zealand, the

derivative standard is called AS/NZS 4024.1:2014.

In the USA, ANSI standards are commonly used to demonstrate the safety of machinery,

rather than ISO 13849-1. However,

rate machinery

safety using ISO 13849-1 may be considered to have met or exceeded their H&S

obligations.

2.3.1 The ISO 13849-1:2015 safety model

-1:2015 uses

model of machinery safety. That is, it takes account of the reliability of

parts as well as other factors to create a comprehensive measure of the risk reduction

achieved by a safety function an indicator called Performance Level (PL).

The standard defines five Performance Levels, ranging from PL(a) (lowest performance) to

PL(e) (highest performance).

The standard also defines the Performance Level that a given safety function must achieve

to reduce the risk to an acceptable level a value called Performance Level required (PLr).

2.3.1.1 Determining the Performance Level required (PLr)

As defined by the ISO 13849-1:2015 safety model, the minimum acceptable PLr for any given

safety function is based on three input parameters:

1. Severity of injury expected from the associated hazard

2. Frequency and/or duration of exposure to the associated hazard

3. Possibility of manually avoiding the associated hazard

The following table may be used to determine the acceptable PLr from these parameters.

Safety Function PLr Determination Table

Severity of injury

expected from hazard

Frequency and/or duration

of exposure to hazard

Possibility of manually

avoiding the hazard

Minimum

acceptable PLr

Slight injury (reversible)

Seldom to quite often

and/or exposure time is

short

Possible under specific

conditions

PL(a)

Scarcely possible

PL(b)

Frequent to continuous

and/or long exposure time

Possible under specific

conditions

Scarcely possible

PL(c)

Serious injury or death

(irreversible)

Seldom to quite often

and/or exposure time is

short

Possible under specific

conditions

Scarcely possible

PL(d)

Frequent to continuous

and/or long exposure time

Possible under specific

conditions

Scarcely possible

PL(e)

To demonstrate compliance with ISO 13849-1:2015, the minimum acceptable PLr of the

safety functions must be assessed for each identified hazard in the specific conditions in

which the machine is to be used.

The safety function PLr may be assessed as part of the regular Hazard and Risk

Assessment described in §2.4. Although this assessment includes all hazards intrinsic to the

Multi-Tip design, other safety functions may be necessary to address hazards specific to

your intended conditions of use. These can be assessed in the blank spaces provided.

2.3.1.2 Achieving the Performance Level required (PLr)

As standard, all hazards intrinsic to the Multi-Tip design are addressed by safety functions with

a minimum performance of PL(c).

Therefore, customised safety systems are only required in the following cases:

1. ds exist which have been addressed in

the standard Multi-Tip design, but which, due to conditions specific to their intended

conditions of use, require safety function performance of PL(d) or PL(e).

2. hich are entirely specific to

their intended conditions of use, and which have therefore not been addressed in

the standard Multi-Tip design.

3. The customer is subject to corporate policies, union contracts, OSH regulations or

other external factors which demand safety function performance of PL(d) or PL(e),

irrespective of the ISO 13849-1:2015 safety model.

In any of these cases, information about the required safety function PLr should be provided

to Simpro before placing an order. Simpro will then propose additional or uprated systems to

achieve the PLr in compliance with ISO 13849-1:2015. This may include any or all of the

following:

-Upgrade of control system architecture to Category 3 or Category 4

-Additional guarding panels

-Remote control systems

-Training of personnel

-Signage and floor markings

2.4 Hazard and Risk Assessment Guide

Most jurisdictions require machinery owners to conduct a Hazard and Risk Assessment for

their equipment, which considers all relevant factors such as the area it is used, the skill and

training of operators, the proximity of other persons, frequency of use, etc.

The following section is not a comprehensive site-specific Hazard and Risk Assessment, but an

assessment of the risk factors that are intrinsic to the Multi-Tip design. Blank template spaces

are provided for additional site-specific hazards.

The procedure for carrying out a Hazard and Risk Assessment is typically defined with

reference to ISO 12100:2010, issued by the International Standards Organisation. This

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 12

standard describes procedures for identifying hazards and estimating and evaluating risks

during relevant phases of a machine life cycle.

As with all industrial lifting equipment, certain

any guarding or safety measures implemented by the manufacturer. It is essential that

operators are aware of these residual hazards and what they must do to prevent harm to

themselves or to others, as set out in §2.4.3.

2.4.1 ISO 12100:2010 risk assessment model

In the ISO 12100:2010 risk assessment model, each identified hazard is given a Risk Factor,

from which is derived a Risk Evaluation. These parameters are determined as follows.

2.4.1.1 Determining the Risk Factor

The Risk Factor associated with any given hazard may be calculated from the following

table, using the formula: Risk Factor = LO x FE x DPH x NP:

2.4.1.2 Evaluating the Risk

Once a Risk Factor has been calculated, the risk can be evaluated using the following table:

LO

Likelihood of

Occurrence

FE

Frequency

of Exposure

DPH

Degree of

Possible Harm

NP

Number of

Persons at risk

0.1

Impossible, or

possible only in

extreme

circumstances

0.1

Infrequently

0.1

Scratch or

bruise

1

1 2 persons

0.5

Highly unlikely

though

conceivable

0.2

Annually

0.5

Laceration,

mild ill-health

2

3 7 persons

1

Unlikely but

could occur

1

Monthly

1

Break minor

bone or illness

(temporary)

4

8 15 persons

2

Possible but

unusual

1.5

Weekly

2

Break major

bone or illness

(permanent)

8

16 50 persons

5

Even chance

could happen

2.5

Daily

4

Loss of 1 limb

or eye/serious

illness

(temporary)

12

51 or more

persons

8

Probable, or not

surprising

4

Hourly

8

Loss of 2 limbs

or eyes/serious

illness

(permanent)

-

-

10

Likely, or only to

be expected

5

Constantly

15

Fatality

-

-

15

Certain, or no

doubt

-

-

-

-

-

-

Risk Factor:

0-1

2-5

6-10

11-50

51-100

101-500

501-1000

1001 +

Evaluation:

Negligible

Very

Low

Low

Significant

High

Very

high

Extreme

Unaccept

able

2.4.2 Identified Hazards

The following hazards have been identified that are intrinsic to the Multi-Tip design. For each

hazard a full Risk Evaluation has been completed and control measures described.

Blank template spaces are provided at the end for machinery owners to identify, assess

and control additional site-specific hazards.

Entanglement or amputation of fingers or limbs in moving parts

Operator

LO:

0.5

FE:

4

DPH:

1

NP:

1

Risk

Factor:

2

Operation of the Multi-Tip requires both hands on the control buttons. This

means the operator cannot reach any moving parts while using the machine.

Other

persons

LO:

1

FE:

4

DPH:

1

NP:

1

Risk

Factor:

4

The operator has a good view of the cradle while using the machine, and can

instantly stop all movement by removing either hand from the control buttons

if any persons approach the cradle while moving.

Control

measures

Operators are responsible to obey all instructions and warning signs regarding

keeping themselves and others clear of moving parts.

Comments

The Multi-Tip is designed so trapping hazards are minimized, and both hands

are needed to operate the machine.

Crushing due to unauthorized rapid descent of cradle

Operator

LO:

0.5

FE:

4

DPH:

2

NP:

1

Risk

Factor:

4

The operator is protected from the cradle by the frame and guarding during

operation. There is nothing to stop an operator or other person moving under

the cradle while it is inverted. Significant safety margins ensure that the

probability of failure of any steel, hydraulic, or control parts failing is low.

Other

persons

LO:

0.5

FE:

4

DPH:

2

NP:

1

Risk

Factor:

4

As above.

Control

measures

Operators are responsible to obey all instructions and warning signs regarding

keeping themselves and others away from the area beneath the cradle while

it is raised.

The machine must be regularly maintained, and all faults repaired

immediately.

Comments

A hydraulic speed-control valve limits the maximum speed of descent in

normal use.

Operator or others being hit by falling or flying debris

Operator

LO:

2

FE:

4

DPH:

0.5

NP:

1

Risk

Factor:

4

The operator is protected from the cradle by the frame and guarding during

operation. There is some risk if product such as broken glass is being tipped.

Other

persons

LO:

1

FE:

2

DPH:

0.5

NP:

1

Risk

Factor:

1

There is some risk if product such as broken glass is being tipped.

Control

measures

Operators are responsible to obey all instructions and warning signs regarding

keeping other persons away from the machine while in use.

If tipping items such as glass, metal or liquids, glasses and gloves should be

worn.

Comments

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 14

Crushing due to machine falling over

Operator

LO:

1

FE:

4

DPH:

8

NP:

1

Risk

Factor:

32

Relatively low risk as the Multi-Tip is very stable, and the bin centre of gravity

Other

persons

LO:

1

FE:

1

DPH:

8

NP:

1

Risk

Factor:

8

As above.

Control

measures

Do not operate on soft ground, or ground with slope ratio greater than 1:12.

Never attempt to empty liquids from closed-top drums.

Comments

Electrocution or electric shock

Operator

LO:

0.5

FE:

4

DPH:

15

NP:

1

Risk

Factor:

30

Some risk is always present with mains leads.

Other

persons

LO:

0.5

FE:

4

DPH:

15

NP:

1

Risk

Factor:

30

As above.

Control

measures

Ensure a Residual Current Device (RCD) is fitted to all power sockets. Check all

leads frequently and repair or replace if damaged. All leads should be

checked and tagged by a registered electrician at regular intervals.

Comments

Mains-powered Multi-Tips are earthed and comply with AS60204.1.

The charger on battery-powered Multi-Tips is double-insulated.

Illness caused by tipping toxic powder and liquid

Operator

LO:

1

FE:

4

DPH:

1

NP:

1

Risk

Factor:

4

Great care should be taken when tipping powder or liquids.

If the product could cause any harm whatsoever to the operator or to any

other person, ensure all persons are well protected.

Other

persons

LO:

0.5

FE:

4

DPH:

1

NP:

2

Risk

Factor:

4

As above.

Control

measures

The operator must wear appropriate protective equipment, and ensure that

all other persons are well clear of the area.

Powder should only be tipped when there is no wind, and/or a wind shield

should be installed.

Comments

Toxic substances that cannot be protected against with PPE should not be

dumped using a Multi-Tip. Alternative methods should be used.

Damage to skin when used in extreme weather conditions

Operator

LO:

2

FE:

4

DPH:

1

NP:

1

Risk

Factor:

8

If the machine is to be used in extreme cold or heat, the operator must wear

gloves and other suitable Personal Protective Equipment.

Other

persons

LO:

2

FE:

4

DPH:

1

NP:

1

Risk

Factor:

8

As above.

Control

measures

Operators are responsible to wear Personal Protective Equipment suitable for

the environment in which the machine is being used.

Comments

See §1.8 for Multi-Tip environmental restrictions.

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 16

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

Site-specific hazard:

Operator

LO:

FE:

DPH:

NP:

Risk

Factor:

Other

persons

LO:

FE:

DPH:

NP:

Risk

Factor:

Control

measures

Comments

2.4.3 Residual Hazards

As with all industrial lifting equipment, certain

guarding or safety measures implemented by the manufacturer.

The machinery owner has a legal responsibility to identify such residual hazards, and to take

all reasonable precautions to eliminate, isolate, or minimize them. This may include any or all

of the following:

-Monitoring and enforcing the training of operators.

-Design and implementation of Standard Operating Procedures.

-Using disciplinary measures to enforce the Standard Operating Procedures.

-Posting signage, floor marking, or other warnings as appropriate.

-Taking steps to develop a culture of safety-awareness and open communication

within the workplace.

2.5 Safety Norms

The following safety norms must be observed for the safe use of a Multi-Tip bin lifter.

Only trained and authorised personnel may use the

machine.

Operators must read and obey all instructions

displayed on the machine.

Never operate the machine on soft ground, or

ground with a slope ratio greater than 1:12.

Never operate the machine on the edge of a raised

loading dock or platform.

Never operate machine with any covers or guards

removed.

Never attempt to empty the contents of closed-top

drums, unless the machine is securely bolted down.

All persons other than the operator must keep at

least 2 metres clear while the machine is in use.

Always keep hands and feet well clear of the bin and

cradle when operating.

Never place limbs, feet or foreign objects under or

through the guarding panels.

Never attempt to empty over-filled bins, or bins

weighing more than 150kg.

User Manual // Simpro Multi-Tip®

Original Instructions // English // v56.0 // November 2021 // Page 18

Before connecting machine to mains supply,

ensure voltage and frequency correspond with

that listed on the rating plate.

Do not use an extension lead longer than 15

metres to connect the machine to mains power.

Do not operate if power lead, insulation or power

plugs are damaged.

Do not connect a damp power plug or socket.

Ensure the power supply socket is fitted with a

residual current device.

Ensure there is complete continuity between the

machine and an effective earthing system which

complies with local and national regulations. The

manufacturer cannot be held liable for the

consequences of an inadequate earthing system.

3.Operating Instructions

3.1 Before operation

Before operating a Multi-Tip, check the following to ensure that the machine is stable and

safe to use:

1. The machine is on firm ground with a slope ratio of less than 1:12.

2. All covers and safety guards are in place.

3. The wheel brakes are applied.

4. All personnel other than the operator are well clear of the machine.

5. The cradle is fully lowered.

6. The key is inserted and turned to the ON position.

7. The battery indicator (if fitted) shows an acceptable level of charge.

3.2 Emplacing and removing bins

All personnel using the machine must know how to correctly emplace and remove bins

from the machine. Bins that are not correctly emplaced may come loose and damage

the machine while being lifted, or fall out when inverted.

The bin cradle is designed to allow bins to be emplaced and removed easily, while also

holding them securely throughout the lifting and tipping cycle. A range of different cradles

may be installed, depending on the types of bin that the machine needs to empty. Use the

following table to identify the correct instructions for your machine.

3.2.1 Cradle identification

Cradle

Usage

Bin Compatibility

Cradle Image

See

Type-E

(EN840

base-lift

cradle)

Standard waste

and recycling

applications in EU,

UK, AU, NZ, Asia,

Africa, and parts of

South America

EN840 mobile

garbage bins

(wheelie bins)

-60L

-80L

-120L

-140L

-240L

§3.2.2

Type-C

(EN840

comb-lift

cradle)

Specialised waste

and recycling

applications

(primarily with 360-

litre bins) in EU, UK,

AU, NZ, Asia,

Africa, and parts of

South America

-60L

-80L

-120L

-140L

-240L

-360L

§3.2.3

Other manuals for Multi-Tip

2

Table of contents

Other Simpro Lifting System manuals

Simpro

Simpro MegaDumper User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro QUIKSTAK QS10MM User manual

Simpro

Simpro EUROVER User manual

Simpro

Simpro MegaDumper Series User manual

Simpro

Simpro Multi-Tip 1600 User manual

Simpro

Simpro Multi-Tip MT1200 User manual

Simpro

Simpro Microstacker User manual

Simpro

Simpro Dumpmaster User manual

Popular Lifting System manuals by other brands

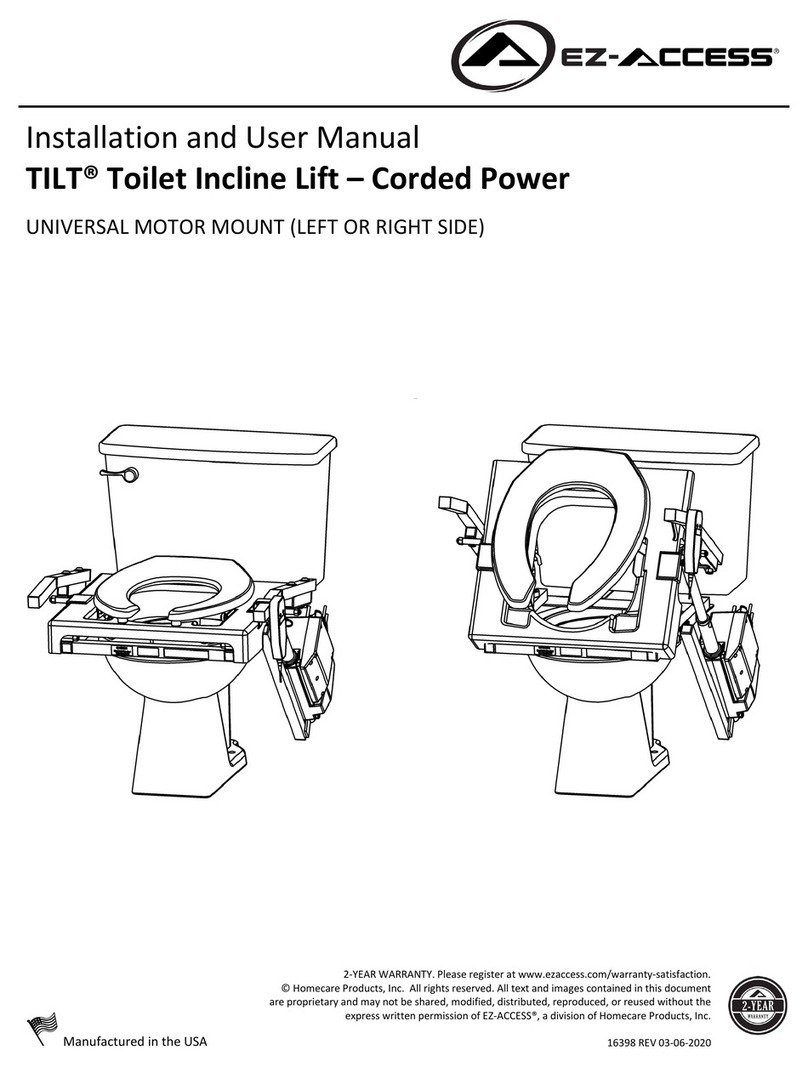

HOMECARE PRODUCTS

HOMECARE PRODUCTS EZ-ACCESS TILT Toilet Incline Lift Corded... Installation and user manual

Poweramp

Poweramp CM Series Owner & user manual

WITTUR

WITTUR servogearless WSG-S2.3 Operating instruction

MW TOOLS

MW TOOLS HB240 manual

Rockler

Rockler 69191 operating instructions

Genie

Genie S-105 Operator's manual