Bigab 7-10 User manual

v1.2 - 2021 - EN

Original Instruction

www.forsmw.com

Instruction manual

G G

2© 2021 FORS MW Ltd

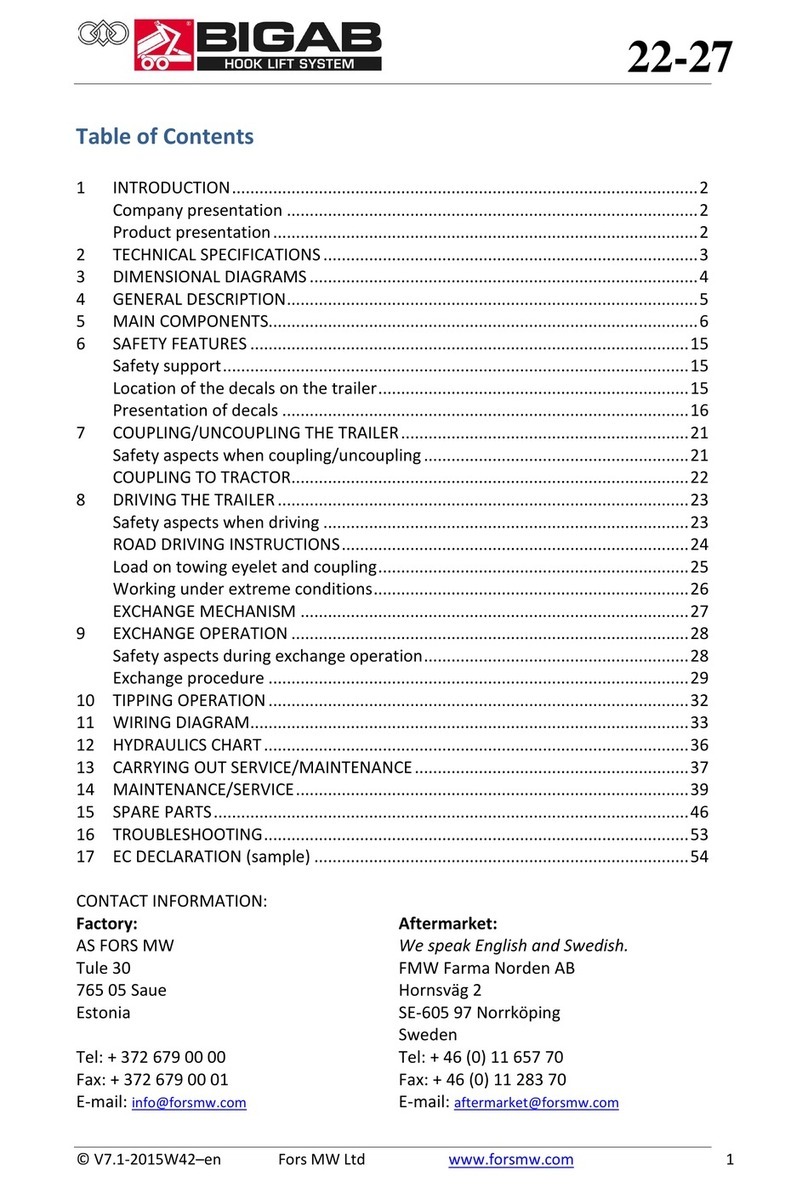

TABLE OF CONTENTS

IDENTIFICATION OF MACHINE.........................................................................................................................2

INTRODUCTION.....................................................................................................................................................3

SAFETY REGULATIONS........................................................................................................................................4

GENERAL SAFETY INFORMATION........................................................................................................4

SAFETY MESSAGES...................................................................................................................................4

LOCATION OF THE LABELS ON THE PRODUCT ...............................................................................5

OPERATION.............................................................................................................................................................8

CONTROLS AND DISPLAYS ....................................................................................................................8

UNLOADING TRAILER...............................................................................................................................8

BEFORE OPERATION.................................................................................................................................9

CONNECTING MACHINE .......................................................................................................................10

WORKING IN EXTREME CONDITIONS...............................................................................................14

DISCONNECTING THE TRAILER...........................................................................................................15

CLEARING BLOCKAGES AND CLEANING.........................................................................................15

TRANSPORT...............................................................................................................................................15

MAINTENANCE.........................................................................................................................................16

DAILY/MONTHLY/YEARLY MAINTENANCE PROCEDURES AND INSPECTION.....................17

MAINTENANCE MATERIALS .................................................................................................................21

TIGHTENING TORQUES..........................................................................................................................22

LUBRICATION SCHEDULE .....................................................................................................................23

STORAGE ....................................................................................................................................................24

CLEANING..................................................................................................................................................24

TROUBLESHOOTING ..............................................................................................................................24

TECHNICAL INFORMATION .............................................................................................................................26

DESIGN OF THE PRODUCT...................................................................................................................26

TECHNICAL DATA ....................................................................................................................................29

DIMENSIONAL DRAWING.....................................................................................................................33

ELECTRICAL AND HYDRAULICAL SYSTEM......................................................................................34

ADDITIONAL INFORMATION...........................................................................................................................43

CONFORMITY OF STANDARDS...........................................................................................................43

WARRANTY................................................................................................................................................43

DISMANTLING AND SCRAPPING........................................................................................................43

PART LIST....................................................................................................................................................43

G G

www.forsmw.com 3

IDENTIFICATION OF MACHINE

This instruction manual applies to the BIGAB hooklift trailers -, -, -, -, - G, - G and

- and contains information for its safe use.

The trailer’s serial number is located on the identification plate and also stamped onto the frame.

The EC declaration of conformity shall always be submitted with this manual which certifies that the

produced vehicle conforms to the requirements established with directive //EC and indicating

serial number of the machine.

G G

4© 2021 FORS MW Ltd

INTRODUCTION

This Manual gives the owner/operator information about maintaining and servicing the BIGAB hook-

lift trailer and provides instruction for safe and proper use of the machine.

Even if you have experience of this type of product, we ask that you read and understand the contents

of this manual completely and become familiar with your new machine before operating it. This Man-

ual contains information that could be vital for safety and eciency, as well as to ensure the validity of

the factory warranty.

If you have questions concerning information or availability of manuals in other languages, contact

your dealer.

Throughout this manual, information is provided by the sign - read carefully and comply with

these messages – it will improve your operating and maintenance eciency, help avoid breakdowns

and damage, and extend your machine’s life.

Message NOTE! indicates that the product, process or environment may cause damage, as well as

indicating the risk of minor injuries. These markings are used to draw the attention of readers to the

fact that this is an area of particular importance.

Do not use this machine for any applications or purposes other than those described in this manual or

applicable for approved attachments. If the machine is to be used with special attachments or equip-

ment other than those approved by Fors MW, consult your dealer. Any person using unapproved at-

tachments or making unauthorized modications is responsible for the consequences.

The dealers are ready to provide you with any assistance you may require, including providing genu-

ine service parts. All service parts should be obtained from your dealer. Provide complete information

about the part and include the model and serial numbers of your machine.

Please be aware that Fors MW continuously improves its products and reserves the right to make

changes and improvements in the design, construction and also in instructions of any part without

obligation to install such changes on any unit previously delivered.

Fors MW conforms to ISO for safety marking in accordance with the directive //EC.

Manufacturer: Dealer:

AS FORS MW

TULE

SAUE

Tel: +

www.forsmw.com

G G

www.forsmw.com 5

SAFETY REGULATIONS

GENERAL SAFETY INFORMATION

Carefully read through the user manual before using the hook lift

trailer. Important data relating to your particular trailer can be

found in the trailer’s technical data. Incorrect usage can result in

injuries to you and damage to the trailer.

Operating a trailer requires a high level of expertise, as well as knowledge about the machine you are

using. It is important for you to train with regard to the trailer’s behaviour. Practice the movement

pattern and always work with smaller loads until you are completely familiar with operating the trailer.

BIGAB Hooklift is intended for use in agricultural, construction and community work for collection and

transportation of waste, scrap, agriculture and other goods.

Bigab Hooklift is not intended for use in transporting people or animals.

Take care to ensure that nobody is within the safety zone 20m.

The recommended ambient working temperature for this machine is -30°C to +40°C.

SAFETY MESSAGES

• Read carefully and understand the user manual before using the device. Consult the user

manual to solve your problems.

• Follow instructions to avoid the risk of accidents. The manufacturer and dealer are not

responsible for any damage in the event of failure to comply with these instructions.

• It is prohibited for unauthorised parties to be within the trailer’s risk zone, which is 20 m! The

user must have full visual control over the working area. Always maintain a visual check on the

work area. Never stand or walk under suspended loads.

• It is important for you to adapt your speed to the driving situation. Drive carefully on sideways

inclines. The same applies on slopes.

• Never drive under obstacles such as bridges, electrical cables, etc with the container bridge

raised.

• Risk of overturning. Ensure that the trailer is always standing on rm ground. Never overload

the trailer.

• Stop working by switching o the engine, engage the parking brake and remove the ignition

key to prevent unauthorised usage.

• Carefully read through the warning information on the oil and grease products you are

using, and follow their instructions accurately! During service works wear correct protective

G G

6© 2021 FORS MW Ltd

equipment and seek medical attention immediately if eyes or skin are exposed. It is prohibited

to release oil onto the ground or into watercourses.

• If repairs or modications require welding work, you must rst contact your dealer, who will

provide you with the necessary welding instructions. Incorrect welding or inexperience during

welding can result in sudden breaks in the structure.

• During loading and transport on public roads follow the applicable trac legislation.

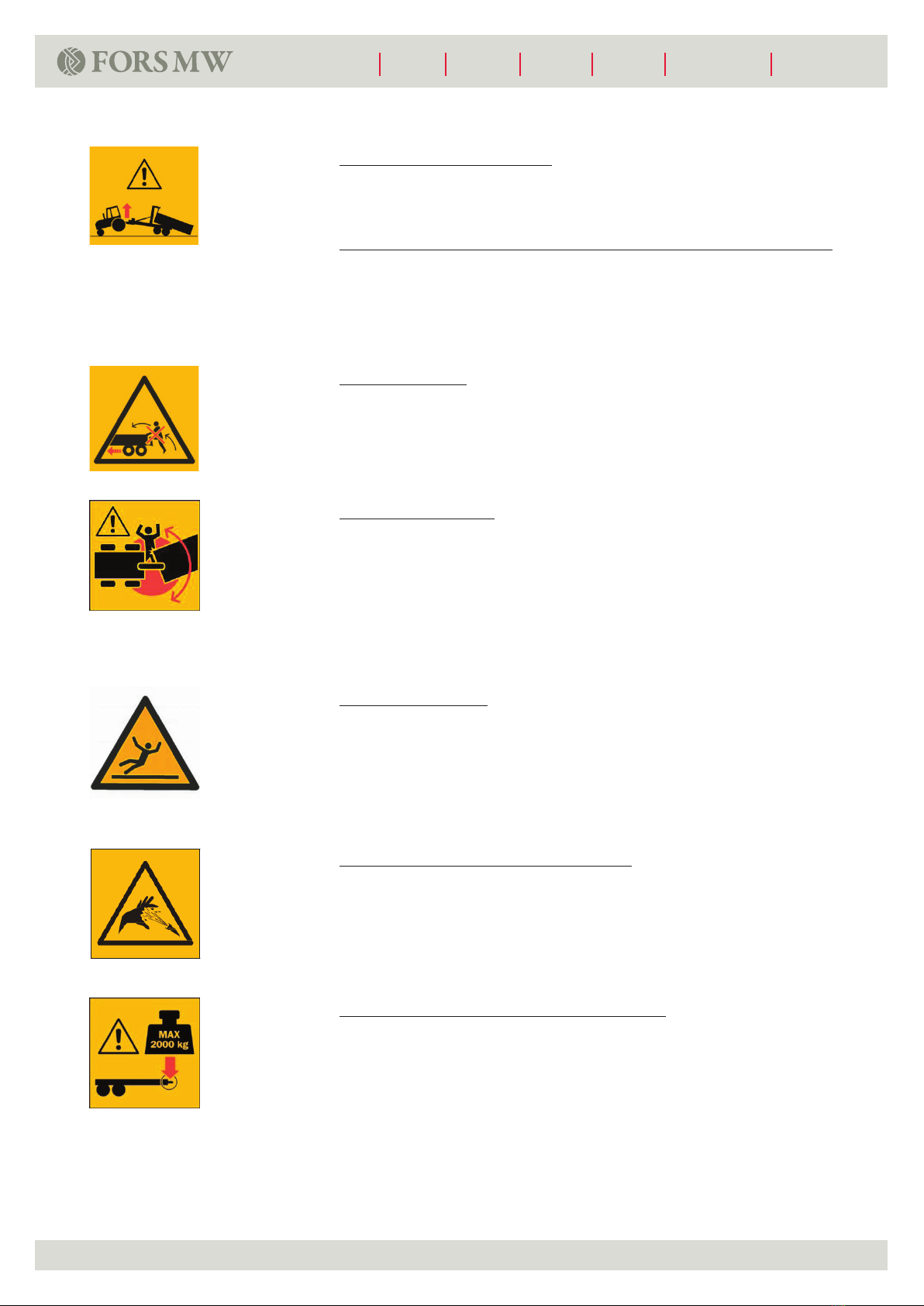

LOCATION OF THE LABELS ON THE PRODUCT

The BIGAB hooklift trailer is equipped with a range of signs and labels relating to both safety and

information of the machine. Check that all the labels are in the correct positions and visible. If signs or

labels peel o or get damaged, they must be replaced. For replacement labels contact your dealer for

a new set and guidance for positioning.

Location of the labels on the product

Label set

Warning and instruction manual

Carefully read and comply with the instruction manual and work

instructions. Read the instruction manual carefully before starting

to use the trailer. Ignoring this can be potentially dangerous.

Total weight

It is absolutely prohibited to load more than the amount your model

of trailer is designed to handle. This will be dangerous for you and

your surroundings. Please check trailer specic total weight from

the ID-plate.

G G

www.forsmw.com 7

Hazardous movement

It is a hazardous movement if the rear end of the tractor lifts.

Note! This warning label is included in the delivery of your trailer.

It must be attached in a clearly visible location in the tractor cab.

If you would like more of these labels, they are available to order,

free of charge, from our after sales department. Contact details are

visible in the rst chapter.

Risk of injury

It is absolutely forbidden to board the trailer when it is moving

Anyone doing so may be at risk of serious or fatal injury.

Hazardous area

Standing between the trailer and the towing vehicle when the

trailer is being driven, moved with frame steering or when other

functions are activated between the trailer and towing vehicle, can

be potentially fatal. As the driver, you must always ensure that no

one is in the area around the machinery.

Risk of slipping

There is a risk of slipping as the surfaces of the trailer can be

slippery due to combination of oil/mud/rain on the surface. The

ground around the trailer can also become slippery, as the tires

can tear up the surface and expose mud and soil.

Hydraulic uid under pressure

Hot hydraulic uid at high pressure levels can occur in the

hydraulic system. Take care when connecting, disconnecting and

replacing hoses.

Maximum load to coupling device

Ensure that you do not load in such a way that the load on the

towing eye exceeds the permitted values.

NB! Check your permitted towing eye vertical load value from

technical data and marked for the towing eye. The load is largely

determined by the way the weight is distributed on the container

bridge, and it is the user´s responsibility to ensure that this is not

exceeded.

G G

8© 2021 FORS MW Ltd

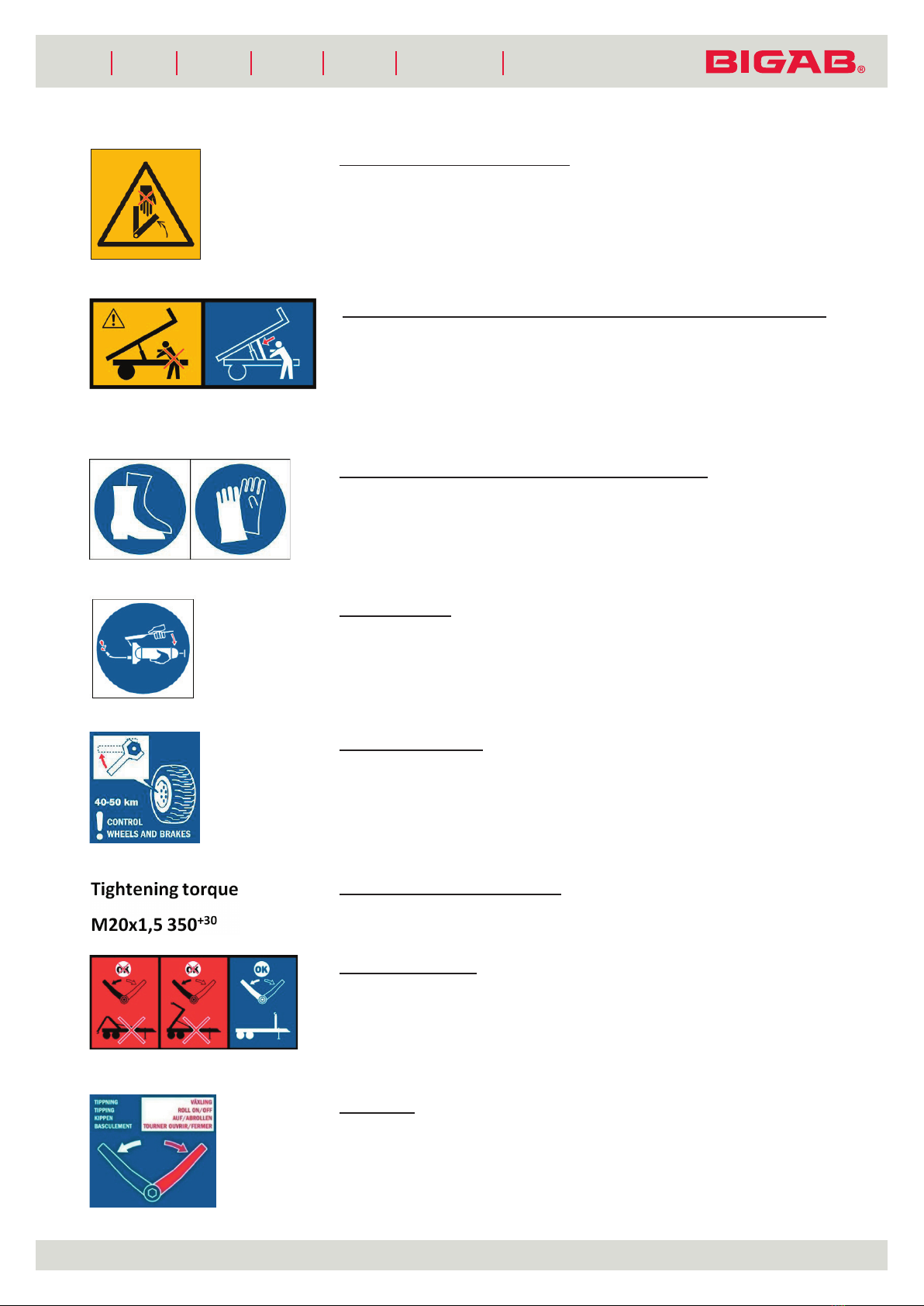

Risk of crushing injuries

There is a risk of clamping or crushing injuries during work and

maintenance. Do not place your hands to the machine or any

other moving part.

Use the security post during all service operations

It is absolutely forbidden to lean under a raised frame unless it is

secured with the security post. Under no circumstances may the

trailer be carrying either a load or a container when using the

security post.

Labels for the use of safety equipment

Use appropriate safety equipment in order to avoid injury when

using the trailer.

Lubrication

This label used to show the importance of regular lubrication of

the trailer. Lubrication points and schedule can be found in the

chapter on lubricaton.

Tire inspection

The tire bolts must be tightened and the brakes must be inspected

and adjusted regularly.

Wheel bolts tightening

This label indicates wheel bolts/nuts tightening torque.

Exchange unit

The exchange unit may not be operated unless the frame is folded

down. During transport with the trailer, the hook must be folded

down in the parking position.

Tipping

Lever must be pushed correctly to the extreme position, otherwise

it might damage the trailer.

G G

www.forsmw.com 9

BIGAB hook trailer ID plate

ID plate contains trailer specic technical data. This plate can be

country specic.

RUP type approval plate

If your trailer is equipped with type approved RUP, it is labelled with

type approval plate that contains RUP specic type approval data.

OPERATION

CONTROLS AND DISPLAYS

The BIGAB hooklift trailer is only intended to be used and operated from the tractors’driver seat

through the tractor hydraulic lever. Always adapt your operations to your level of experience, current

load and road conditions. Do not exceed the trailers maximum travel speed and maximum loading

values.

NOTE: If damage should occur during use, the work must be stopped immediately.The fault should

be identied and eliminated before starting to use the trailer again.

NOTE: It is recommended to place load symmetrically. Always be sure that the container is rmly

xed before driving. Long containers need enough working space and turning area. Never make sharp

turns at a high travel speed.

Don’t forget to lift the parking leg up before driving.

UNLOADING THE TRAILER

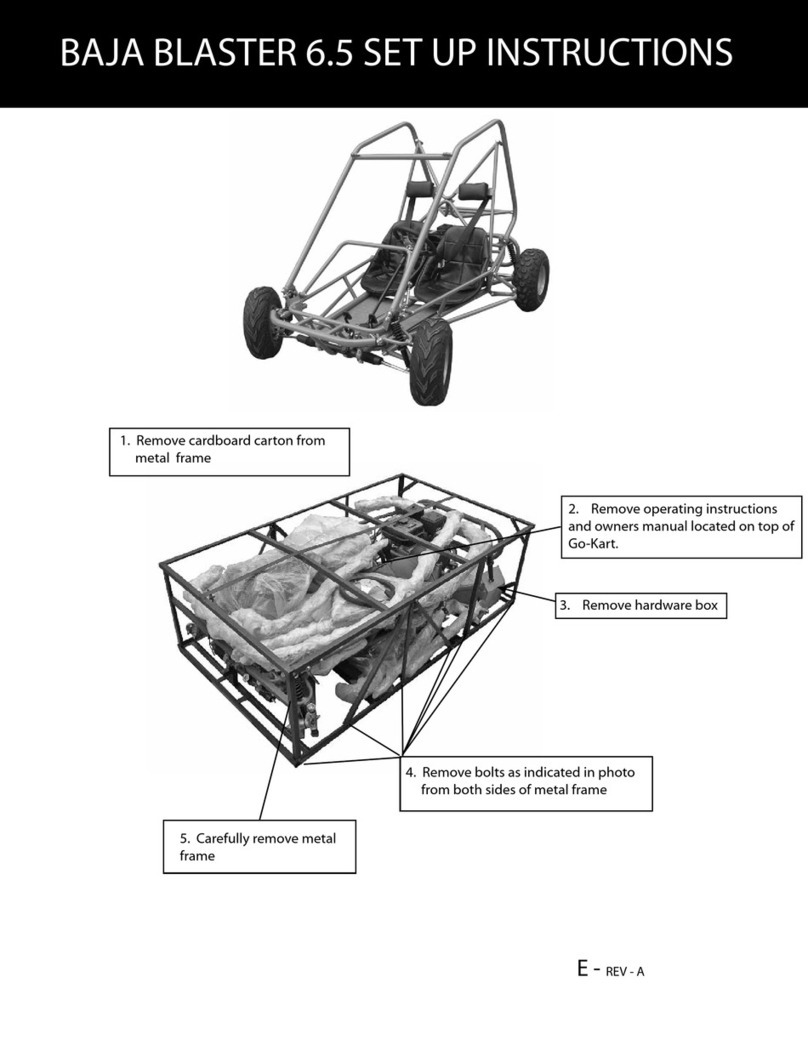

When unloading (loading) the trailer from the transportation platform the general principles of

workplace rules for health and safety shall be complied. The hooklift trailer is rmly attached to the

transportation platform with straps and chains. Wheels are secured by wedges or other objects without

sharp edges to avoid rolling.

Before starting up, check visually that the trailer is not damaged during transportation. If the trailer

is damaged, inform the company that transported the trailer and the dealer or manufacturer of the

product immediately (follow CMR).

G G

10 © 2021 FORS MW Ltd

• Ensure that you have enough space for unloading the product. Wear personal protective

equipment such as helmet and footwear. Lifting operator must be certied.

• Be careful when unloading and unpacking the trailer: do not damage sensitive components,

do not change factory settings or damage paint or other surface nishes. Be careful when

lifting so that cables, connectors or other components are not damaged for instance

between lift fork and trailer frame.

• Lifting up the trailer from transportation frame. See lifting points below.Weight depends on

the type of trailer (see chapter Technical information);

• Lower the trailer to the ground.

• Usage of the trailer is strictly forbidden if safety devices of the trailer are damaged. For more

detailed information about safety advice see the chapter on Safety Regulations.

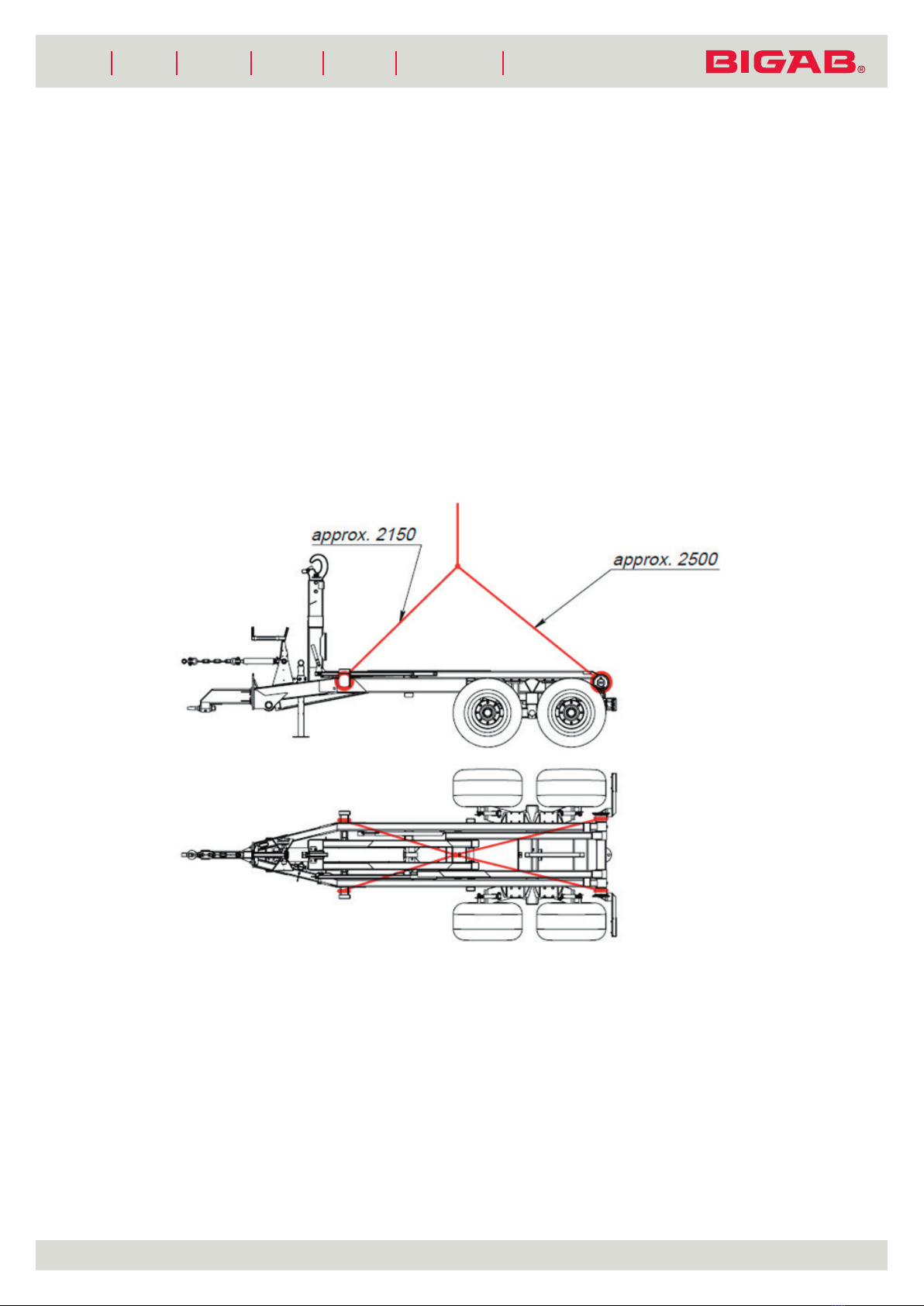

Lifting points for (un)loading

BEFORE OPERATION

A pre-operation checklist is provided for the operator for careful examination of trailer to ensure safe

use of the trailer.

Before operating the machine and each time thereafter, the following areas chould be checked:

G G

www.forsmw.com 11

Pre-operation checkpoint OK/

NOK

Check that personal protection equipment is used and isin good condition.

Check and lubricate the machine per the schedule ( see Maintenance Section)

Check that all bolts, nuts and hoses are connected tightly

Check the towing eyelet for defects

Check that the trailer is s securely and appropriately xed to the towing vehicle

Checkconditionofallhydrauliccomponents. Replace if needed

Check that all hydraulic functions are working

Control the lights

Check that brakes are functioning

Verify that the hook is the right height to suit the container

Check if there is enough working space and turning area

Check the condition of the tires and air pressure.

Check that the wheel nuts are tightened.

CONNECTING MACHINE

Note: When connecting and disconnecting the BIGAB, bear in mind the risk of clamping injuries, the

risk of slipping, the tipping risk and the risk of hydraulic high-pressure jets and hot oil. Ensure that

neither the hydraulic pump nor the power take-o is connected.

• Check that the towing eyelets’ lock is undamaged and properly tightened.

• Connect the trailer‘s towing eyelet to the towing vehicle’s tow hook. Ensure that the towing

device is properly locked.

• Connect the frame lock.

• Before driving, parking leg must be lifted up and xed with the pin.

Note:Parking brake is only for parking. Not for use during tipping, hooking or loading.

Brakes

• Connect the hoses to the tractor’s brake outlet.

Travel lights

• Connect the light connector to the tractor’s trailer outlet (12V or 24V).

Hydraulic system connections

• Always check that the quick couplings are clean and that they lock properly.

G G

12 © 2021 FORS MW Ltd

• If trailer is equipped with electronic control system, supply voltage must be observed

according to trailer options.

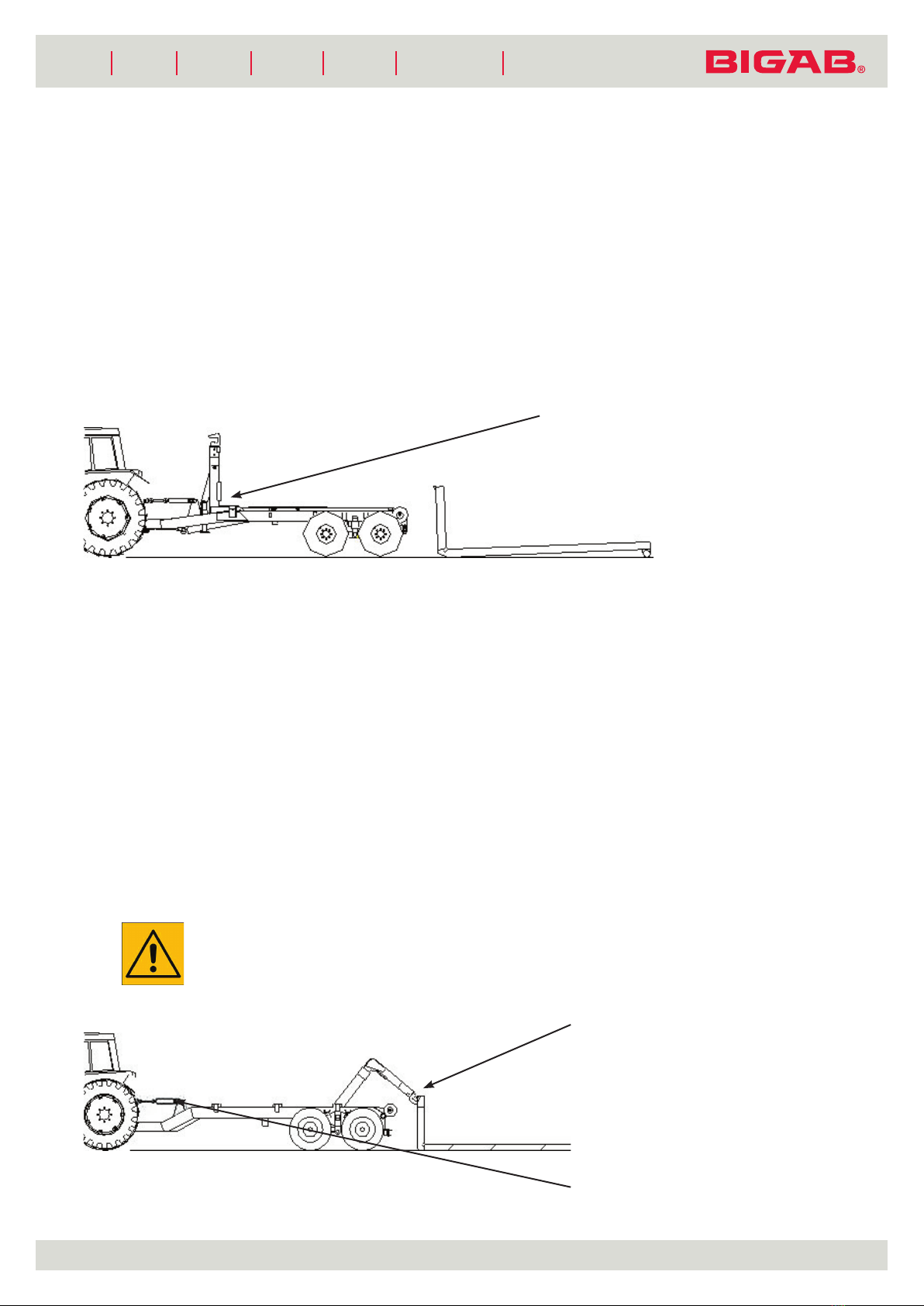

HANDLING IN ROLL ON - ROLL OFF

Exchange and tipping must be operated from the operator’s seat in the towing

vehicle! If your BIGAB is equipped with suspension there is no bogie blocking.

Ensure that the trailer is straight in

front of the load!

Ensure that the position

selector for exchange or

tipping is in the exchange

position, not in the tipping

position!

On-loading!

• Check that the load carrier is within the discs. Release the brakes on both the towing vehicle

and the trailer to make it easier to roll on the load. Check the position of the tower during on-

loading, so that the container frame does not catch on to the rollers from behind.

• The tower must be completely retracted when rolling on the container bridge in order to increase

lifting force and reduce the strain on the coupling device. Ensure that the container frame does

not catch in the rollers at the back of the trailer. Adjust the tower outwards continually during

exchange in order to move clear past the rollers. If the tower is not adjusted upwards during

on-loading, there is a considerable risk of the exchange’s lock being damaged if the container

frame catches in the rollers.

Stop if the tractor lifts o the ground!

Check that the hook

catches around the loop!

Check that the frame lock

and bogie blocking are

activated!

G G

www.forsmw.com 13

Follow the movement with the extendable tower so that the front

of the hooklift trailer’s frame does not catch on to the rollers.

When you have passed the rollers, always keep the hooklift

trailer’s frame close to the rollers.

O-loading!

Release the brakes on both the towing vehicle and the trailer to make it easier to roll o the load. Check

the position of the tower during o-loading so that the container frame does not catch on the rollers

from above.

• Lock the frame and activate bogie blocking between the towing vehicle and trailer.

• Raise the hook lift frame slightly so that the container bridge does not scratch against the frame

when you slide it backwards

• Then retract the tower backwards so that the locking rails/wings on the container bridge frame

move freely and cannot be damaged.

• Adjust the tower upwards continually so that the container frame does not catch on the rollers

at the back of the trailer during o-loading.

• If the tower is not adjusted during o-loading, there is a considerable risk of the exchange’s lock

being damaged if the container frame catches in the rollers.

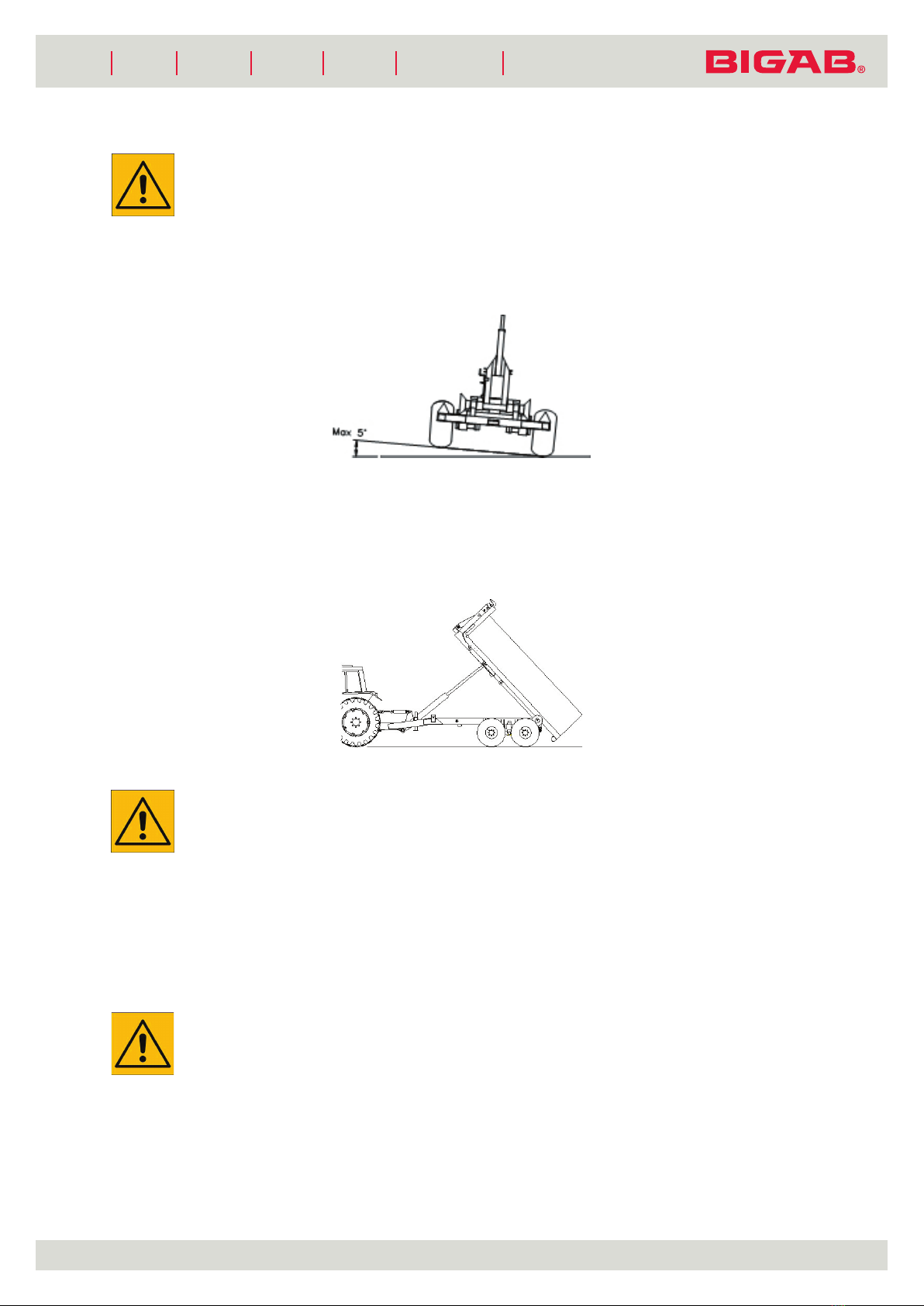

HANDLING IN TIPPING

Ensure that the towing vehicle and the trailer are securely coupled

before tipping!

Ensure that the position

selector is in the

tipping position before

commencing tipping!

G G

14 © 2021 FORS MW Ltd

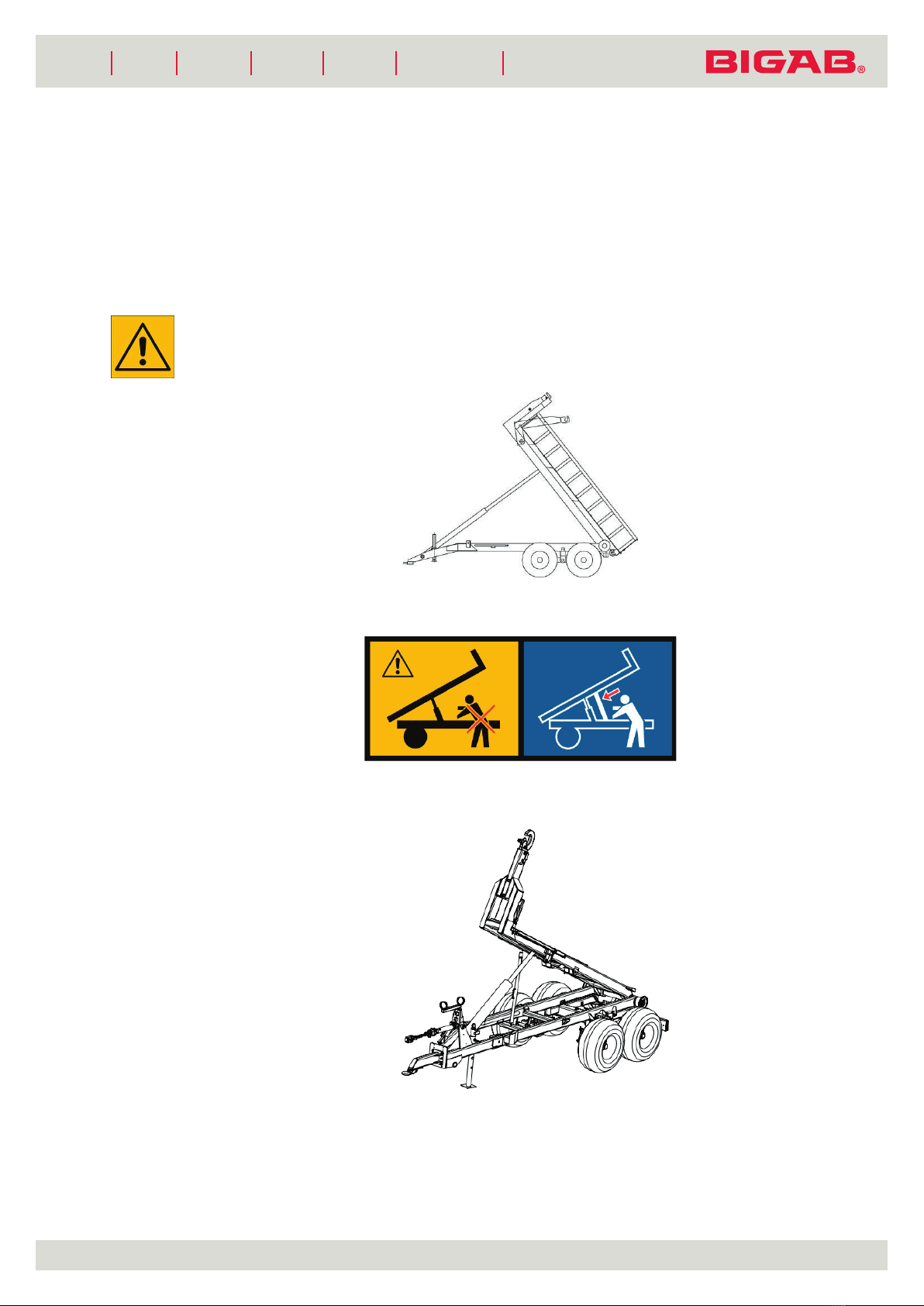

At maximum load, the telescope must be retracted 40 cm (400

mm) in order for the maximum load to be able to be tipped.

Place the hooklift trailer on a at surface.

The sideways incline may not exceed 5 degrees!

At maximum tipping angle – drive slowly forwards until the container is empty. Lower the container

before continuing to drive.

NOTE: Ensure that the container bridge is locked in the correct position before driving.

When tipping, use the brakes to ensure that the machine does

not roll away when the load slides o.

OPERATION WHEN DRIVING

It is the responsibility of the user to ensure that a suciently

powerful and heavy towing vehicle is coupled to the trailer

in all situations. The use of a towing vehicle that is too small

and insuciently powerful can entail risks for the user and the

environment, as well as leading to damage to the vehicle and

trailer

G G

www.forsmw.com 15

Table 1. Example of weight of dierent types of load

Load, kg Kg/m³ Full container 7 m³ 14 m³ 21 m³ 27 m³

Peas, Wheat, water content 15% 800 5.600 kg 11.200 16.800 21.600

Rye, water content 15% 750 5.250 kg 10.500 15.750 20.250

Barley, water content 15% 680 4.760 kg 9.520 14.280 18.360

Oats, water content 15% 560 3.920 kg 7.840 11.760 15.120

Silage, newly harvested 850 5.950 kg 11.900 17.850 22.950

Macadam 1 400 9.800 kg 19.600 29.400 37.800

Gravel 1 550 10.850 kg 21.700 32.550 41.850

Clay 1 800 12.600 kg 25.200 37.800 48.600

Wood chips (50% moisture content) 350 2.450 kg 4.900 7.350 9.450

*The higher the moisture content of the load, the heavier the load, a fact that the user has to take into consideration.

This table is only an approximate estimate of the weights that can occur, and it is the responsibility of the user to ensure

that the vehicle’s limits and the applicable legislation are not being exceeded. The specied values are not exact values,

just examples.

For information purposes and for examples of how the weight of dierent loads may vary, please refer

to the above table. This table should only be viewed as guidance and information. The manufacturer

cannot be held responsible for dimensions or volumes specied in the table, and the table may only be

viewed as a recommendation.

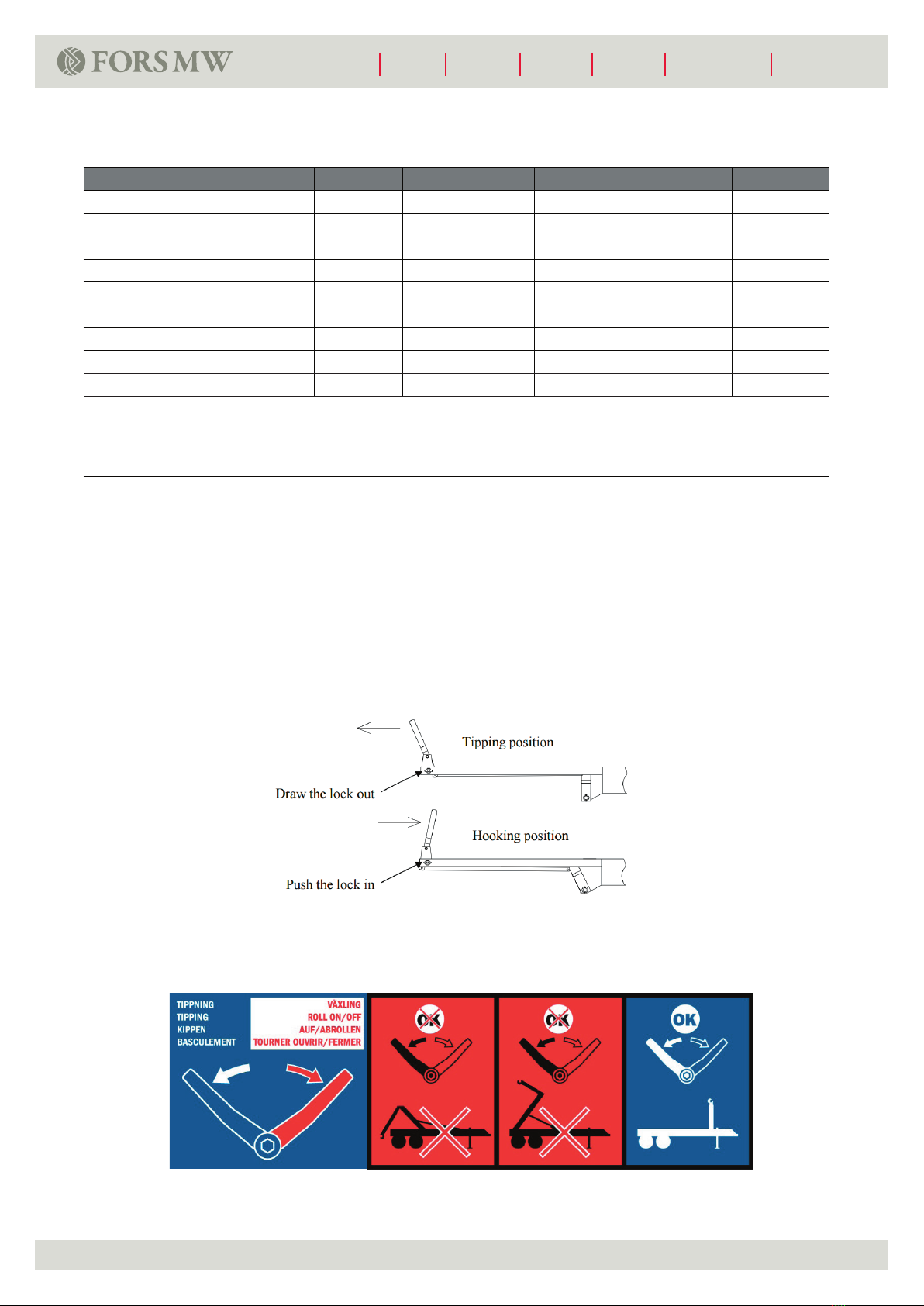

Changing operating function

Figure below shows the lever for manually changing between the operating functions. The lever is

located on the left side of the chassis. This operating function is also available with hydraulic drive.

Changing operating function

NOTE! The bolt needs to be locked within the handles extreme position.

NOTE! It is not allowed to change the changing unit unless the frame is in locked position.

G G

16 © 2021 FORS MW Ltd

WORKING IN EXTREME CONDITIONS

Recommended working temperature range for a Bigab trailer is from –30°C up to +40°C. Note that

working at low temperatures accelerates hydraulic gaskets wear and increases hydraulic hoses exposure

to damages and steel constructions exposure to brittle fracture. When working at lower temperature

than recommended, lift lighter loads than usual.

Before starting to work in cold conditions let the oil circulate freely through the system a few minutes.

Slowly work every hydraulic function through several times so that gaskets become exible before they

receive full pressure.

At exceptionally warm conditions beware of hydraulic oils excessive heating. Too high oil temperature

(above +80°C) degrades the oil and can damage gaskets.

ACTING IN DANGEROUS SITUATIONS

If the trailer comes into contact with high voltage electric wires

comply with the following instructions:

If you are outside the machine

Do not attempt to get into the machine. Keep everybody away from the machines vicinity. Do not touch

any part of the machine.

If you are inside the machine

Get out of it by JUMPING. Avoid touching any conducting parts. Do not make yourself a wire through

which electricity may ow. Get away from the machine by JUMPING so that both feet do not touch

the ground at the same time. The electrical eld of the ground can cause electrocution if both legs are

touching simultaneulsy (closing the circuit). You should be safe 20 meters away but this is of course a

questions of circumstances.

DISCONNECTING THE TRAILER

The oil can be very hot! Do not allow the hydraulic hoses to hang

down to the ground

• Park the trailer on a at, stable surface. Position a parking leg.

• Switch o the tractor’s hydraulic pump and power take-o. Release the remaining hydraulic

pressure.

• Disconnect the hydraulic hoses. Start with the pressure line rst, followed by the return lines

and nally any electrical contacts. Ensure that protective plugs are installed in the hose.

• Finish by disconnecting the trailer’s coupling device from the towing vehicle’s tow hook.

G G

www.forsmw.com 17

CLEARING BLOCKAGES AND CLEANING

• When cleaning, rst perform a rough cleanse using just water. Avoid using high-pressure sprays

on electrical components;

• Use an environmentally friendly detergent. Allow it to work for the specied time. Rinse o with

hot water;

• Always lubricate the BIGAB after cleaning.

TRANSPORT

The hooklift trailer is meant to be transported attached to the tractor at maximum design speed.

• Ensure that none of the additional equipment connected to the trailer can cause accidents

during transport;

• You must always maintain control of the unit in all situations;

• Always check that the LGV sign and reective signs are in the correct locations;

• The permitted transport dimensions, must never be exceeded;

• Before driving, check that no one is in the vicinity of the machine and that your visibility is

unrestricted;

• Bear in mind the height of the machine when driving under yovers;

• Trac rules are there to be followed - comply with the applicable legislation.

NOTE: Observe the specied safety distance to electrical cables when you are in the vicinity of such

cables.

MAINTENANCE

• Make sure that the trailer is standing on a at surface;

• Make sure that the trailer can’t move;

• When lubricating or servicing the trailer, turn o the vehicle engine;

• Be sure that the trailer can’t slip when using support leg, jack or similar equipment;

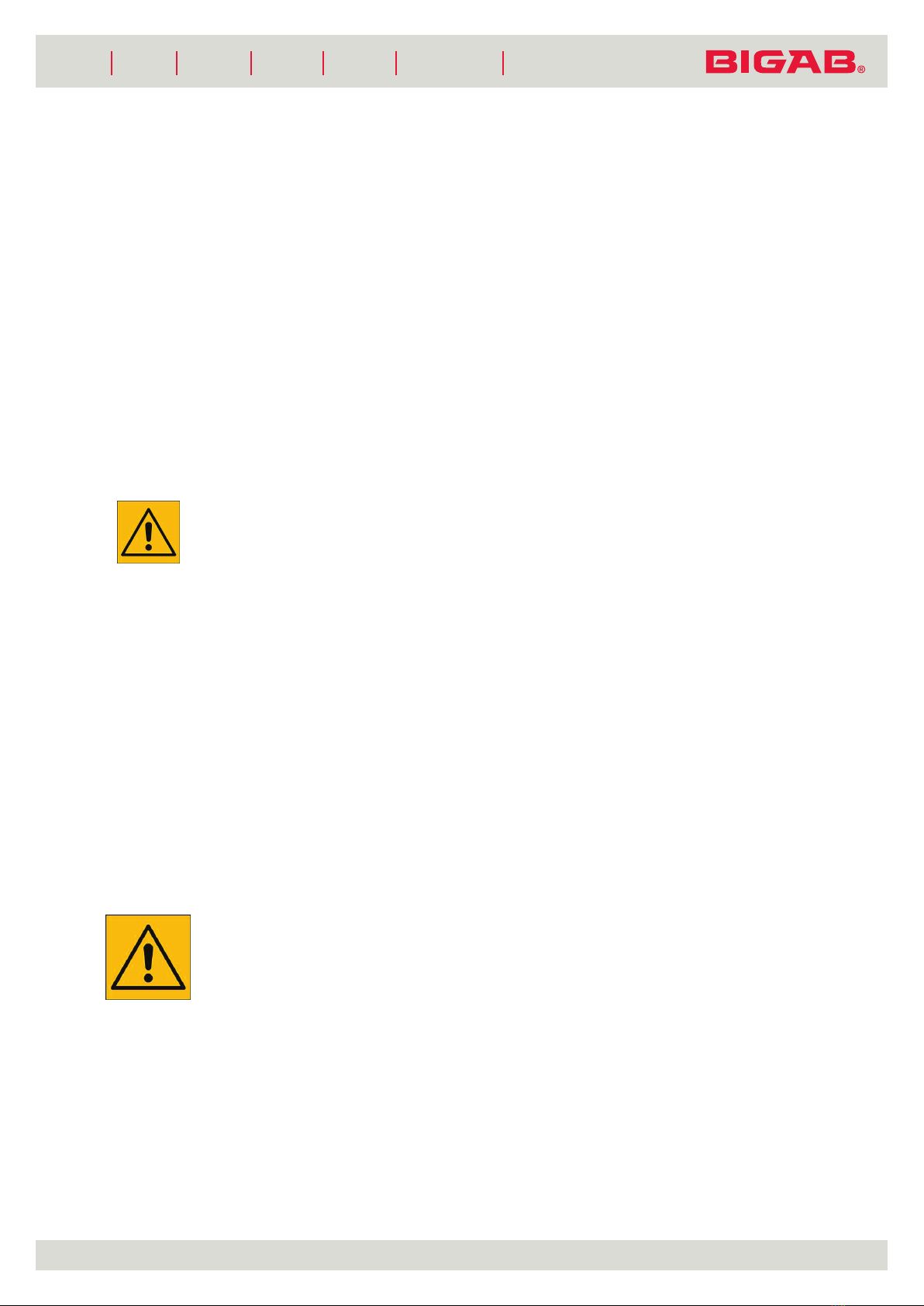

• Always use the security post in tipping position when servicing. The security post must

always be used when carrying out service work in the tipped position. There must not be

any load on the trailer when carrying out service work in the tipped position (see gures

below);

• Never attempt to do maintenance work on the hydraulic system before you are sure there

is no pressure;

• Do not tighten or repair leaking hydraulic couplings while the system is pressurized;

G G

18 © 2021 FORS MW Ltd

• Never attempt to localize a leakage from hoses or connections by feeling with your hand.

The high-pressure oil jet blaze can penetrate skin and cause serious burns and damages.

High-pressure oil is also highly ammable;

• Avoid getting oil into eyes. Use safety goggles and gloves. If eyes are exposed to oil, ush

them with cool water and immediately contact a doctor.

It is strictly forbidden to lean underneath the container without

using the security post!

Raised container bridge

Use of security post

Security post position

Service and maintenance must be carried out regularly in order to guarantee problem-free, economical

use.

G G

www.forsmw.com 19

NOTE: Failure to comply with the Fors MW instruction manual invalidates all the machine’s guarantees.

Regular, correct maintenance is a precondition for the guarantees applying.

NOTE: Only genuine spare parts may be used during repair and maintenance work.

DAILY/MONTHLY/YEARLY MAINTENANCE PROCEDURES AND INSPECTION

All kinds of maintenance work are subdivided into two groups: operating (preventive) and compulsory

(scheduled). The need for operating maintenance is determined based on the results of checking the

equipment.

General:

• Maintenance work must be carried out regularly to ensure safe and malfunction-free

operations;

• Maintenance work does not require any special tools. The user can perform most of the

operations;

• Use correct tools;

• Attempt to localize the defects as precisely as possible; you should try to avoid opening the

system unnecessarily;

• Keep disassembled parts and repair area free from dirt;

• Keep spare parts in their packages until needed for installation;

• Valve adjustments and repairs are recommended to be handled by trained service personnel.

Daily inspections:

• Examine the trailer visually. Note defects and failures that might aect safety. Repair possible

defects and failures. Look extra carefully at the position of the Towing eyelet;

• Check so there is no leakages from the hydraulic system, or damaged hoses;

• Work through every function to its extreme position;

• Check the tires and brakes;

• Check that all bolts, nuts and hoses are connected tightly;

• Check the oil level if trailer is equipped with pump and oil tank set;

• The towing eyelet must be controlled for excessive wear and tear every time before the

trailer is used. The towing eyelet needs to be changed at least once a year under normal

operation conditions. It is up to the user of the trailer to ensure that this is done.

G G

20 © 2021 FORS MW Ltd

Weekly maintenance:

• Tightening of the main cylinder bolts;

• Clean the trailer regularly with sponge and soap;

• When cleaning never use hot water under high pressure, it will remove the grease from

bearings;

• Check the operation of the device;

• Check hydraulic pressure;

• Check the brake condition;

• Check wheel nut tightness;

• Check the bolts connecting the drawbar;

• Check the lights, reectors and lamps.

Monthly maintenance:

• Check the air pressure in tires;

• Check if there is enough lubricant on glide surfaces;

• Clean and lubricate hydraulic cylinders;

• Check hydraulic hoses for damages.

Yearly maintenance:

The towing eyelet needs to be changed at least once a year under normal operating conditions. It is

up to the user of the trailer to ensure that this is done.

Maintenance of the hydraulic units:

• Clean and lubricate piston rods of hydraulic cylinders;

• Check the hydraulic valves: Visually check the hydraulic valves. In case of leaking replace the

damaged valve;

• Check hydraulic hoses: Visually check the hydraulic hoses and pipe connections. Replace a hose

in case of leaking or if there are ruptures or slashes on it;

• Check the oil level, add and replace oil if trailer is equipped with pump and oil tank set. If not

then please check tractor oil level;

• Check the operation of the device;

When replacing hydraulic components such as hoses, gaskets etc, make sure they correspond with

original parts. To avoid malfunctions and ensure safe operation use original spare parts.

Changing the seals

Change all the cylinder seals at the same time. The piston cannot be split.The seals must be slipped over

the piston edge. Be careful not to break the seals when tting them in place!

Other manuals for 7-10

1

This manual suits for next models

9

Table of contents

Other Bigab Utility Vehicle manuals