8 | P a g e

MIXING INGREDIENTS

Follow the capacity chart located on page 11

Overloading or not following this chart will damage the mixer and void the warranty

IMPORTANT: Make sure the speed control dial is in the off position.

1. Add the appropriate mixing ingredients into the bowl.

2. If desired, place the bowl guard on top of the bowl and align the pins on the guard with the

holes on the rim of the bowl (see Fig. 8-1 and 8-2).

Note: In order for the SP50 mixer to operate, the bowl guard must be in place and clicked into

locked position.

3. Lift completely up on the bowl lift lever until the bowl locks into position.

4. Select the appropriate speed setting by rotating the speed selector knob clockwise starting

from 0. To increase mixer speed, continue turning the selector button clockwise to desired

speed.

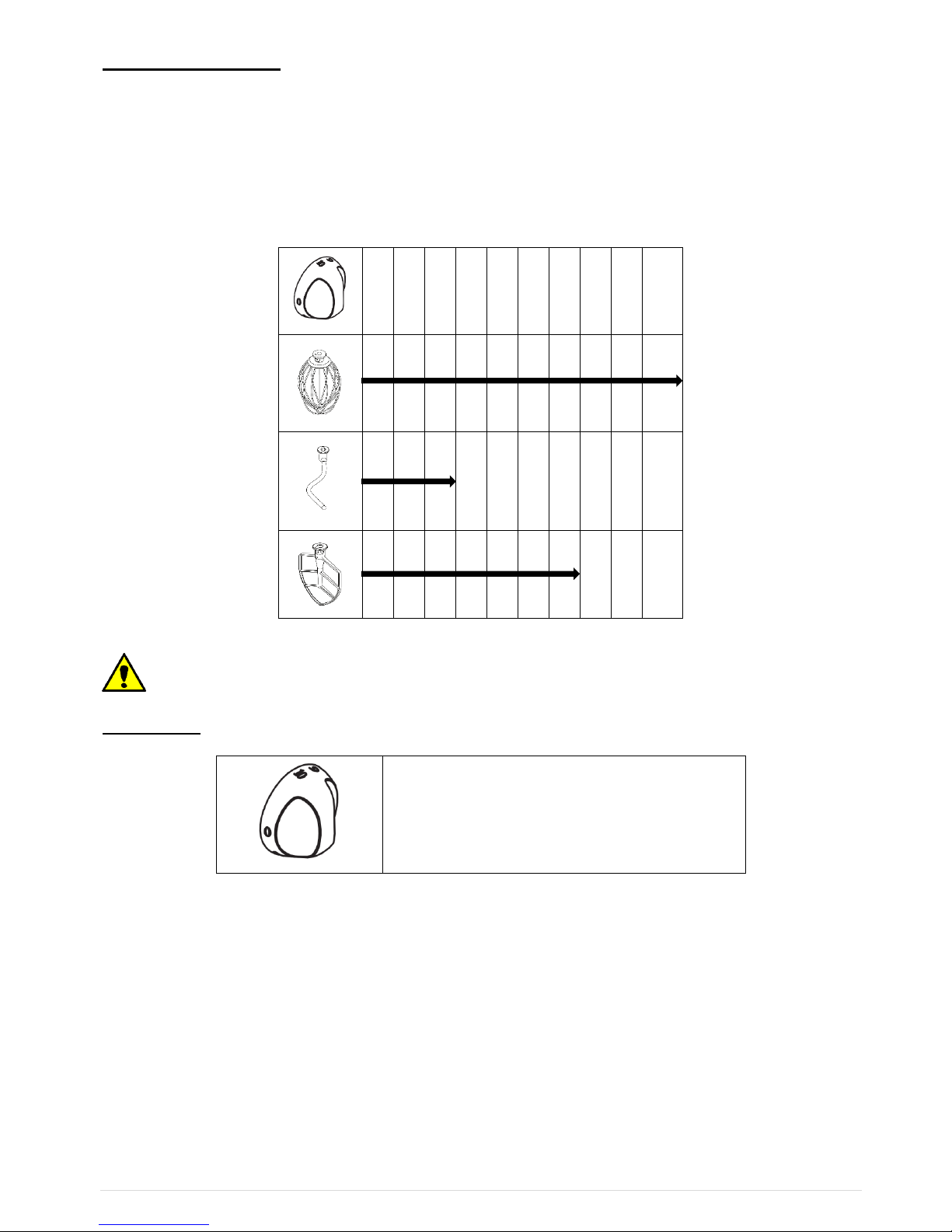

Recommended speeds while mixing:

Position Speed Attachment Product Type/Ingredient

1 (stir) All Start to incorporate ingredients

2 (low) Dough Hook Heavy: mixing pizza, bread, pasta,

stuffing and donut dough’s, cake,

batter, mashed potatoes, etc.

3-7 (medium) Beater Medium: 2nd stage of mixing for

donut dough, etc.

8-10 (high) Whip Light: whipping cream, egg whites,

meringue, mousse, pancake mix,

sponge cakes, etc.

IMPORTANT: When mixing product always follow the recommended agitator and

speed setting according to the capacity chart located on page 12 of this manual.

Always STOP the mixer BEFORE changing or fitting accessories! Failure

to do so may cause harm to the operator; it may also damage the gears

or other parts and WILL void the warranty!

5. During the mixing process, additional ingredients can be added to the mixture using the

food chute located on the splash cover.

6. To turn off the mixer, turn the variable speed control counter clockwise until the dial is

aligned with the selector notch to the zero “0” position and the mixer turns off

NOTE: If the mixer shuts off during operation, return the speed control dial back to the zero

“0” position.