Bigab T-7 User manual

INSTRUCTION MANUAL

T- (T-8)

Instructions

v1 - 2012

V1.1-2016-EN

Original instructions

Dump trailer T-7

2© AS FORS MW

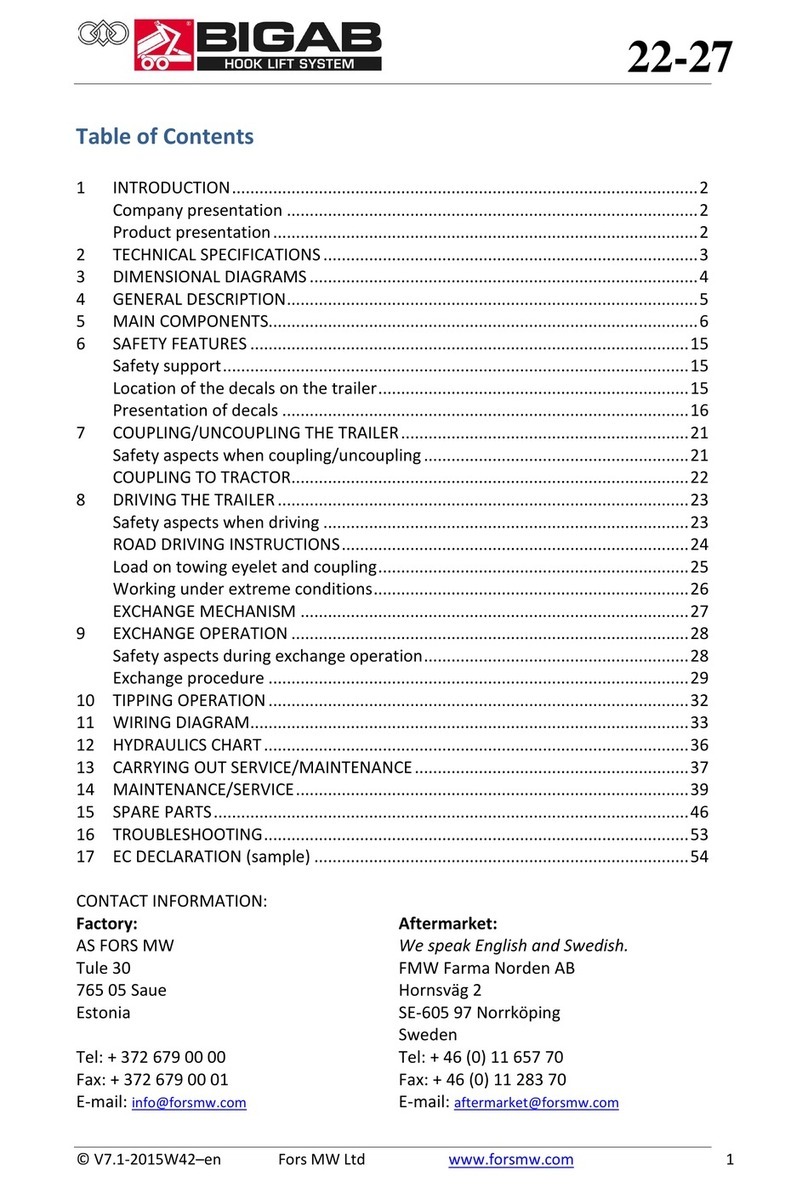

INTRODUCTION ..........................................

Company presentation ...........................................

Product presentation...............................................

TECHNICAL SPECIFICATION ......................

DIMENSIONAL DIAGRAM...........................

GENERAL DESCRIPTION OF

THE PRODUCT .............................................

Principal components and

functional devices.....................................................

SAFETY REGULATIONS..............................

Hazardous areas.......................................................

Trailer safety ..............................................................

SAFETY DEVICES........................................

Safety support..........................................................

Location of decals on the trailer ........................

Presentation of decals ...........................................

INSTALLATION OF THE PRODUCT............

Inspection of new trailer.......................................

Adjustments..............................................................

COUPLING/UNCOUPLING THE TRAILER .

Safety aspects, connection/disconnection...

Marking of hydraulic hoses..................................

DRIVING THE TRAILER..............................

Safety aspects while driving................................

Loading of towing eyelet and coupling..........

Table of load weights.............................................

Working in extreme conditions.........................

TIPPING THE TRAILER................................

Safety aspects when tipping ..............................

ELECTRICAL CIRCUIT DIAGRAM..............

Wiring diagram .......................................................

Spare parts................................................................

HYDRAULICS CHART .................................

Schedule.....................................................................

Spare parts.................................................................

HANDLING DURING SERVICE/

MAINTENANCE..........................................29

Safety aspects during

service/maintenance .............................................29

MAINTENANCE/SERVICE.......................... 1

Schedule for maintenance intervals.................1

Procedure during maintenance/service ........2

TROUBLESHOOTING.................................38

SPARE PARTS .............................................

In this manual, we have gathered all the information regarding a particular procedure in a single same chapter. As always, safety issues are

of the utmost importance and are presented at the start of the instruction manual, along with technical data and dimensional diagrams.

The "Installation" chapter contains important information for familiarising yourself with the trailer. The chapter on the use of the trailer,

such as coupling/uncoupling, driving and tipping, must be read before you start to use the product, as must the safety aspects and safety

devices. Be sure to extend the service life of your product by following the information in the "Service/Maintenance" chapter.

CONTENTS

CONTACT INFORMATION:

Tel.: +

Fax: +

Email: info@forsmw.com

Factory:

AS FORS MW

Tule

Saue

Estonia

Tel.: + ()

Fax: + ()

Email: aftermarket@

forsmw.com

Aftermarket:

We speak English and Swedish.

FMW Farma Norden AB

Hornsväg

Norrköping

Sweden

Dump trailer T-7

www.forsmw.com 3

INTRODUCTION

High demands are placed on manufacturers regarding conformance to directives that have been drawn up

for their products. This product is covered by the Machinery Directive, and the CE marking indicates that it

satises the requirements in the Directive. On delivery, it is incumbent upon the dealer to provide operating

instructions for the product.

Company presentation

AS FORS MW was established in Estonia in .The company develops, manufactures, markets and sells, via

dealers, the three market-leading brands: BIGAB hooklift trailers and dump trailers, FARMA lumber trailers

and cranes, and NIAB tractor processors. The company comprises the parent company AS FORS MW, as well

as the subsidiary companies Farma Norden AB (Norrköping, Sweden) and Fors MW/China (China). You can

read more about both the product you have selected and our -year journey on our website, www.forsmw.

com, and on our blog, www.forsmw.blogspot.com

Product presentation

The BIGAB dump trailer is a relatively simple yet robust dump trailer designed to withstand hard use which

is just as suitable for contractors as for farmers. The dump trailer has a trailer bed and sides constructed in

welded steel with robust reinforcements. The trailer loads tons and has a tipping angle of degrees.

The dump trailer is equipped as standard with ./ x . tyres, bolted drawbar and mechanical hung

tailgate with side doors. The trailer can be further equipped with -wheel drum brakes and hydraulic

stabiliser legs. The trailer meets the requirements necessary for operation at km/h (Swedish market) or

km/h (Norwegian market).

We understand your curiosity and desire to put your BIGAB dump trailer to work, but we ask you to spend a

little time reading through this instruction manual before you start using the machine. If not used correctly,

theBIGAB dumptrailercancauseunwantedoperationalstoppagesand,in theworstcase,itcanbedangerous.

A little time spent reading this instruction manual could save you both time and money in the future. For

your safety, it is extremely important that you follow the instructions presented in this instruction manual.

EU-declaration of Conformity

Fors MW AS, represented by Leif Fors,

Tule 30

76505 Saue

Estonia

The technical file compiled by Leif Fors;

Hereby confirm that this equipment:

1. Vehicle type: complete lumber trailer with crane

2. Manufacture: (FARMA) CT 6,0-9

3. Chassis number: CT096007792

4. Manufacture code: CT 6,0-9

5. Manufacture year: 2010

Consist of trailer, crane, grapple.

Is manufactured accordingly to demands in directive 2006/42 EG and wherefore can

be used mounted together with over equipment to provide a machine.

The equipment can’t be used before the machine or the formation that it will take

place in is accordingly to the demands of the EG machine directive.

Signature:

Leif FORS, CEO

Tule 30

765 05 Saue

Estonia

Tel: +372 679 00 00

Fax: +372 679 00 01

Reg. no. 10094723

E-mail: [email protected]

Webb: www.forsmw.com

VAT-no. EE100189685

EU declaration of conformity with Directive / EC

Dump trailer T-7

4© AS FORS MW

TECHNICAL SPECIFICATION

Technical data Dump trailer T-

Total length mm

Total width mm

Height mm

Internal dimensions of load surface . x . x .

Load capacity in m . m

Panel thickness at bottom/sides mm/ mm

Trailer dead weight kg

Max. payload kg

Total weight with load kg

Axles x

Brakes -wheel brakes as optional

extra

Brake force requirement bar

Parking brake -

Max. speed km/h

Towing eyelet, vertical/horizontal max. ,/ kg

Load on towing eyelet, empty trailer kg

Load on towing eyelet, fully loaded

trailer kg

Tipping angle °

Dump trailer T-7

www.forsmw.com 5

DIMENSIONAL DIAGRAM

K K

247

1883

1510

89

566

417

234

81

170

1592,5

9

2511,44

4009

SECTION

K-K

990

66°

4570

919

6028

450

4009

3654

917

Dump trailer T-7

6© AS FORS MW

990 874

701

1100

3675

467

628

871

1500

5304

450

1788

4011

917

Dump trailer T-7

www.forsmw.com 7

1788

2174

701

2250

2307

400

450

Dump trailer T-7

8© AS FORS MW

GENERAL DESCRIPTION

Principal components and functional devices

The trailer consists of the following principal components and functional devices.

The towing eyelet is suitable for

hitch hooks. It is very important

that the towing eyelet is checked for

defects every time the trailer is used.

The towing eyelet must be greased

regularly. The towing eyelet must be

replaced at least once a year.

The trailer bed loads

5.6m3 with 5 mm

plate thickness at the

bottom and 3 mm at

the sides.

Bolted drawbar – The trailer is

equipped with a bolted drawbar for

optimum comfort and increased

exibility since it oers the

opportunity to use the drawbar at

dierent heights as required.

Tyres – The trailer

is delivered with

11.5/80 x 15.3 tyres,

but other tyres are

available as optional

extras.

The chassis is constructed

from rectangular steel

sections.

Dump trailer T-7

www.forsmw.com 9

Tailgate

The trailer is equipped with a mechanical hung tailgate with side doors.

The illustration shows the hung tailgate and that the side doors can be opened fully.

NOTE! Do not drive with the side doors open, because the doors will then extend beyond the trailer's

normal dimensions. Accidents can occur if the driver is not careful.

The trailer is delivered with hung tailgate with locking catches on the bottom edge. It has notches for

spreader chains. The doors are released on the left side by using a mechanical handle.

Dump trailer T-7

10 © AS FORS MW

NOTE! It is important that you check the doors before driving o to make sure they are securely locked

after they have been opened. Checking this is the driver's responsibility.

Tyres

The dump trailer is equipped as standard with:

11.5/80x15.3 A8. 40 km.

Name Hose Wheel

dim

Width

mm

Diameter

mm

Load

Kg

Air pressure

Bar

6-161-205 10Pr YES 9.00x15.3" 297 844 1950 4.6

The trailer can be equipped with optional extras:

400/60x15.5” A8. 40 km.

Name Hose Tyres

pattern

Wheel

dim

Width

mm

Diameter

mm

Load

Kg

Air pressure

Bar

400/60x15.5” Rib 900 13.00x15.5" 405 875 2725 4.50

Dump trailer T-7

www.forsmw.com 11

Hydraulic system

The trailer is equipped with a hydraulic system for the various work stages.

Electrical system

The trailer is manufactured with a 12V electrical system.

Braking system

The trailer can be equipped with a hydraulic braking system. A pneumatic braking system is also

available as an optional extra. Note! The hydraulic pressure in the brake pipes should not exceed 160

bar. If too high a hydraulic pressure is used, the brake arm cam can go over the centre and lock the

brakes.

Dump trailer T-7

12 © AS FORS MW

SAFETY REGULATIONS

IMPORTANT!

READ THE ENTIRE INSTRUCTION MANUAL BEFORE USING THE TRAILER. CONSULT THE

MANUAL IF YOU ENCOUNTER ANY PROBLEMS. THE TRAILER HAS A DATA PLATE.

BEFORE USING THE TRAILER, MAKE SURE THAT THE FACTORY SETTINGS HAVE NOT

BEEN CHANGED AND THAT NO PARTS HAVE COME LOOSE DURING TRANSIT. MAKE

SURE THAT ALL SAFETY FEATURES AND SIGNS ARE IN PLACE.

HAZARDOUS AREAS

To avoid injuries or damage while working with the trailer, the dump trailer must be

operated by only one person. Do not allow anyone inside the trailer's hazard zone,

which is 8 m around the trailer.

Never let anyone stand behind or by the side of the trailer when tipping the trailer bed.

Warning – risk of crushing due to moving parts!

Unauthorised persons are not permitted near the machine when it is in use or being repaired. It is

strictly forbidden for anyone under the inuence of alcohol or drugs to work with the trailer.

Trailer safety

To ensure the safe use of the product, for trouble-free operation and for the warranty to be

valid, maintenance must be carried out in accordance with the service described in the chapter

"Maintenance/Service".

The trailer must be loaded evenly and must be on level ground when tipping. Consult the section

"Tipping the trailer" to avoid overturning. The trailer is equipped with lashing loops.

Check the locking pins before tipping.

Do not remove the tipping cylinder's oil hose during tipping.

The estimated coupling load from drawbar to tow hook at maximum and evenly distributed load is

1260 kg.

The towing eyelet is adjusted to the tow hitch on the towing vehicle. It is very important that the

towing eyelet is checked for defects every time the trailer is used. The towing eyelet must be replaced

at least once a year. It is the user's responsibility to ensure that this is done. Note! Never weld onto the

towing eyelet, as this will change the material's strength.

Dump trailer T-7

www.forsmw.com 13

Pay attention to the warning decals.

The trailer is not known to cause noise exceeding 70 decibels.

Transport of people or animals in the dump trailer is not permitted.

WARNING!

The manufacturer does not accept any liability for damage that is caused by

overloading or which arises in the case of drawbar failure if the trailer detaches from

the vehicle. The maximum load is stated in the technical data.

Dump trailer T-7

14 © AS FORS MW

SAFETY DEVICES

Safety support

Always use the safety support when carrying out service in the tipping position. The safety support

must not be used under any circumstances when the trailer bed is loaded.

Safety support

Location of the decals on the trailer

The trailer is equipped with a range of decals for both safety and information. Check that all signs are

in the correct position.

Dump trailer T-7

www.forsmw.com 15

Presentation of decals

WARNING!

Warning triangle and instruction manual decal.

The trailer is supplied with a warning triangle alongside the instruction manual decal in

order to emphasise the requirement for the user to read the entire instruction manual ca-

refully before starting to use the trailer. Ignoring this can entail a danger to life.

INFORMATION!

Decal for the use of safety equipment.

These decals encourage the user to use the appropriate safety equipment in order to avoid

injury when using the trailer.

DANGER!

Risk of crushing injuries

There is a risk of being trapped or crushed during work and maintenance.

WARNING!

Hazardous area

It is potentially fatal to stand between the trailer and the towing vehicle when the trailer is being driven,

moved with frame steering or when other functions are activated between trailer and tractor. As the dri-

ver, you must always ensure that the area around the machine is free of people.

WARNING!

It is totally forbidden to board the trailer when it is in motion.

This can potentially be fatal.

Dump trailer T-7

16 © AS FORS MW

WARNING!

Warning – If the rear of the tractor lifts, a hazardous movement has started.

When the rear of the tractor starts to lift this is a warning that you have started a hazardous movement.

Note! One copy of this warning decal is included with your trailer on delivery. It must be placed conspi-

cuously in the tractor's cab. If you would like to more, they can be ordered free of charge from our after-

market department. See the first page of the instruction manual for contact details.

WARNING!

Risk of slipping

There is a risk of slipping as the surfaces of the trailer can be slippery due to precipitation combined with

pre-existing oil and/or clay on the surface.The ground around the trailer can also be slippery, because the

tyres can tear up the surface and expose clay and soil.

DANGER!

Hydraulic uid under pressure

Hot hydraulic fluid at high pressure may occur in the hydraulic system. Take care when connecting, and

replace damaged hoses.

WARNING!

Warning – contact with electrical power lines

The trailer may only be driven in the transport position. Never drive or tip with raised trailer bed. If you

drive with the trailer bed raised, you risk colliding with obstacles such as bridges, electrical power lines

etc.

WARNING!

Always use the safety support during service.

It is absolutely prohibited to lean in under the raised frame, unless it is secured with

the safety support. Under no circumstances may the trailer be carrying a load or a

container when using the safety support.

Dump trailer T-7

www.forsmw.com 17

WARNING!

Max. load

It is absolutely forbidden to load more than the amount your model is intended to handle.This can result

in danger to you and your surroundings. For information on your model, please consult the technical

data.

WARNING!

Max. strain on towing eyelet

Ensure that you do not load so the strain on the towing eyelet exceeds that permitted by statute and

regulations. The trailer is designed for a maximum strain of kg on the towing eyelet. The strain is

largely determined by the way the load is distributed on the trailer bed, and it is the user's responsibility

to ensure that this is not exceeded.

INFORMATION

Wheel inspection

The wheels must be tightened and the brakes checked regularly.

INFORMATION

Lubrication

This decal is used to show the importance of regular lubrication of the trailer.

INFORMATION

20

KG

MAX LAST INKL FLAK: TIPPNING

MAX LOAD INCL BODY:TIPPING

MAX. GewIChT INKL. CONTAINer BeI KIPPeN

TILLVerKNINGSNUMMer

SerIAL NUMBer

herSTeLLUNGSNUMMer

TILLVerKNINGSÅr

YeAr OF PrODUCTION

SerIeNNUMMer

PrODUKTTYP

PrODUCT T YPe

PrODUKTTYP

MAX LAST INKL FLAK: FLAKVÄXLING

MAX LOAD INCL BODY: rOLL ON/rOLL OFF

MAX. GewIChT INKL. CONTAINer BeI AUF/ABhAKeN

KG

KG

KG

KG

TOTALVIKT

TOTAL weIGhT

ZUL. GeSAMTGewIChT

AXeL TrYCK

AXLeLOAD

ZUL. AChSLAST

MAX DrAGBeLASTNING KrOK

MAX PULL PreSSUre hOOK

ZUL. STÜTZLAST

Data plate

Dump trailer T-7

18 © AS FORS MW

Tightening torque

Dump trailer T-7

www.forsmw.com 19

INSTALLATION

Inspection of your new BIGAB dump trailer

The following checks must be made before the trailer is taken into use:

It is strictly prohibited to use the trailer if its safety devices are damaged. For more detailed

information about the safety devices, see the chapter "Safety Devices".

Check that the wheel nuts are tight. See the table for tightening torques. Recheck after 2–3 hours

driving and then 2–3 times a year.

Check that the indicators, brake lights and taillights are working. For information on the electrical

system, consult the wiring diagram.

Check that the hydraulic connections for tipping and brakes are correctly connected.

Bleed the brakes if the brakes are optional extras. See Maintenance/Service for information on how to

do this.

Dump trailer T-7

20 © AS FORS MW

COUPLING/UNCOUPLING THE TRAILER

Positioning of parking chocks

The illustration shows where parking chocks should be placed when coupling/uncoupling the trailer

and when parking.

Safety aspects when coupling/uncoupling

The following must be checked before each use:

Inspect the trailer carefully.

Check the air pressure in the tyres. This must always be at least the recommended pressure. See

Maintenance/Service for more detailed information.

Check that all connections are correctly connected.

Check that the trailer is locked to the towing vehicle.

Check the towing eyelet and the coupling device on the tractor.

This manual suits for next models

1

Table of contents

Other Bigab Utility Vehicle manuals