STINAR DPT-512 Manual

sales@stinar.com |P651.454.5112 |F651.454.5143 |www.stinar.com

DISABLED PASSENGER LIFT

OPERATION & MAINTENANCE MANUAL

MODEL: DPT-512

SERIAL NO: 25781

MANUFACTURE DATE: 09/2021

REV.02.2022

Disabled Passenger Lift DPT-512 | 2

Eective Pages SECTION PAGE DATE

Title Page 1October 2021

List of Eective Pages 2October 2021

Contents 3-5 October 2021

Introduction 6October 2021

SECTION 1

Introduction 7-10 October 2021

Section 1-1 11-30 October 2021

Section 1-2 31-44 October 2021

Section 1-3 45-48 October 2021

SECTION 2

Introduction 49 October 2021

Section 2-1 50-56 October 2021

Section 2-2 57-71 October 2021

Section 2-3 72-74 October 2021

SECTION 3

Introduction 75 October 2021

SECTION 4

Introduction 76 October 2021

Section 4-1 77 October 2021

Section 4-2 78 October 2021

Parts Order Form 79 October 2021

FIGURES

Disabled Passenger Transporter, Model DPT-512 80-83 October 2021

Electrical System 84-89 October 2021

Hydraulic System 90-91 October 2021

Scissors Assembly 92-93 October 2021

Platform Assembly 94-95 October 2021

Van body Interior 96-98 October 2021

Rear Stabilizer Assembly 99-100 October 2021

Front Stabilizer Assembly 101-102 October 2021

Emergency Lift Gate Manual Override

Schematic 103-104 October 2021

Electrical Box Interior 105-106 October 2021

Cab Controls and Indicators 107-108 October 2021

Van Body Control Station 109-110 October 2021

Rear Van Control Station 111-112 October 2021

Disabled Passenger Lift DPT-512 | 3

Table of Contents MANUAL OVERVIEW � � � � � � � � � � � � � � � � � � � � � � � � � � 7

SECTION 1 | GENERAL INFORMATION & OPERATING

PROCEDURES � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

1�1 | Description � � � � � � � � � � � � � � � � � � � � � � � � � � � 11

1.1.1 | Equipment Systems and Components . . . . . . . . . . . . . . . . . . . 11

1.1.1.1 | Truck Chassis-cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

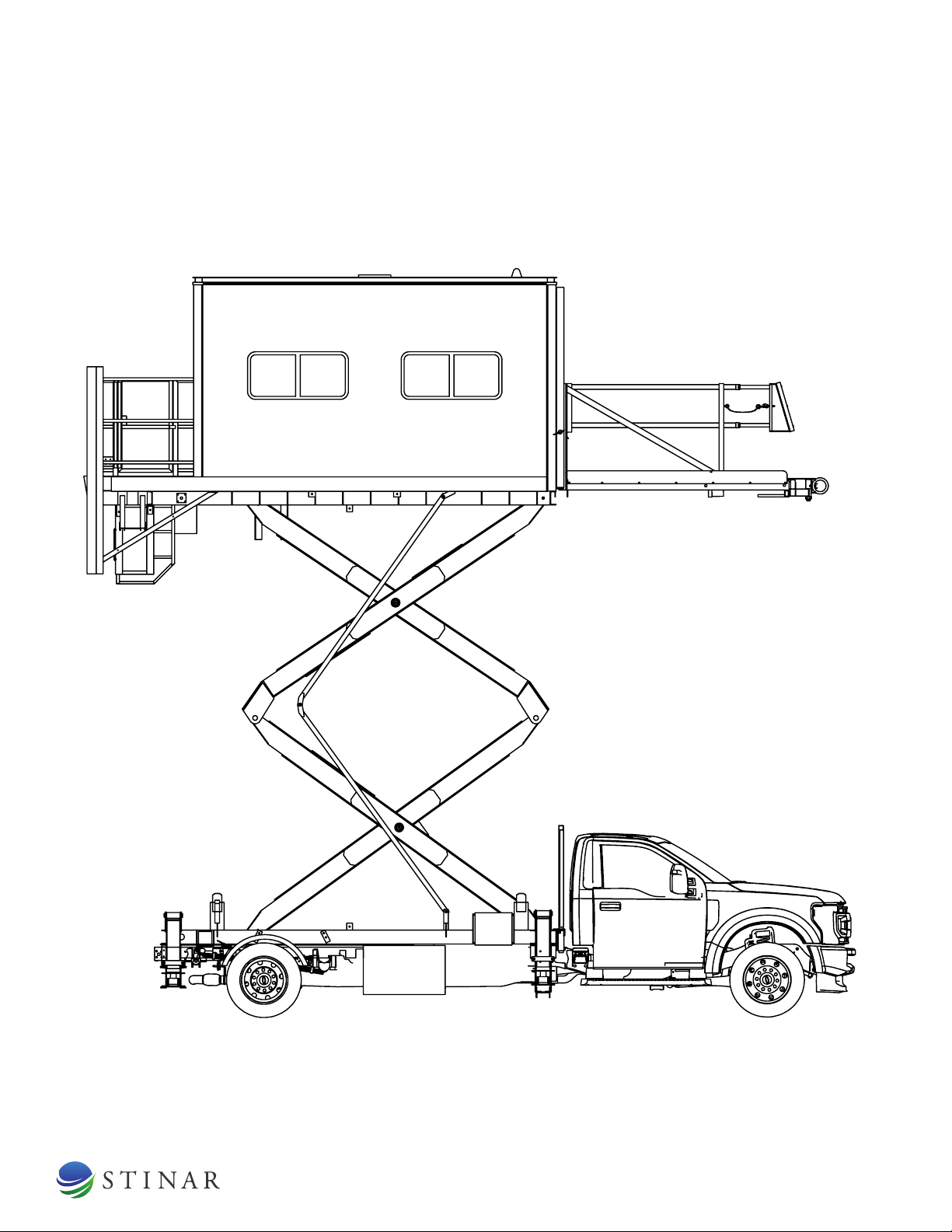

Figure 1.1.1 | Disabled Passenger Transporter, Model DPT-512. . . . . . . . .12

Figure 1.1.1 | Disabled Passenger Transporter, Model DPT-512. . . . . . . . .13

1.1.2 | Hydraulic Stabilizers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1.3 | Body Lift Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.1.4 | Van Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.1.5 | Front Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.6 | Screen Guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.7 | Power Lift Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1.8 | Generator Set and Related Components . . . . . . . . . . . . . . . . . 17

Figure 1.1.9 | Hydraulic System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . .18

1.1.9 | Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.1.10 | Power Lift Gate Electro-Hydraulic System . . . . . . . . . . . . . . . 21

Figure 1.1.10 | Hydraulic Component Group . . . . . . . . . . . . . . . . . . . . . . . . .22

1.1.11 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.1.11.1 | Master Control Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

1.1.11.2 | Intercom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 1.1.11 | Electrical System Schematic (Page 1 of 4) . . . . . . . . . . . . . .28

Figure 1.1.11 | Electrical System Schematic (Page 2 of 4) . . . . . . . . . . . . . .29

Figure 1.1.11 | Electrical System Schematic (Page 3 of 4) . . . . . . . . . . . . . .30

Figure 1.1.11 | Electrical System Schematic (Page 4 of 4) . . . . . . . . . . . . . .31

1�2 | Operation � � � � � � � � � � � � � � � � � � � � � � � � � � � � 32

1.2.1 | Operating Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . .32

1.2.1.1 | Cab Controls and Indicators (See Figure 1.2.1.1) . . . . . . . . . . . . 32

Figure 1.2.1.1 | Cab Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . .33

1.2.1.3 | Van Body Control Station (See Figure 1.2.1.3) . . . . . . . . . . . . . . . 34

1.2.1.4 | Rear Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 1.2.1.3 | Van Body Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . .36

1.2.1.5 | Generator Set Operating Controls . . . . . . . . . . . . . . . . . . . . . . . 37

1.2.1.6 | Mini Split Unit Operating Controls. . . . . . . . . . . . . . . . . . . . . . . . . 37

1.2.1.7 | Emergency Operating Controls (See Figure 1.2.1.7) . . . . . . . . . . . . . 37

Figure 1.2.1.7 | Emergency Operating Controls . . . . . . . . . . . . . . . . . . . . . .38

1.2.2 | Pre-Operation Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

1.2.3 | Operating Procedures – Normal Operation . . . . . . . . . . . . . . 40

1.2.3.1 | Starting and Driving Unit – Engine and Transmission . . . . . . . . . 40

1.2.3.2 | Operating the Hydraulic Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Disabled Passenger Lift DPT-512 | 4

1.2.3.3 | Operating Stabilizers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

1.2.3.5 | Operating Over-Cab Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.2.3.6 | Operating Rear Lift Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.2.3.7 | Operating Generator Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.2.3.8 | Operating Van Mini Split Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.2.3.9 | Operating Intercom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1.2.3.10 | Emergency Lift Gate Manual Override. . . . . . . . . . . . . . . . . . . 42

1.2.4 | Transporting Passengers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1.2.5 | Emergency Operating Procedures . . . . . . . . . . . . . . . . . . . . . . 44

1.2.5.1 | Emergency Shutdown Procedure . . . . . . . . . . . . . . . . . . . . . . . . 44

1.2.5.2 | Emergency Van Body Lowering Procedure . . . . . . . . . . . . . . . . 44

1.2.5.3 | Emergency Hydraulic System Operation . . . . . . . . . . . . . . . . . . 45

1.3 | Specications & Capabilities � � � � � � � � � � � � � � � � � 46

1.3.1 | General Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.3.2 | Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.3.3 | Truck Cab and Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

1.3.4 | Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1.3.5 | Power Lift Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1.3.6 | Mini Split Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SECTION 2 | SERVICING THE HIGH LIFT TRUCK� � � � � � � � � � � 50

2�1 | Servicing � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 51

2.1.1 | Use of Maintenance Stops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.2 | Truck Chassis-Cab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.2.1 | General Engine/Chassis Servicing . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.3 | Structural Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.3.1 | Sheet, Bar, and Tubular Member (Non-Load Bearing) . . . . . . . 51

2.1.4 | Scissors and Platform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.5 | Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.5.1 | Hydraulic Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2.1.5.2 | Hydraulic Oil Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1.5.3 | Pressure Relief Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1.5.4 | Hydraulic Pump and Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1.5.5 | Flow Control Valve, Van Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1.5.6 | Hydraulic Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.1.6 | Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.1.6.1 | Truck Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.1.6.2 | Control and Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

2.1.6.3 | Electrical Cables, Wiring, and Lights . . . . . . . . . . . . . . . . . . . . . . 53

2.1.7 | Scheduled Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

2.1.8 | Non-Scheduled Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.1.9 | Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.1.9.1 | Truck Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.1.9.2 | Tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.1.9.3 | Scissors Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Disabled Passenger Lift DPT-512 | 5

2.1.9.4 | Front Platform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.1.9.5 | Lubrication Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

2.1.9.6 | Special Lubrication Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 2.1.9.3 | Lubrication Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

2.2 | Troubleshooting � � � � � � � � � � � � � � � � � � � � � � � � 58

2.2.1 | Troubleshooting Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 2.2.1 | Hydraulic System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 2.2.2 | Electrical System Schematic (Page 1 of 4). . . . . . . . . . . . . . .69

Figure 2.2.2 | Electrical System Schematic (Page 2 of 4). . . . . . . . . . . . . . .70

Figure 2.2.2 | Electrical System Schematic (Page 3 of 4). . . . . . . . . . . . . . .71

Figure 2.2.2 | Electrical System Schematic (Page 4 of 4). . . . . . . . . . . . . . .72

2�3 | Adjustments � � � � � � � � � � � � � � � � � � � � � � � � � � 73

2.3.1 | Hydraulic Pressure Relief Valve Adjustment . . . . . . . . . . . . . . 73

2.3.2 | Flow Control Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.3.2.1 | Increasing the rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.3.2.2 | Decreasing the rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

2.3.3 | Bleeding Air from Hydraulic Lines . . . . . . . . . . . . . . . . . . . . . . 73

Figure 2.3.1 | Hydraulic Component Group . . . . . . . . . . . . . . . . . . . . . . . . .74

2.3.4 | Hydraulic Pressure Switch Adjustment . . . . . . . . . . . . . . . . . . 75

SECTION 3 | OVERHAUL � � � � � � � � � � � � � � � � � � � � � � � � 76

3.1 | Truck Chassis-cab � � � � � � � � � � � � � � � � � � � � � � � 76

SECTION 4 | PARTS LIST � � � � � � � � � � � � � � � � � � � � � � � � 77

4.1 | Manufacturer Identication � � � � � � � � � � � � � � � � � � 78

4.2 | Detailed Parts List � � � � � � � � � � � � � � � � � � � � � � � 79

4.2.1 | Understanding the Columns . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.1.1 | Figure/Item No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.1.2 | Manufacturer’s Part No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.1.3 | Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.1.4 | Vendor Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.1.5 | QTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

4.2.2 | Instructions for Ordering Parts and Assemblies . . . . . . . . . . 79

PARTS ORDER FORM � � � � � � � � � � � � � � � � � � � � � � � � � � 80

Figure 4.2.1 | Disabled Passenger Transporter, Model DPT-512 (1 of 2). .81

Figure 4.2.1 | Disabled Passenger Transporter, Model DPT-512 (2 of 2). .82

Figure 4.2.2 | Electrical System (Page 1 of 4) . . . . . . . . . . . . . . . . . . . . . . . .85

Figure 4.2.2 | Electrical System (Page 2 of 4) . . . . . . . . . . . . . . . . . . . . . . . .86

Figure 4.2.2 | Electrical System (Page 3 of 4) . . . . . . . . . . . . . . . . . . . . . . . .87

Figure 4.2.2 | Electrical System (Page 4 of 4) . . . . . . . . . . . . . . . . . . . . . . . .88

Figure 4.2.3 | Hydraulic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Figure 4.2.4 | Scissors Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Disabled Passenger Lift DPT-512 | 6

Figure 4.2.5 | Platform Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Figure 4.2.6 | Van body Interior (Page 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . .97

Figure 4.2.6 | Van body Interior (Page 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . .98

Figure 4.2.7 | Rear Stabilizer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Figure 4.2.8 | Front Stabilizer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Figure 4.2.10 | Electrical Box Interior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

Figure 4.2.11 | Cab Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . .107

Figure 4.2.12 | Van Body Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Figure 4.2.13 | Rear Van Control Station . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Disabled Passenger Lift DPT-512 | 7

This publication provides operating and maintenance instructions,

including detailed part lists for the Maintenance High Lift Truck, Model

MHL-216. This truck was manufactured by:

Stinar, LLC

500 Stinar Way

Blooming Prairie, MN 55917

Section 1 | General Information & Operating

Instructions

Includes a unit description, recommended procedures for operation, plus

specications and capabilities.

Section 2 | Servicing The High Lift Truck

Provides unit maintenance information, service and lubrication data, a

troubleshooting guide, and adjustment information.

Section 3 | Maintenance

Presents instructions for component maintenance and repair.

Section 4 | Parts List

Contains a manufacturers’ list, and illustrated part lists for the

assemblies, subassemblies, and systems within the unit.

MANUAL OVERVIEW

Disabled Passenger Lift DPT-512 | 8

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

SAFETY ALERT SYMBOL – Look for this symbol to point out important

safety precautions.

DANGER: The word “DANGER” denotes a most serious specic potential

hazard. A forbidden practice should denitely be avoided in connection

with a serious hazard.

WARNING: The word “WARNING” is used to denote a specic potential or

hidden hazard which, if not avoided, has the potential for serious injury.

CAUTION: The word “CAUTION” is used to denote a general reminder of

good safety practices or to direct attention to unsafe practices. Following

safe behavioral practices consistent with operating and maintenance

instructions will help the operator and others avoid accident involvement.

NOTE: The word “NOTE” is used to denote something that can cause minor

machine damage or poor performance if ignored.

IMPORTANT: The word “IMPORTANT” informs the reader of something

they need to know to prevent minor machine damage if a certain

procedure is not followed.

General Safety

• Do not rush

• Do not alter your machine

• Read and follow all warning labels. Replace any labels that are

missing or illegible.

• Check all controls and operating functions of the machine in a safe

area before starting work

• Never allow unauthorized persons around machinery when

performing operation functions

• A re extinguisher and rst aid kit should be carried in the truck at

all times

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

NOTE:

Example

WARNING!

Example

DANGER!

Example

CAUTION!

Example

Disabled Passenger Lift DPT-512 | 9

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

Before Operation

1. Perform a general all-around visual inspection and equipment check

of the entire unit

2. Check all markings and nameplates for legibility.

3. Perform any checks required by airport or airline regulations

4. Always determine hydraulic oil level and ll tank to proper level

with all hydraulic cylinders fully retracted. Overlling may occur if

cylinders are not retracted which may damage the system

5. If operating at night, check compartment lights for proper operation.

6. Check lights, horn, mirrors, wipers, safety belt, and all other safety

equipment for proper operation

During Operation

Engine and Transmission

• To operate the engine, refer to the truck operator’s manual for

recommended engine starting and operating procedures

• Failure to follow towing procedure may result in transmission

damage. Please check the manufacturer’s recommendations before

towing your unit

• These procedures are suggested general operating procedures. For

specic aircraft servicing, follow procedures specied by your airline

After Operation

• Stop engine and allow machine to come to a complete stop before

leaving the cab or allowing anyone near the unit

• Remove ignition key when parked

Service Safety

• Do not clean, adjust or service this unit while it is in motion

• Periodically check tightness of nuts and bolts, and check for loose,

worn or misaligned parts. Use only approved replacement parts.

• Any new components installed during repair must include the

current safety signs specied by Stinar.

• Perform all work in accordance with authorized standard shop

practices.

• Perform no welding, cutting, patching, and such on any load bearing

or supporting structure. If such repairs are necessary, contact the

Engineering department of Stinar before making any alterations.

• Do not mix hydraulic oils of dierent specications. Oils may not

Disabled Passenger Lift DPT-512 | 10

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

be compatible and could result in damage to hydraulic system

components.

• A thin oil lm should be visible on the hydraulic cylinder shaft. A

steady drip of oil indicates a need for service.

• Should there be a hydraulic system associated with this unit, always

determine hydraulic oil level and ll tank to the proper level with all

hydraulic actuating cylinders fully retracted. Otherwise, damage may

occur to the tank when the system is operated.

Your safety and the safety of those around you depend upon the operator

using care and good judgment in the operation of this unit. Know the

positions and functions of all controls before attempting to operate.

All equipment has limitations. Understand the speed, braking, steering,

stability and load characteristics of the unit before starting operation.

READ YOUR OPERATOR’S MANUAL!

Disabled Passenger Lift DPT-512 | 11

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

The Stinar Disabled Passenger Transporter Model DPT-512, is a truck

mounted aircraft service vehicle designed for transporting injured or

disabled personnel to and from aircraft.

The vehicle consists of a truck chassis cab equipped with a hydraulic scissors

lift mechanism capable of elevating the van body to aircraft door threshold

heights of 90 to 228 inches (2286 to 5791 mm). A hydraulic rear lift gate

transfers passengers between ground level and the van body.

The van body has a rated capacity of 3000 pounds (1361 kg). Hydraulically

operated stabilizers are provided for stabilizing the vehicle whenever the

van body is raised.

The scissors lift and the stabilizers are powered by a hydraulic pump driven

from the trucks transmission. The hydraulic pump functions only when the

PTO is turned on from the cab control station. The van lights, the controls,

and the linear actuator on the front platform are all run o the truck’s 12

VDC electrical system. A hand hydraulic pump provides hydraulic power for

emergency use.

The unit is designed to transport personnel on airport ramp areas, service

roads, and public highways.

1.1.1 | Equipment Systems and

Components

The major operating systems and components of the Disabled Passenger

Transporter are described in the paragraphs below. See Figure 1.1.1 for the

locations of components.

1.1.1.1 | Truck Chassis-cab

The Disabled Passenger Transporter is built on a Ford F-550, 4 x 2 chassis

cab and is powered by a 6.8 liter, V-10 gas engine. The transmission is a

5-speed automatic. The chassis is equipped with dual rear wheels.

Controls and indicators added to the cab include:

• Van body raise/lower controls

• Stabilizer raise/lower controls

• Flashing beacon on/o switch

• PTO on/o switch

• Front/rear on/o oodlights

• Van body lighting on/o controls

1.1 | DESCRIPTION

Disabled Passenger Lift DPT-512 | 12

FIGURE 1.1.1 | DISABLED PASSENGER TRANSPORTER, MODEL DPT-512

32

1

Disabled Passenger Lift DPT-512 | 13

FIGURE 1.1.1 | DISABLED PASSENGER TRANSPORTER, MODEL DPT-512

32

1

Disabled Passenger Lift DPT-512 | 14

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

The truck includes the following features:

Hydraulic pump and PTO- mounted on transmission. This unit is driven by

the transmission through a hydraulically engaged clutch mounted directly

to the hydraulic pump. It runs on demand whenever the engine is running,

the PTO switch is ON, and a stabilizer up or down or body up control

switch is engaged.

Warning alarm – sounds whenever the vehicle is being driven in reverse,

the lift is being lowered, or the stabilizers are being lowered.

Truck electrical system – provides electrical power for all functions.

Additional regulatory switches and electrical components added to the

engine compartment are dened in the electrical system description.

1.1.2 | Hydraulic Stabilizers

The stabilizers are hydraulically actuated legs that extend to the ground on

both sides of the vehicle. The four stabilizers provide stability while the van

body is extended upward.

1.1.3 | Body Lift Mechanism

The van body is mounted on a double scissors lift mechanism, enabling

the body to be raised vertically while the van body oor remains parallel to

the ground. The double scissors design is constructed of 8” x 3” (203 mm

x 76 mm) reinforced steel tubing. All pivot points are provided with grease

ttings. The scissors mechanism is raised by two hydraulic lift cylinders. A

solenoid-actuated control valve located on the truck chassis regulates the

ow of hydraulic uid to the cylinders. This control valve is activated by

electrical switches in the cab or in the van body.

• The scissors lift mechanism consists of a lower sub-frame and track,

attached to the chassis; an upper sub-frame and track, attached to

the van body, and inner and outer double scissors. The scissors are

secured to the two sub-frames at the front of the lift mechanism.

Rollers on the rear of the scissors travel in the sub-frame channels

as the scissors are raised and lowered.

• Two hydraulic cylinders raise and lower the scissors. Each of these

telescopic cylinders is tted with an electrically released lock valve

to prevent undesired downward movement. A ow control valve

controls the rate of descent of the cylinders.

• Scissors are supplied with maintenance stops to hold the scissors in

elevated positions for routine maintenance. These are described in

Chapter 2, Servicing.

Disabled Passenger Lift DPT-512 | 15

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

1.1.4 | Van Body

The van body is constructed of white painted aluminum and steel,

with diamond plate ooring. The van body ceiling and side walls are

constructed with 1/4” plywood backing and are covered with Kemlite

glassboard interior lining. The roof and side panels are insulated. This

body is equipped with front and rear sliding doors. The van body is

equipped with the following features:

COMPONENT DESCRIPTION

Mini Split and Air

Conditioning Unit

One 4800 watt wall mounted mini split unit may

be used to heat the van interior. This unit runs

on 240 VAC power supplied by a gas engine-

driven generator set below the van body.

Van Body Control

Station

The van body control station is fastened

to the inside left wall near the front of the

van body. This station contains van body

controls, lighting controls, a front platform

control, and a stop switch. See Section

2 in this chapter for an illustration and

description of this control station.

Van Interior Lights

4 incandescent light xtures (2 mounted

on each side) are located on the van ceiling.

These interior lights are controlled by a van

lights switch located in the cab and a body

lights switch located in the van body.

Front Work Lights

Two work oodlights illuminate the front

platform ramp. These lights are controlled

by the ramp lights control switch on the van

body front control station.

Rear Work Lights

Two work oodlights illuminate the rear

platform. These lights are controlled by rear

lights switches in the cab and in the van body

control station.

Beacon

Flashing amber beacon is located on the van

body roof. The beacon operates whenever the

beacon control switch in the cab is switched on.

Fire Extinguisher A re extinguisher is located in the van.

Window Units

There are two window units on each side of

the van body. The window units have sliding

glass windows. The dimensions are 20” x 43”

(508 mm x 1092 mm).

Roof Vent A roof vent with a 12 VDC electric fan is

installed in the van body ceiling.

Passenger Seats A bench seat is provided for up to two

Disabled Passenger Lift DPT-512 | 16

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

1.1.5 | Front Platform

The front platform extends 24” (610 mm) out from the van body on steel

rollers, and serves as a forward extension of the van body to bridge the gap

between the van body oor and the door threshold of the aircraft being

serviced. The platform is attached to the forward end of the van body by

a system of rollers that run in vertical tracks welded to the front of the van

body. The platform rests on the screen guard when the van body is lowered.

When the van body is raised, the platform continues to rest on the screen

guard until the van oor and the platform are even. Beyond this point,

stops in the bottom of the vertical tracks on the van body lift the platform

to the same height as the body oor. The front part of the platform can be

extended and retracted electrically using a control switch in the van body

control station. The platform has telescoping side rails with rubber bumpers

on the extended railings and a full-width rubber bumper at the front of

the platform. The railings on the sides of the platform are painted in safety

yellow. The oor is constructed from diamond plate ooring.

1.1.6 | Screen Guard

The screen guard behind the truck provides support for the front platform

to rest on when the platform is fully down.

1.1.7 | Power Lift Gate

The power lift gate is attached to the platform at the rear of the van body.

Its purpose is to move passengers and equipment between ground level

and the van body oor. The lift gate has a rated capacity of 2000 pounds

(908 kg). It has its own hydraulic system that is separate from the primary

hydraulic system. The emergency operating system has a hand pump used

for raising the lift gate, two valves to fold/unfold the lift gate, and a valve to

lower the lift gate.

COMPONENT DESCRIPTION

Lift Gate Platform

This is a 85 x 55 inch (2159 x 1397 mm)

aluminum platform with 42” (1067 mm) high

folding railings that moves between ground

level and the van body oor level. When not in

use it can be pivoted upwards and stowed in

place.

Lift Gate Power System

The lift gate has its own hydraulic system,

driven by a 12 VDC motor that is powered

by the truck's electrical system. It is self-

contained, with its own pump, reservoir,

hydraulic cylinder, and electrical switches.

This system is built into the lift gate structure.

Disabled Passenger Lift DPT-512 | 17

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

COMPONENT DESCRIPTION

Lift Gate Controls

The main external control box is located on

the driver side of the DPT under the van body

towards the rear of the vehicle (left rear). The

pendant mounted control box is located on the

driver side rear of the back platform. These

control boxes have a lift up/down control

switch for raising and lowering the lift gate.

1.1.8 | Generator Set and Related

Components

This disabled passenger transporter is equipped with wiring for an engine-

powered generator to supply 240 VAC power to the van heating and air

conditioning unit. The generator set is to be located on the right side of the

unit, below the van body.

COMPONENT DESCRIPTION

Mini SplitUnit

This unit is mounted in the right sidewall of

the van. It is powered by the generator set

while the vehicle is running or not running.

Operating controls are located on the unit.

Disabled Passenger Lift DPT-512 | 18

FIGURE 1.1.9 | HYDRAULIC SYSTEM SCHEMATIC

FILTER

LINE

STRAINER

RESERVOIR

FILL/VENT

RELIEF VALVE

VALVES

DIRECTIONAL

RETURN

PUMP

PTO

PUMP

HAND

HIGH PRESSURE

FILTER

GAUGE

CONTROL

PRESSURE

VALVES

LOCK

SWITCH

STABILIZERS

FLOW

VALVES

LOCK

LIFT CYL.

19

5

6

15

13

14

12

22

10

11

32

4

1

17

18

16

3

7

POWER PACK

OPTIONAL EMERGENCY

PUMP

L FRONT

R FRONT

L REAR

R REAR

2300 MAX

15 GPM @ 1470 RPM

2.48 CIR

1.5 CU. IN PER CYCLE

(1400 RPM ENGINE SPEED)

5 x 16 w/ 2.5 rod

8

20

PTO 1.05:1 SPEEDUP RATIO

9

055719B

6/5/4 X 80-1/4

1608 CU. IN TO

STROKE 80-1/4

PER CYLINDER

Disabled Passenger Lift DPT-512 | 19

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

1.1.9 | Hydraulic System

The hydraulic system provides hydraulic power to raise and lower the

van body and the stabilizers. See Figure 1.1.9 for the Hydraulic System

Schematic, and Figure 1.1.10 for the Hydraulic Components Group. The

primary hydraulic system components are described in the following:

COMPONENT DESCRIPTION

Hydraulic Reservoir

This 30 U.S. gallon (114 liter) stainless steel

tank is located on the left side of the unit.

A drain plug is located at the bottom of the

tank. A ll cap and strainer are part of the

cleaning port. There is a separate vent cap on

top of the tank. On the side of the tank there

is a sight glass uid level indicator. A suction

line strainer is located inside the tank.

Suction Line Strainer

A suction line strainer is located in the outlet

port from the hydraulic tank. This strainer has

a 100 mesh stainless steel element.

Gate Valves

Gate valves are located at the outlet and

return ports of the hydraulic oil reservoir.

These valves must be kept open during

normal operation

Hydraulic Pump

The hydraulic pump is mounted to the PTO.

It is a rotary gear pump. The pump delivers

hydraulic uid to the van body lift and

stabilizer cylinders. See Section 1.3 of this

chapter for pump specications.

Hydraulic Hand Pump

(inside hydraulic box)

The hand pump provides emergency

hydraulic power in situations when the main

pump fails.

Check Valves

Check valves prevent reverse ow of hydraulic

uid into one pump when another pump is in

use.

Hydraulic Return Line

Filter

This lter is located at the return port of the

hydraulic reservoir. It has a 10-micron spin-on

cartridge and a condition indicator.

Hydraulic Pressure

Filter

A high-pressure lter is located between the

hydraulic pump and the directional control

valve. It has a 10-micron disposable element.

Hydraulic Pressure

Gauge

(inside hydraulic box)

The pressure gauge is calibrated from 0 to

3000 psi and indicates the system hydraulic

pressure at the pump outlet.

Disabled Passenger Lift DPT-512 | 20

SECTION 1 | GENERAL INFORMATION & OPERATING PROCEDURES

COMPONENT DESCRIPTION

Directional Control

Valve

(inside hydraulic box)

Separate hydraulic valves control the lift

and the stabilizers. Both valves are two

spool, solenoid actuated valves. They direct

hydraulic uid to the lift cylinders and

the stabilizers when engaged by electrical

switches in the cab or van control stations.

Each valve is equipped with a manual override

lever. By engaging these levers, the lift can

be lowered and the stabilizers lifted when

electric power is disabled.

Hydraulic Pressure

Relief Valve

This adjustable pressure relief valve is preset

to 1900 psi (131 bar) to prevent damage to

hydraulic system components. It is part of the

directional control valve.

Stabilizer Hydraulic

Cylinders

Each of the four stabilizers is double acting,

single stage type. They extend, retract, and

hold the stabilizer legs in place.

Hydraulic Pressure

Switch

A hydraulic pressure switch is mounted on the

right side. This switch prevents the lift from

being raised unless the stabilizers are down

and pressurized. The switch tripping pressure

is set at 1000 psi (69 bar).

Stabilizer Cylinder Lock

Valves

Double acting lock valves are installed on

each of the four stabilizer cylinders. They

prevent the stabilizers from extending or

retracting under load. These valves are

unlocked by the actuating pressure from the

directional control valve.

Platform Lift Hydraulic

Cylinders

These single-acting, 3-stage, telescoping

cylinders have strokes of 60.125 in (1524 mm).

Lock Valve Release

Lever and Cables

A lever located on the left side of the truck

chassis controls two cables that activate the

manual override feature on the lift cylinder

lock valves.

This manual suits for next models

1

Table of contents

Other STINAR Lifting System manuals

Popular Lifting System manuals by other brands

APlusLift

APlusLift MT1500 Installation manual & operation instructions

Opera

Opera Signature Dual Link Kit Installation guide and technical specifications

Sealey

Sealey MT500 instructions

MAHA

MAHA MLS Series Original operating instructions

GSi

GSi InterSystems PNEG-2116 Installation and operation manual

OMCN

OMCN 126/B INSTRUCTIONS FOR USE, MAINTENANCE AND SPARE PARTS