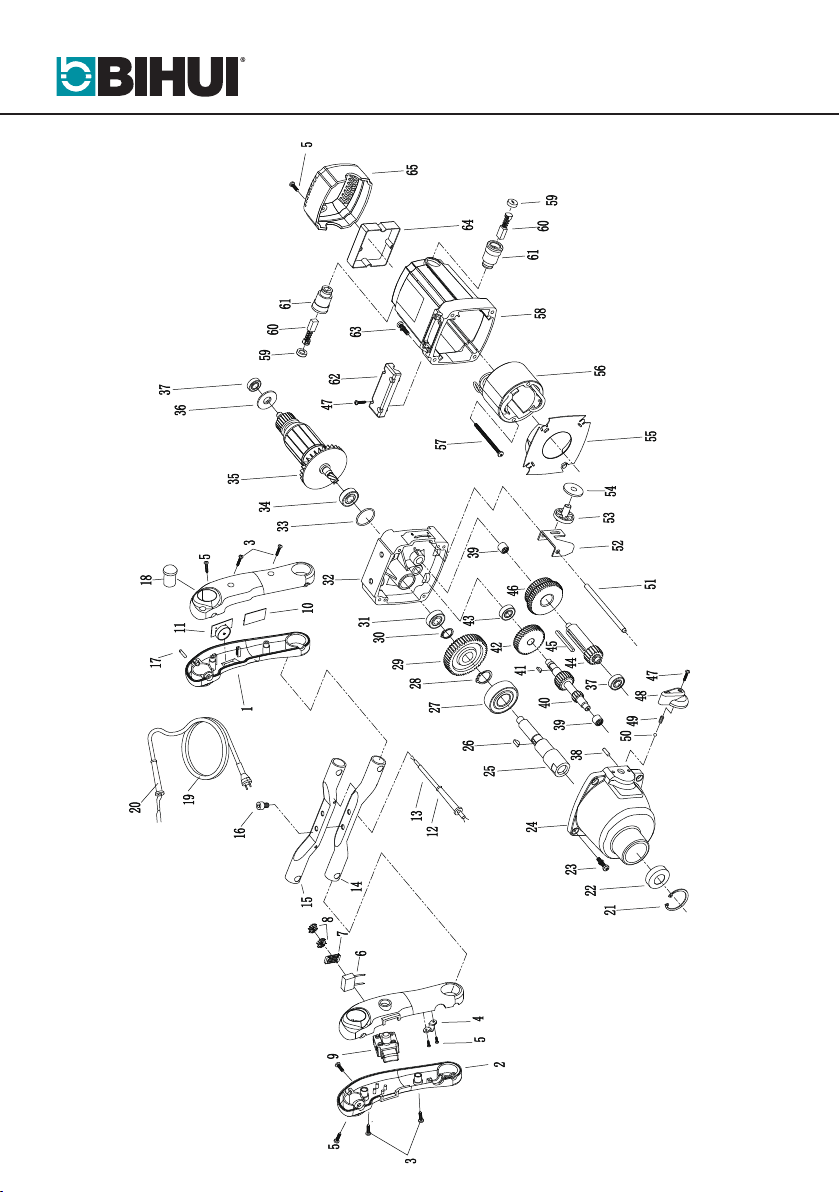

Bihui MME1200 Parts list manual

MIXER 1200W

Usage Instructions

MME1200

Read before use

WARRANTY

Usage Instructions

English

2

Usage Instructions

English

3

Spare Part List

Left Handle

Right Handle

Screw ST3.9X20

Clamp

Screw ST3.5X16

Capacitance

The inductance

Round inductance

Switch

speed governing plate

Speed control knob

Sleeve (small)

Cable

Steel pipe ( without hole)

Steel pipe ( with hole)

Screw M8X12

Round pin

Round tube plug

Power cord

Sleeve (big)

Safety ring ¢35

Dust cover

Screw M5X20

Bearing cover

Output shaft

Hemicycle key4X5X12

Bearing 6003 ZZ

Safety ring ¢17

Spindle gear

Safety ring ¢15

Bearing 62900ZZ

Gear box

Sealring ¢25.8X1.8

Bearing 6000 2RS

The rotor

M insulation gasket

Bear 608ZZ

Pin 4X14

Needle bearing HK0810

The second active gear shaft

Hemicycle key2.5X3.7X10

First driven gear

Bearing 698ZZ

The third active gear shaft

Parallel key 4X4X45

Change gear set

Screw ST3X16

Lever

Lever spring ¢0.5X¢3.9XL12

Ball ¢4

Pivot ¢6X76

Coulisse

Partial core + eccentric wheel core

Distance ring

Break wind ring

The stator (including the brush

Screw ST4X70

Motor housing

Brush cap

Carbon brush 6.5X9X17

Brush holder

Clamp

Screw M5X25

Circuit board seats

Rear cover

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

4

Usage Instructions

English

INDEX

1Safety Warnings

2Application

3

4

Using Instructions

5

Cleaning and Maintenance

6

Accessories

7

8

Environmental Protection

Caution

!

Read all safety instructions and warnings provided with power tool. Failure to follow the instructions below may result in electric

shock, fire and / or serious injury.

Keep all warnings and instructions for future reference.

The term "power tool" used in the safety instructions refers to mains operated power tools (with power cord) or to battery operated tools

(without power cord).

1.1 Safety in work area

a) Keep your work area clean and well lit. Disarray or unlit work areas can lead to accidents.

b) Do not work with the power tool in a potentially explosive environment in which flammable liquids, gases or dusts are present.

Power tools generate sparks that can ignite the dust or fumes.

c) Keep children and bystanders away while using the power tool. Distractions can result in a loss of control.

1.2 Electrical Safety

a) The plug of the power tool must fit into the socket. The plug must not be changed in any way. Do not use adapter plugs together

with electrically grounded power tools. Unmodified plugs and matching sockets reduce the risk of electric shock.

b) Avoid body contact with grounded surfaces such as pipes, heaters, stoves, and refrigerators. There is an increased risk of

electric shock if your body is grounded.

c) Keep power tools away from rain or moisture. The penetration of water into a power tool increases the risk of electric shock.

d) Do not misuse the power cord to carry the power tool, hang it up, or unplug it from the power outlet. Keep the connection cable

away from heat, oil, sharp edges or moving parts. Damaged or entangled leads increase the risk of electric shock.

e) When working outdoors with a power tool, only use extension cables that are also suitable for outdoor use. Using an extension

cord suitable for outdoor use reduces the risk of electric shock.

f) If operation of the power tool in a damp environment is unavoidable, use a residual current device. Using a residual current circuit

breaker reduces the risk of electric shock.

1.3 Personal Safety

a) Be attentive, pay attention to what you are doing and be reasonable about working with a power tool. Do not use a power tool

when you are tired or under the influence of drugs, alcohol or medication. A moment of carelessness when using the power tool

can cause serious injury.

b) Wear personal protective equipment and always safety goggles. Wearing personal protective equipment such as a dust mask,

non-slip safety shoes, hard hat or ear protection, depending on the type and use of the power tool, reduces the risk of personal injury.

Warranty

Attachments

1. Safety Warnings

General safety warnings for power tools

The following are the icons that are used for the tool. Make sure you

fully understand them before using them.

Symbols

!

Read the instruction manual

CE mark

Caution

Conforms to WEEE

Class II machine Warning risk of cutting by the saw

Use of segmented blades prohibited

Wear safety glasses

Wear hearing protectors

Wear safety gloves

Class II machine

5

Usage Instructions

English

c) Avoid unintentional startup. Make sure that the power tool is switched off before connecting, receiving or carrying it to the

power supply and / or the battery. Keeping your finger on the switch when you are wearing the power tool or plugging the power

tool into power can cause an accident.

d) Remove setting tools or wrenches before turning on the power tool. A tool or key located in a rotating part of the power tool can

cause injury.

e) Avoid an abnormal posture. Ensure a secure footing and maintain balance at all times. This allows you to better control the

power tool in unexpected situations.

f) Wear suitable clothing. Do not wear loose clothing or jewelry. Keep hair and clothing away from moving parts. Loose clothing,

jewelry or long hair can be caught by moving parts.

g) If dust extraction and collection equipment can be installed, they must be connected and used properly. Using a dust extractor

can reduce dust hazards.

h) Do not weigh yourself in false safety and do not overstep the safety rules for power tools, even if you are familiar with the

power tool after many uses. Careless action can lead to serious injuries within fractions of a second.

1.4 Use and care of the power tool

a) Do not overload the power tool. Use the appropriate power tool for your work. With the right power tool you work better and safer

in the specified power range.

b) Do not use a power tool whose switch is defective. A power tool that can not be turned on or off is dangerous and must be repaired.

c) Unplug the power cord and / or remove a detachable battery before making any adjustments to the device, changing the tool

bits, or putting the power tool away. This precaution prevents the unintentional start of the power tool.

d) Store unused power tools out of the reach of children. Do not allow persons to use the power tool that are unfamiliar or have

not read these instructions. Power tools are dangerous when used by inexperienced people.

e) Maintain power tools and insert tools with care. Check that moving parts are working properly and do not jam, that parts are

broken or damaged enough to impair the functioning of the power tool. Have damaged parts repaired before using the power

tool. Many accidents are caused by badly maintained power tools.

f) Keep cutting tools sharp and clean. Carefully maintained cutting tools with sharp cutting edges become less jammed and easier to guide.

g) Use power tools, accessories, tools etc. according to these instructions. Take into account the working conditions and the

activity to be performed. The use of power tools for other than intended applications can lead to dangerous situations.

h) Keep handles and grips dry, clean and free of oil and grease. Slippery handles and gripping surfaces do not allow safe operation

and control of the power tool in unforeseen situations.

1.5 Use and care of the battery tool

a) Charge the batteries only with chargers recommended by the manufacturer. A charger suitable for a particular type of battery may

cause a fire when used with other batteries.

b) Use only the appropriate batteries in the power tools. Use of other batteries may cause injury or fire.

c) Keep the unused battery away from paper clips, coins, keys, nails, screws, or other small metal objects that could cause the

contacts to bridge. A short circuit between the battery contacts can cause burns or fire.

d) If used incorrectly, liquid may leak from the battery. Avoid contact with it. In case of accidental contact, rinse with water. If the

fluid gets into your eyes, seek additional medical attention. Leaking battery fluid may cause skin irritation or burns.

e) Do not use a damaged or modified battery. Damaged or altered batteries can behave unpredictably and cause fire, explosion or injury.

f) Do not expose a battery to fire or high temperatures. Fire or temperatures over 130 ° C can cause an explosion.

g) Follow all charging instructions and never charge the battery or the cordless tool outside the temperature range specified in the

operating instructions. Incorrect charging or charging outside the permitted temperature range can destroy the battery and increase

the risk of fire.

1.6 Service

a) Only have your power tool repaired by qualified personnel and only with original spare parts. This ensures that the safety of the

power tool is maintained.

b) Never use damaged batteries. All battery maintenance should only be done by the manufacturer or authorized service centers.

Follow the instructions for lubricating and changing accessories.

6

Usage Instructions

English

Additional safety warning from the manufacturer

- Observe also other safety directions that are a part of each instrument delivery.

- Check the flexible lead and plug before each use of the instrument. Have the faults removed by an expert.

- The instrument should not be operated in damp, wet premises; during a rain, fog and snow in the open, and in environment with

a risk of explosion.

- Before putting the plug in the mains socket the switch should be in the “off” position.

- Take care of long hair and fashion accessories, work in properly buttoned-up clothes, without freely flowing parts.

- Secure the vessel with the mixed substance against moving on the floor.

- Always direct backwards the flexible lead from the instrument, Flexible lead should not be exerted by tensile stress and should not lie on

or pass over sharp edges.

- Take care that you take a safe and firm stand at work.

- Use the supplementary handle.

- Consider possible reaction torque.

2. Application

- Heavy duty gear system with large torque

- With 300 hours continued working time

- Paddle swing < 0.5mm without fatigue

- Maximum mixture loading 40L

- Suitable for mixing cement, paints, tile adhesive, glue etc

- Also available in 110V version

Model MME1200

Voltage/Frequency 230V/50Hz

Input Power 1200W

1st Gear 150-300RPM

2nd Gear 300-650RPM

Two-section mixing paddle

600x120mm x M14

Accessories

No Load speed

Manufacturer reserves the right to change specifications without notice.

Specifications may differ from country to country

Technical Data

3. Instructions

Improper use may damage the instrument.

Observe therefore these instructions:

- Use a tool up to the specified diameter.

- Load the instrument in such a way that the speed would not drop considerably or that it would stop.

- Check if the data on the rating plate correspond with the actual mains voltage.

- Instrument scheduled for 110V/230V can be plugged to 110V/220V/240V mains.

3.1 Operation and Use

Fixing a whisk

- Screw tools with thread M14 x 2 as far as possible in the tool mount and tighten properly with an open-end wrench from among

the accessories.

Switching on and off

- By pressing the switch button the apparatus is brought into operation and it stops when this is relieved.

Permanent run

- By pressing the switch button to the stop and simultaneous pressing the arresting pin permanent run is achieved.

- By subsequent pressing and relieving of the switch button, the permanent run is interrupted.

Unloading the tool (whisk)

- Fit a flat open-end wrench on the hexagon end of the tool (whisk) and unscrew the tool from the spindle by turning it to the left.

Caution

!

3.2 Electronic Motor Control

Starting current limiting

- The electronically controlled smooth start takes care that the machine starts without jerk. In this manner, the splashing of thin liquid

materials is prevent at the same time when switching on the machine.

- As a result of the machine's reduced starting current, a 16A fuse is sufficient.

Usage Instructions

English

7

4. Cleaning and Maintenance

Always be sure that the tool is switch off and unplugging before attempting to perform inspection and maintenance.

- The tool and its air vents have to be keep clean, regularly clean the tool's air vents or whenever the vents start to become obstructed.

- Check the all screws if be loosened or no periodically.

- Usually check the cord insulation if broken or not.

5. Accessories

- Do not dispose of electrical appliances in the household waste.

- Follow the local provisions for the disposal of electrical or battery products.

- Valuable materials can be recovered by recycling.

- The electrical or battery components used for construction are in accordance with the regulation European Directive 2012/19 / EU on

waste electrical and electronic equipment and transposition into national law., used electrical appliances must be collected separately

and recycled in an environmentally sound manner.

- Contact us for further information.

7. Warranty

- The guarantee covers all manufacturing or assembly defects in accordance with the legislation in force. The guarantee does not cover

malfunctions caused by improper use, overloads, failure to follow the operating instructions and normal wear and tear.

- For more detials and information, consult the general guarantee conditions at www.bihuitools.com

8. Attachments

CE Declaration of Conformity

- This accessory is recommended for use with your device specified in this manual.

- Using other accessories or attachments may result in personal injury. Only use accessories or accessories for the stated purpose.

6. Environmental Protection

Caution

!

No-load speed reduction

- The electronic control reduces the no-load speed of the machine which results in reduced noise and wear of motor and gear.

Speed pre-selection

- With the speed control, the speed can be continuously pre-selected.

- The necessary speed is dependent on the type of material to be mixed. it is recommended that it be confirmed, with a practical trial.

Speed selection

- Two rpm ranges can be pre-selected with the speed selector switch.

Speed 1: 150 - 300RPM

Speed 2: 300 - 650RPM

- The necessary speed depends on the type of the material mixed and it is recommended to verify it by a practical test.

Constant Electronics

- The constant electronics keeps the speed between no-load and load nearly constant and ensures uniform mixing of the materials.

Electronic overload protection

- In case that the machine is extremely overloaded, an electronic overload protection protects the motor from damage. In this case,

the motor stops and restarts only after the feeding pressure is reduced.

Temperature-dependent overload protection

- To protect the motor from overheating at extreme permanent load, it is switched off by the protective electronic system when a

critical temperature is reached.

- After a cooling-down period of approx. 3-5 min., the machine is again ready for use and can be fully loaded.

- When the machine is warmed by use, the temperature-dependent overload protection reacts earlier as a result.

8

www.bihuitools.com

Table of contents