Bigab 22-27 User manual

22-27

© V7.1-2015W42–en Fors MW Ltd www.forsmw.com 1

Table of Contents

1

INTR DUCTI N ...................................................................................................... 2

Company presentation .......................................................................................... 2

Product presentation ............................................................................................. 2

2

TECHNICAL SPECIFICATI NS .................................................................................. 3

3

DIMENSI NAL DIAGRAMS ..................................................................................... 4

4

GENERAL DESCRIPTI N .......................................................................................... 5

5

MAIN C MP NENTS.............................................................................................. 6

6

SAFETY FEATURES ................................................................................................ 15

Safety support ...................................................................................................... 15

Location of the decals on the trailer .................................................................... 15

Presentation of decals ......................................................................................... 16

7

C UPLING/UNC UPLING THE TRAILER ............................................................... 21

Safety aspects when coupling/uncoupling .......................................................... 21

C UPLING T TRACT R ....................................................................................... 22

8

DRIVING THE TRAILER .......................................................................................... 23

Safety aspects when driving ................................................................................ 23

R AD DRIVING INSTRUCTI NS ............................................................................ 24

Load on towing eyelet and coupling .................................................................... 25

Working under extreme conditions ..................................................................... 26

EXCHANGE MECHANISM ..................................................................................... 27

9

EXCHANGE PERATI N ....................................................................................... 28

Safety aspects during exchange operation .......................................................... 28

Exchange procedure ............................................................................................ 29

10

TIPPING PERATI N ............................................................................................ 32

11

WIRING DIAGRAM ................................................................................................ 33

12

HYDRAULICS CHART ............................................................................................. 36

13

CARRYING UT SERVICE/MAINTENANCE ............................................................ 37

14

MAINTENANCE/SERVICE ...................................................................................... 39

15

SPARE PARTS ........................................................................................................ 46

16

TR UBLESH TING ............................................................................................. 53

17

EC DECLARATI N (sample) .................................................................................. 54

C NTACT INF RMATI N:

Factory:

AS F RS MW

Tule 30

765 05 Saue

Estonia

Tel: + 372 679 00 00

Fax: + 372 679 00 01

E-mail:

Aftermarket:

We speak English and Swedish.

FMW Farma Norden AB

Hornsväg 2

SE-605 97 Norrköping

Sweden

Tel: + 46 (0) 11 657 70

Fax: + 46 (0) 11 283 70

E-mail:

aftermarket@forsmw.com

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

2

1INTRODUCTION

Stringent demands are placed on manufacturers to comply with the directives for

the product they produce. This product is covered by the Machinery Directive and

the CE marking indicates that it meets the requirements of the Directive. n delivery

of a product, the dealer is required to provide operating instructions for the product.

Company presentation

AS F RS MW was established in Estonia in 1992. The company develops,

manufactures, markets and sells, via dealers, its three market-leading brands. These

are BIGAB hook lift trailers and dump trailers, FARMA lumber trailers and cranes, and

NIAB tractor processors. The company comprises the parent company AS F RS MW,

as well as the subsidiary companies Farma Norden AB (Norrköping, Sweden) and

ForsMW/China. You can find out more about the product you have selected and our

20-year journey by visiting our websitewww.forsmw.com and our blog

www.forsmw.blogspot.com

Prod ct presentation

The BIGAB hook lift exchange system includes a range of models, all offering the

same high level of versatility. A wide and varied range of accessories is also available.

The versatility lies in its ability to handle different kinds of loads on one and the same

chassis. You will find your BIGAB indispensible for a wide range of tasks.

The 22 – 27 is our largest hook lift trailer. Simple, impressive and powerful are all

fitting ways to describe the BIGAB 22 – 27. This is the ideal trailer for transporting

particularly heavy loads. For your safety, it is extremely important that you follow

the instructions in this instruction manual for your BIGAB model.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

3

2TECHNICAL SPECIFICATIONS

Hook lift trailer 22-27

Frame: Rectangular sections 300*100

Bogie: Parabolic sprung triple axles Axle distance 1525 mm

H bs: 130*130, 10 bolts

Tyres: 560/60-22.5

Brakes:

Hydraulic drum

*

Depending on

market 406*120 on 6 wheels

Towing eyelet: For hitch hook

Stabiliser legs: Manual Yes

Light system: 12 volt Yes

Tractor hydra lics: *For brakes

Pressure & return, 1 single

-

action brake/

1 double-action with floating position

Oil vol me: With full system 23 l

Oil vol me: Press 89 l, draw 66 l

Oil flow: 60-120 l/min

Max working press re: Max. 22 MPa

Tipping angle: 50 degrees

Chassis weight (±1%): Standard equipped 6600 kg

Chassis length (±50mm): 7550 mm

Distance eyelet to centre tridem (±20mm): Centered tridem axle 5155 mm

Distance eyelet to gro nd s rface: Min. 475 mm

Height nloaded: 1330mm excl. load carrier frame

Width across wheels (±30mm): 2590 mm

Bridge length: 5700-6500 mm

Total weight (±1%): 28 600 kg

Max. load incl. bridge: tipping (±1%): 22 000 kg

Max. load incl. bridge: roll on/roll off (±1%): 21 000 kg

Load on towing eyelet:

Depending on the position of the trailer bed 2500 – 3500 kg

Max. speed 40 km/h

REF: 150923

/REF:150706

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

4

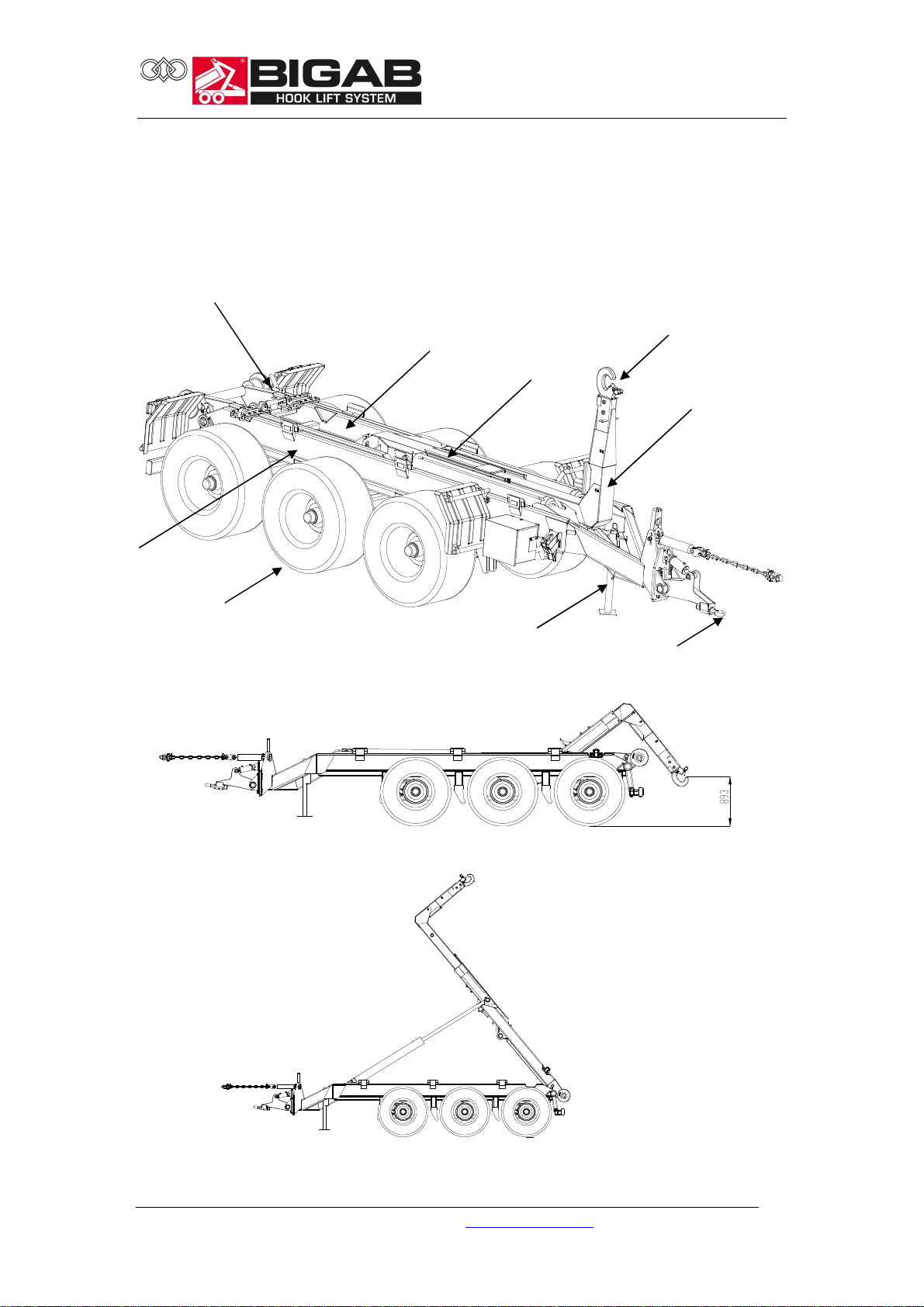

3DIMENSIONAL DIAGRAMS

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

5

4GENERAL DESCRIPTION

The trailer is steady when used for both tipping and exchanging. The trailer is

equipped with a torsional parabolic spring bogie on three axles with brakes on all

wheels.

Chassi

Hook

Wheels

Rear

frame

Hook

frame

Steering

roller

Stabilise

r leg

Towing

Exchange

position

Tipping

position

Telescop

e

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

6

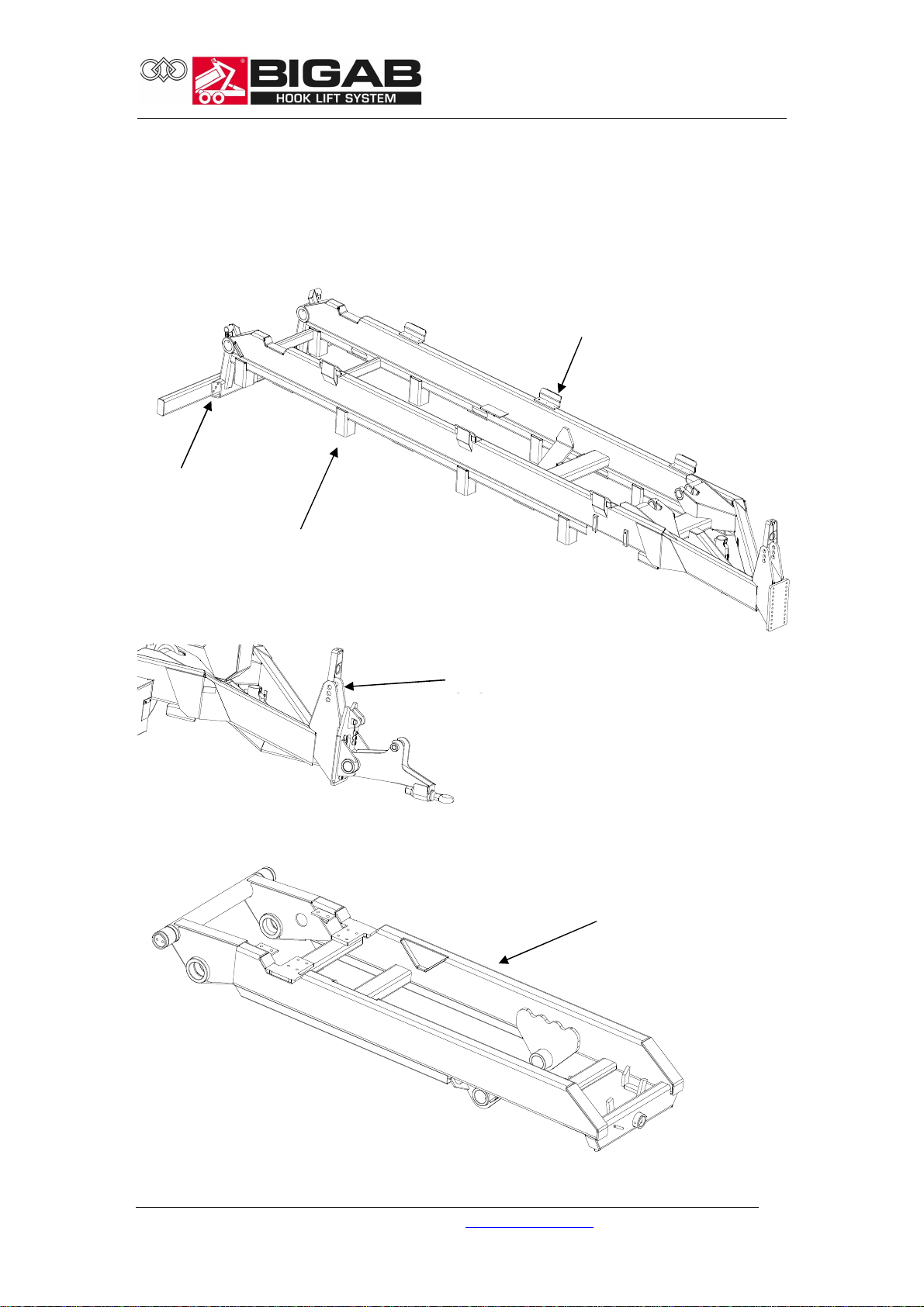

5MAIN COMPONENTS

The trailer comprises the following principal components and functional devices.

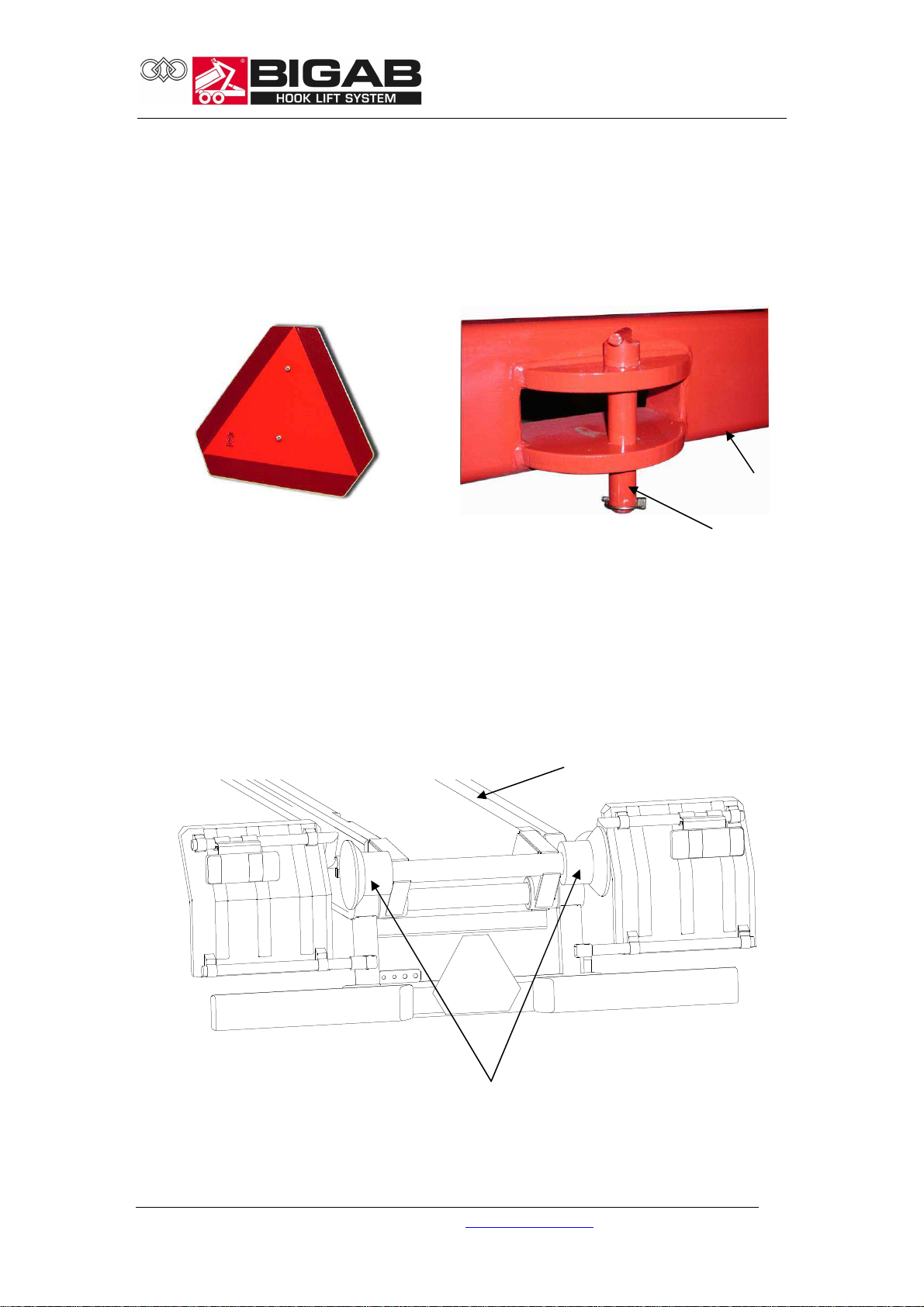

Chassis

Rear frame

Rear beam

Suspension

bracket

Side

support

Rear frame

Bracket for frame

lock

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

7

Hook frame

Bogie

The trailer is equipped with a powerful sprung tridem bogie with brakes on all six

wheels.

Brake cylinder

Axle with brake

x 3

Sprung tridem

bogie

Hook

Hook

frame

Telescope

Extended tower

1300 mm

Hydraulic cylinder (inside)

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

8

Hook

The trailer is equipped with an adjustable hook for two different heights.

Stabiliser leg

The stabiliser leg is designed to support the trailer when not in use. The stabiliser leg

must not be used when the trailer is loaded. The stabiliser leg must be raised and

secured in place with the pin before moving off.

Stabiliser leg

Pin

Chassis

Standard height: 1450

Standard height: 1570

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

9

Exchange nit

The unit is designed for

the procedure when switching between

tipping and exchange.

The lever is located in the middle

of the rear frame.

Exchange nit container lock

The trailer is equipped with a

hydraulic container lock

that secures the container to the frame

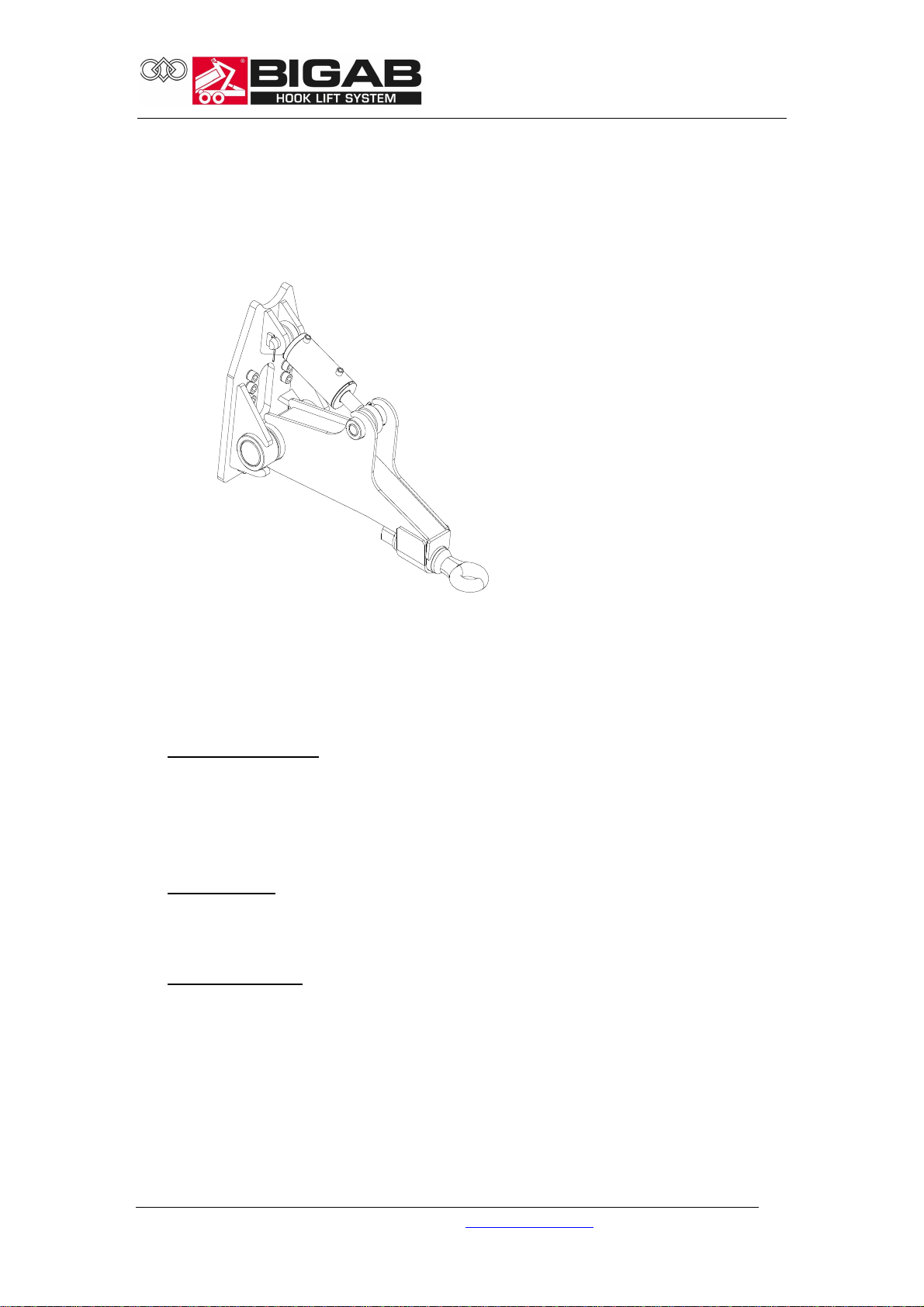

Towing eyelet

The towing eyelet is adapted to the hitch on the towing vehicle. It is extremely

important that the towing eyelet is inspected for defects every time the trailer is

used.

Hydraulic cylinder

Locking bolt

Rear frame

Chassis

Towing eyelet

Hydraulic cylinder

Locking lug

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

10

Drawbar

The drawbar is used for coupling other equipment to the trailer. It is also used for

attaching the warning triangle. Note! Do not couple excessively heavy loads to the

drawbar. The maximum permitted trailer weight is 10 tonnes.

Steering rollers

The steering rollers are designed to guide the bed correctly. The bed frame must be

inside the steering rollers during exchange operations.

Rear beam

Pin

Steering roller Left Right

Chassis

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

11

Frame lock

The hydraulic frame lock is used to lock the frame during heavy exchange operations.

When mounting the chain on the tractor for the first time, adjust the length of the

chain so that it is slack when the cylinder is half extended.

When you then tension the cylinder, the pressure relief valve is set at about 100 bar

and it can be adjusted to the size of the tractor.

It is very important to slacken it after exchanging so as not to impede the tractor

during transport.

Frame lock hydraulic

cylinder

Chain to tractor

Manometer

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

12

S spended drawbar

Drawbar f nctions

The trailer is equipped with an adjustable drawbar that can be used for the following

three functions. Use the position switch on the control unit to regulate the drawbar.

Select a function and regulate the pressure with the toggle switch.

Suspended drawbar

Set the mode switch to suspension mode and then apply pressure. Watch the

manometer to see how much pressure you apply. The valve has a pressure

limiter that controls the amount of pressure you can apply. Check at regular

intervals during transport that the pressure remains constant.

Fixed drawbar

This function is used to stabilise the trailer when exchanging containers. Set the

mode switch to fixed mode and apply pressure to stabilise the drawbar.

Swinging drawbar

Set the mode switch to swinging mode. No pressure is applied to the drawbar.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

13

Tyres

List of standard tyres and alternative tyres that are used for the different trailer

models.

Model

Standard tyres Alternative tyres Air press re

(bar)

Speed

(km/h)

22-27 560/60-22.5 3.6 40

445/65R-22.5 5-10 40

650/50R-22.5 TL

10B -70

4.0 40

* The air press re may vary slightly depending on the make of tyre. Contact the tyre

man fact rer for exact air press res.

Hydra lic system

The trailer is equipped with a hydraulic system for the various work operations. For

more information, see the Hydraulics Chart chapter.

Electrical system

The trailer has a 12 volt electrical system. For more information, see the Wiring

Diagram chapter.

Brake system

The trailer is equipped with a hydraulic brake system. A pneumatic brake system is

also available as optional equipment. Note! The hydraulic pressure in the brake lines

should not exceed 16 Mpa. Too much hydraulic pressure can cause the brake arm

cam to go over-centre and lock the brakes.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

14

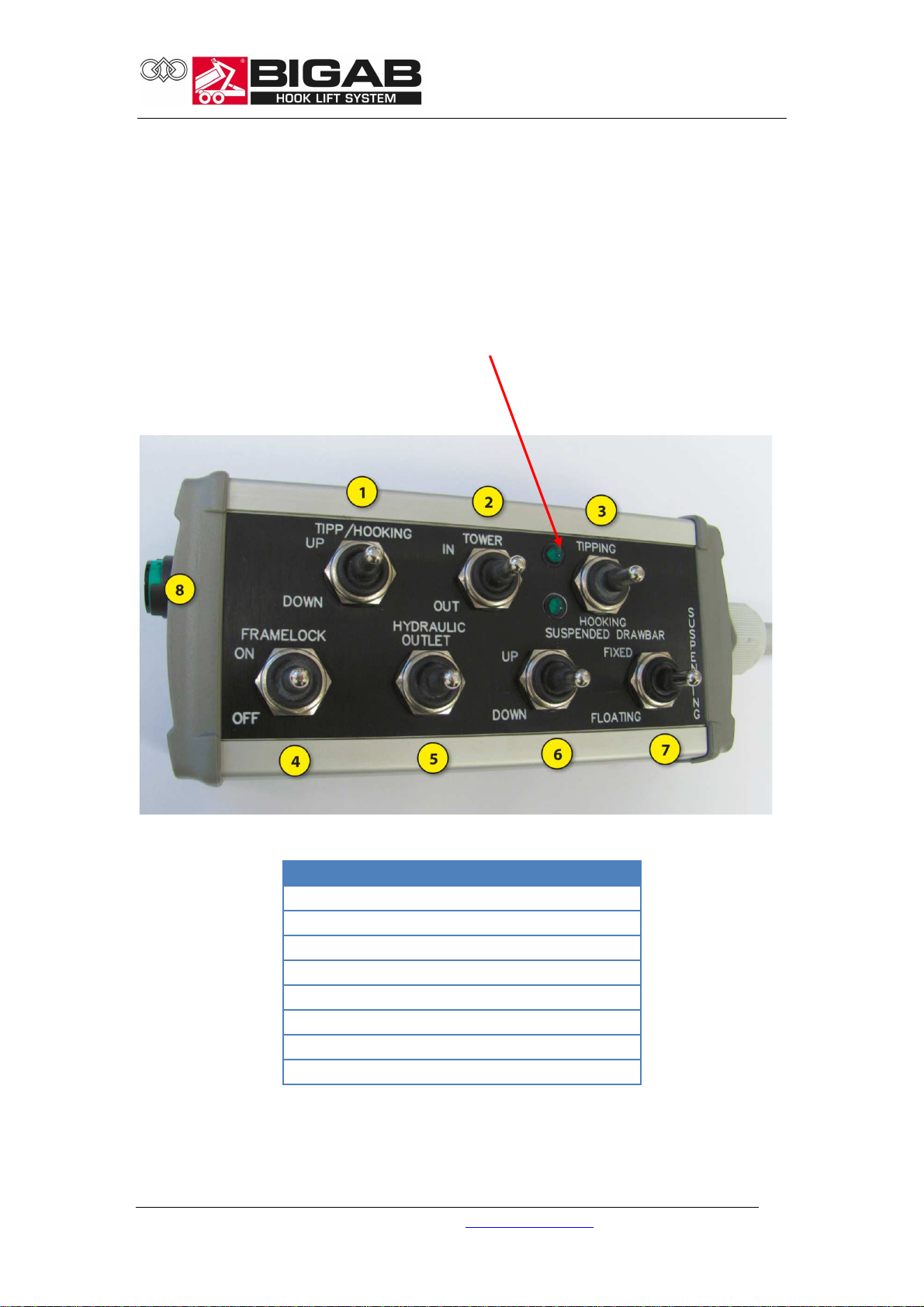

Electric on-off control

The trailer is equipped with a hydraulic system that is operated via a control unit.

With regard to position 3, it is important to run this function until the signal lights

come on. This indicates that the locks have reached their end stop position.

No.

Description

1

Tipping/Exchange

2

Telescope in/out

3

Exchange/tip/container lock

4

Frame lock

5

Hydraulic outlet

6

Suspended drawbar up

-

down

7

Suspended drawbar locked

-

sprung

-

floating

8

n

-

ff

With regard to position 3, it is important to run

this function until the signal lights come on.

This indicates that the locks have reached their

end stop position.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

15

6SAFETY FEATURES

Safety s pport

Always use the safety support when carrying out service work when the trailer bed is

raised. The safety support must not, under any circumstances, be used when the

trailer bed is loaded.

Location of the decals on the trailer

The trailer is marked with various signs relating to safety and information. Check that

all signs are correctly positioned.

Safety support

Chassis

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

16

Presentation of decals

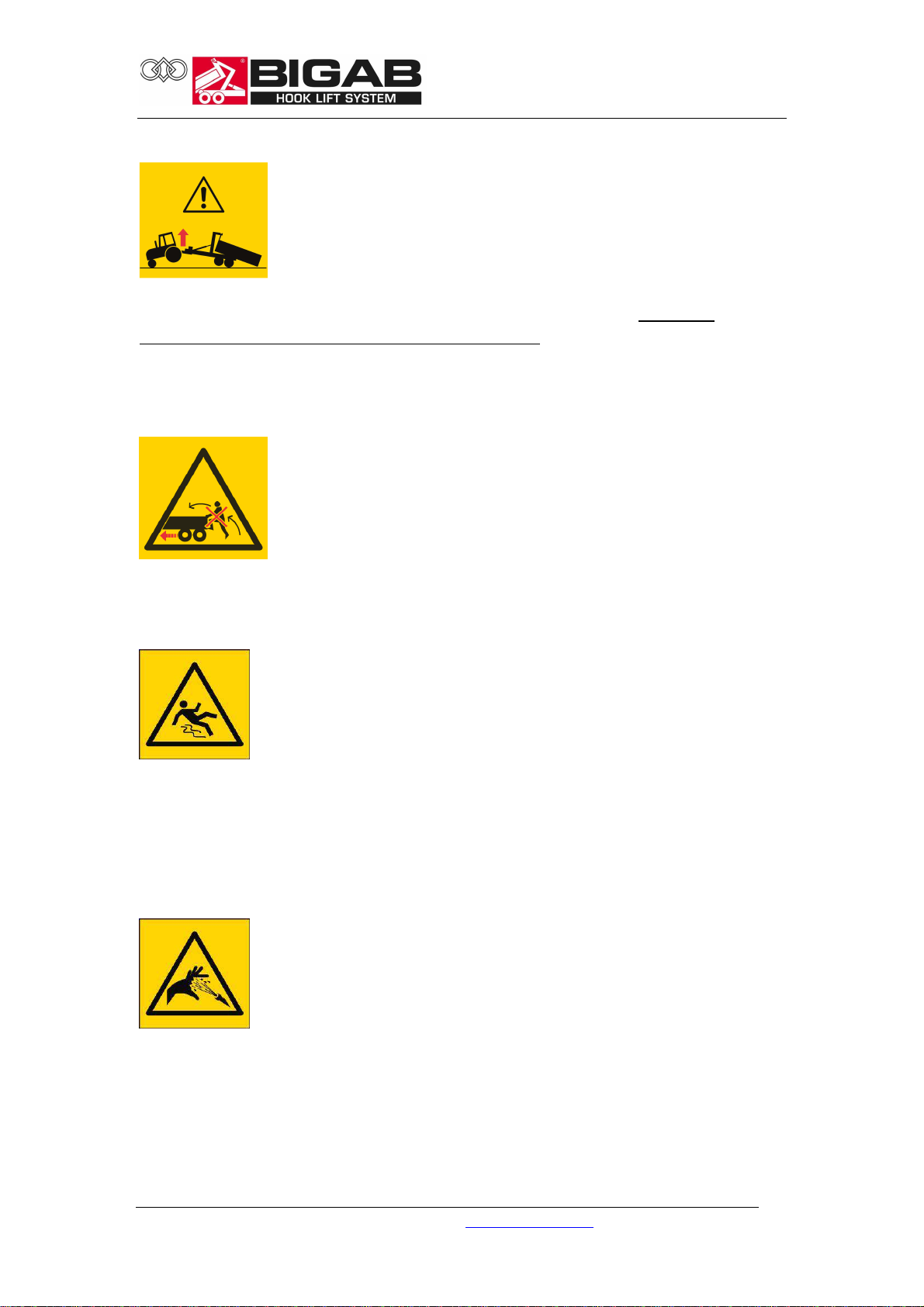

WARNING!

Warning triangle and instruction manual decal.

The trailer has a warning triangle next to the instruction manual decal to emphasis

the importance of reading the entire instruction manual carefully before using the

trailer. Failure to observe this may result in serious or fatal injury.

INFORMATION!

Decal for the use of safety equipment.

These decals encourage the use of appropriate safety equipment in order to avoid

injury when using the trailer.

DANGER!

Risk of crushing injuries

There is a risk of trapping and crushing injuries during work and maintenance.

WARNING!

Hazardous area

Standing between the trailer and the towing vehicle when the trailer is being driven,

moved with frame steering or when other functions are activated between the

trailer and towing vehicle, can be potentially fatal. As the driver, you must always

ensure that no one is in the area around the machinery.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

17

WARNING!

Warning - It is a hazardous movement if the rear end of the tractor lifts

Note! This warning label is included in the delivery of your trailer. It must be

attached in a conspicuous position in the tractor cab. If you would like more of these

labels, they are available to order, free of charge, from our after sales department.

Contact details are printed on the first page in the instruction manual.

WARNING!

It is absolutely forbidden to board the trailer when it is moving

Anyone doing so may be at risk of serious or fatal injury.

WARNING!

Risk of slipping

There is a risk of slipping as the surfaces of the trailer can be slippery due to a

combination of precipitation and oil and/or clay on the surface. The ground around

the trailer can also become slippery, as the tyres can tear up the surface and expose

clay and soil.

DANGER!

Hydraulic fluid under pressure

Hot hydraulic fluid at high pressure levels can occur in the hydraulic system. Take

care when connecting. Replace worn or damaged hoses.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

18

INFORMATION!

Using the exchange unit

Do not operate the exchange unit unless the frame is folded down. During transport

with the trailer, the hook must be folded down in the parking position.

WARNING!

Use the safety support during all service operations

It is absolutely forbidden to lean under a raised frame unless it is secured with the

safety support. Under no circumstances may the trailer be carrying a load or

container when the safety support is being used.

WARNING!

Maximum load

It is absolutely prohibited to load more than the amount your model of trailer is

designed to handle. This can be dangerous for you and your surroundings.

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

19

WARNING!

Max. pressure on towing eyelet

Do not load so much that the pressure on the towing eyelet exceeds the permitted

laws and regulations. The trailer is designed for a maximum pressure of 3000 kg on

the towing eyelet. The pressure is largely determined by the way the load is

distributed on the container bridge, and it is the user’s responsibility to ensure that

this is not exceeded.

INFORMATION!

Tyre inspection

The tyres must be tightened and the brakes must be inspected regularly.

INFORMATION!

Lubrication

This decal is used to show the importance of regular lubrication of the trailer.

INFORMATION!

ID- plate

22-27

© V7.1-2015W42-en Fors MW Ltd www.forsmw.com

20

Marking of hydra lics

All of the hydraulic hoses are marked with coloured labels. See the table below for

more detailed information. The functions depend on the configuration of the

hydraulic system.

Hydraulic hose label (example tipping cylinder)

Hose label colors:

•Red - il from pump

•Blue - il to tank

•Yellow - Brake

Marking of the hydraulic hoses

.

No. Colo r F nction

1 Yellow Brakes

26 Red Steering (p)

27 Blue Steering (t)

Table of contents

Other Bigab Utility Vehicle manuals