Big Sprinkler 4200HR Instruction Manual

Instruction Manual for Operation & Maintenance

BigSprinkler.com | 15250 Sunshine Rd. Yukon, OK. 73099 | 1-855-805-7901

Model 4200HR

Thank you for purchasing a Lay-Flat Hose Quick Reel Model 4200HR. Please read this manual

carefully before operation in order to become familiar with all components and their function. Safety

is the main priority and failure to follow these instructions may cause serious injury. Neither Lay-Flat

Hose Quick Reel Model 4200HR nor BigSprinkler.com are to be responsible for machine failure or

personal injury if these procedures and operation instructions are not followed.

Personal injury and/or equipment damage may result if proper safety precautions are not observed.

• ALWAYS REMOVE THE HANDLE WHEN UNWINDING HOSE TO PREVENT

BODILY HARM!

• Be aware of personnel around the reel when operating the reel.

•Donotwearloosettingclothingwhileoperatingthereel.

• Ensure that the reel has been properly secured before using the reel to wind or

unwind hose.

•Allowhosetobeabletodrainfreelyofstoredwateroruidbeforestoringhose

on reel.

• Treat and respect the hose reel as any other piece of machinery, observing all

common safety practices

!

Introduction

Caution !!

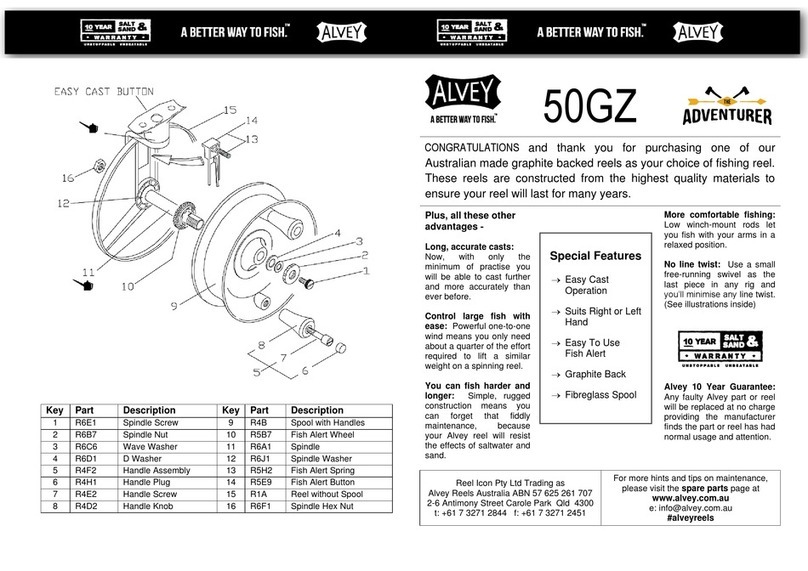

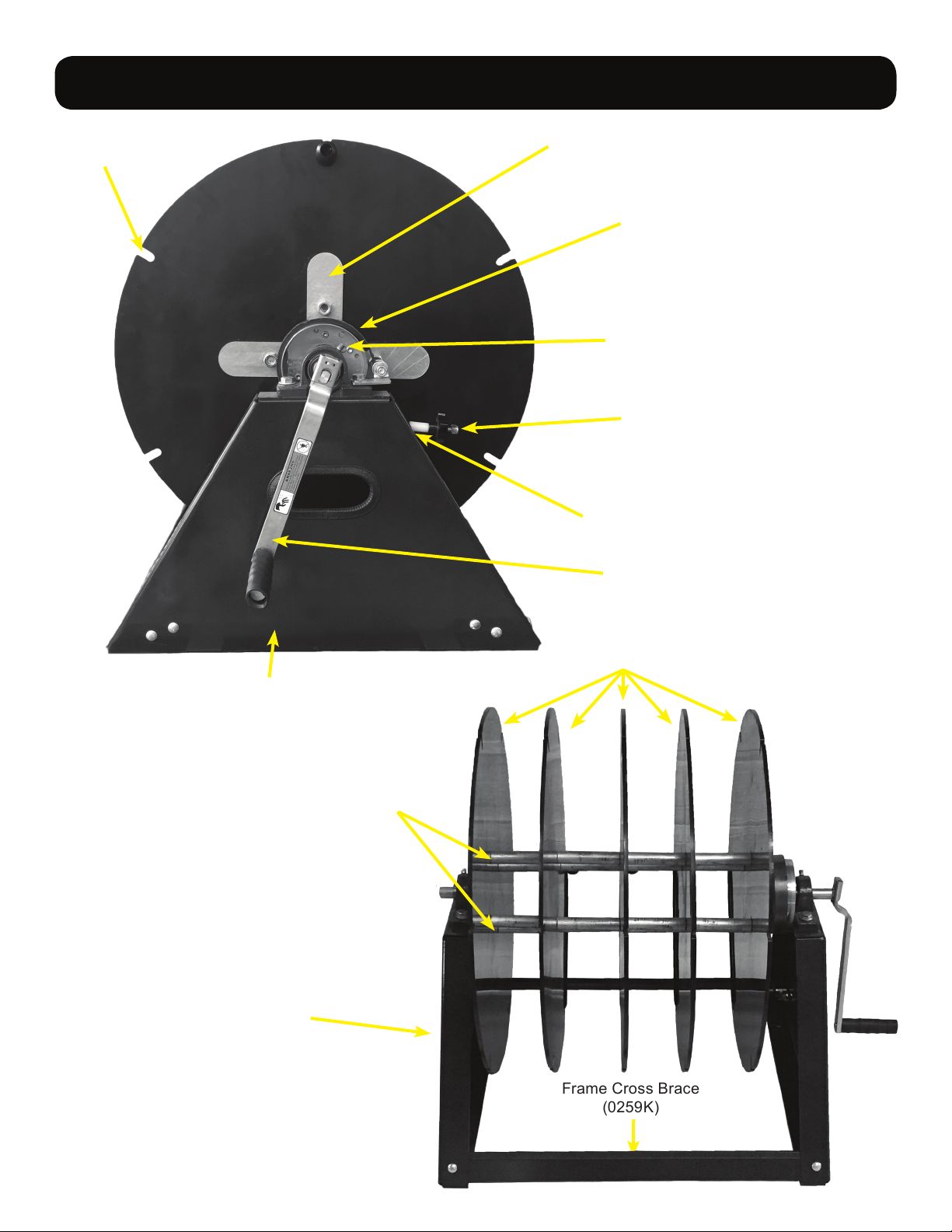

Drum Mount - Side Plate

(0255K)

Brake Tension-Adjustment Knob

(0272K)

Nylon Spacer

(0273K)

Frame - Side Plate (Crank Side)

(0257K)

Frame - Side Plate (Non Crank Side)

(0258K)

HDPE Hose Dividers

(0267K)

Inner Hub - Spacer

Frame Cross Brace

(0259K)

Brake Band

(0271K)

Brake Drum

(0270K)

Crank Handle

(0265K)

Open Slot for

Bungee Strap

Machine Controls & Components

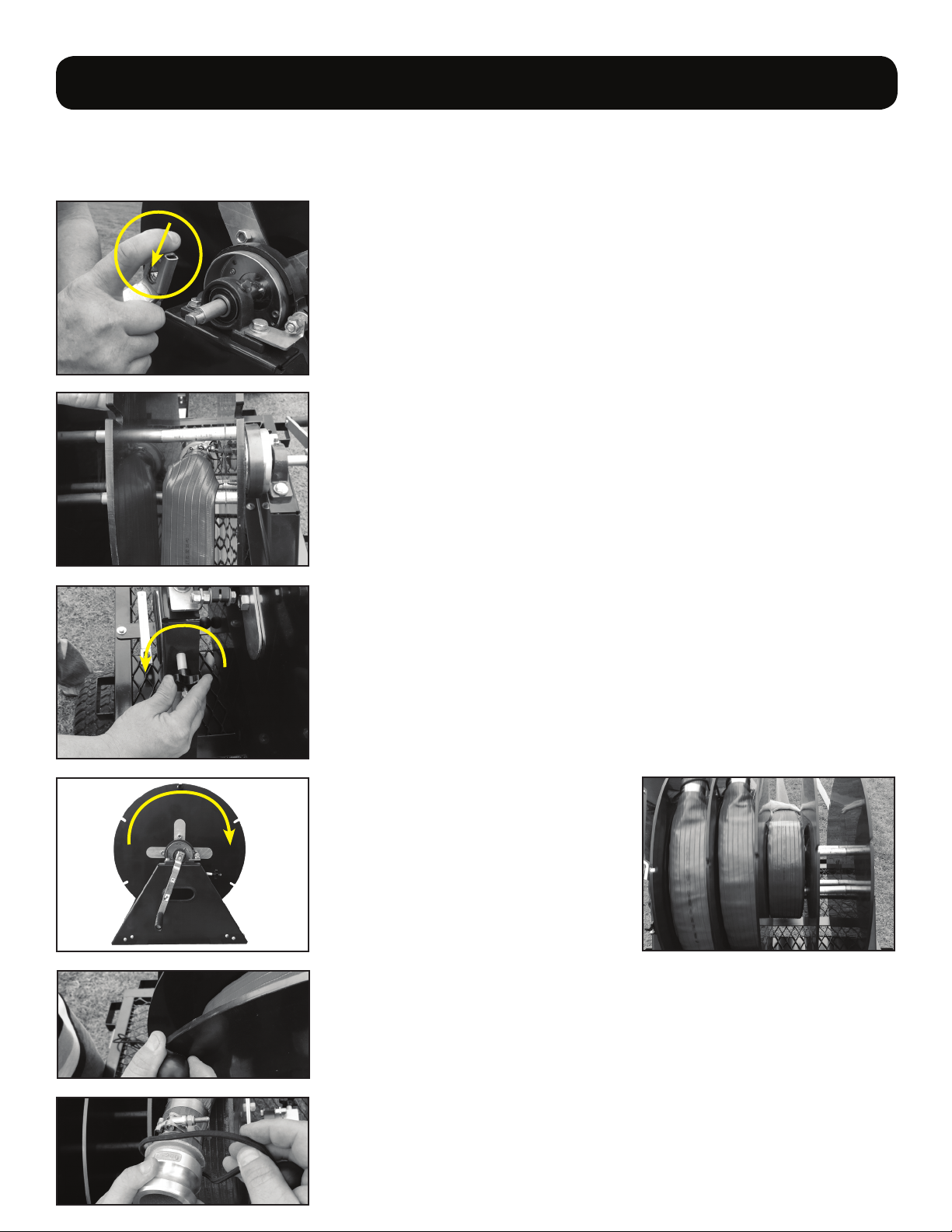

Topreventinjury,theoperatorshouldrstcheckthatthehandcrankhasbeen“REMOVED”

from the reel before deploying hose. Care should be taken to ensure that the hose does not kink

or get entangled while being taken off the reel.

1) ALWAYS REMOVE CRANK HANDLE

• Depress the end of the crank in

order for the handle to be slip off of

the crank shaft.

• Secure the crank handle by inserting

in the 2 mounted clips.

2) Unhook the bungee strap from slot on the divider and remove

from the hose end.

3) Apply brake tension on the reel to prevent the hose from

unwinding faster than the rate of deployment.

• To increase brake tension, turn the brake adjustment knob to

the right until the preferred tension is reached.

(Note: Brake tension will help to prevent the reel from continuing to freely turn

with momentum during deployment.)

4) Pull the hose in a straight path away from the hose reel until

the entire hose has been deployed.

(NOTE: Deploying the hose at an angle away from the machine may damage

to the hose and reel.)

5) Once the hose is fully

deployed, dislodge the end

connector of the hose from

between the center-hub

rodsof the hose reel and

fully remove the hose from

the reel.

Deployment of Hose

Retrieval of Hose

The water and pressure in the hose should be relieved and allowed to completely drain prior to

rewinding. Care must be taken so that the hose does not kink or twist during winding.

1) Re-Attach crank handle to drum shaft as shown.

• Depress and hold the top of the crank handle to allow the

handletotsecurelybackontothecrankshaft,then

release to lock crank handle in place.

2) Select an open slot on the reel and feed the hose end connection

through the opening between the center-hub spacers so the hose

can be secured to begin retrieval.

(Note: Hose should be disconnected at the end allowing water to freely drain from

the hose before winding onto the reel.)

3) Decrease the brake tension so the reel can freely turn. This

will allow for easier hose retrieval.

• To decrease brake tension, turn the brake adjustment knob

to the right until the preferred tension is reached.

4) Turn the crank handle clock-

wise to begin retrieval. The hose

should begin to coil on top of itself

between the hose dividers.

(Note: If the hose becomes snagged

during rewind, clear or free the hose

by hand, do not use the crank to break

hose free.)

5) Upon reaching the end of your hose, use the bungee cords to

secure the hose in place.

• Use the bungee cord to loop around the end connection of the

hose and then stretch bungee to slip into an “open slot” on the

divider that will keep the hose secure.the hose dividers.

(Note: Once all you hose is retrieved, increase the brake tension on the reel

enough to prevent the reel from freely turning.)

If you experience any problems with your Quick Reel, please contact a representative at Big

Sprinkler for assistance. (855) 805-7901.

Troubleshooting

Maintenance Schedule

Bearings: Grease 1 time per year

Options

Quick Reel and ATV Trailer

Model 4200HR-TM

The Flatbed ATV cart has a sturdy 34 in. x 48 in. expanded metal

deck with 16 gauge steel tube frame supporting up to a 1000 lb.

The trailer can be pulled by an ATV or UTV.

• Expandedmetalatbed;1000lb.loadcapacity

• Deck tilts to dump load

• 18 in. ATV wheels with roller bearings

• 1 in. steel axle

• Blackpowdercoatnishresistsrust

• Hitch pin included

BigSprinkler.com

Distributor, Dealer/Seller, Purchaser Agreement

Limited Warranty and Remedy

BigSprinkler.com is committed to providing our customers with quality irrigation products. If at any timea product falls

short of your expectations due to defective workmanship or materials, the following will apply.

Warranty

BigSprinkler.com warrants to the original purchaser only of the products described in the face hereof as of the date

of the original invoice, that the product is merchantable and free from defects in material and workmanship. Warranty

shallbeprovidedbytheoriginalmanufacturerofproductssoldonBigSprinkler.comforthelengthoftimespeciedby

the manufacturer of the given product.

Remedy

If BigSprinkler.com determines that the above warranty was breached with respect to any part or component provided

bythemanufactureroftheproduct(andifallconditionssetforthbelowhavebeensatised)then,

a) BigSprinkler.com will (at BigSprinkler.com’s option) provide purchaser a refund of the purchase price

less the freight costs to or from the customer, or provide a replacement product of the same kind.

b) All remedies provided herein are for goods only, no labor or freight allowance for return goods is

implied. This warranty extends only to the original purchaser of products purchased from BigSprinkler.

com.

Conditions to Enforceability and Claims:

1) Product has been maintained and operated within the guidelines outlined in the manufacturer’s product guide and

maintenance manual.

2) Product warranty shall be considered void if any component or function of the equipment has been altered in any

form other than what has been provided or intended by the original product manufacturer.

3) Any return must be submitted on form provided by BigSprinkler.com in writing immediately and in no event longer

than 20 days from occurrence. You can reach our sales department through the “contact us” form on our website

should such an event occur.

4) Purchaser must return all goods within 30 days of BigSprinkler.com’s authorization date, that have been determined

by BigSprinkler.com to be defective to the Purchaser with Purchaser being responsible for freight.

Limitations:

NeitherBigSprinkler.comnoritsafliatesshallbeliableforanyincidentalorconsequentialdamages(includingbut

notlimitedto,damagesforinjurytotheperson,propertyorlostturf,cropsorprots)byreasonofanydefectinthe

equipment or its manufacture, design, or function.

Table of contents

Popular Cables And Connectors manuals by other brands

Schneider Airsystems

Schneider Airsystems SLA 8 A Original operating manual

Factor Electronics

Factor Electronics HD-1x4-4K user manual

Philips

Philips SWV3232W Specifications

Knoll

Knoll DIR55 instructions

Altera

Altera USB-Blaster user guide

CommScope

CommScope SYSTIMAX 360 iPatch 360-iP-G2-1U-LC-FX instructions