BIL Skoots User manual

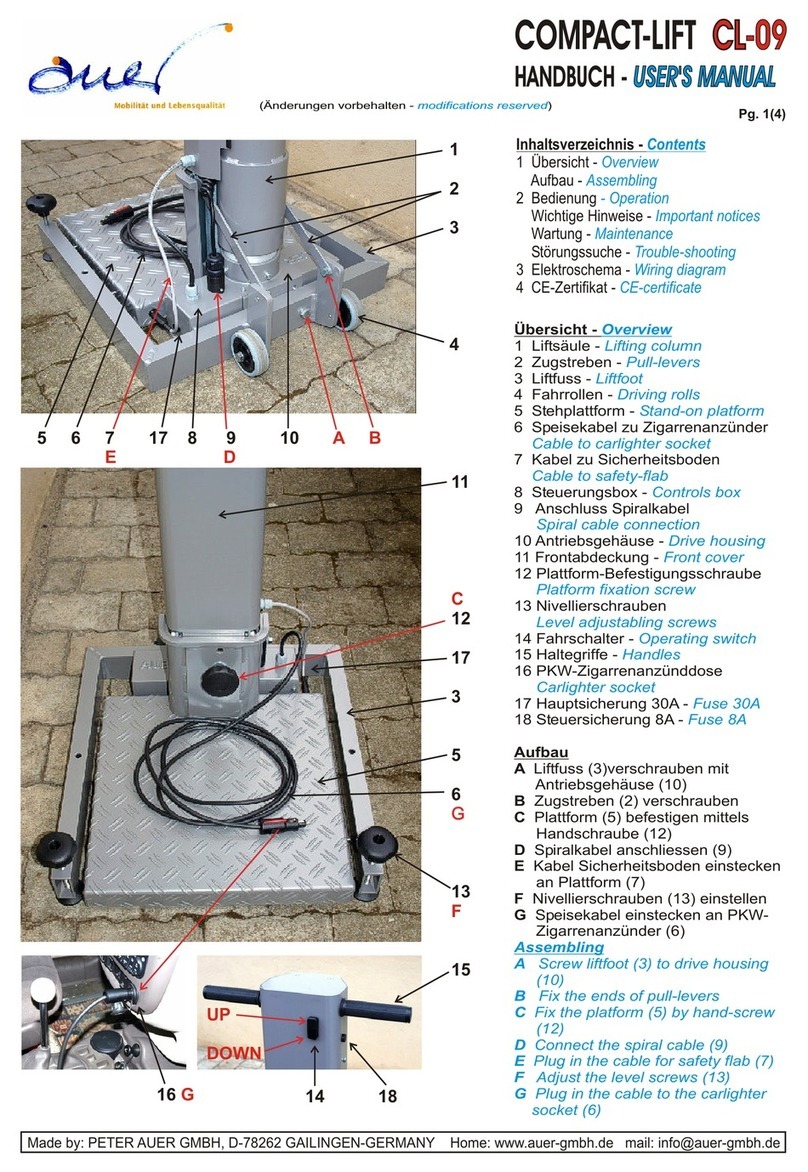

Depth Width

Height

380mm 600mm120mm 150mm

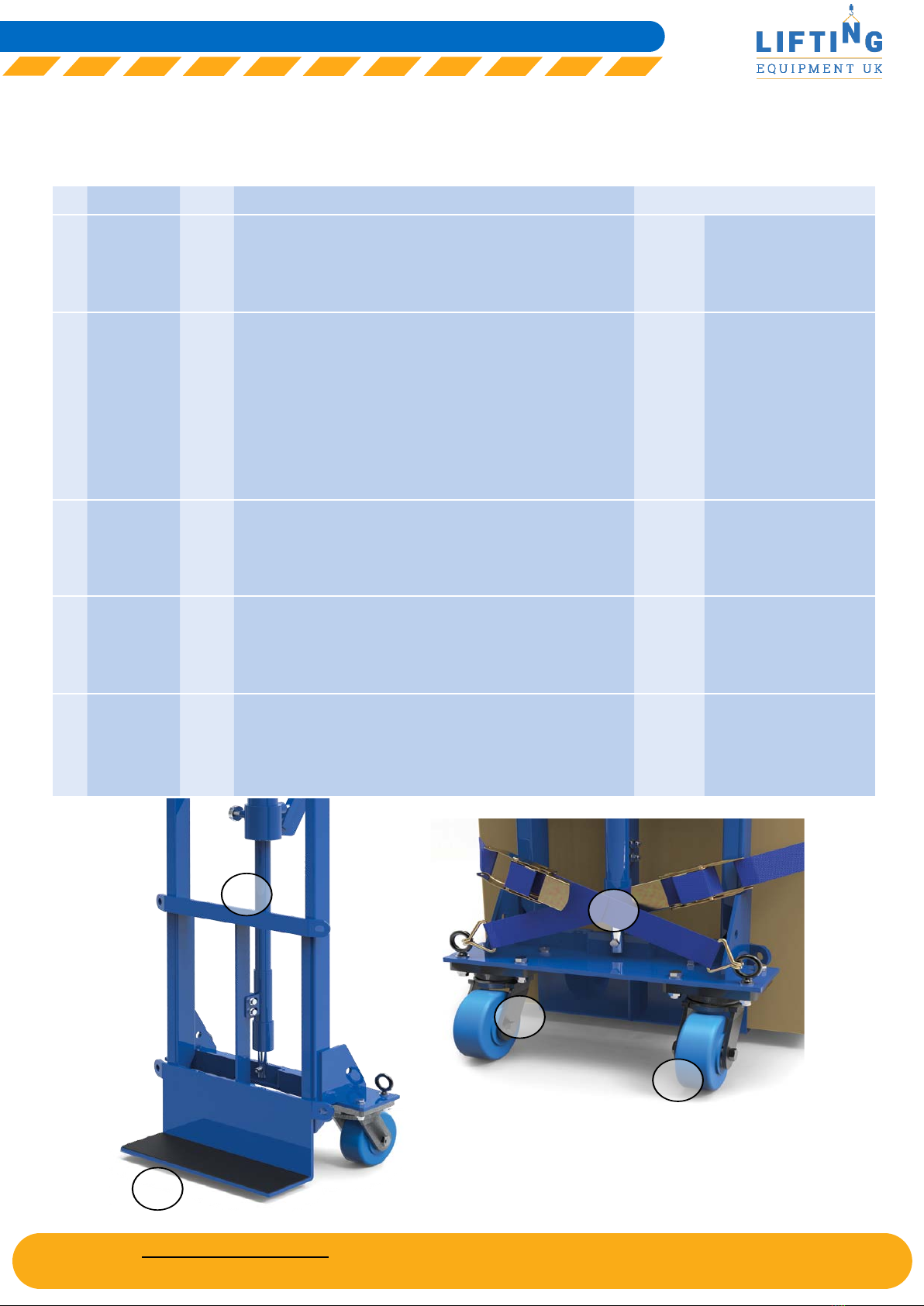

Model Dimensions (mm) SWL

pair

Wheel

diameter

Lifting

height

Toeplate

(A or B)

Total weight

pair

H W D

SK600 1160 510 330 600kg 125mm 400mm A 87.2kg

SK900 1160 510 330 900kg 125mm 400mm A 98.2kg

SK1400 1160 510 330 1400kg 125mm 400mm A 98.6kg

SK2000 1160 510 330 2000kg 125mm 400mm A 94.0kg

SK3500 1160 510 400 3500kg 125mm 375mm A 99.4kg

SK5000 1170 790 490 5000kg 150mm 200mm B 230.0kg

Each set of Skoots is supplied with a matching pair of

main frames which are designed to work at opposite

ends of the load. A pair of heavy-duty straps is

supplied to bind the Skoots units tightly to the load.

Skoots are portable moving systems which

hydraulically lift a load of up to 5000kg* off the

floor onto castors, allowing easy movement in any

direction. For heavy and bulky loads of all shapes and

sizes they can be used in a wide range of commercial

and amenity situations...

•Air conditioning installation & maintenance

•Commercial refrigeration

•Security safe installation

•Switchgear panel manufacture & installation

•Vending machine installation

•Museums and galleries

•Hire shops – speciality lifting equipment

•Data cabinets and server equipment

•Machinery installation

and many more...

* Load capacity according to model number

Toe plate A Toe plate B

Website: Www.liftingequpmentuk.com

Email: [email protected]

Check Skoots units for loose or missing nuts and bolts, stress cracks, worn wheel treads, bearings

and general wear and tear – and any missing ancillary equipment such as straps.

Keep within the safe working load as designated on the side of the Skoots units – remember, load

capacity is for a pair of Skoots not per side.

Keep the working area and transport route free from hazards such as debris, electrical cables,

potholes, deep gullies, large gaps between floor and goods lifts.

Ensure that the working area and transport route are adequately lit.

Lift the load evenly and use minimum ground clearance when transporting loads.

Ensure you can see where you are going or get a colleague to guide you.

Push but do not pull loaded Skoots.

Watch the Skoots unit and load at all times during any movements.

Use protective pads between the Skoots frame and the load if considered necessary.

Underestimate weight and overload the Skoots units.

Raise a load without it being fully secured by correctly positioned straps – see operating instructions.

Raise the load higher than necessary.

Raise a top-heavy, high-centre-of-gravity load by more than 20mm to avoid the risk of overbalancing.

Remove straps or release tension while a load is in a raised position.

Place your hands, feet or other under the load or moving parts when the load is raised.

Use Skoots units on a hill or incline without prior full risk assessments.

Move the load faster than is safe to ensure that you can keep it under control and upright.

Leave a raised load unattended.

Attach cranes or other lifting tackle to Skoots units.

Interfere with seals or hydraulics.

Attempt the lifting and moving procedure without wearing safety shoes to avoid the risk of injury from

the load potentially rolling over and crushing feet.

Attempt to engage/disengage directional locks on castors whilst the load is raised or on a gradient to

prevent the risk of a crushing injury caused by uncontrolled loaded equipment.

Use other equipment to move loaded Skoots. They are designed to be manually propelled unless when

used with a BIL Group recommended product such as PowerDrive.

Failure to follow user instructions carefully each time could result in serious

injury or death, or damage to property.

Website: Www.liftingequpmentuk.com

Email: [email protected]

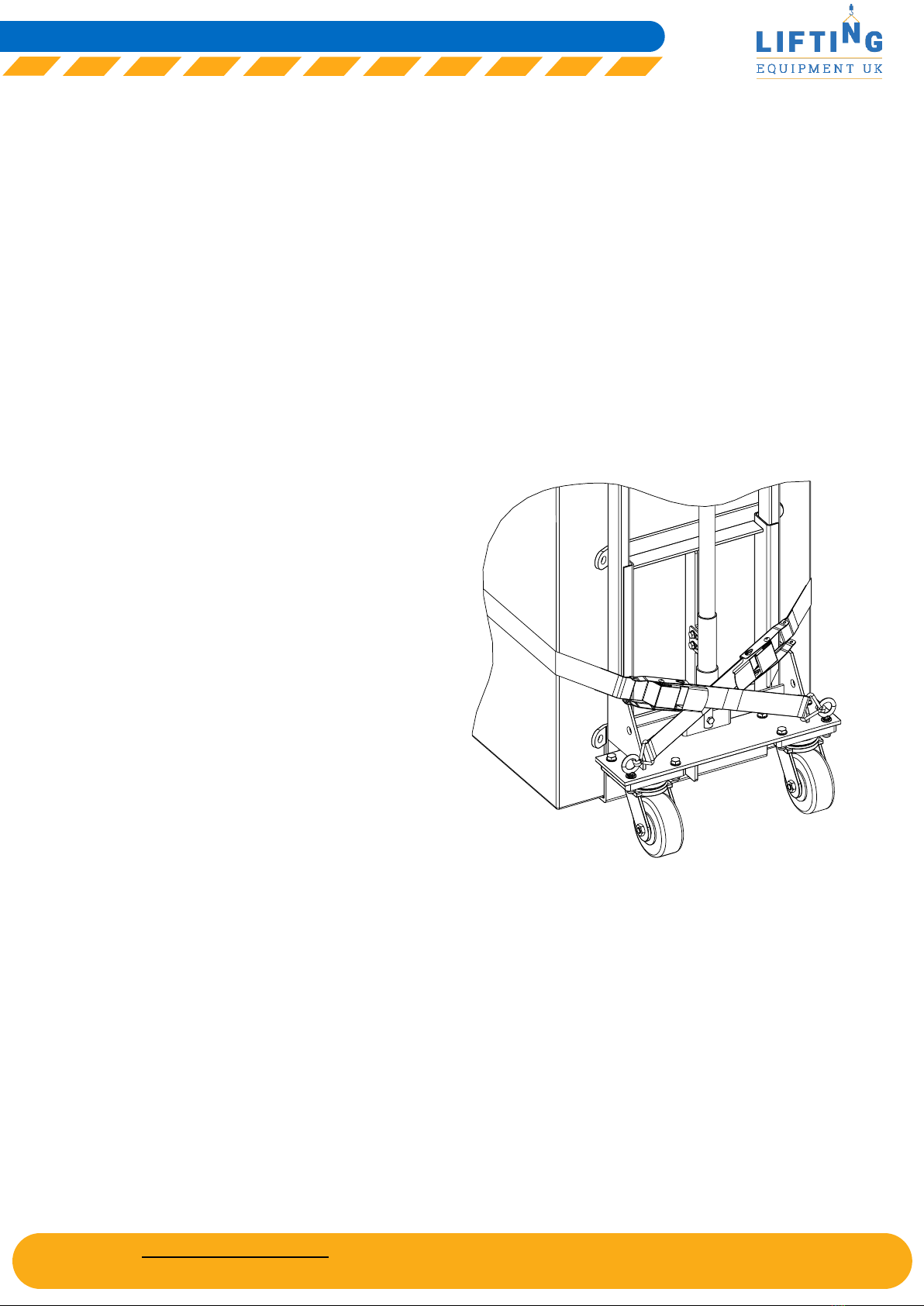

2. Place Skoots units centrally under each end of the

load, ensuring that the load is located firmly in the heel

of the toe plate. Note that the toe plate will try to push

away from the load whilst the top of the frame will

try to push into the load. Use protective pads, such as

carpet tiles, between the Skoots frame and the load if

considered necessary.

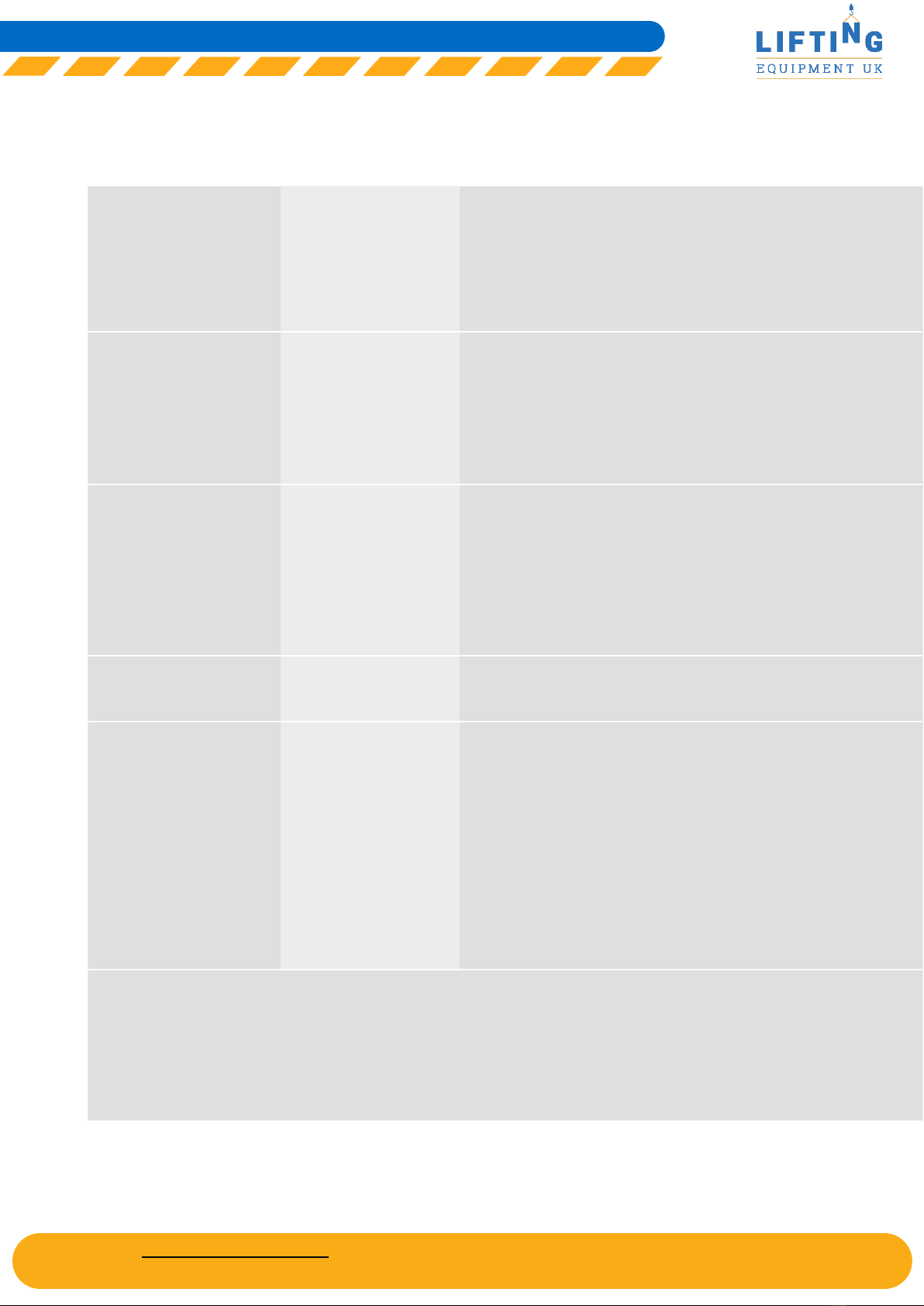

3. Secure load using both straps, ensuring that they

are hooked into the eyebolts at each end and cross at

the back of the Skoots units. It is important to cross

the straps over at the rear of the Skoots frames to

allow the position of the cam buckle to sit behind the

frame rather than at the side of the load. This also

enables the straps to be fixed at greater tension than

would otherwise be the case.

4. SK600 to SK3500 models: Pull the strap tight so

that the Skoots units are hard against the load, and

close the over-cam buckle to lock so that the straps

are held firmly.

SK5000 model: Pull the strap tight so that the Skoots

units are hard against the load before using the ratchet

lever to tightly lock the strap.

IMPORTANT: Be careful not to over-tighten the straps

as this may damage the load if its outer frame casing

is weak.

WARNING: Potential crush injury or damage to

property. Do not attempt to raise the load without

using straps to secure the load.

Pay close attention to the safety notes opposite before attempting to use your Skoots units.

1. Ensure the load is within the safe working capacity

of the Skoots as identified by the data plate affixed to

the Skoots, all the floors are suitable for the total load

and that the route is clear of all hazards. A formal risk

assessment should be carried out by a competent

person, if necessary.

IMPORTANT: Consider the floor surface and

structure before attempting to transport a load,

floors should be suitably boarded or plated first if

necessary.

Straps cross over at rear

of load, hooked to the

eyebolts with cam buckles

behind the Skoots frames

Website: Www.liftingequpmentuk.com

Email: [email protected]

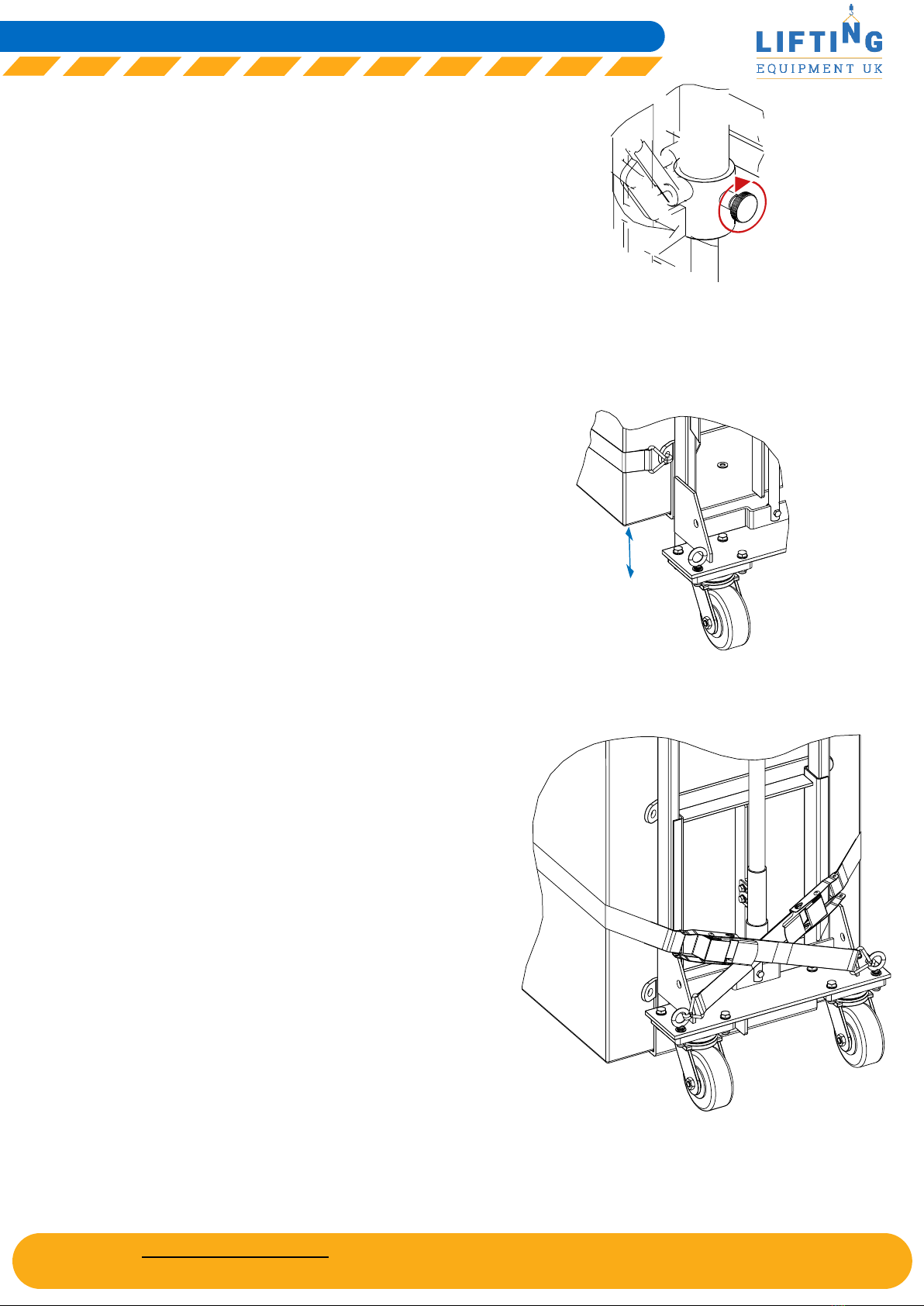

5. Before attempting to lift the load, close the

relief valve by turning the valve wheel clockwise

on the side of the jacks on both Skoots frames.

Do not over tighten as this could damage the jack.

The load is now ready for lifting.

6. Use the pump handles on the jacks maintaining

slow, full strokes to raise the load to obtain the

minimum ground clearance of about 20mm. Lift

evenly, alternating each end to keep the load

horizontal.

NOTE: Attempting to lift loads which are greater

than SWL will activate the relief valve. Whilst

the jack handle can still be pumped, the toe plate

will not raise until the load is reduced to within

safe SWL.

IMPORTANT: The default method of strap

engagement crossing straps over behind each

frame should be used to raise a low-centre-

of-gravity load to no more than 200mm when

the load is intended to remain in a stationary

position, for example when removing the load

from a plinth or block. It should also be used

when transporting a load at the minimum

ground clearance height of no more than 20mm.

However, if the user wishes to raise the load

to a maximum lift height of over 200mm then

the straps should be fixed to the Skoots using

the eyelets on the toe plate rather than the

eyebolts at the rear of the frame before the load

is raised. Proceed to raise the load first to the

desired height, and then lower it back to the

floor when the straps should be reconnected to

the eyebolts, crossing the straps over behind the

frame before transporting the load.

Never attempt to remove the straps whilst the

load is raised, never attempt to transport a

raised load at more than the minimum ground

clearance level of no more than 20mm and never

raise a top-heavy, high-centre-of-gravity load

more than 20mm from the floor regardless of

strap positions.

Stationary load

raised to 200mm+

Then revert to default strapping

method before attempting to

transport the load...

200mm+

Website: Www.liftingequpmentuk.com

Email: [email protected]

7. You may now move the load, pushing rather than

pulling.

IMPORTANT: For safety, the load should be

transported with a minimum ground clearance of

around 20mm to reduce the risk of overbalancing.

8. Make sure that control and stability of the load is

maintained at all times. On cambers and slopes use

the direction locks fitted to the castors.

WARNING: Safety risk assessments by a competent

person should be conducted before attempting to

transport loaded Skoots on cambers or slopes.

Never attempt to push a load over a drop such as a

kerb or over a gully.

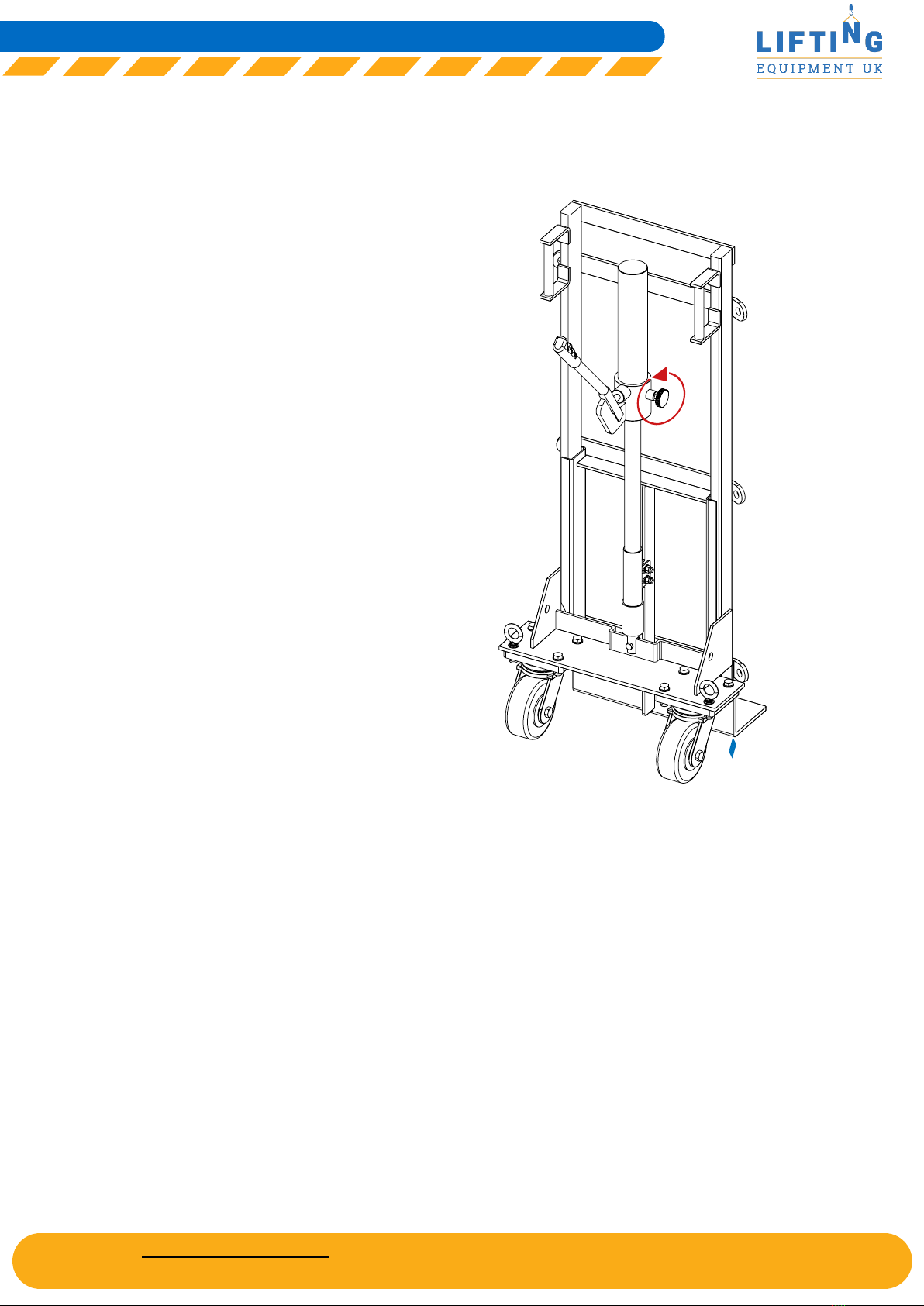

9. Once the load is in position, release the valve

wheels approximately one quarter turn anti-

clockwise, remembering that the less open the

release valves are, the slower the load is lowered.

WARNING: Potential crush injury. Open the valve

very slowly to control the rate of descent. Do not

lower the load without first checking for obstacles

underneath the load.

The load should be lowered in tandem by both

users at either end. Be careful to keep the load level

continuously as it is being lowered.

10. Release and remove the straps from the Skoots

and then the Skoots from underneath the load.

11. The Skoots units should then be stored in an

upright position.

No more than 20mm

ground clearance for

dynamic loads

20mm max

Turn anti-

clockwise

to lower

loads

Website: Www.liftingequpmentuk.com

Email: [email protected]

Unit lifts when pumped

but lowers when the

handle returns to the

rest position.

Unit will only lift a few

inches.

Handle pumps but will

not raise.

Oil leakage.

Load slipping on toe

plate.

Airlock.

Lack of oil.

Pressure relief valve

actuated.

Pumping handle too

quickly.

Worn or damaged

seals.

Worn or damaged

rubber mats.

Load incorrectly

secured. Tied with

loose straps.

Frames not

supported against

the side of the load.

Untighten the jack filler plug. Release the valve wheel

one quarter turn and pump handle 20 to 30 times.

Close the jack filler plug.

Stand jack vertically, fully retract ram and remove

filler plug using an 8mm allen key. Remove dipstick,

wipe clean, reinsert into oil and check oil level. Top

up with Varpress 68VG oil so fluid level is between

notched markers on the dip stick plug. Refit and tighten

down filler plug using the correct 8mm allen key.

Check load is within SWL and not unevenly

distributed. Reduce the load to within the marked

SWL as necessary. Consider upgrading to a higher

rated model if required.

Pump handle with slow, steady strokes.

Jack should be serviced or replaced with a new

exchange unit.

Replace rubber mats. Use recommended 3M

ScotchWeld 80 spray on prepared surfaces.

Check straps are correctly fitted and are under

tension without crushing the load. Ensure load is also

seated into the heel of the toe plate.

Ensure that the Skoot frames are presented to

a flush, vertical face on the load which extends

vertically through the full height of the Skoots frame.

Keep Skoots in an upright position at all times including during

transportation and storage to avoid airlocks in the hydraulic jacks.

If an airlock is present then refer to first symptom above.

Website: Www.liftingequpmentuk.com

Email: [email protected]

1 Main body

castor

Single Steel fabricated heavy-duty bracket. Directional lock. SK600

SK900

SK1400

SK2000

SK3500

SK5000

BZJ125NYBJDL

2BZSAB125ENPBJDL/SK

2BZSAB125XPNBJDL/SK

BZSAB125NYBJDL/SK

BZSAB125NYBJDL/SK

2BZQX150NYBJDL/SK

2 Main body

castor wheel

Single SK600: 125mm dia. white nylon with ball bearing, tread width 45mm

SK900: 125mm diameter, 82 shore A

Blue PU on nylon with ball bearing, tread width 40mm

SK1400: 125mm diameter, 97 shore A

Blue PU on nylon with ball bearing, tread width 49mm

SK2000: 125mm diameter

Blue HD solid cast nylon with ball bearing, tread width 55mm

SK3500: 125mm diameter

Blue HD solid cast nylon with ball bearing, tread width 55mm

SK5000: 150mm diameter

Blue HD solid cast nylon with ball bearing, tread width 50mm

SK600

SK900

SK1400

SK2000

SK3500

SK5000

BZXH125WNYBJM20

BZH125WENPBJM20

BZXH125WPNBJM20/BLUE

BZXH125WNYBJM25HDSK

BZXH125WNYBJM25HDSK

BZXH150WNYBJM25HDSK

3 Hydraulic jack Single Bespoke long ram hydraulic jack. SK600

SK900

SK1400

SK2000

SK3500

SK5000

SKJACK600

SKJACK900

SKJACK1400

SKJACK2000

SKJACK3500

SKJACK5000

4 Rubber mat Single Fluted rubber mat to be bonded to Skoots toe plate.

Note: Rubber mats should be bonded to prepared surface using

recommended 3M ScotchWeld 80 spray.

SK600

SK900

SK1400

SK2000

SK3500

SK5000

RM15X5

RM15X5

RM15X5

RM15X5

RM15X5

RM600X150

5. Straps Pair Pair of straps to suit Skoots SK600 to SK3500 supplied with cam

buckle. SK5000 straps supplied with ratchet.

SK600

SK900

SK1400

SK2000

SK3500

SK5000

STR2

STR2

STR2

STR2

STR2

STR5

Website: Www.liftingequpmentuk.com

Email: [email protected]

– Ensure that a pair of straps with intact webbing, buckles/ratchets and

hooks are available.

– Cut, chunked or damaged wheels on main frames or outriggers.

– Missing mats.

– Leaking rams.

– Toe-plate not at 90 degrees.

– Damaged directional locking mechanisms on main body castors.

– Check the state of markings and that the markings remain as the original one.

Before each use,

visually check for

wear and defects

such as...

Six monthly –

oil level in hydraulic

jacks...

(unless leakage of fluid

is noticed during pre-

use check whereby oil

level should be assessed

before use or otherwise

remove from service)

– With jacks standing vertically and fully retracted i.e. unraised, unscrew the

top filler bolt using an 8mm allen key. Carefully remove the top filler bolt/

dipstick. Wipe clean the surface of the dipstick and insert carefully back

into the oil before removing once more to check the level of fluid. Add

hydraulic oil grade Varpress 68 so fluid level is between the notched

markers on the dipstick plug. Tighten the filler bolt using the allen key.

If a top-up of hydraulic oil is required use only Varpress 68VG.

NEVER USE ENGINE OIL OR BRAKE FLUID.

– Store Skoots upright at all times.

– Jacks should be maintained and repaired in accordance with the manufacturer’s

instructions. Such work should be carried out by qualified persons.

– No modifications shall be carried out which adversely affect the compliance

of the jack with this standard.

Website: Www.liftingequpmentuk.com

Email: [email protected]

A limited warranty is offered on a back-to-base basis.

To make a claim, in the first instance you must contact BIL via email at service@bilgroup.eu with full

details of the product, its geographic location, unique batch serial number, purchase date, nature of

the problem and your contact information.

All claims should be accompanied by any documented evidence of service history.

Any part or component returned to our UK factory at the customer’s expense within twelve months

of despatch, will be refunded, repaired or replaced (the choice of which being at our discretion)

without charge if it is found to be defective due to fault of manufacture or workmanship. Subject to

any express warranty given in our terms and conditions or any other contractual agreement with

you, we do not accept liability under this Warranty & Returns Policy for losses or expenses incurred

by customers in relation to such defective products, or for any direct, indirect or consequential

damage arising from such defect. Normal wear and tear is not covered, neither is damage resulting

from overloading or exertion. Any unauthorized modifications found to have been made to the

product will nullify the warranty.

BIL may, unless the customer reasonably believes that the repair would involve specialist

knowledge, skills or equipment, offer to send replacement parts without charge for the customer to

repair (at the customer’s own expense) without the requirement to return the faulty product to our

UK factory.

This warranty will not apply if any of the following events occurs in relation to your product during

the applicable warranty period stated above:

1. The product’s serial number or any rating label is removed, defaced or changed in any way.

2. The product is serviced or otherwise altered using non-genuine replacement parts or

accessories, or if genuine parts are fitted incorrectly and/or not in accordance with the

manufacturer’s instructions.

3. You use a product contrary to the technical or operating environment guidelines recommended

in the BIL user guide or manual.

4. A component part of your product, reaches the end of its service life.

5. The product’s malfunction or failure to perform according to BIL specifications results from;

(a) deliberate or accidental damage;

(b) neglect or modification by or on behalf of an end user; or

(c) the use of non-genuine replacement parts or accessories.

The manufacturer’s decision shall be final and conclusive.

Website: Www.liftingequpmentuk.com

Email: [email protected]

This manual suits for next models

6

Table of contents