Wigersma & Sikkema UNIGAS 300 User manual

Installation and operating manual

CI-module UNIGAS 300

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 1

All rights reserved.

Copyright © 2023 Wigersma & Sikkema B.V.

All the figures and descriptions in this installation and operating manual have been compiled only after careful

checking. Despite this, however, the possibility of errors cannot be completely eliminated. Therefore, no

guarantee can be given for completeness or for the content. Also, the manual cannot be taken as giving

assurance with regard to product characteristics. Furthermore, characteristics are also described that are only

available as options.

The right is reserved to make changes in the course of technical development. We would be very grateful for

suggestions for improvement and notification of any errors, etc.

With regard to extended product liability the data and material characteristics given should only be

taken as guide values and must always be individually checked and corrected where applicable. This

particularly applies where safety aspects must be taken into account.

Further support can be obtained from the branch or representative responsible for your area. The address is

printed on the back of this manual or simply enquire at Wigersma & Sikkema B.V.

Passing this manual to third parties and its duplication, in full or in part, are only allowed with written permission

from Wigersma & Sikkema B.V.

Preface

◼This manual provides important information about the use of the CI-Module. Please read this manual

carefully.

◼Various remarks and warnings in this manual are marked with symbols. Read these carefully and

take measures were necessary.

The symbols used have the following meaning.

REMARK

Suggestions and recommendations to make tasks easier.

NOTE

A note draws user's attention to potential problems.

WARNING

If the procedure is not carried out correctly, a dangerous situation may

develop, or data or settings may be lost.

The guarantee becomes invalid if the product described here is not handled properly, repaired or modified by

unauthorized persons or if replacement parts are used which are not genuine parts from Wigersma & Sikkema

B.V.

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 2

Table of contents

1Introduction CI module UNIGAS 300......................................................................... 3

2Installing the CI-module............................................................................................. 4

3IDOM............................................................................................................................ 5

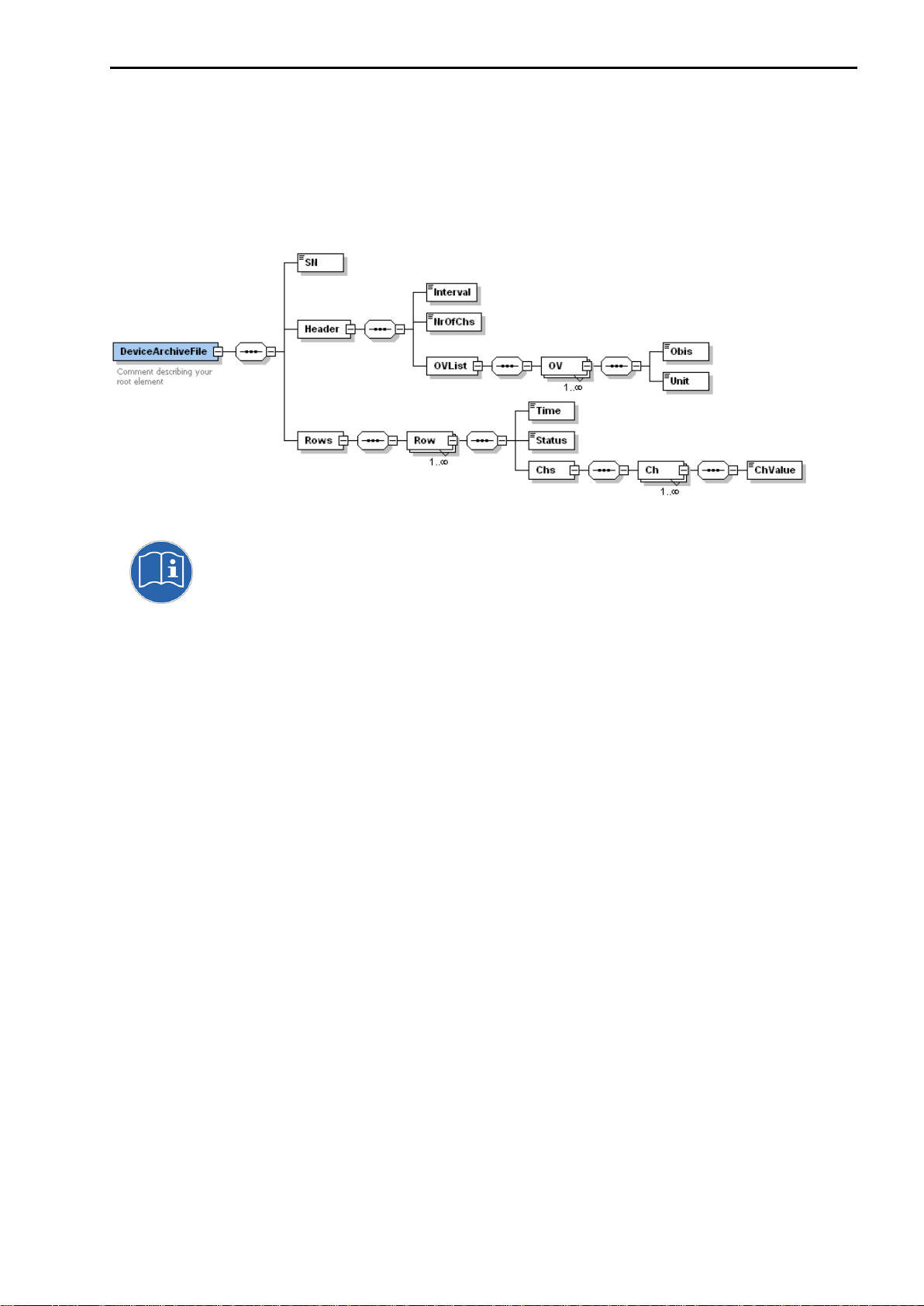

3.1 Data structure ...................................................................................................................................... 5

3.2 Data format.......................................................................................................................................... 5

3.3 IDOM settings...................................................................................................................................... 5

4FTP messages............................................................................................................. 6

4.1 Start FTP ............................................................................................................................................. 6

4.2 First FTP message .............................................................................................................................. 6

4.3 FTP file................................................................................................................................................. 6

4.4 XML file format..................................................................................................................................... 7

4.4.1 XSD................................................................................................................................................ 7

4.5 IEC 62056-21 file format...................................................................................................................... 8

4.6 CSV file format..................................................................................................................................... 8

4.7 FTP settings......................................................................................................................................... 8

5Modbus........................................................................................................................ 9

5.1 Introduction:......................................................................................................................................... 9

5.2 Modbus Registers.............................................................................................................................. 10

5.3 Data types.......................................................................................................................................... 12

5.3.1 Ushort........................................................................................................................................... 12

5.3.2 ULONG ........................................................................................................................................ 12

5.3.3 Counter ........................................................................................................................................ 13

5.3.4 BCDDate...................................................................................................................................... 13

5.3.5 BCDNO........................................................................................................................................ 13

5.3.6 BCDNO3...................................................................................................................................... 13

5.3.7 BCDNO4...................................................................................................................................... 14

5.3.8 IEEEFLOAT ................................................................................................................................. 14

5.3.9 HEX2............................................................................................................................................ 15

5.4 Read out examples............................................................................................................................ 16

5.4.1 Register 1 -7 ................................................................................................................................ 16

5.4.2 Register 101 -104 ........................................................................................................................ 16

5.4.3 Register 301 –324....................................................................................................................... 17

5.4.4 Register 327 –351....................................................................................................................... 17

5.4.5 Register 501 –506....................................................................................................................... 18

5.4.6 Register 801 -812 ........................................................................................................................ 18

5.4.7 Register 813 –820....................................................................................................................... 19

5.4.8 Register 822 –833....................................................................................................................... 19

5.5 Device identification........................................................................................................................... 20

6Parameters.................................................................................................................21

7Recognition of modules installed in UNIGAS 300 ..................................................23

8UNITOOL and CI module...........................................................................................23

9Appendix 1; Specification.........................................................................................24

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 3

1 Introduction CI module UNIGAS 300

UNIGAS 300 communicates using the IEC 62056-21 protocol (previously 1107).

The CI module for UNIGAS 300 is a module to add one or more communication protocols to UNIGAS 300:

−IDOM

−FTP

−MODBUS

UNIGAS 300 is equipped with two communication ports; depending on the selected protocol, it will be available

on communication port 1 (modem port) or communication port 2 (user port).

Protocol

Communication port

1

2

IDOM

V

-

FTP

V

-

MODBUS

V

V

If the service port of UNIGAS 300 is used during or in a 30 second period prior to the

forwarding of an IDOM or FTP message, it is possible that forwarding the IDOM or

FTP message fails.

Communication port 2

Communication port 1

Service port

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 4

The following must be taken into account when using both communication ports:

•When using MODBUS on either port, IEC 62056-21 cannot be communicated on the other port

simultaneously. There should be at least 5 s space between the use of both ports.

•When using MODBUS on both ports, MODBUS cannot be communicated simultaneously. There should

be at least 5 s space between the use of both ports.

If it cannot be guaranteed that simultaneous communication will not occur when using both communication

ports, the use of both ports is not recommended. This may lead to interference or blocking of communication

for both ports.

•If no protocol is configured on the CI module, IEC 62056-21 can be communicated on both ports

simultaneously.

•When using FTP or IDOM, while sending the FTP or IDOM message, on port 2 IEC 62056-21 can be

communicated simultaneously.

2 Installing the CI-module

Mounting instruction DDG6006MHML describes installation of the CI-module in UNIGAS 300.

Installing the CI module in UNIGAS 300 will not affect the programmed settings of the CI module.

Consequently, it is possible to exchange the CI module between several UNIGAS 300 units without any

need to change the settings in the CI module.

CI module located in UNIGAS 300

Only place the CI module in UNIGAS 300 if the pillar (figure above (1)) is present.

When installing a CI module, as indicated at (3) in the installation manual

DDG6006MHML, the ring must not be replaced!

(1)

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 5

3 IDOM

The IDOM protocol can be used as follows. UNIGAS 300 is connected to an RTU. The RTU will collect the

data forwarded by the CI module in UNIGAS 300. Subsequently, the RTU will forward the data to a central

system.

At a 5-min interval on the 5-min moment, UNIGAS 300 will forward the data over the users port

(communications port 1). The RTU will receive these data and process into a load profile.

3.1 Data structure

The IDOM protocol will forward the following data.

Sequence

Description

Output/ format

Unit

Remarks

1

Non-converted volume

Va:########[CR]

m3

2

Converted volume

Vr:######## [CR]

m3

3

Pressure

P#.###[CR]

bar

4

Temperature

T±##.##[CR]

Degrees

Celsius

5

Alarm

@[CR]

Only present in case of an

alarm.

Example:

Va:01209188[CR]

Vr:01206764[CR]

P0.999[CR]

T+01.60[CR]

An alarm is set under the conditions specified in Chapter 6 of UNIGAS 300 manual DDG6004MHGB, table:

"Status register 1; calibration relevant alarms" (97:97.1).

3.2 Data format

Baud rate: 4800

Parity: Even

Data bits: 7

Stop bits: 1

3.3 IDOM settings

The settings for IDOM in the CI module are made by means of UNITOOL.

The settings are

•System information; Protocol: Off, FTP, IDOM, MODBUS

•All the other settings are not relevant

Settings marked in bold shall be made to activate the IDOM mode.

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 6

4 FTP messages

For sending FTP messages a UNICOM 300 (or UNILOG GPRS/300)shall be connected to the modem port

(communication port 1) of UNIGAS 300. FTP communication will send a file to the designated FTP server.

The CI module will request UNICOM 300 (or UNILOG GPRS/300) to establish a FTP connection. It is

therefore important that UNICOM 300 (or UNILOG GPRS/300) is provided with the correct settings of the

FTP server which messages will be sent towards. The module reads and transfers the load profile P.01 of

UNIGAS 300. The load profile P.01 can be set in UNIGAS 300 (5, 10, 15, 30, 60 min. or 24 hour).

The number of channels in the FTP file corresponds with the number of channels of the UNIGAS 300. More

information on the load profile can be found in the UNIGAS 300 user manual.

Three different file formats of the FTP file are supported:

•XML

•IEC 62056-21

•CSV

When FTP is active, it will have priority communication on any other connections with

UNIGAS 300. When a modem connection is active, UNICOM 300 (or UNILOG GPRS/300)

will terminate the current connection and start a FTP session.

4.1 Start FTP

The FTP session will be activated depending on the programmed FTP interval. The FTP session starts 10

seconds after rogrammed interval. It is also possible to set up a additional delay (FTP offset) to the FTP

session. The moment of starting the FTP is FTP interval + 10 Seconds + FTP offset, example given; FTP

interval 5 minutes and FTP offset 25 seconds. The FTP session will commence on 5 min + 10 seconds + 25

second = xx:05:25. The next FTP message will be sent on xx:10:25, xx:15:25 and so forth.

4.2 First FTP message

The first FTP message the CI module sends, is a maximum of 7 days of data of the programmed interval of

the load profile. In case of a five minuten interval, the FTP message will consist out of a maximum of 7 days *

24 hours * 12 (5 minutes interval) = 2016 entries.

Once every hour (5 minutes before the hour) the date of the last received load profile is saved. This prevents

that when the CI module is reinstated in the same UNIGAS 300, the FTP message will contain 7 days of

loggings. The FTP message will contain only last hours data.

When the CI modules is reinstated in a different UNIGAS 300 , the FTP message will contain

a maximum of 7 days of data.

4.3 FTP file

The ftp filename consists of:

•Manufacturer ID

•Device serial number

•Date and Time

•Fixed text

•File extension depending on format.

E.g.: KAM[27000100][0091014161055]LP.txt

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 7

4.4 XML file format

The XML file format has the extension .xml. CR and LF are not applied to show line breaks.

4.4.1 XSD

An XSD is available which defines XML message structure.

Channel 12 of the xml message (ChValue) has the same value as status.

Next examples contain 2 loggings of 5 minute interval.

Example:

<?xml version="1.0" encoding="UTF-8"?><DeviceArchiveFile

xmlns:xsi="http://www.w3.org/2001/XMLSchema-

instance"><SN>27000412</SN><Header><Interval>5</Interval><NrOfChs>12</NrOfChs><OVList><OV

><Obis>7-1:11.2.0</Obis><Unit>m3</Unit></OV><OV><Obis>7-1:12.1.0</Obis>

<Unit>m3</Unit></OV><OV><Obis>7-1:13.0.0</Obis><Unit>m3</Unit></OV><OV><Obis>7-

1:11.1.0</Obis><Unit>m3</Unit></OV><OV><Obis>7-2:13.0.0</Obis><Unit>m3</Unit></OV>

<OV><Obis>7-3:13.0.0</Obis><Unit>m3</Unit></OV><OV><Obis>7-1:41.0.0</Obis>

<Unit>C</Unit></OV><OV><Obis>7-1:42.0.0</Obis><Unit>mbar</Unit></OV><OV>

<Obis>97:97.1</Obis><Unit></Unit></OV><OV><Obis>97:97.2</Obis><Unit></Unit></OV><OV><Obi

s>97:97.3</Obis><Unit></Unit></OV><OV><Obis>97:97.4</Obis><Unit></Unit></OV></OVList></He

ader><Rows><Row><Time>2010-03-22 00:45:00</Time>

<Status>0000</Status><Chs><Ch><ChValue>20631215</ChValue></Ch><Ch><ChValue>00006138</Ch

Value></Ch><Ch><ChValue>21992096</ChValue></Ch><Ch><ChValue>21992096</ChValue></Ch><C

h><ChValue>00000002</ChValue></Ch><Ch><ChValue>00000002</ChValue></Ch><Ch><ChValue>00

001764</ChValue></Ch><Ch><ChValue>00102190</ChValue></Ch><Ch><ChValue>0010</ChValue><

/Ch><Ch><ChValue>0000</ChValue></Ch><Ch><ChValue>00FF</ChValue></Ch><Ch><ChValue>000

0</ChValue></Ch></Chs></Row><Row><Time>2010-03-22

00:50:00</Time><Status>0000</Status><Chs><Ch><ChValue>20631499</ChValue>

</Ch><Ch><ChValue>00006138</ChValue></Ch><Ch><ChValue>21992396</ChValue></Ch><Ch><Ch

Value>21992396</ChValue></Ch><Ch><ChValue>00000002</ChValue></Ch><Ch><ChValue>0000000

2</ChValue></Ch><Ch><ChValue>00001763</ChValue></Ch><Ch><ChValue>00102187</ChValue></

Ch><Ch><ChValue>0010</ChValue></Ch><Ch><ChValue>0000</ChValue></Ch><Ch><ChValue>00F

F</ChValue></Ch><Ch><ChValue>0000</ChValue></Ch></Chs></Row></Rows></DeviceArchiveFile>

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 8

4.5 IEC 62056-21 file format

The FTP file has the extension .txt. The IEC 62056-21 file consists out of one or more data blocks with a max

of 99 entries (loggings) bestaat uit één of meerdere datablokken met maximaal 99 entries (loggings) each.

Each data block is provided of a data header, a BCC and characters [STX] and [EOT]. The file is terminated

with marking of the character [ETX].

Example given:

[STX]P.52(0100215150000)(0000)(5)(11)(7-1:11.2.0)(m3)(7-1:12.1.0)(m3)(7-1:13.0.0)(m3)(7-1:11.1.0)(m3)(7-

2:13.0.0)(m3)(7-3:13.0.0)(m3)(7-1:41.0.0)(C)(7-1:42.0.0)(mbar)(97:97.1)()(97:97.2)()(97:97.3)()[CR][LF]

(17772111)(00006138)(19019721)(19019721)(00000002)(00000002)(-00000176)(00100555)(0010)

(0000)(00FF)[CR][LF]

(17772410)(00006138)(19020021)(19020021)(00000002)(00000002)(-00000141)(00100551)(0010)

(0000)(0033)[CR][LF]

[ETX][ENQ]

4.6 CSV file format

The FTP file has the extension .csv. The CSV file has one more channel than the load profile of UNIGAS 300.

The last channel is the VDEW status bit .

Example given:

0.9.2,0.9.1,7-1:11.2.0(m3),7-1:12.1.0(m3),7-1:13.0.0(m3),7-1:11.1.0(m3),7-2:13.0.0(m3),7-3:13.0.0(m3),7-1:41.0.0(C),7-

1:42.0.0(mbar),97:97.1(),97:97.2(),97:97.3(),97:97.4()[CR][LF]

2010-02-15,15:20,17773309,00006138,19020921,19020921,00000002,00000002,-00000162,00100540,0010,0000

,00FF ,0000[CR][LF]

2010-02-15,15:25,17773608,00006138,19021221,19021221,00000002,00000002,-00000136,00100547,0010,0000

,00FF,0000[CR][LF]

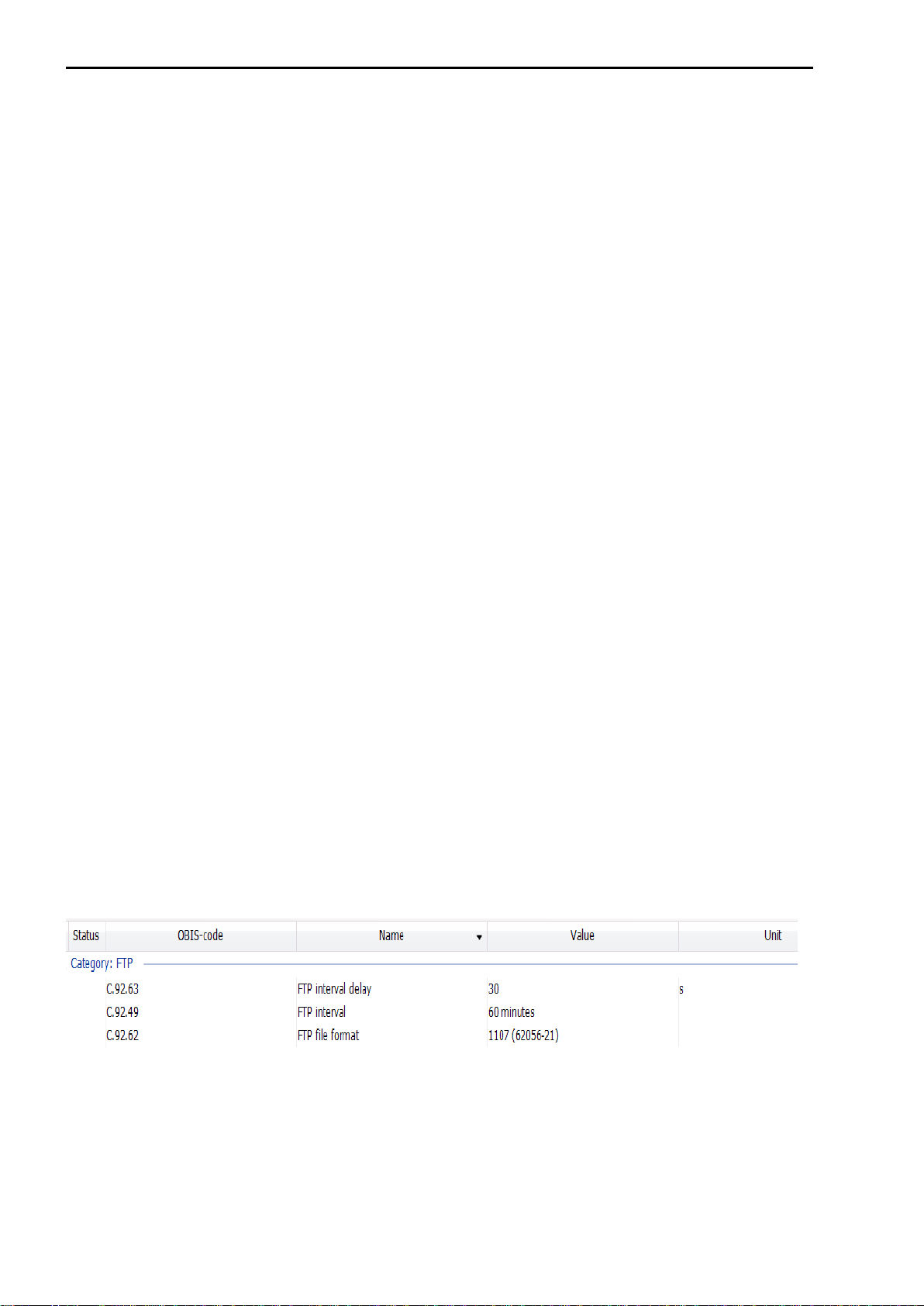

4.7 FTP settings

FTP settings of the CI module can be programmed with UNITOOL. Connect with UNITOOL to MODULE1B,

device address MODULE1B.

Open the menu GPRS for all settings regarding FTP.

Programmable settings are:

•Menu GPRS; FTP interval; off, 5 minutes, 10 minutes, 15 minutes, 30 minutes, 60 minutes, 1day

•Menu GPRS; FTP file format; IEC 62056-21,CSV, XML

•Menu GPRS; FTP interval offset; 0till 999 seconds.

•Menu System information; Protocol: Off, FTP, IDOM, MODBUS

Bold marked settings must be set for FTP communication.

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 9

5 Modbus

5.1 Introduction:

Modbus protocol can be read out easily by use of RS485 or RS232. Communication takes place through

communication port 1 or communication port 2 of the UNIGAS 300.

Each Modbus message has the same structure, supporting the modes ASCII and RTU. The advantage of

RTU is that fewer characters are sent.

Modbus supports mode RTU and ASCII with 300, 600, 1200, 2400, 4800 and 9600 baudrate.

Table: Modbus ASCII or RTU

Modbus/ASCII

Modbus/RTU

Characters

ASCII 0...9en A..F

Binary 0...255

Checksum

LRC Longitudinal Redundancy

Check

CRC Cyclic Redundancy

Check

Frame start

character ':'

3,5 characters’ silence

Frame end

characters CR/LF

3,5 characters’ silence

Holes in

message

1 sec

1,5 times character length

Start bit

1

1

Data bits

7

8

Parity

even

none

Stop bits

1

1

When the Modbus protocol is active on communication port 1, it is not possible to read out the CI module of

the UNIGAS 300 by means of IEC 62056-21. For reading out with IEC 62056-21, a command must first be

issued to temporarily deactivate Modbus.

The registers of Modbus are not configurable. The adressing of the Modbus register is defined in the

mapping table (see 5.2 Modbus Registers). The mapping table also defines the Modbus format, the link with

the correct OBIS parameter and the size of the OBIS parameter. The multipliers for read out of OBIS

parameter Modbus are also defined in this table.

Example given:

Register address 1: OBIS parameter C.6.1 with OBIS multiplier 10.

When reading out the parameter from UNIGAS 300 the read out divided by the multiplier. Actual value 631 is

the same as 63.1Ah. However, Modbus multiplies this value times 10

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 10

5.2 Modbus Registers

Register

Modbus

format

Sca-

ling

Ab.

Description

OBIS code

Unit

1

USHORT

10

Ah_used

Battery capacity

C.6.1

10-1 Ah

2

HEX2

1

Register 1

calibration relevant alarms

97:97.1

-

3

USHORT

1

Vm1

unconverted volume, total volume at

measuring conditions, input 1

Post decimal places

7-1:13.0.0

10-3 m3

4

USHORT

1

Vb1

converted volume, undisturbed

volume at base conditions, input 1

Post decimal places

7-1:11.2.0

10-3 m3

5*

HEX2

1

Register 2

Operational_status

97:97.2

-

6*

HEX2

1

Register 3

Alarm_reports

97:97.3

-

7*

HEX2

1

Register 4

VDEW status

97:97.4

-

101

ULONG

1

Vm1

unconverted volume, total volume at

measuring conditions, input 1

Pre decimal places

7-1:13.0.0

m3

103

ULONG

1

Vb1

converted volume, undisturbed

volume at base conditions, input 1

Pre decimal places

7-1:11.2.0

m3

301

IEEEFLOAT

1

pb

Reference pressure (base

conditions)

7-1:42.2.0

mbar

303

IEEEFLOAT

1

tb

Reference temperature (base

conditions)

7-1:41.2.0

°C

305

IEEEFLOAT

1

p

Pressure

7-1:42.0.0

mbar

307

IEEEFLOAT

1

p

Pressure

7-1:42.0.0

mbar

309

IEEEFLOAT

1

t

Temperature

7-1:41.0.0

°C

311

IEEEFLOAT

1

C

Calculated conversion factor

7-1:52.2.0

-

313

IEEEFLOAT

1

Z/Zbfix

Fixed value used for conversion

7-1:53.3.0

-

315

IEEEFLOAT

1

pfix

Fixed value for the pressure used for

conversion

7-1:42.3.0

mbar

317

IEEEFLOAT

1

tfix

Fixed value for the temperature used

for conversion

7-1:41.3.0

°C

319

IEEEFLOAT

1

N2

Nitrogen concentration N2

C.96.3

mol %

321

IEEEFLOAT

1

H2

Hydrogen concentration H2

C.96.2

mol %

323

IEEEFLOAT

1

CO2

Carbon dioxide concentration CO2

C.96.1

mol %

327

IEEEFLOAT

1

Qc1_5

Flow at measuring conditions based

upon 5 minutes interval, total value

7-1:43.1.1

m3/h

329

IEEEFLOAT

1

Qb1_5

Flow at base conditions, undisturbed

value based upon 5 minutes interval

7-1:43.2.1

m3/h

333

IEEEFLOAT

1

Hs

Calorific value of 1 m3 gas at 25 °C

7-1:54.11.0

MJ/m3

335

IEEEFLOAT

1

d

Relative density compared to air at 0

°C

7-1:45.11.0

-

337

IEEEFLOAT

1

pb

Reference pressure (base

conditions)

7-1:42.2.0

mbar

339

IEEEFLOAT

1

tb

Reference temperature (base

conditions)

7-1:41.2.0

°C

341*

IEEEFLOAT

1

Qc1_nx5

flow rate corrected operating volume

on the basis of

moving average of n x 5 min

7-1:43.1.2

m3/h

343*

IEEEFLOAT

1

Qc1_inst

flow rate corrected operating volume

on the basis of

increase ΔVc/t

7-1:43.1.0

m3/h

345*

IEEEFLOAT

1

Vc1_60

corrected operating volume (current

clock hour

consumption)

7-1:43.1.71

m3

347*

IEEEFLOAT

1

Qb1_nx5

flow rate converted volume on the

basis of moving

average of n x 5 min,

7-1:43.2.2

m3/h

349*

IEEEFLOAT

1

Qb1_inst

flow rate converted volume on the

basis of Qc1_inst x

C-factor

7-1:43.2.0

m3/h

351*

IEEEFLOAT

1

Vb1_60

converted volume (current hour)

7-1:43.2.71

m3

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 11

Register

Modbus

format

Scali

ng

Ab.

Description

OBIS code

501

COUNTER

1

Vm1

unconverted volume, total volume at

measuring conditions, input 1

7-1:13.0.0

m3

504

COUNTER

1

Vb1

converted volume, undisturbed

volume at base conditions, input 1

7-1:11.2.0

m3

507*

COUNTER

1

Vc1_err

unconverted volume, disturbed

volume at measuring conditions,

under circumstances of a calibration

error condition and corrected for the

gas meter measuring error

p, t, Z, Zb or CRC error, input 1

7-1:12.0.0

m3

510*

COUNTER

1

Vb1_err

converted volume, disturbed volume

at base conditions, under

circumstances of a calibration error

condition, input 1

p, t, Z, Zb or CRC error

7-1:12.1.0

m3

513*

COUNTER

1

Vm2

unconverted volume, total volume at

measuring conditions, input 2

7-2:13.0.0

m3

516*

COUNTER

1

Vm3

unconverted volume, total volume at

measuring conditions, input 3

7-3:13.0.0

m3

801

BCDNO4

1

Vm1

unconverted volume, total volume at

measuring conditions, input 1

7-1:13.0.0

10-4 m3

805

BCDNO4

1

Vb1

converted volume, undisturbed

volume at base conditions, input 1

7-1:11.2.0

10-4 m3

809*

BCDNO4

1

Vc1_err

unconverted volume, disturbed

volume at measuring conditions,

under circumstances of a calibration

error condition and corrected for the

gas meter measuring error

p, t, Z, Zb or CRC error, input 1

7-1:12.0.0

m3

813

BCDTIME2

1

Time

Current time (Read/Write)

0.9.1

-

815

BCDDATE

1

Date

Current date (Read/Write)

0.9.2

-

817

BCDNO3

1

Serial number

Serial number UNIGAS 300

C.1.0

-

820

BCDNO

100

Gas day

Moment at which UNIGAS 300

closes and logs the day, as in day

logger (end of gas day)

C.91.2

-

822*

BCDNO4

1

Vb1_err

converted volume, disturbed volume

at base conditions, under

circumstances of a calibration error

condition, input 1

p, t, Z, Zb or CRC error

7-1:12.1.0

m3

826

BCDNO4

1

Vm2

unconverted volume, total volume at

measuring conditions, input 2

7-2:13.0.0

m3

830

BCDNO4

1

Vm3

unconverted volume, total volume at

measuring conditions, input 3

7-3:13.0.0

m3

60000

USHORT

1

Disable Modbus (**)

Deactivate modbus for IEC 62056-

21 communication. Modbus is

enabled if no communication during

40 seconds (protocol time-out)

N.A.

-

(*) Register added in firmware version 2.0.24 .

(**) This address is used to temporarily disable Modbus. This way, direct communication over IEC 62056-21

is possible with UNIGAS 300. Modbus will become active again after a protocol time-out of 40 seconds.

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 12

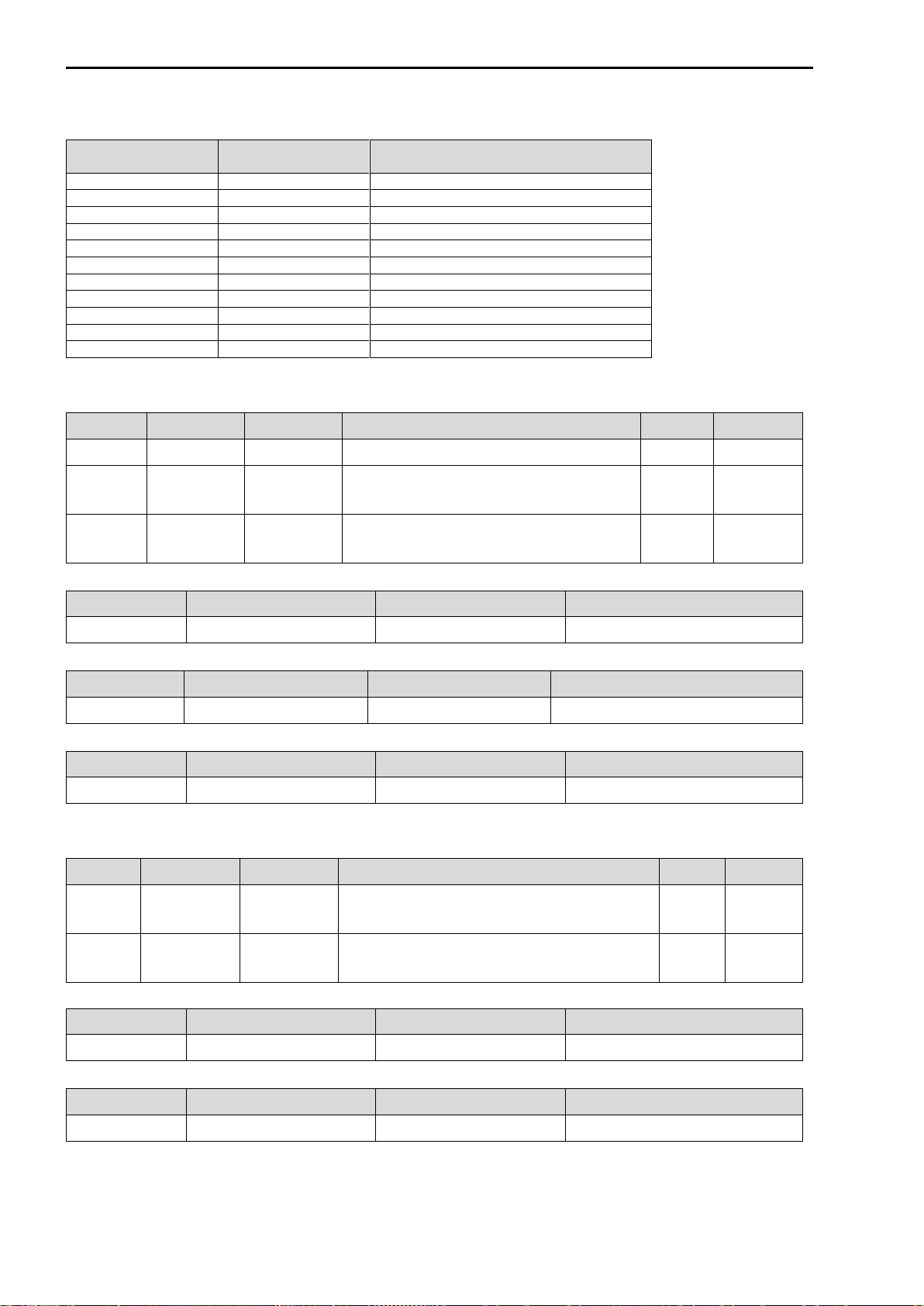

5.3 Data types

Type

Size in 16bit

registers

Format

USHORT

1*16bit

Binary digit

ULONG

2*16bit

Binary digit

COUNTER

2*16bit + 1*16bit

Binary counter

BCDTIME

1*16bit

BCD

BCDTIME2

2*16bit

BCD

BCDDATE

2*16bit

BCD

BCDNO

1*16bit

BCD

BCDNO3

3*16bit

BCD

BCDNO4

4*16bit

BCD

IEEEFLOAT

2*16bit

Binary. Single precision floating point

HEX2

1*16bit

Hex formatted code

5.3.1 Ushort

Register

OBIS code

Ab.

Description

Unit

Scaling

1

C.6.1

Ah_used

Battery capacity

Ah

10-1

3

7-1:13.0.0

Vm1

unconverted volume, total volume at

measuring conditions, input 1

Post decimal places

m3

10-3

4

7-1:11.2.0

Vb1

converted volume, undisturbed volume at

base conditions, input 1

Post decimal places

10-3 m3

10-3

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 01 00 01 BC

3F 03 02 00 04 B8

0,4 Ah

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 03 00 01 BA

3F 03 02 00 E7 D5

xxx.231 m3(post dec. Places)

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 04 00 01 B9

3F 03 02 00 49 73

xxx.730 m3(post dec. Places)

5.3.2 ULONG

Register

OBIS code

Ab.

Description

Unit

Scaling

101

7-1:13.0.0

Vm1

unconverted volume, total volume at measuring

conditions, input 1

Pre decimal places

m3

-

103

7-1:11.2.0

Vb1

converted volume, undisturbed volume at base

conditions, input 1

Pre decimal places

m3

-

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 65 00 02 57

3F 03 04 01 8E C8 B5 AE

26134709 m3

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 67 00 02 55

3F 03 04 01 8E 9D 8E 00

26123662 m3

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 13

5.3.3 Counter

Register

OBIS code

Ab.

Description

Unit

Scaling

501

7-1:13.0.0

Vm1

unconverted volume, total volume at

measuring conditions, input 1

m3

-

504

7-1:11.2.0

Vb1

converted volume, undisturbed volume at

base conditions, input 1

m3

-

507

7-1:12.0.0

Vc1_err

unconverted volume, disturbed volume at

measuring conditions, under circumstances of

a calibration error condition and corrected for

the gas meter measuring error

p, t, Z, Zb or CRC error, input 1

m3

-

510

7-1:12.1.0

Vb1_err

converted volume, disturbed volume at base

conditions, under circumstances of a

calibration error condition, input 1

p, t, Z, Zb or CRC error

m3

-

513

7-2:13.0.0

Vm2

unconverted volume, total volume at

measuring conditions, input 2

m3

-

516

7-3:13.0.0

Vm3

unconverted volume, total volume at

measuring conditions, input 3

m3

-

Function Code

Modbus Command

Answer

Meaning

03

3F 03 01 F5 00 03 C5

3F 03 06 01 8E EE 24 00 E7 30

➔01 8E EE 24 =

26144292 m3

➔00 E7 = ,231 m3

➔26144292,231 m3

5.3.4 BCDDate

Register

OBIS code

Ab.

Description

Unit

Scaling

815

0.9.2

Date

Current date

-

-

Function Code

Modbus Command

Answer

Meaning

03

3F 03 03 2F 00 02 8A

3F 03 04 20 14 02 13 71

13 februari 2014

71

5.3.5 BCDNO

Register

OBIS code

Ab.

Description

Unit

Scaling

820

C.91.2

Gas day

Moment at which UNIGAS 300 closes and

logs the day, as in day logger (end of gas day)

-

-

5.3.6 BCDNO3

Register

OBIS code

Ab.

Description

Unit

Scaling

817

C.1.0

Serial

number

Serial number UNIGAS 300

-

-

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 14

5.3.7 BCDNO4

Register

OBIS code

Ab.

Description

Unit

Scaling

801

7-1:13.0.0

Vm1

unconverted volume, total volume at

measuring conditions, input 1

10-4 m3

-

805

7-1:11.2.0

Vb1

converted volume, undisturbed volume at

base conditions, input 1

10-4 m3

-

809

7-1:12.0.0

Vc1_err

unconverted volume, disturbed volume at

measuring conditions, under circumstances of

a calibration error condition and corrected for

the gas meter measuring error

p, t, Z, Zb or CRC error, input 1

10-4 m3

822

7-1:12.1.0

Vb1_err

converted volume, disturbed volume at base

conditions, under circumstances of a

calibration error condition, input 1

p, t, Z, Zb or CRC error

10-4 m3

826

7-2:13.0.0

Vm2

unconverted volume, total volume at

measuring conditions, input 2

10-4 m3

830

7-3:13.0.0

Vm3

unconverted volume, total volume at

measuring conditions, input 2

10-4 m3

Function Code

Modbus Command

Answer

Meaning

03

3F 03 03 21 00 04 96

3F 03 08 00 00 26 14 53 27

23 10 CF

000026145327,2310 m3

53 27 23 10 CF

5.3.8 IEEEFLOAT

Register

OBIS code

Ab.

Description

Unit

Scaling

301

7-1:42.2.0

pb

Reference pressure (base conditions)

mbar

-

303

7-1:41.2.0

tb

Reference temperature (base conditions)

°C

-

305

7-1:42.0.0

p

Pressure

mbar

-

307

7-1:42.0.0

p

Pressure

mbar

-

309

7-1:41.0.0

t

Temperature

°C

-

311

7-1:52.2.0

C

Calculated conversion factor

-

-

313

7-1:53.3.0

Z/Zbfix

Fixed value used for conversion

-

-

315

7-1:42.3.0

pfix

Fixed value for the pressure used for

conversion

mbar

-

317

7-1:41.3.0

tfix

Fixed value for the temperature used for

conversion

°C

-

319

C.96.3

N2

Nitrogen concentration N2

mol %

-

321

C.96.2

H2

Hydrogen concentration H2

mol %

-

323

C.96.1

CO2

Carbon dioxide concentration CO2

mol %

-

327

7-1:43.1.1

Qc1_5

Flow at measuring conditions based upon 5

minutes interval, total value

m3/h

-

329

7-1:43.2.1

Qb1_5

Flow at base conditions, undisturbed value

based upon 5 minutes interval

m3/h

-

333

7-1:54.11.0

Hs

Calorific value of 1 m3gas at 25 °C

MJ/m3

-

335

7-1:45.11.0

d

Relative density compared to air at 0 °C

-

-

337

7-1:42.2.0

pb

Reference pressure (base conditions)

mbar

-

339

7-1:41.2.0

tb

Reference temperature (base conditions)

°C

-

341

7-1:43.1.2

Qc1_nx5

flow rate corrected operating volume on the

basis of moving average of n x 5 min

m3/h

-

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 15

Register

OBIS code

Ab.

Description

Unit

Scaling

343

7-1:43.1.0

Qc1_inst

flow rate corrected operating volume on the

basis of increase ΔVc/t

m3/h

-

345

7-1:43.1.71

Vc1_60

corrected operating volume (current clock

hour consumption)

m3

-

347

7-1:43.2.2

Qb1_nx5

flow rate converted volume on the basis of

moving average of n x 5 min,

m3/h

-

349

7-1:43.2.0

Qb1_inst

flow rate converted volume on the basis of

Qc1_inst x C-factor

m3/h

-

351

7-1:43.2.71

Vb1_60

converted volume (current hour)

m3

-

Function Code

Modbus Command

Answer

Meaning

03

3F 03 01 2D 00 02 8E

3F 03 04 44 7D 50 00 A9

1013,2500 mbar

5.3.9 HEX2

Register

OBIS code

Ab.

Description

Unit

Scaling

2

97:97.1

Register 1

calibration relevant alarms

-

-

5

97:97.2

Register 2

Operational status

-

-

6

97:97.3

Register 3

Alarm reports

-

-

7

97:97.4

Register 4

VDEW status

-

-

Function Code

Modbus Command

Answer

Meaning

03

3F 03 00 02 00 01 BB

3F 03 02 00 0A B2

000A

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 16

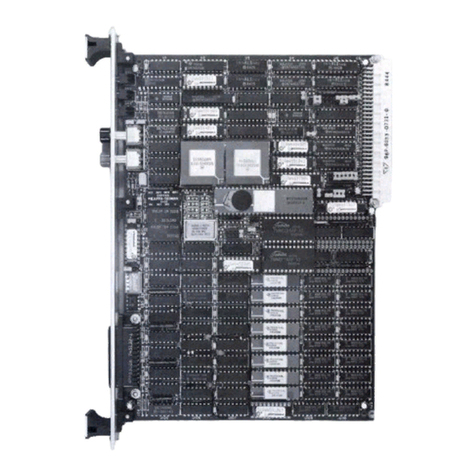

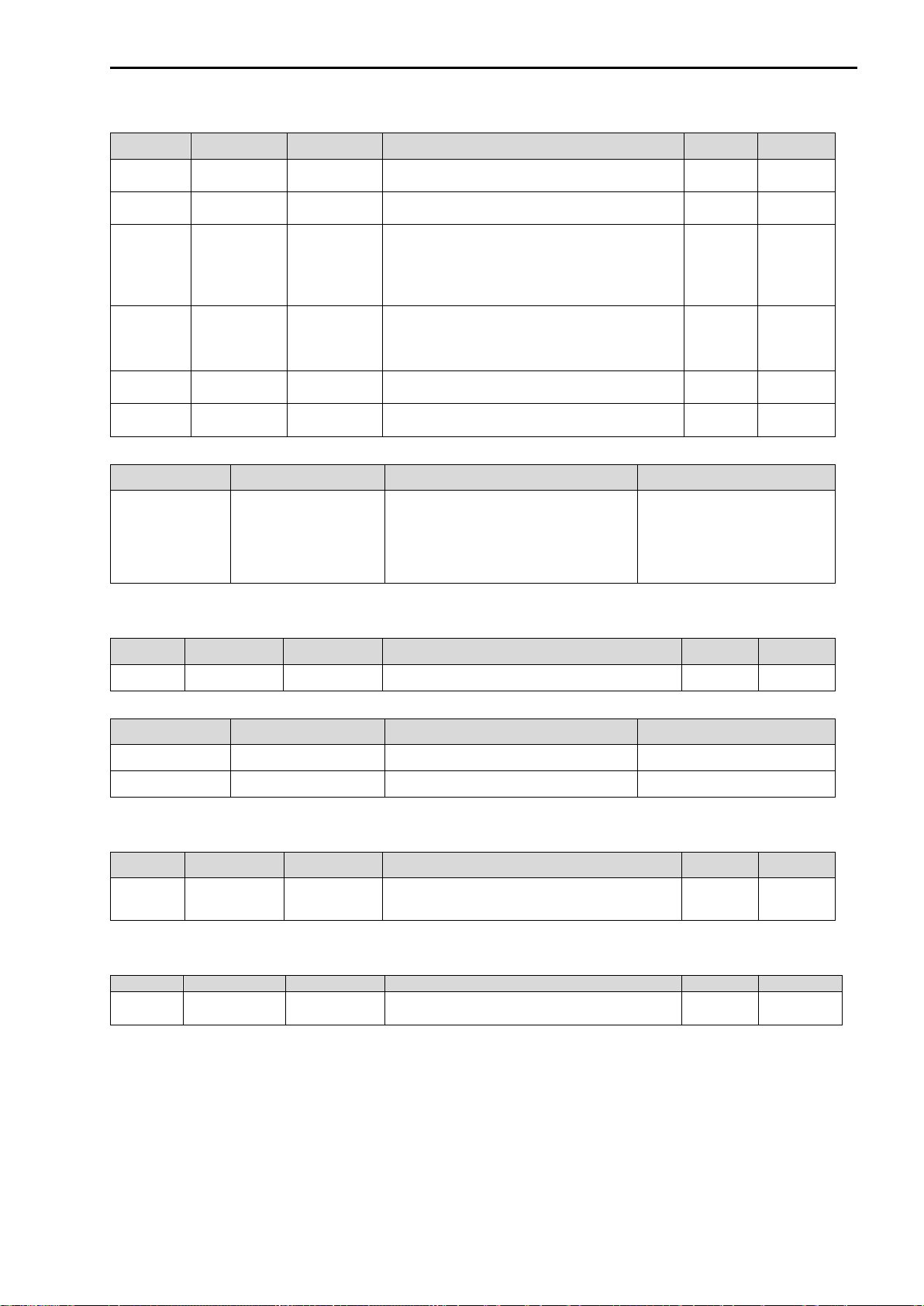

5.4 Read out examples

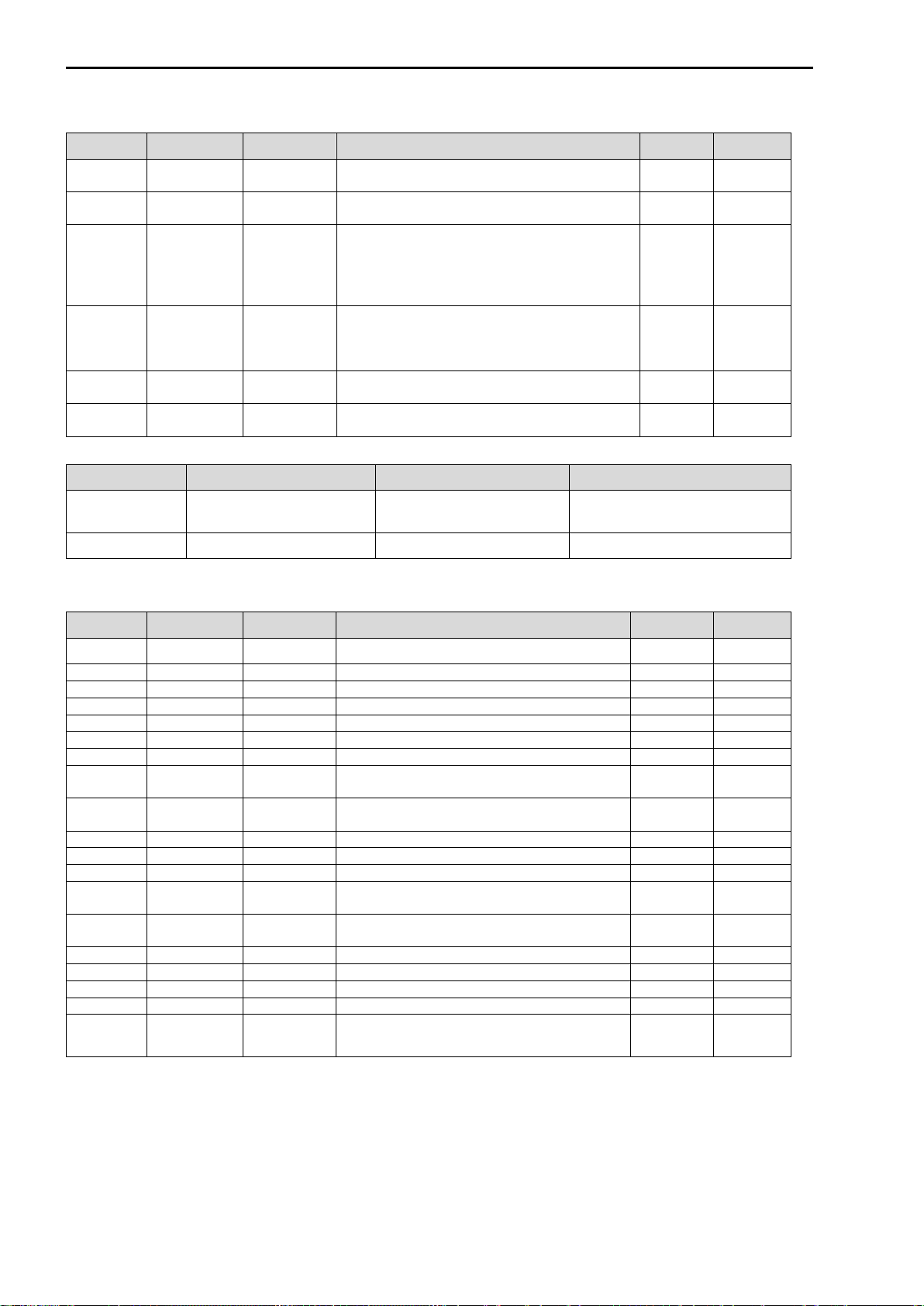

5.4.1 Register 1 -7

5.4.2 Register 101 -104

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 17

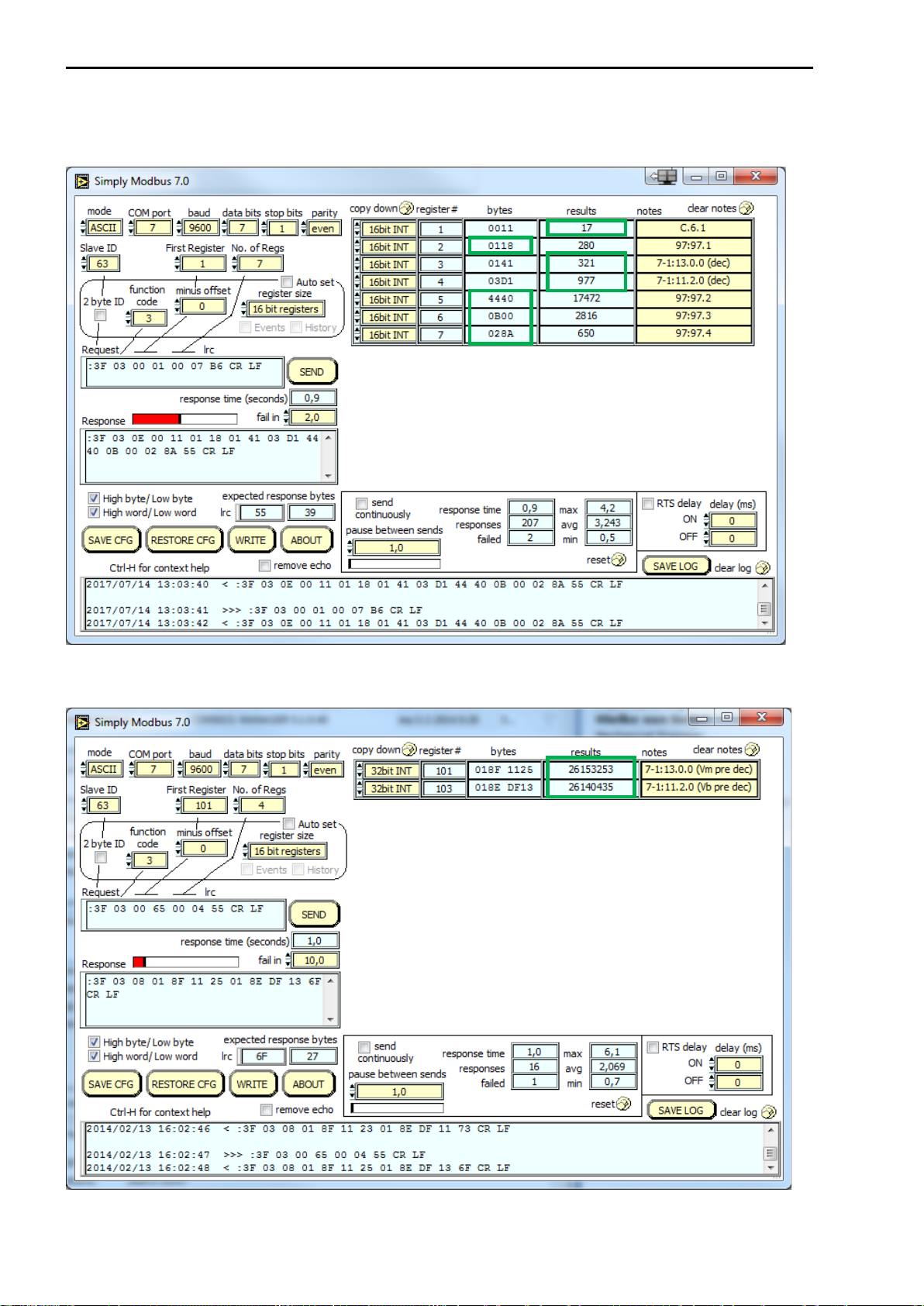

5.4.3 Register 301 –324

5.4.4 Register 327 –351

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 18

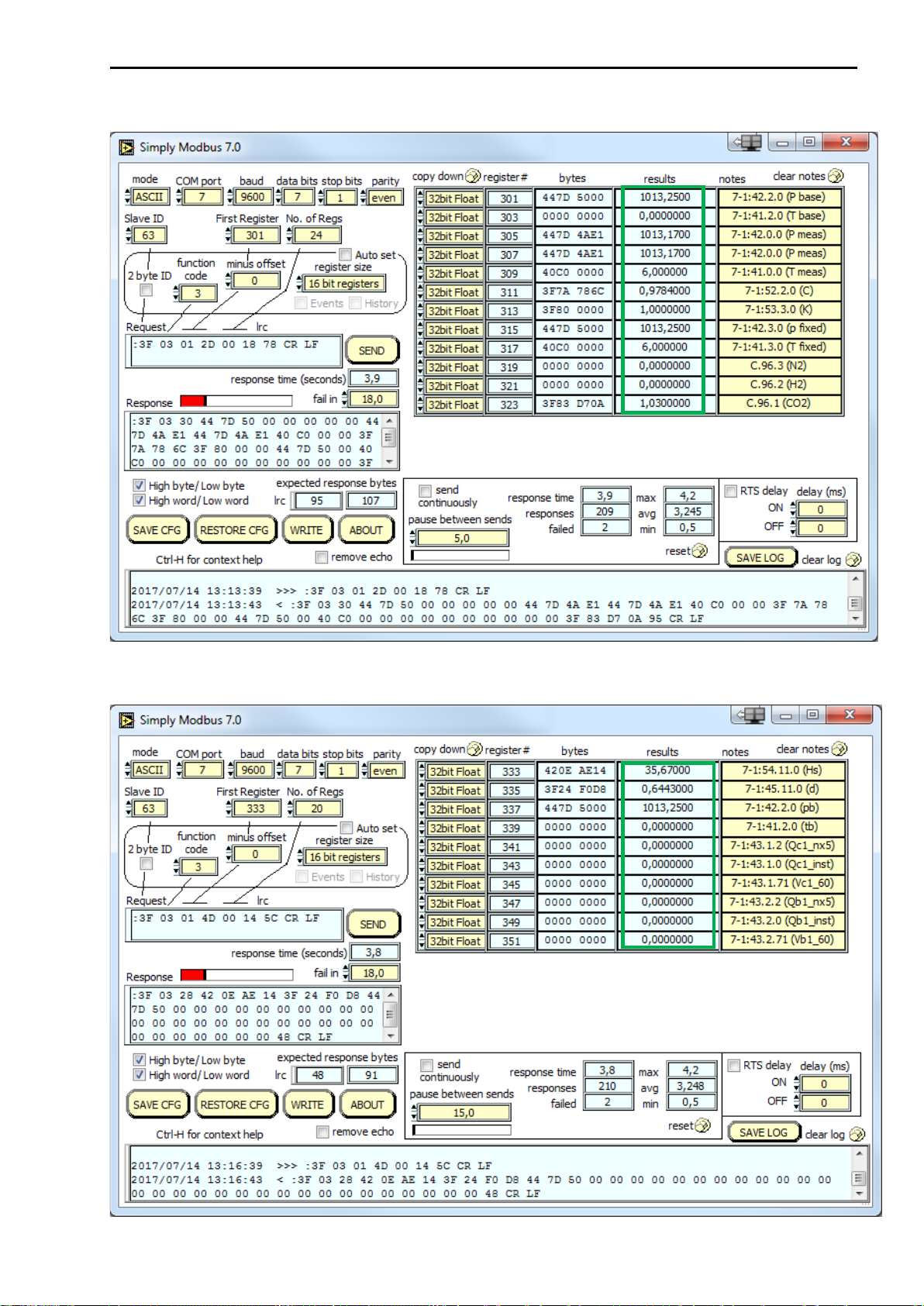

5.4.5 Register 501 –506

5.4.6 Register 801 -812

Installation and operating manual CI-module UNIGAS 300

DDG6010MHEN/09-2023/Rev.A5 19

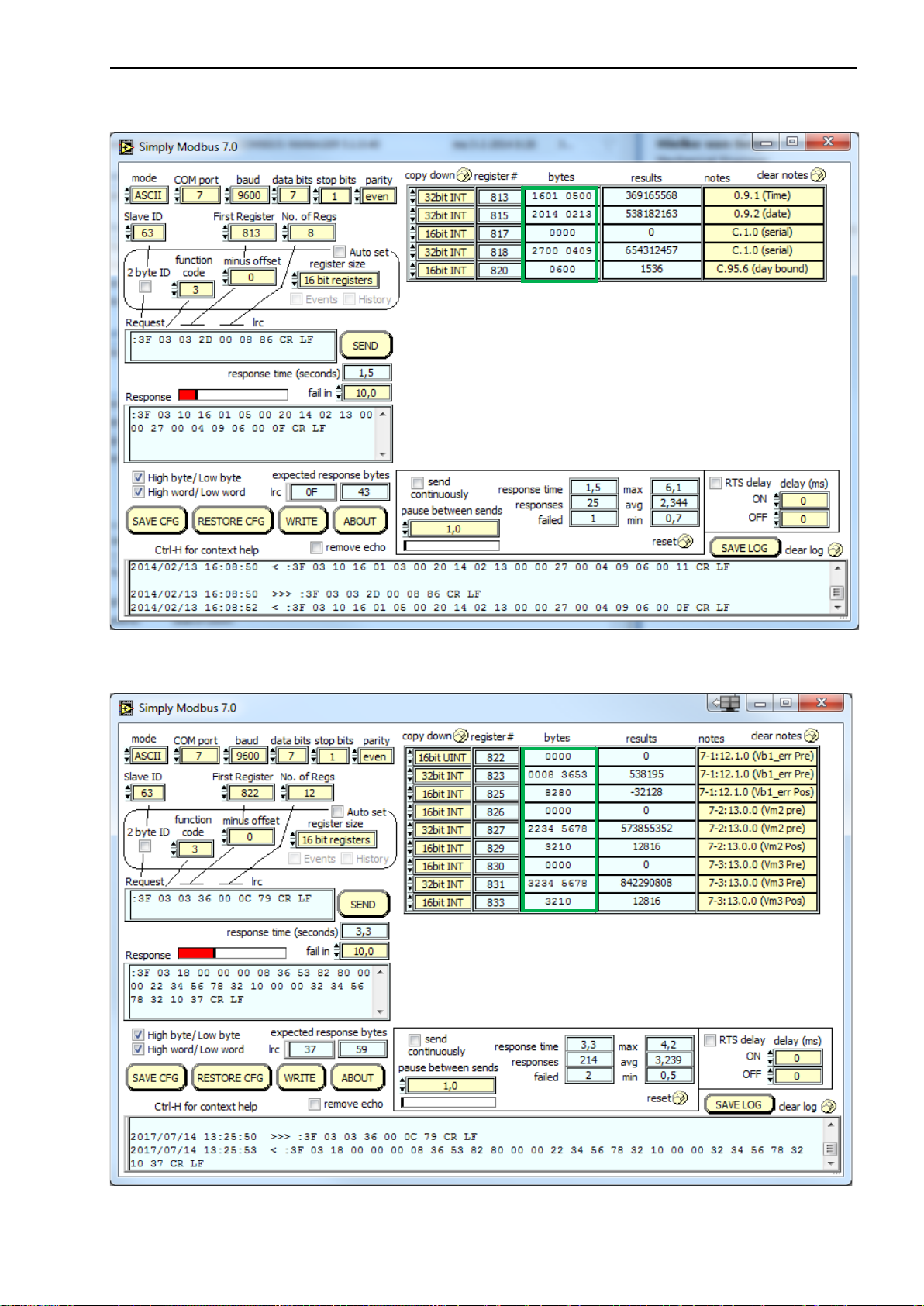

5.4.7 Register 813 –820

5.4.8 Register 822 –833

Other manuals for UNIGAS 300

1

Table of contents

Other Wigersma & Sikkema Control Unit manuals