Bigab 20-24 User manual

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com 1

Table of contents

1. INTRODUCTION .................................................................................................2

1.1. PURPOSE......................................................................................................2

1.2. TECHNICAL SPECIFICATIONS................................................................3

1.3. DESIGN OF THE DEVICE ..........................................................................4

1.4. MAIN MODULES.........................................................................................5

1.5. SAFETY DEVICES.....................................................................................13

2. INSTALLATION ................................................................................................20

2.1. UNPACKING..............................................................................................20

2.2. ADJUSTMENTS.........................................................................................20

2.3. WITHDRAWAL FROM USE AND STORAGE........................................20

3. FUNCTIONAL DESCRIPTION.........................................................................21

3.1. HANDLING IN ROLL ON – ROLL OFF ..................................................21

3.2. HANDLING IN TIPPING...........................................................................23

3.3. OPERATION WHEN DRIVING................................................................24

3.4. CHANGING OPERATING FUNCTION ...................................................25

3.5. ELECTRICAL SYSTEM ............................................................................26

3.6. HYDRAULIC SYSTEM.............................................................................28

4. SAFETY INSTRUCTIONS.................................................................................30

4.1. GENERAL...................................................................................................30

4.2. WORKING AT EXTREME CONDITIONS...............................................32

4.3. ACTING IN DANGEROUS SITUATION .................................................32

5. MAINTENANCE / SPARE PARTS ...................................................................34

5.1. MAINTENANCE SCHEDULE ..................................................................34

5.2. MAINTENANCE OPERATIONS ..............................................................35

5.3. SPARE PARTS............................................................................................40

6. TROUBLESHOOTING.......................................................................................51

Factory:

CONTACT INFORMATION:

AS FORS MW

Tule 30

765 05 Saue

Estonia

Tel: + 372 679 00 00

Fax: + 372 679 00 01

E – mail: [email protected]

Aftermarket:

Language spoken is English and Swedish.

FMW Farma Norden AB

Hornsväg 2

605 97 Norrköping

Sweden

Tel: + 46 (0) 165 770

Fax: + 46 (0) 128 370

E – mail: afterm[email protected]

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

2

1. INTRODUCTION

1.1. PURPOSE

Bigab hook lift trailer exists in 9 different types of modules with a variety of

additional extras which all has it’s own purpose but with the same unique flexibility.

The flexibility lays in its ability to handle different kinds of loads on one and the same

chassed. This allows the Bigab to be used at a wide range of different user

applications.

Bigab 20 – 24 is the largest trailer within our assortment. Simple, impressive

and powerful are expressions that all suit the Bigab 20 – 24. This is a trailer for those

in need of extra heavy transportation.

For your safety, it is extremely important that you follow the instructions

presented in this instruction manual for your particular BIGAB model.

The unique flexible system gives operators the most cost effective and flexible

transport system available. Behind the Bigab trailers lays more then forty year of

knowledge and 25 years of product development.

We understand that you are anxious to get to work the trailer, but stop for a bit

and take time to carefully read through this instruction book. The Bigab trailer is

unique which also if not used properly could turn out to be dangerous. A few

moments reading through the instruction book might save you time and money in the

future. We congratulate you at your chose of trailer and wish you and your Bigab all

the best for the future!

EU declaration of conformity with Directive 2006/42 EC

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

3

1.2. TECHNICAL SPECIFICATIONS

Technical specifications.

Table 1.

Hooklift trailer 20-24

Frame:Hollow sections 300*100

Bogie:Pendulum Axel distance 1470 mm

Hubs: 110*110, 10 bolts

Wheels: 600/50-22,5

Brake: Hydraulic drum *Depending on market 400*120 on 4 wheels

Towing eyelet: Type for hitch hook

Support leg: Manual yes

Light system:12 volt yes

Tractor hydraulic: *For brakes 3 double, *1 single action

Oil volume: With system filled 23 L

Oil volume cylinders: Press 89 L, draw 66 L

Oil flow: 60 – 120 L/min

Hydraulic pressure: 22 Mpa

Tipp angle: 50 degrees

Chassi weight (±1%): Standard equipped 4300 kg

Chassi length (±50mm): 7925 mm

Distance eyelet to centred bogie (±20mm): 6270 mm

Distance eyelet to ground surface: 475

Height at skid surface: 1240 mm excluding the hook frame

Wide over tyres (±30mm): 2660 mm

Container length: 5500-6500 mm

Total weight (±1%): 24300 kg

Max load including container (±1%): 20000 kg

Max hooking load including container (±1%): 20000kg

Pressure on eyelet: depending of lenght of container and load 2500 –4500 kg

Max speed: 40 km/h

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

4

1.3. DESIGN OF THE DEVICE

The Trailer is constructed out of cold hollow steel sections. Through this

construction the trailer receives maximum endurance and stiffness regarding both

bending as well as twisting. The trailer is steady both in the tip as well as in the

changing movement. The trailer is equipped with a strong pendulum bogie that has

been equipped with brakes on all wheels.

Figure 1. Design of the device

Chassis

Hook

Wheels

Back frame

Hook frame

Rollers

Support leg

Towing eyelet

Roll on – roll off position

Tipping position

Telescope

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

5

1.4. MAIN MODULES

The trailer consists of the following subassemblies and functional devices.

1.4.1. Chassis

Chassis is constructed out of cold hollow steel sections. It exists in two

different variants. Chassis for Bigab with bogie block system (figure 2a) and chassis

for Bigab with frame block system (figure 2b).

Figure 2a. Chassis with bogie block system

Figure 2b. Chassis with frame locking system

Rear beam

Bracket for bogie block cylinder

Bogie axle brackets

Bracket for bogie lift cylinder

Guide

Towing eyelet

Coupling

hitch

Brackets for frame locking

system

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

6

1.4.2. Back frame

Back frame is constructed out of cold hollow steel sections

Figure 3. Back frame

1.4.3. Hook frame

The hooking frame with hydraulic telescope cylinder is constructed from sheet

metal.

Figure 4. Hooking frame

Hook

Frame

Frame

Telescope

Stroke 1300 mm

Hydraulic cylinder (inside)

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

7

1.4.4. Bogie

The Trailer is equipped with a strong pendulum bogie that has been equipped

with brakes on all wheels.

Figure 5. Bogie

1.4.5. Hook

The Trailer is equipped with adjustable hook for two different standard

heights.

Standard height: 1450 mm

Standard height: 1570 mm

Figure 6. Hook

Brake cylinder

Axle with brake

Body

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

8

1.4.6. Support leg

Support leg is designed to be of supporting use when the trailer is under

maintenance or when trailer is not in use. Before driving the support leg must be lifted

up and fixed with the pin. Also available is adjustable support leg as additional

equipment.

Figure 7. Support leg

1.4.7. Changing operation unit

This unit is designed for changing operation from rolling on - rolling off to

tipping. The changing unit is located in the middle of the back frame.

Figure 8. Changing operation unit

Hydraulic cylinder

Sliding pin

Back frame

Support leg

Pin

Chassis

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

9

1.4.8. Towing eyelet

The eyelet is used to hitch the trailer to the pulling vehicle. It is extremely

important that the towing eyelet is checked for defaults every time the trailer is used.

The towing eyelet needs to be replaced at least once a year. It is the users

responsibility to see to that this is done.

Figure 9. Towing eyelet

1.4.9. Coupling hitch

The coupling hitch is used for coupling other trailed devices to the trailer.

Coupling hitch is also used for coupling reflector.

Figure 10. Reflector Figure 11. Coupling

hitch

Rear beam

Pin

NB! Max load 10 ton

Chassis

Towing eyelet

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

10

1.4.10. Steering rollers

The steering rollers are designed to guide the container. During handling roll

on – roll off the container frame must be inside the rollers.

Figure 12. Steering rollers

1.4.11. Bogie block

The hydraulic bogie block is used for bogie blocking during the handling of

roll on – roll off.

Figure 13. Bogie block

Pin

Chassis

Bogie block hydraulical

cylinder

Steering

roller

Steering roller

Chassis

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

11

1.4.12. Frame locking

The hydraulic frame locking is used for frame blocking during the handling of

roll on – roll off.

Figure 14. Frame lock

1.4.13. Wheels

Wheels

Table 2.

Trailer type

Standard wheel type

Alternative wheel

type

Air pressure

(bar)

Speed

(km/h)

20-24

600/50-22,5

3,6

40

600/55-26,5

3,2

40

700/50-26.5

2,8

40

445/65R-22.5

5-10

40

* The air pressure might be different between different wheel manufacturers. For exact air

pressure we recommend taking contact with the wheel manufacturer.

Frame lock hydraulical

cylinder

Chain to the tractor

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

12

1.4.14. Hydraulic system

The trailer is equipped with a hydraulic system for working movements. See

chapter 3.5

1.4.15. Electrical system

The trailer is manufactured with 12V electrical system. See chapter 3.4

1.4.16. Brake system

The trailer is equipped with hydraulic brake system. Also is available

pneumatic brake system as an additional extra.

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

13

1.5. SAFETY DEVICES

1.5.1. Security post

Always use the safety support when carrying out service work in the tipped position.

The safety support may not be used under any circumstances when the container

bridge is loaded.

Figure 15. Security post

1.5.2. Locations of decals on the trailer

The trailer is equipped with a range of signs relating both to safety and information.

Check that all the signs are in the correct positions.

Figure 16. Location of the decals on the trailer

Security post

Chassis

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

14

1.5.3. Presentation of decals

Figure 17. Warning triangle and instruction manual decal.

The trailer is supplied with a warning triangle alongside the instruction manual

decal in order to reinforce the requirement for the user to read the entire

instruction manual carefully before starting to use the trailer. Ignoring this can

entail a danger to life.

Figure 18. Decal for the use of safety equipment.

These decals challenge the user to employ appropriate safety equipment in

order to avoid injury when using the trailer.

Figure 19. Risk of clamping injuries

There is a risk of clamping or crushing injuries during work and maintenance.

Figure 20. Hazardous area

Standing between the trailer and the towing vehicle when the trailer is being

operated, moved with frame steering or when other functions are activated

between trailer and tractor, can be potentially fatal. As the driver, you must

always ensure that the area around the machine is free of people.

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

15

Figure 21. Risk of slipping

There is a risk of slipping as the surfaces of the trailer can be slippery due to

precipitation in combination with pre-existing oil and/or clay on the surface.

The ground around the trailer can also become slippery, as the tyres can tear

up the surface and expose clay and soil.

Figure 22. Hydraulic fluid under pressure

Hot hydraulic fluid at high pressure levels can occur in the hydraulic system.

Take care when connecting, and replace poor quality hoses.

Figure 23. Using the exchange unit

The exchange unit may not be operated unless the frame is folded down.

During transport with the trailer, the hook must be folded down in the parking

position.

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

16

Figure 24. Use the safety support during all service

Leaning under the raised frame is absolutely prohibited unless it is

blocked with the safety support. Under no circumstances may the

trailer be carrying either a load or a container when using the safety

support.

Figure 25. Max. load

It is absolutely prohibited to load more than the amount your model is

intended to handle. This can result in danger to you and your

surroundings.

Figure 26. Max. pressure on towing eyelet

Ensure that you do not load in such a way that the pressure on the

towing eyelet exceeds the permitted laws and regulations. The

trailer is designed for a maximum pressure of 3,500 kg on the

towing eyelet. The pressure is largely determined by the way the

load is distributed on the container bridge, and it is the user’s

responsibility to ensure that this is not exceeded.

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

17

Figure 27. Tyre inspection

The tyres must be tightened and the brakes checked regularly at a

minimum interval of 40–50 kilometres.

Figure 28. Lubrication.

This decal is used to show the importance of regular lubrication of the

trailer.

Figure 29. Data plate

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

18

Nut tightening torque

Table 3.

Nuts with spherical

collar,conical nuts.

Screws with

spherical collar.

Thread

Dished discs

Flat discs st 37

Flat discs St52

Screw Class.

8.8

Screw Class.

10.9

N.m.

M18x1,5

310

330

460

M20x1,5

-

490

630

M22x1,5

-

630

740

Flat collar nut with

lock washer

M18x1,5

210

270

360

M20x1,5

-

360

450

M22x1,5

-

460

550

Nut with flat seat

captive washer

M18x1,5

260

360

M20x1,5

350

500

M22x1,5

450

650

Screwed connection

disc/rim on track

adjustable wheels

Thread

Flat discs

Screw Class. 8.8

M18x1,5

260-330

Figure 30. Lubricate points.

All of the hydraulic hoses of the trailer are marked with colored labels. See

table below for more detailed information. Functions depend of the hydraulic system

configuration.

Figure 31. Hydraulic hose label (example tipping cylinder)

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

19

Hose label colors:

•Red - oil from pump.

•Blue - oil to tank.

•Yellow - Brake

Marking for hydraulic hoses

Table 4.

No.

Color mark

Function

1

Yellow

Brake

10

Red

Tipping cyl. ( up )

11

Blue

Tipping cyl. ( down )

12

Red

Tower ( front )

13

Blue

Tower ( back )

14

Red

Telescope ( in )

15

Blue

Telescope ( out )

16

Red

Frame-lock for tipping

17

Blue

Frame-lock for hooking

18

Red

Bogie-block ( on )

19

Blue

Bogie-block ( off )

20

Red

Bogie-lift ( on )

21

Blue

Bogie-lift ( off )

22

Red

Extra port ( a )

23

Blue

Extra port ( b )

24

Red

Rear tailgate ( a )

25

Blue

Rear tailgate ( b )

26

Red

Steering control ( p )

27

Blue

Steering control ( t )

28

Blue

Straight steering control (t)

20-24

© 2005 Ver. 1 Fors MW Ltd www.forsmw.com

20

2. INSTALLATION

2.1. UNPACKING

Before unpacking, check visually that the trailer is not damaged during

transportation. If the trailer is damaged, inform about this to the company that

transported the trailer and the manufacturer of the product immediately.

•Usage of the trailer is strictly forbidden if safety devices of the trailer are

damaged. For more detailed information about safety devices see 1.5

•When you are unpacking the trailer be careful: do not damage sensitive

components, do not change factory settings or damage paint or other

surface finishes.

•Lift up the trailer from transportation frame.

•Lower the trailer to the floor.

•Be careful when lifting so that cables, connectors or other components are

not damaged for instance between lift work and trailer frame.

•Weight depends of each type of trailer see technical information for data.

2.2. ADJUSTMENTS

Quick couplings are used in the operation of connecting the vehicle in use with

the trailer. These couplings serve to disconnect the hoses without their breakage

and to prevent loss of oil under accidental strain and pull.

2.3. WITHDRAWAL FROM USE AND STORAGE

•It is not allowed to store the trailer in a cold and/or damp environment for a

long period.

•All metal parts are recyclable and should when time comes be handed over to

a recycler.

This manual suits for next models

3

Table of contents

Other Bigab Lifting System manuals

Popular Lifting System manuals by other brands

Bruno

Bruno CRE-2110 Operator's manual

Power Towers

Power Towers pecolift Operating and maintenance manual

Oshkosh

Oshkosh JLG 400S Service and maintenance manual

Lippert Components

Lippert Components ground control 3.0 user manual

WilTec

WilTec 61127 operating manual

RITE-HITE

RITE-HITE RHE-300 installation manual

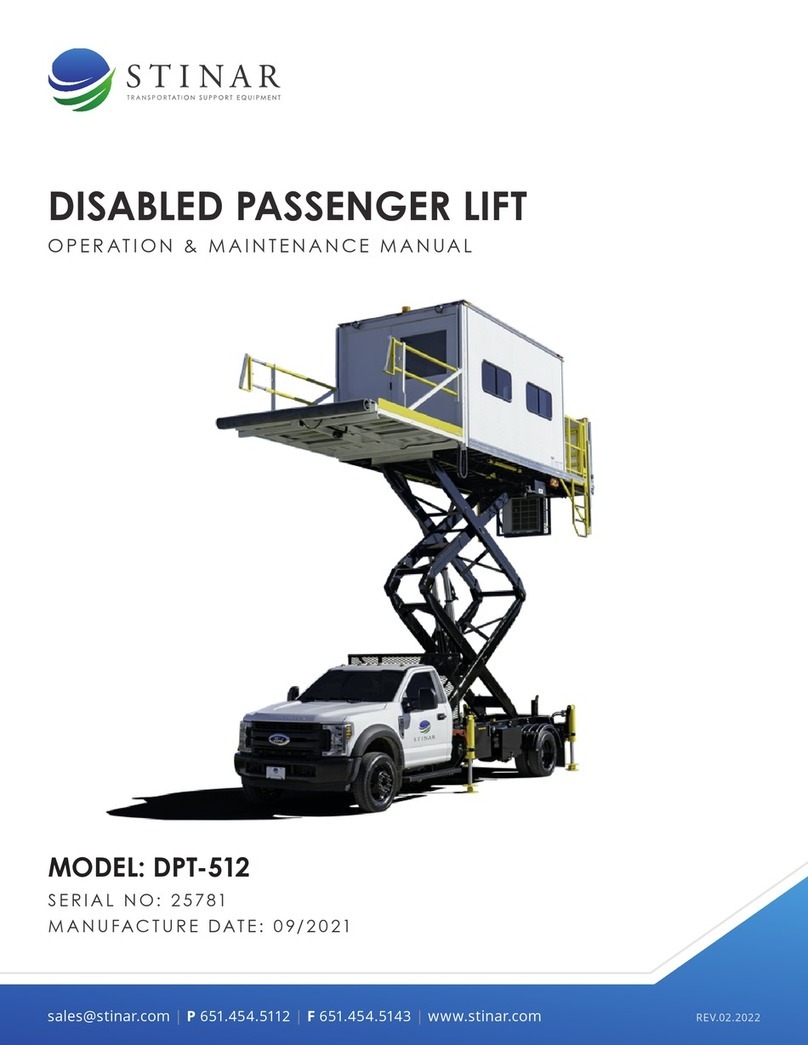

STINAR

STINAR DPT-512 Operation & maintenance manual

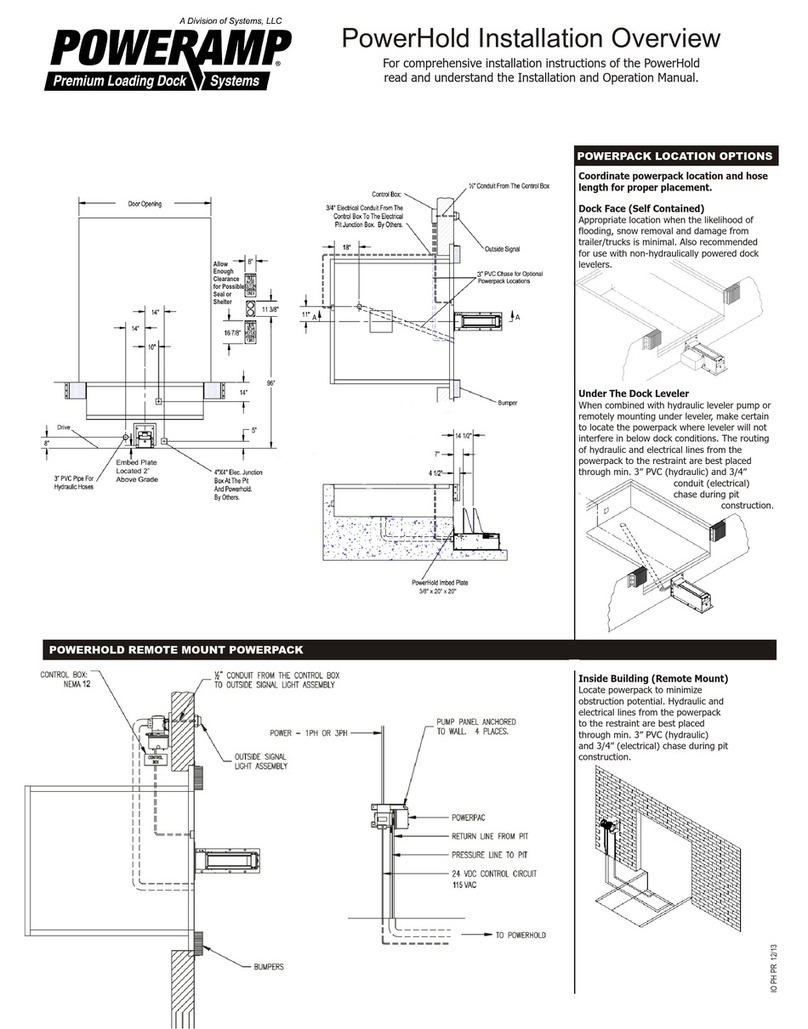

Poweramp

Poweramp PowerHold Installation overview

R. Beck Maschinenbau

R. Beck Maschinenbau HS 300 MIDI operating manual

Mec

Mec Speed Level 2684 RT Service and parts manual

Custom Equipment

Custom Equipment Hy-Brid Lifts 2 Series Maintenance and troubleshooting manual

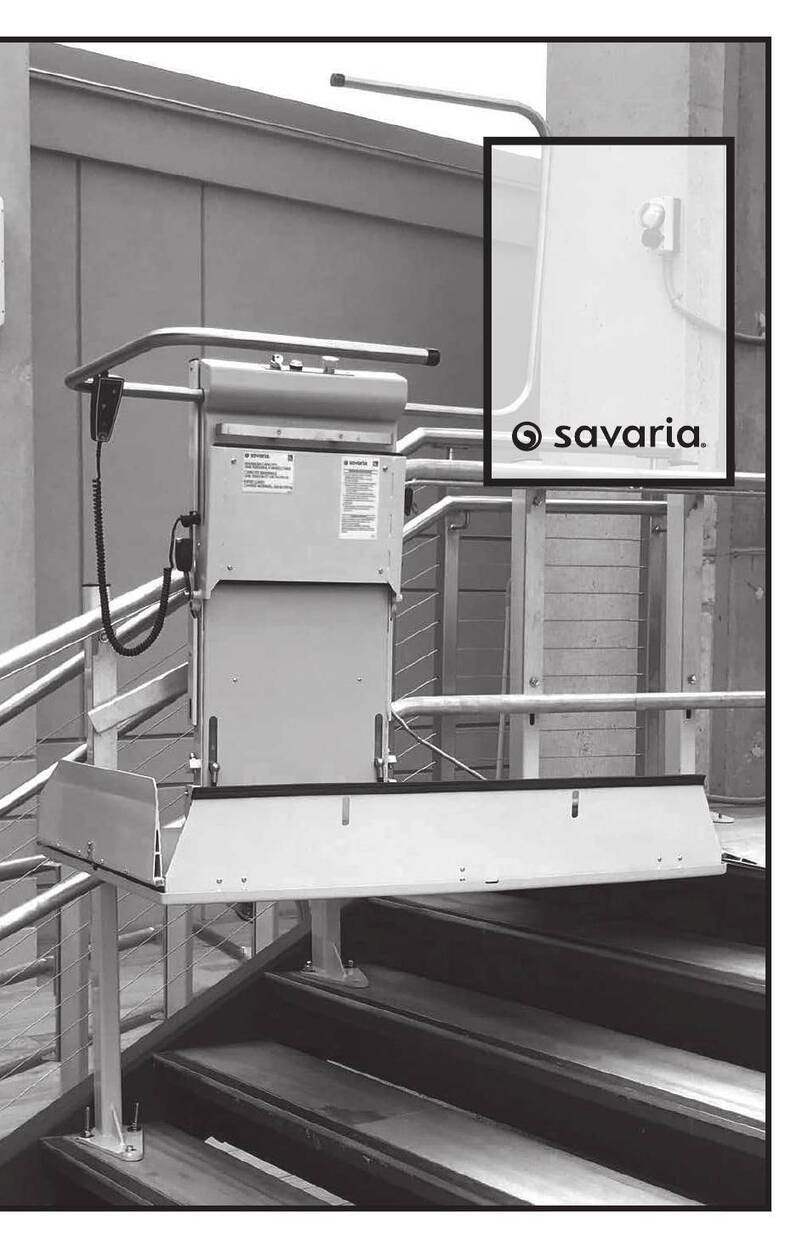

Savaria

Savaria omega owner's manual