bihl+Wiedemann C Series User manual

C-Series AS-i Master Module

User manual

Name: en_system_manual_3023.pdf | Revision: 1.6 | Revision date: 2015-04-16

AS-i 3.0 specification

Subject to modifications without notice.

Generally, this manual refers to products

without mentioning existing patents,

utility models, or trademarks.

The absence of any such references does

not indicate that a product is patent-free.

© Bihl+Wiedemann GmbH

Flosswoerthstr. 41

D-68199 Mannheim

C-Series AS-i Master Module

Table of contents

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 3

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

Table of contents

C-Series AS-i Master Module

1 Symbol catalog.....................................................................................6

1.1 Abbreviations................................................................................................... 6

2 General ..................................................................................................7

2.1 Product information......................................................................................... 7

2.2 Product description and intended use .......................................................... 7

2.3 Conformity statement......................................................................................7

2.4 Certification according to EN ISO 9001:2008................................................ 7

2.5 Bihl+Wiedemann hotline .................................................................................8

3 Safety.....................................................................................................9

3.1 Intended use..................................................................................................... 9

3.2 No user-serviceable parts...............................................................................9

3.3 General safety information ............................................................................. 9

3.4 Safety Guidelines for Hazardous Locations.................................................. 9

3.4.1 Special Conditions for Hazardous Locations Use in Europe ................................... 10

3.5 Disposal.......................................................................................................... 10

4 Technical Specifications....................................................................11

4.1 Data sheet.......................................................................................................11

4.2 Instructions for cleaning............................................................................... 12

5 Description..........................................................................................13

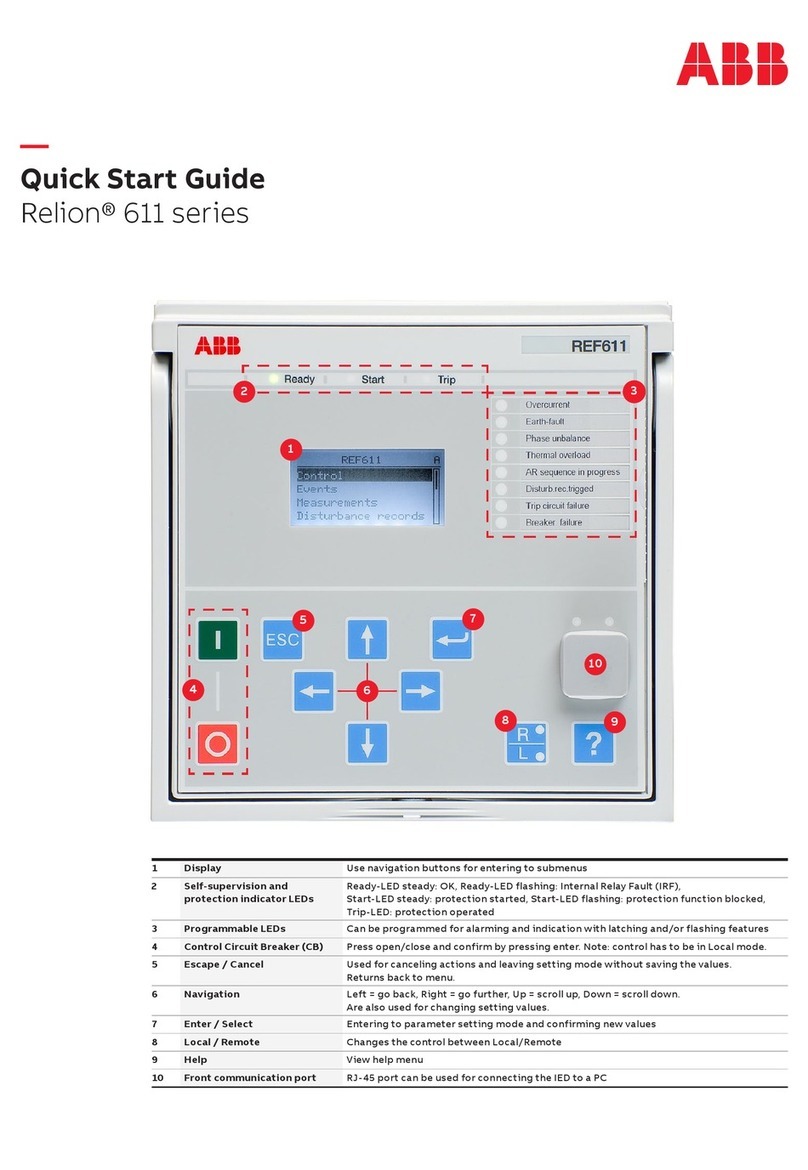

5.1 LED Indicators................................................................................................ 13

5.2 Connection of the AS-i Master......................................................................13

5.2.1 Connection samples for the AS-i power supply ........................................................ 13

5.3 Display and Operating Elements.................................................................. 14

6 Configuration......................................................................................15

6.1 I/O Data Interpretation ................................................................................... 15

6.2 Output/Input Data Image ............................................................................... 15

6.3 Analog Output/Input Data Image.................................................................. 16

Issue date: 16.4.2015

4Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Table of contents

6.3.1 Execution Control Flags (EC-Flags) ............................................................................16

6.3.2 Slave Lists......................................................................................................................16

7 Operating the AS-i.............................................................................. 17

7.1 Master Start-Up...............................................................................................17

7.2 Configuration Mode .......................................................................................17

7.3 Examples of address assignment ................................................................19

7.3.1 Example of automatic address assignment................................................................19

7.3.2 Example of manual address assignment....................................................................19

7.4 Abbreviations used within the Status List Control.....................................20

7.5 Protected Operating Mode ............................................................................20

8 Appendix: Codes indicated by the Display...................................... 21

9 Your opinion is important to us!....................................................... 22

C-Series AS-i Master Module

EC Declaration of Conformity

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 5

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

EC Declaration of Conformity

Issue date: 16.4.2015

6Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Symbol catalog

1. Symbol catalog

1.1 Abbreviations

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peripheral systems, or plant, potentially leading to total mal-

functioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal inju-

ries that could be fatal or result in material damages and destruction.

Information!

Additional information can be found in section <Glossary>.

C-Series AS-i Master Module

General

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 7

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

2. General

2.1 Product information

This system manual applies to the following Bihl+Wiedemann GmbH equipment:

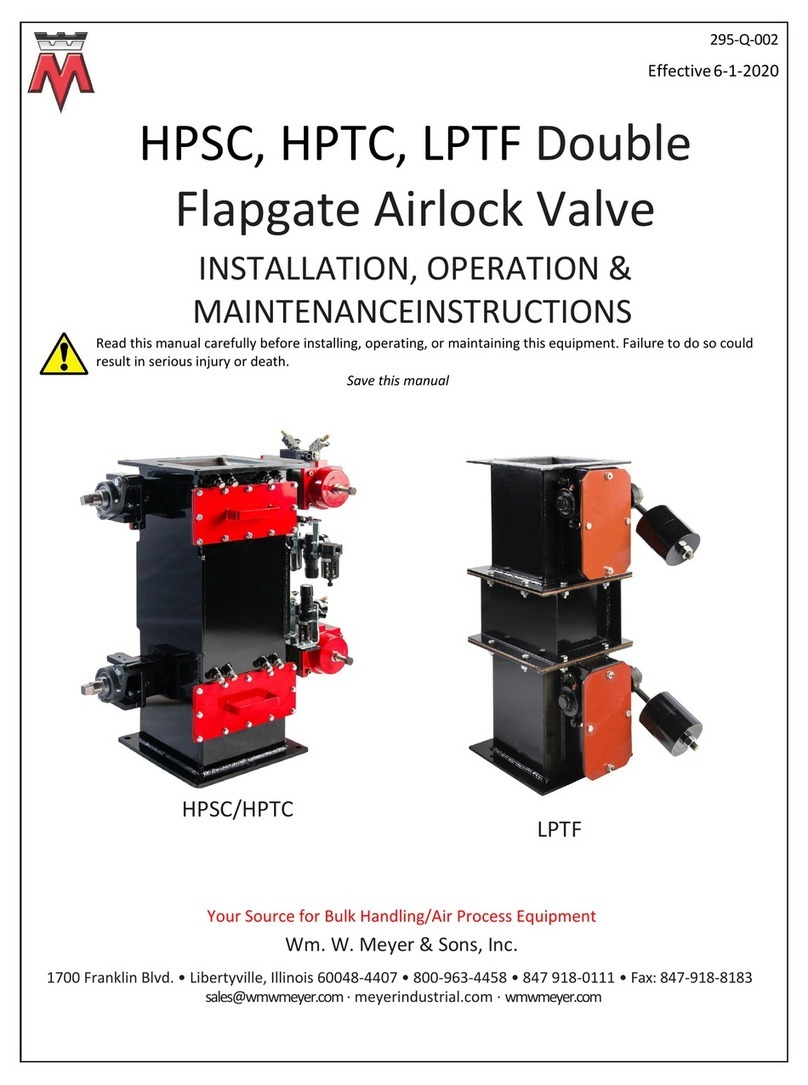

2.2 Product description and intended use

The BW3023 is an AS-interface master according to specification 3.0. It is also

backward compatible because previous specifications (2.0 and 2.1) are support-

ed as well.

It enables configuration, control and diagnosis of up to 31 single slaves or 62 A/B

slaves via LabVIEW.

Fast changing data such as I/O data or execution control flags is directly located

in the SPI frame while slower changing data and data which is only needed in

special situations is located in the command interface.

The LEDs located on the module indicate the current module status, configura-

tion errors or peripheral faults and the activity on AS-i. Diagnostics, which go far

beyond the standard diagnostics facilitate the simple detection of the occasionally

occurring configuration errors and further irritations towards the AS-i communica-

tion. So in case of an error the down time of machines can be minimized or you

can initiate preventive maintenance.

The BW3023 is suitable for use in Class I, Div. 2, Groups A, B, C, D, T4 hazard-

ous locations; Class I, Zone 2, AEx nA IIC T4, and Ex nA IIC T4 hazardous loca-

tions; and nonhazardous locations only.

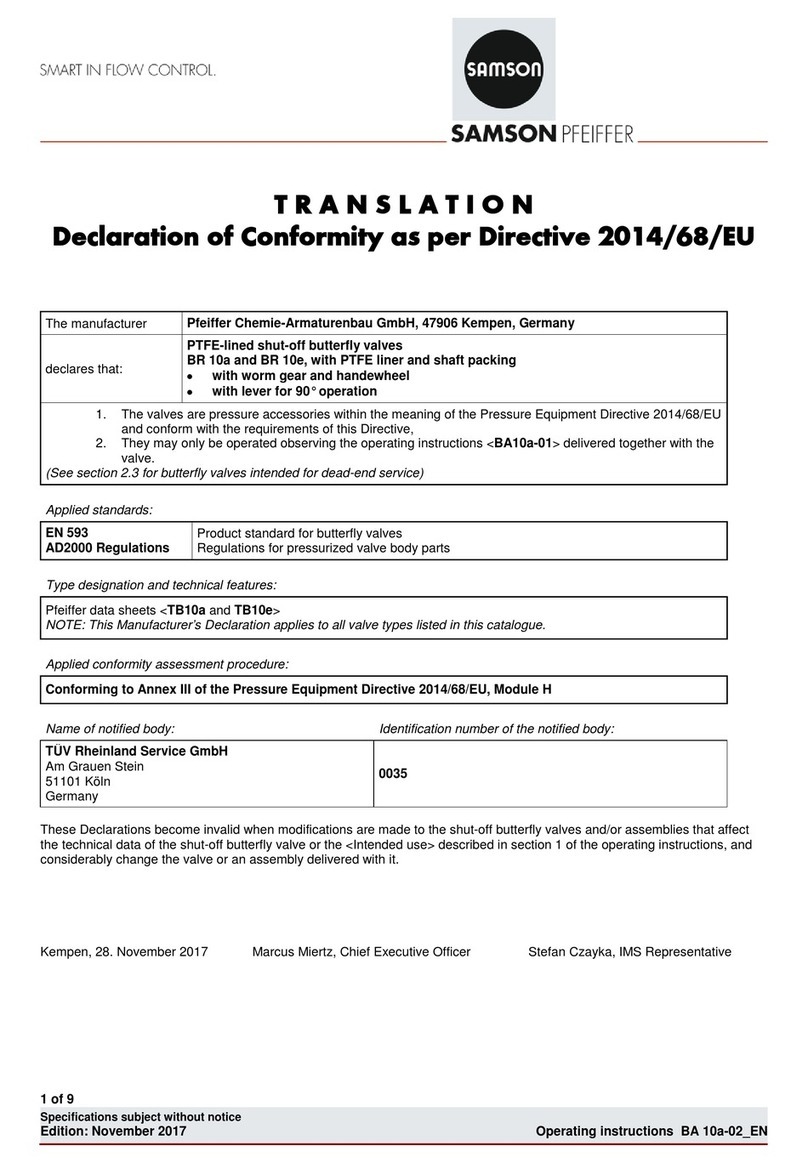

2.3 Conformity statement

The C-Series AS-i Master Module has been developed and manufactured in ac-

cordance with the applicable european standards and directives.

2.4 Certification according to EN ISO 9001:2008

The manufacturer of the product possesses a certified quality assurance system

in accordance with ISO 9001.

C-Series AS-i Master Module

AS-i master module for compactRIO BW3023

Tab. 2-1.

Information!

The corresponding conformity statement can be found at the very beginning of

this system manual.

Information!

The current certificate can be viewed in internet:

http://www.bihl-wiedemann.de

Issue date: 16.4.2015

8Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

General

2.5 Bihl+Wiedemann hotline

If problems or faults occur which you cannot rectify yourself and which are not de-

scribed in this user‘s manual, please contact the Bihl+Wiedemann GmbH service

hotline.

Please make a note (see lateral label) of the following details before calling

Bihl+Wiedemann GmbH:

Phone: +49 (0) 621-33 996-0 (Central)

Fax: +49 (0) 621-33 92 22 39

mail: info@bihl-wiedemann.com

web: www.bihl-wiedemann.com

Device type:

Art.-no.:

Ident.-no.:

Date of delivery:

C-Series AS-i Master Module

Safety

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 9

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

3. Safety

3.1 Intended use

3.2 No user-serviceable parts

3.3 General safety information

3.4 Safety Guidelines for Hazardous Locations

The BW3023 is suitable for use in Class I, Division 2, Groups A, B, C, D, T4

hazardous locations; Class I, Zone 2, AEx nA IIC T4, and Ex nA IIC T4 hazard-

ous locations; and nonhazardous locations only. Follow these guidelines if you

are installing the BW3023 in a potentially explosive environment. Not following

these guidelines may result in serious injury or death.

Warning!

This symbol warns of a possible danger. The protection of operating personnel and the

system against possible danger is not guaranteed if the control interface unit is not

operated in accordance to its intended use.

Warning!

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired!

Warning!

No user serviceable parts inside. Do not open!

Warning!

Safety and correct functioning of the device cannot be guaranteed if any operation

other than described in this operation manual is performed. Connecting the equipment

and conducting any maintenance work under power must exclusively be performed by

appropriately qualified personnel. In case a failure cannot be eliminated, the device

must be taken out of operation and inadvertently operation must be prevented. Repair

work must be performed by the manufacturer only. Additions or modifications to the

equipment are not permitted and will void the warranty.

Information!

The operator is responsible for the observation of local safety standards.

Issue date: 16.4.2015

10 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Safety

3.4.1 Special Conditions for Hazardous Locations Use in Europe

This equipment has been evaluated as equip-

ment under DEMKO Certificate No. 14 ATEX 1413X and IECEx Certificate

No. IECEx UL 14.0112X. Each module is marked II 3G and is suitable for use in

Zone 2 hazardous locations. If you are using the BW3023 in Gas Group IIC

hazardous locations or in ambient temperatures of – 40 °C Ta 70 °C, you

must use the device in a chassis that has been evaluated as EEx nA IIC T4,

Ex nA IIC T4, or Ex nL IIC T4 equipment.

3.5 Disposal

Caution:

• Do not disconnect I/O-side wires or connectors unless power has been

switched off or the area is known to be nonhazardous.

• Do not remove modules unless power has been switched off or the area is

known to be nonhazardous.

• Substitution of components may impair suitability for Class I, Division 2.

• For Zone 2 applications, install the system in an enclosure rated to at least

IP54 as defined by IEC 60529 and EN 60529.

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances when

disposing this product!

The device does not contain batteries that need to be removed before disposing it.

C-Series AS-i Master Module

Technical Specifications

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 11

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

4. Technical Specifications

4.1 Data sheet

Function

AS-i I/O data and status information is mapped into the PLC

processor‘s I/O data.

AS-i Scope

Diagnostics, which go far beyond the standard diagnostics facili-

tate the simple detection of the occasionally occurring configura-

tion errors and further irritations towards the AS-i

communication.

So in case of an error the down time of machines can be mini-

mized or you can initiate preventive maintenance.

Article No. BW3023: AS-i 3.0 Master for Compact RIO and Labview

Article No. BW3023

AS-i

Operating current approx. 40 mA out of AS-i

approx. 50 mA out of the backplane

Operating voltage AS-i voltage 29,5 … 31,6 VDC

AS-i cycle time 150 ȝs * (number of slaves + 2)

Total power dissipation max. 1,5 W

Display

LED AS-i powered (green) on: AS-i voltage O.K.

LED AS-i active (green) AS-i normal operation active

LED prj mode (yellow) configuration mode active

LED config error (red) on: at least 1 configured AS-i slave is missing, or at least 1 detected AS-i Slave is not configured, or

for at least 1 configured and detected AS-i slave the actual configuration data does not match the

nominal configuration data, or the master is in the startup process

flashing: peripheral fault

Environment

Applied standards EN 61000-6-2 : 2005

EN 61000-6-4 : 2007 + A1:2011

IEC 60079-0, 6th edition

IEC 60079-15, 4th edition

EN 60079-0 : 2012 + A11:2013

EN 60079-15: 2010

ISA 12.12.01 : 2013

UL 60079-0 : 6th Edition

UL 60079-15 : 4th Edition

CSA C22.2, No 223 : 1987 (R2013)

Operating temperature -40 °C … +70 °C

Storage temperature -40 °C … +85°C

Intended environment for indoor use only

Maximum altitude for use 5000 m

Maximum relative humidity 90%, non condensing

Pollution degree of the intended

environment

II

Protection category

acc. EN 60529

housing IP20

(only suitable for use in electrical operating rooms/cabinets with IP54 minimum protection rating)

Voltage of insulation AS-i to compactRIO: t500 V

60 VDC CAT I Ch-to-Earth Isolation

Weight 420 g

Dimensions (W / H / D in mm) 23 / 71 / 89

Article No. BW3023

Issue date: 16.4.2015

12 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Technical Specifications

4.2 Instructions for cleaning

If you need to clean the module, wipe it with a dry towel.

Attention!

Provision shall be made to prevent the rated voltage being exceeded by the transient

disturbance of more than 140% of the peak rated voltage.

The system shall be mounted in an ATEX/IECEx certified enclosure with a minimum

ingress protection rating of at least IP54 as defined in IEC/EN60529 and used in an

environment of not more than pollution degree 2.

The enclosure must have a door or cover accessible only by the use of a tool.

C-Series AS-i Master Module

Description

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 13

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

5. Description

5.1 LED Indicators

5.2 Connection of the AS-i Master

5.2.1 Connection samples for the AS-i power supply

Indicator Color Description

AS-i powered Green AS-i Master power

Peripheral fault

AS-i active Green Normal operation active

prj mode Yellow Configuration state

config error Red Config error occurred

Tab. 5-2.

AS-

i Master

max. 5 A

PELV according to EN

50178 (Protective

extra low voltage)

A

S-i

power

supply

-

+

AS-i Slave

-

+

AS-i Slave

-

+

AS-

i Master

max. 8 A

PELV according to EN 50178

(Protective extra low voltage)

A

S-i

power

supply

-

+

AS-i Slave

-

+

AS-i Slave

-

+

Attention!

In the wiring schemes above the current through the AS-i master must not

exceed 5 A.

10

10

AWG 24 ... 12

0,2 ... 2,5 mm

2

0,2 ... 2,5 mm

2

Torque 0,5 ... 0,6 Nm

Temperature rating for cable 105 oC

Use copper conductors only

Issue date: 16.4.2015

14 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Description

5.3 Display and Operating Elements

PINs

0/1 AS-i +/AS-i-

Connection AS-i circuit

2/3 AS-i PWR +/AS-i PWR -

Supply voltage AS-i circuit

4FE

Functional earth

LEDs

3config error

Configuration error

At least one configured slave is missing, at least one detected slave is not

projected or for at least one projected and detected slave the actual con-

figuration data does not match the nominal configuration data.

0AS-i powered

The AS-i circuit is sufficiently powered.

1AS-i active

Normal operation active.

2prj mode

The AS-i master is in configuration mode.

C-Series AS-i Master Module

Configuration

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 15

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

6. Configuration

6.1 I/O Data Interpretation

Fast changing data is directly located in the SPI frame while slower changing data

and data which is only needed in special situations is located in the Command In-

terface.

6.2 Output/Input Data Image

Index Length

[Byte] Direction Carrier to

Module Direction Carrier from Module

0 16 Reserved Reserved

16 32 Output Data Image (ODI) Input Data Image (IDI)

48 256 Analogue Output Data

Image (AODI) Analogue Input Data Image (AIDI)

304 2 Reserved Execution Control Flags (EC-Flags)

306 2 Reserved Reflected HI-Flags

308 8 Reserved List of active slaves LAS

316 8 Reserved List of detected slaves LDS

324 8 Reserved List of projected slaves LPS

332 8 Reserved List of peripheral faults LPF

340 40 Command Interface Command Interface

380 4 Checksum Checksum

= 384

Tab. 6-3.

ODI, IDI

Adresse 215 214 213 212 211 210 29282726252423222120

+ 0x00 Slave 3 Slave 2 Slave 1 Slave 0

+ 0x02 Slave 7 Slave 6 Slave 5 Slave 4

::

+ 0x10 Slave 3b Slave 2b Slave 1b Slave 0b

::

+ 0x1E Slave 31b Slave 30b Slave 29b Slave 28b

Tab. 6-4.

Issue date: 16.4.2015

16 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Configuration

6.3 Analog Output/Input Data Image

6.3.1 Execution Control Flags (EC-Flags)

Cok: ConfigOk

S0: LDS.0

AAs: AutoAddressAssign

AAv: AutoAddressAvailable

CA: ConfigurationActive

NA: NormalOperationActive

APF: APF

OR: OfflineReady

Pok: PeriperyOk

6.3.2 Slave Lists

AODI, AIDI

Adresse 215 214 213 212 211 210 29282726252423222120

+ 0x00 Slave 0 1st Channel

+ 0x02 Slave 0 2nd Channel

::

+ 0x7E Slave 15 4th Channel

::

+ 0xFE Slave 31 4th Channel

Tab. 6-5.

EC - Flags

Address 215 214 213 212 211 210 29282726252423222120

+ 0x0 Pok OR APF NA CA AAv AAs S0 Cok

Tab. 6-6.

LAS, LDS, LPS, LPF

Address 215 214 213 212 211 210 29282726252423222120

+0x0 s15s14s13s12s11s10s9s8s7s6s5s4s3s2s1s0

+ 0x2 s31 s30 s29 s28 s27 s26 s25 s24 s23 s22 s21 s20 s19 s18 s17 s16

+ 0x4 s15b s14b s13b s12b s11b s10b s9b s8b s7b s6b s5b s4b s3b s2b s1b s0b

+ 0x6 s31b s30b s29b s28b s27b s26b s25b s24b s23b s22b s21b s20b s19b s18b s17b s16b

Tab. 6-7.

C-Series AS-i Master Module

Operating the AS-i

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 17

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

7. Operating the AS-i

The LabVIEW API ships with two examples "AS-i RT Basic.lvproj" and

"AS-i FPGA Basic.lvproj" referenced throughout the rest of this Manual. The ex-

amples can be located by the following steps:

1. Open LabVIEW if not already opened.

2. In LabVIEW click Help > Find Examples and then search for "AS-i".

3. Open the AS-i RT Basic or AS-i FPGA Basic project.

4. For addition help, click Help > Bihl-Wiedemann in LabVIEW to open the

user manual.

7.1 Master Start-Up

Connect the AS-i module as described in section <Connection samples for

the AS-i power supply> and plug the AS-i module into one slot of your pow-

ered cRIO chassis. All LEDs of the module should be Off.

Then if you run the example “BW-3023 AS-i Commissioning.vi” as described

in section <Configuration Mode> some LED’s should turn ON, depending on

the state of master.

1. If the AS-i network is not sufficiently powered.

2. If the AS-i network is sufficiently powered.

On the VI Frontpanel press the the “Operation Mode” switch and notice your

modules being marked in the address table, then press the “Store Actual

Configuration” button, to turn OFF the Config Error LED.

7.2 Configuration Mode

All slaves, except the slave with zero address, that are members of the list of de-

tected slaves (LDS) shall be automatically detected and activated in the above

mentioned way according to AS-i specification.

Configuration mode is demonstrated in both shipping examples referenced in

section <Examples of address assignment>. The AS-i C-Series module can be

placed into configuration mode by completing the following steps:

1. Connect the AS-i C-Series module as described in section <Connection of

the AS-i Master>.

2. Open the “AS-i RT Basic.lvproj” example.

AS-i powered AS-i active prj mode config error

Off Off If configuration mode is active,

LED is ’on’. Otherwise ’off’. On

Tab. 7-8.

AS-i powered AS-i active prj mode config error

On On If configuration mode is active,

LED is ’on’. Otherwise ’off’. If there is config

error, LED is ’on’.

Otherwise, ’off’.

Tab. 7-9.

Issue date: 16.4.2015

18 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Operating the AS-i

3. Verify that your cRIO is connected properly by right clicking the target within

your project and going to "Connect"

4. Open the front panel of the "BW3023 AS-i Commissioning.vi"

Assigning an AS-i Address in the Configuration Mode

Assigning a Slave Address

1. Connect a new slave in the AS-i network, the state of this slave is showed in

the “Slave List” indicator.

2. Select the devices old address within the “Old Address” control.

3. Select the new address within the “New Address” control.

4. Click the button “Change Slave Address”.

5. If the indicator “Result Code” is 0, address assignment was successful.

C-Series AS-i Master Module

Operating the AS-i

Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH 19

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

Issue date: 16.4.2015

Programming the Address in Case of Configuration Errors

1. Click the button “Store Actual Configuration” to store the current AS-i net-

work configuration for all connected slaves, then repeat step 2 – 5 from

above.

Erasing the Slave Address

1. Remove a slave from the AS-i network

2. The status of this slave in “Slave List” indicator should change to P (Pro-

jected Only)

3. Click the button “Store Actual Configuration” to delete the address from the

module.

Automatic Address Assignment ( shall be processed only if):

1. the Master module execution control mode is the protected mode,

2. the "Auto_Address_Enable” mode is ON

3. the "Auto_Address_Assign" mode is set, and If one and only one configured

slave is not detected.

7.3 Examples of address assignment

7.3.1 Example of automatic address assignment

1. Select an existing Slave (e.g Slave1) within the “Old Address” control.

2. Select Slave0 within the “New Address” control.

3. Click the button “Change Slave Address”. The status List should change

like this.

4. Remove the slave from the AS-i network.

5. Click button “Operation Mode” to change to protected mode

6. Connect this slave back to the AS-i network

7. Address 1 is assigned to this slave automatically.

7.3.2 Example of manual address assignment

1. Connect a slave to the AS-i network.

2. If the slave address is zero, the status list should look like this.

Issue date: 16.4.2015

20 Subject to technical modifications; no responsibility is accepted for the accuracy of this information © Bihl+Wiedemann GmbH

Internet: www.bihl-wiedemann.de • Flosswoerthstr. 41 • D-68199 Mannheim phone: +49 621 33 996-0 • fax: +49 621 3 39 22 399

C-Series AS-i Master Module

Operating the AS-i

3. Select Slave0 within the "Old Address" control.

4. Select the new address (e.g. Slave2) within the "New Address" control.

5. Click the button "Change Slave Address".

6. If the indicator "Result Code" is 0, address assignment was successful.

7.4 Abbreviations used within the Status List Control

7.5 Protected Operating Mode

Only those slaves shall be activated which are both members of the list of detect-

ed slaves (LDS) and members of the list of projected slaves (LPS), and whose

configuration data image (CDI) value equals the permanent configuration data

(PCD) value for that specific slave.

1. Follow steps 1-5 of section <Configuration Mode> to bring the AS-i network

to Configuration mode

2. Click the "Operation Mode" control to change to "Protected Mode"

X (O.K.) The configuration data for the detected AS-i slave matches

the stored configuration data.

D (Detected Only) An AS-i slave is detected at this address, but it was not

stored before.

P (Projected Only) An AS-i slave was stored at this address, but it was not

detected.

C (Type Conflict) The configuration data for the detected AS-i slave does not

match the stored configuration data. The actual exiting con-

figuration of the connected AS-i slave is displayed.

F (Periph. Fault) The AS-i slave has a peripheral error.

A (Duplicate Addr.) Two AS-i slaves use the same address.

This manual suits for next models

1

Table of contents

Other bihl+Wiedemann Control Unit manuals

Popular Control Unit manuals by other brands

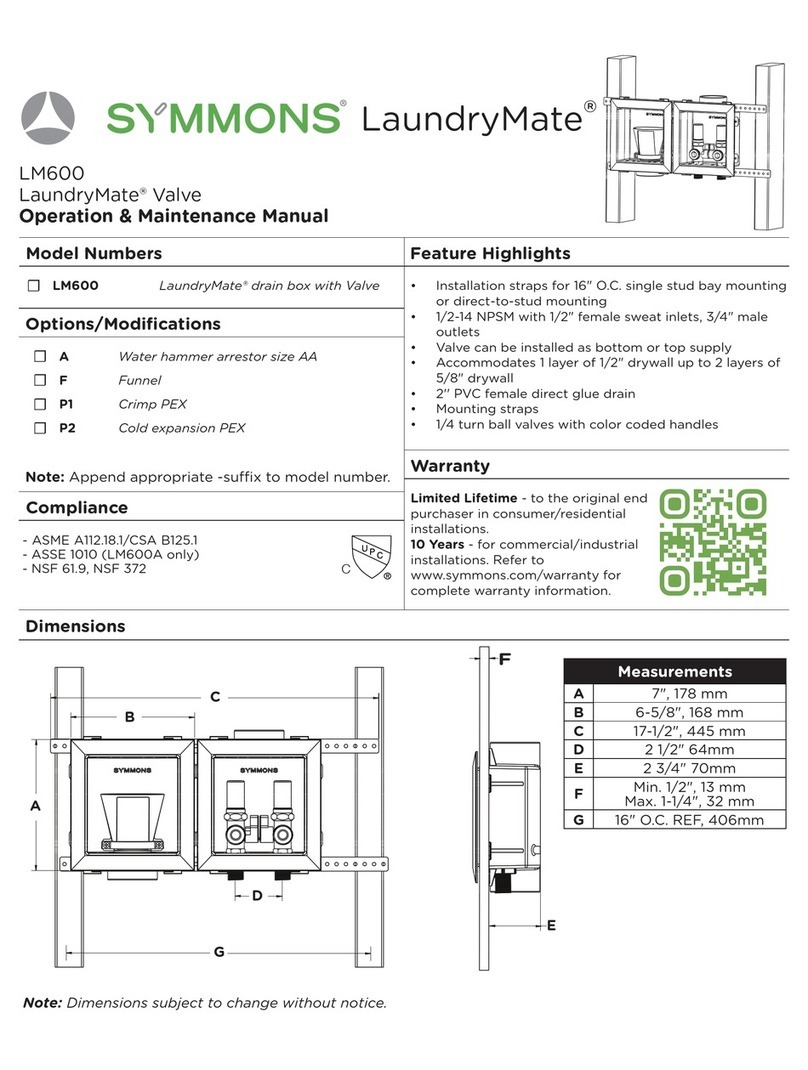

Symmons

Symmons LaundryMate LM600 Operation & maintenance manual

dixell

dixell ichill ic100l series instruction manual

Wigersma & Sikkema

Wigersma & Sikkema UNIGAS 300 Installation and operating manual

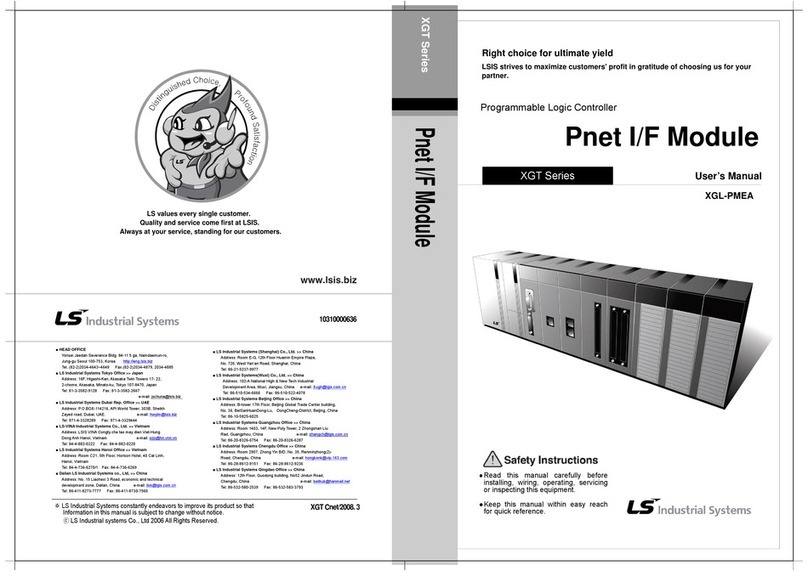

LS Industrial Systems

LS Industrial Systems XGT Series user manual

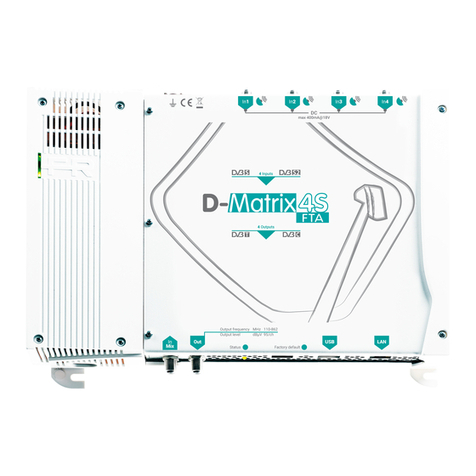

Fracarro

Fracarro D-MATRIX 4S-FTA quick guide

Interlogix

Interlogix RF-KF101-K4 Installation sheet