Symmons Industries, Inc. ■31 Brooks Drive ■Braintree, MA 02184 ■Phone: (800) 796-6667 ■ Fax: (800) 961-9621

Copyright

©

20

22

Symmons

Industries,

Inc.

■symmons.com ■[email protected]om ■ZV-3466 REV C ■ 102522Installation

11 10

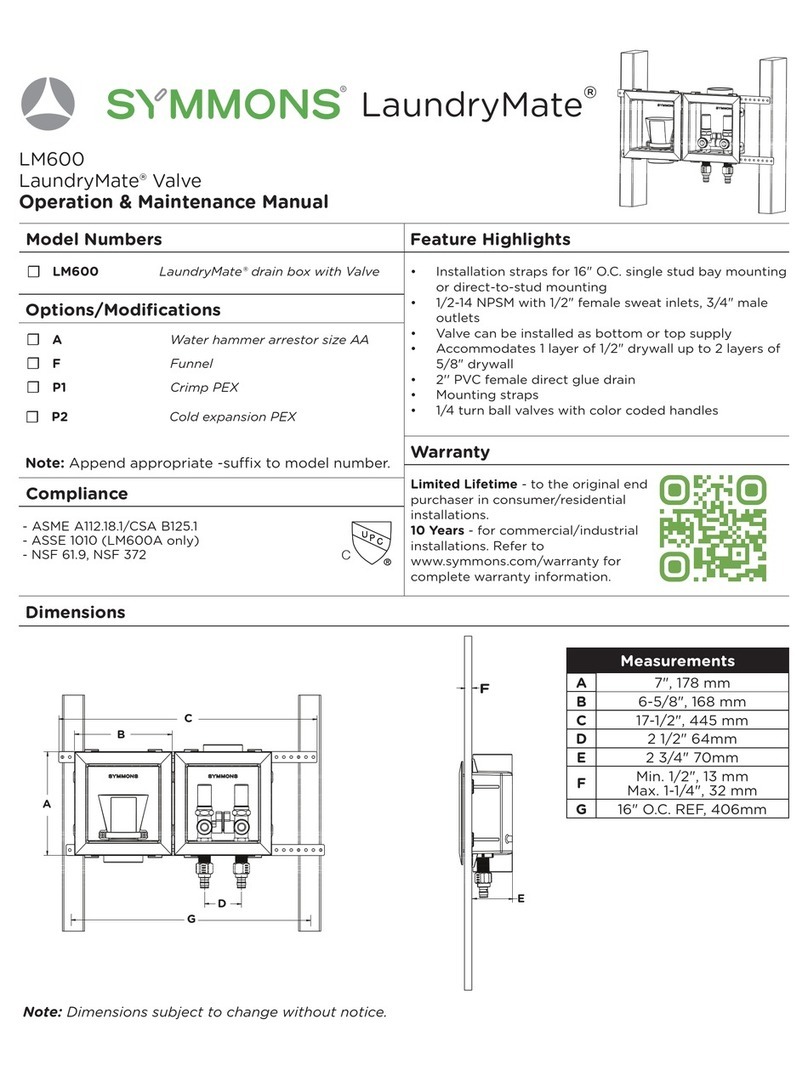

Section A (Steps 1-10)

1. Slide straps in mounting tabs

2. Attach strap to studs with user provided screws

3. Secure valve to box with two supplied nuts

4. Glue 2’’ PVC pipe into bottom of drain box

5. Knockout outside two holes of supply box for hot and

cold supply (shown in A.1)

6. Insert provided screws through tabs to secure box in

place

7. Connect supplies to valves with either:

a. Sweat connect

b. Includes integral PEX fittings. P1 Models use a

crimp PEX connection and P2 Models include

cold expansion PEX connections

8. If condensate drain is used, knockout back hole in

drain box (shown in A.1)

9. Knockout center plug of drain box with screwdriver

or hammer and use pliers to remove

Section B (Steps 10&11)

10 After finish wall is in place, press on covers

a. If finish wall is 1/2’’ thick, break tabs from cover

o

b. If 2 layers of 5/8” drywall leave tabs on

Funnel Installation:

Before installation of funnel deburr drain hole as necessary

11. If 1-1/4’’ drain line hose is used, use provided clamp to

secure hose in place

Section C (Step 12)

Double Bay Installation:

12. Mount boxes on adjacent side of wall stud with

provided tabs. Continue steps starting at step 4.

Section D (Step 13)

Surface Mount Installation:

13. Drill holes out of box and use user provided screws

to attach to wall

Section A

Section B

Section A.1

Section C Section D

12

8

5

1

5

3

7

6

8

4

2

9

13